- Collection and disposal of biogas

- Purification of impurities

- Gas tank and compressor

- What is a biogas plant?

- What it is

- How is biodiesel produced?

- Options for Biofuel Plants

- Biogas - a complete fuel from waste

- What factors affect production?

- Bioinstallation by Yuri Davydov

- Recommended composition of raw materials for processing

- How to build a biomaterial reactor

- Heating system and thermal insulation

- What to heat and where to place

- Water heating methods

- How to insulate

- Why do you need a biogas plant for farming

- Equipment

- Benefits of biofuels

- low cost

- Renewable sources

- Emission reduction

- Reducing dependence on imports

- Criteria for the composition of manure

- Biofuel efficiency

- We produce fuel for biofireplaces

- Getting gas from a mixture of waste

- What is bio-based gas made of?

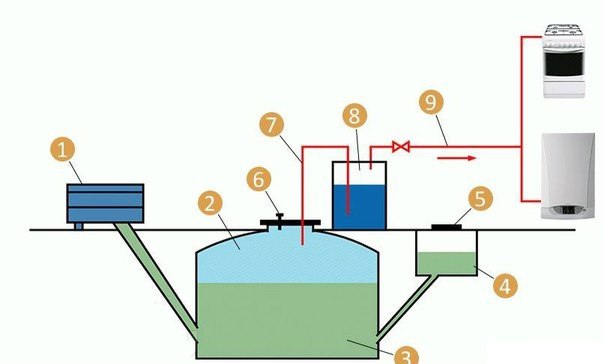

Collection and disposal of biogas

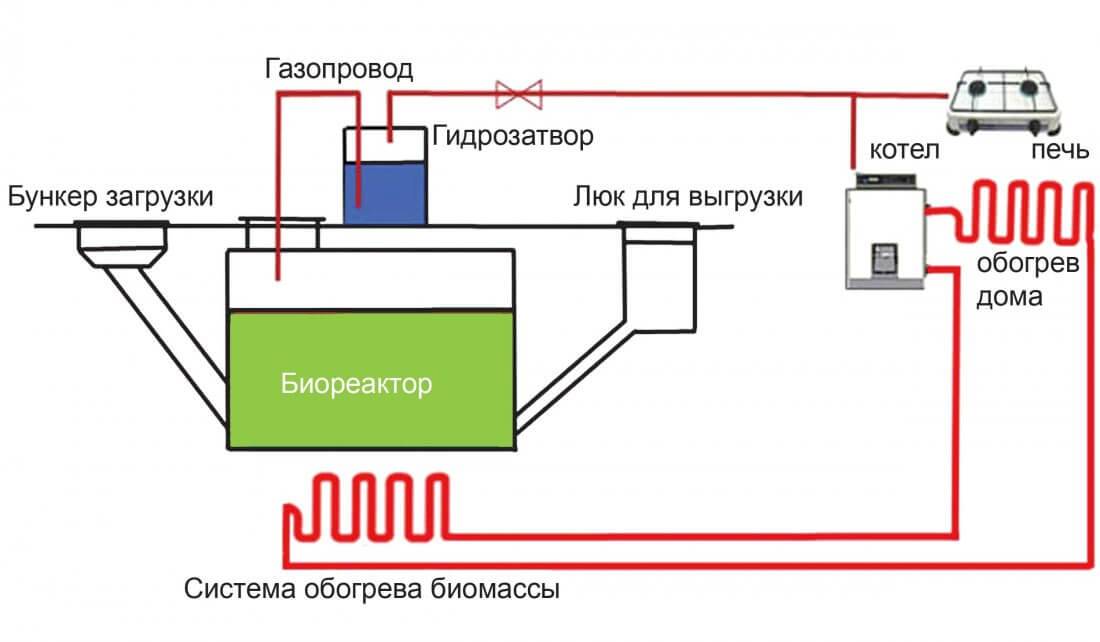

The removal of biogas from the reactor occurs through a pipe, one end of which is under the roof, the other is usually lowered into a water seal. This is a container with water into which the resulting biogas is discharged. There is a second pipe in the water seal - it is located above the liquid level. More pure biogas comes out into it. A shut-off gas valve is installed at the outlet of their bioreactor.The best option is ball.

What materials can be used for the gas transmission system? Galvanized metal pipes and gas pipes made of HDPE or PPR. They must ensure tightness, seams and joints are checked with soap suds. The entire pipeline is assembled from pipes and fittings of the same diameter. No contractions or expansions.

Purification of impurities

The approximate composition of the resulting biogas is as follows:

Approximate composition of biogas

- methane - up to 60%;

- carbon dioxide - 35%;

- other gaseous substances (including hydrogen sulfide, which gives the gas an unpleasant odor) - 5%.

In order for biogas to have no smell and burn well, it is necessary to remove carbon dioxide, hydrogen sulfide, and water vapor from it. Carbon dioxide is removed in a water seal if slaked lime is added to the bottom of the installation. Such a bookmark will have to be changed periodically (as the gas starts to burn worse, it's time to change it).

Gas dehydration can be done in two ways - by making hydraulic seals in the gas pipeline - by inserting curved sections under the hydraulic seals into the pipe, in which condensate will accumulate. The disadvantage of this method is the need for regular emptying of the water seal - with a large amount of collected water, it can block the passage of gas.

The second way is to put a filter with silica gel. The principle is the same as in the water seal - the gas is fed into the silica gel, dried out from under the cover. With this method of drying biogas, silica gel has to be dried periodically. To do this, it needs to be warmed up for some time in the microwave. It heats up, the moisture evaporates. You can fall asleep and use again.

Filter for cleaning biogas from hydrogen sulfide

To remove hydrogen sulfide, a filter loaded with metal shavings is used.You can load old metal washcloths into the container. Purification occurs in exactly the same way: gas is supplied to the lower part of the container filled with metal. Passing, it is cleaned of hydrogen sulfide, collects in the upper free part of the filter, from where it is discharged through another pipe / hose.

Gas tank and compressor

The purified biogas enters the storage tank - gas tank. It can be a sealed plastic bag, a plastic container. The main condition is gas tightness, the shape and material do not matter. Biogas is stored in the gas tank. From it, with the help of a compressor, gas under a certain pressure (set by the compressor) is already supplied to the consumer - to a gas stove or boiler. This gas can also be used to generate electricity using a generator.

One of the options for gas tanks

To create a stable pressure in the system after the compressor, it is desirable to install a receiver - a small device for leveling pressure surges.

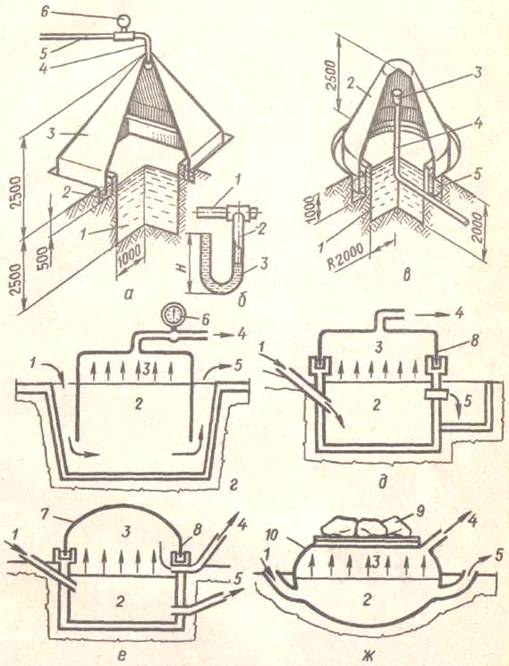

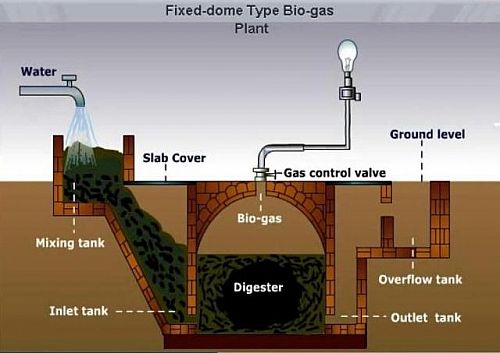

What is a biogas plant?

The most efficient shape for this setup is a cylinder with a tapered bottom and a tapered or rounded top, with little difference between diameter and height.

The most efficient shape for this setup is a cylinder with a tapered bottom and a tapered or rounded top, with little difference between diameter and height.

In such a design, it is easiest to implement mixing of the stratified material, and to increase the temperature, it is not the shape of the vessel that is important, but a sufficient amount of thermal energy and a minimum of heat radiation to the atmosphere.

The body and cover, in which the primary gas tank is located, can be made of concrete or stainless steel.The main advantage of concrete buildings is that they do not have to be transported in whole or in parts from afar, and the formwork for pouring is assembled on site from boards.

The main disadvantage is the difficulty of creating and maintaining a sufficient temperature in the bioreactor, because it is necessary to warm up not only the contents of the digester, but also the concrete walls of the device. Small volume devices (1–20 m3) are often made from polypropylene, polyethylene, and other polymers.

The first method is used in concrete structures, and the second in stainless steel. The inner surface of walls made of any materials is often covered with materials that are chemically inert with respect to manure, due to which the service life of the digester increases many times over.

The inlet hole through which the source material enters the container, and the hole for draining the technical water are located where the water area is located before mixing. In most cases, the location of this hole corresponds to half of the maximum fill level.

A hole is made in the lowest part of the bottom to drain sapropel. An elastic bag is made in the lower part of the lid, which acts as a primary gas tank and is connected through a valve to the gas pipeline.

A hole is made in the lowest part of the bottom to drain sapropel. An elastic bag is made in the lower part of the lid, which acts as a primary gas tank and is connected through a valve to the gas pipeline.

There are models without a bag, where the free space between the lid and the wall serves as a place for accumulating gas.

However, such a scheme has a drawback - a high probability of gas leakage through poorly sealed gaps.

In most bioreactors, the mixing system consists of a vertical shaft and blades mounted on it. When rotated, they create an upward or downward movement of most of the contents, due to which the layers are mixed.

But such a mixing system is appropriate only where the ratio of the volumes of the daily portion of the substrate and the entire contents of the digester does not exceed 1:10.

What it is

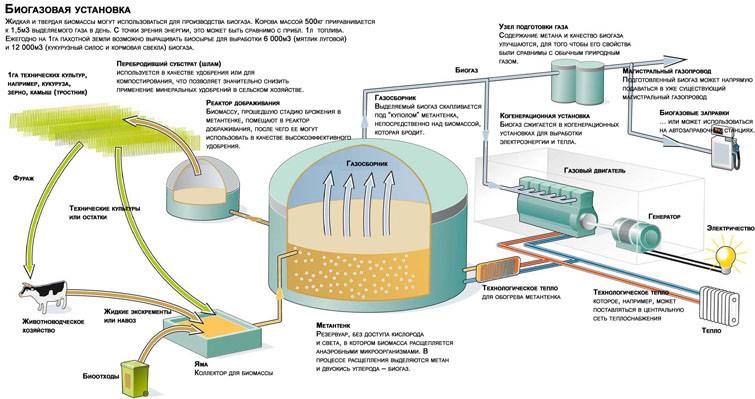

The composition of biogas is similar to natural gas produced commercially. Stages of biogas production:

- A bioreactor is a container in which the biological mass is processed by anaerobic bacteria in a vacuum.

- After some time, a gas is released, consisting of methane, carbon dioxide, hydrogen sulfide and other gaseous substances.

- This gas is purified and removed from the reactor.

- Processed biomass is an excellent fertilizer that is removed from the reactor to enrich the fields.

DIY production biogas at home possible, provided you live in a village and have access to animal waste. It is a good fuel option for livestock farms and agricultural businesses.

The advantage of biogas is that it reduces methane emissions and provides a source of alternative energy. As a result of biomass processing, fertilizer is formed for vegetable gardens and fields, which is an additional advantage.

To make your own biogas, you need to build a bioreactor to process manure, bird droppings, and other organic waste. As raw materials are used:

- wastewater;

- straw;

- grass;

- river silt.

Use of straw for biogas production

Use of straw for biogas production

It is important to prevent chemical impurities from entering the reactor, as they interfere with the reprocessing process.

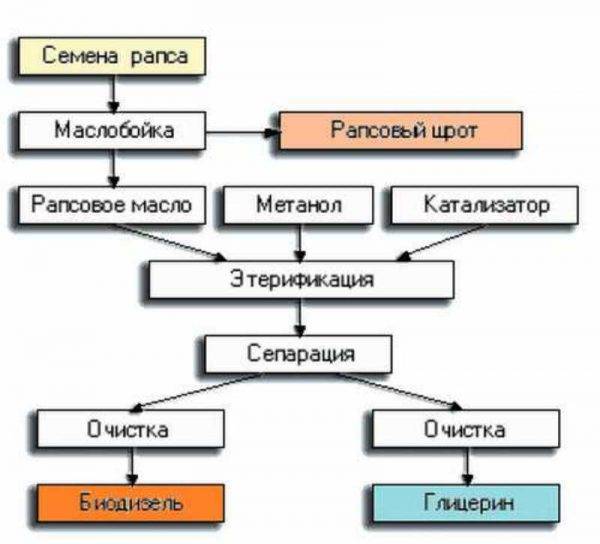

How is biodiesel produced?

A variety of vegetable crops can be successfully used as raw materials, allowing to obtain a large amount of vegetable oil. Among the most popular types of raw materials, rapeseed and soybeans should be noted. It is from these crops that most biodiesel is produced.

Another good raw material is animal fats, which are most often formed as a by-product at various meat processing plants.

The technology for the production of biodiesel, both in the case of plant crops and in the case of using animal fats for these purposes, is quite simple. In this technology, the following stages can be distinguished:

- Purification of raw materials, while the presence of even the smallest impurities should not be allowed.

- A mixture of two components: oil and methyl alcohol (9 to 1), as well as the addition of an alkaline catalyst to the resulting mixture.

- Etherification is performed, that is, the resulting mixture is heated to a temperature of 60 C. The mixture should be in this state for 2 hours.

- The resulting substance after the esterification process is divided into two components: biodiesel and glycerol fraction.

- The passage of biodiesel heat treatment, the task of which is the evaporation of water.

The equipment used for the production of biodiesel is not very complex. In most cases, a number of containers are used, which are interconnected by special pipes, as well as several pumps, among which one main one stands out, and all the rest are dosing.

If the production of biodiesel is carried out at special enterprises, then the whole process is controlled by automation, and special temperature sensors are installed on the tanks.

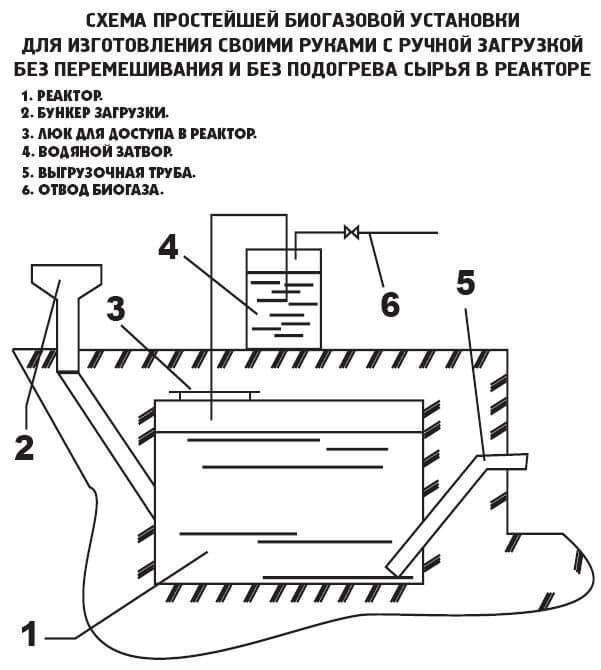

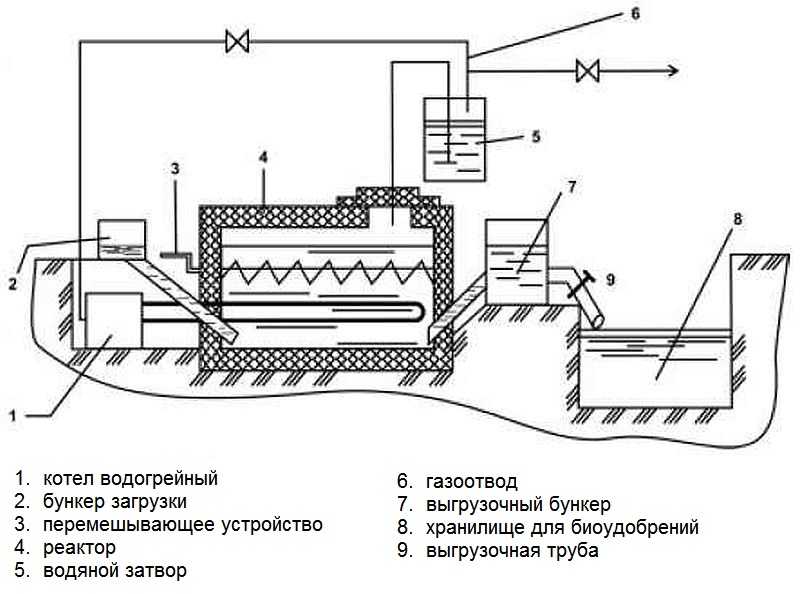

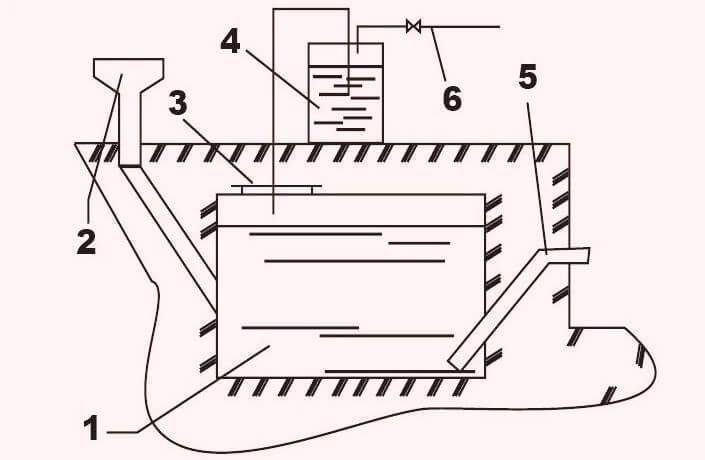

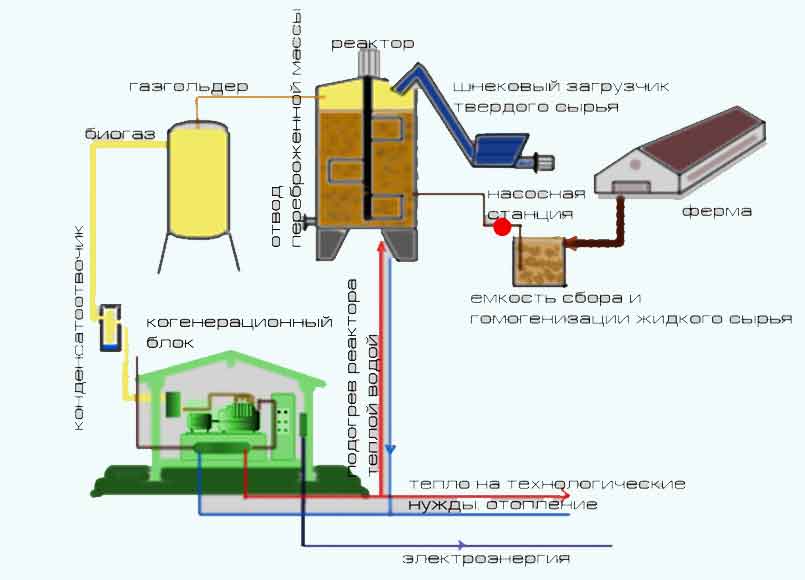

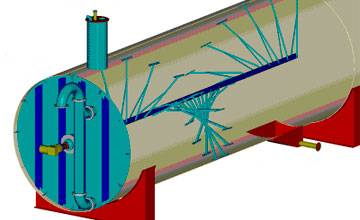

Options for Biofuel Plants

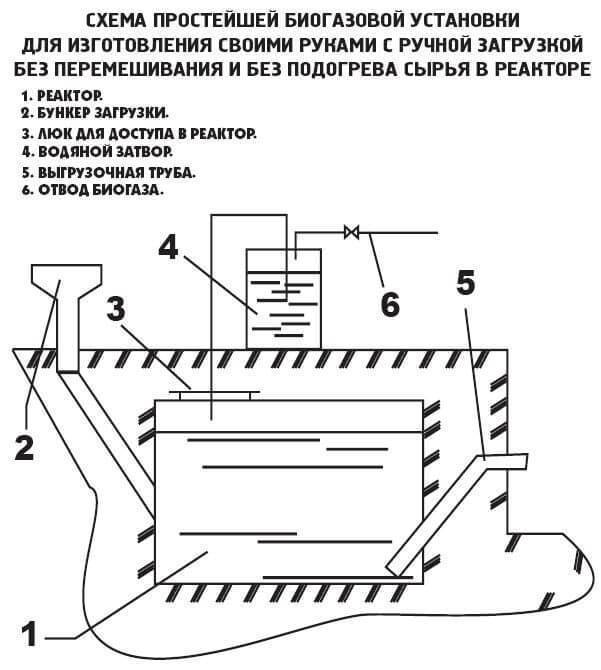

After carrying out the calculations, it is necessary to decide how to make an installation in order to obtain biogas in accordance with the needs of your farm. If the livestock is small, then the simplest option is suitable, which is easy to make from improvised means with your own hands.

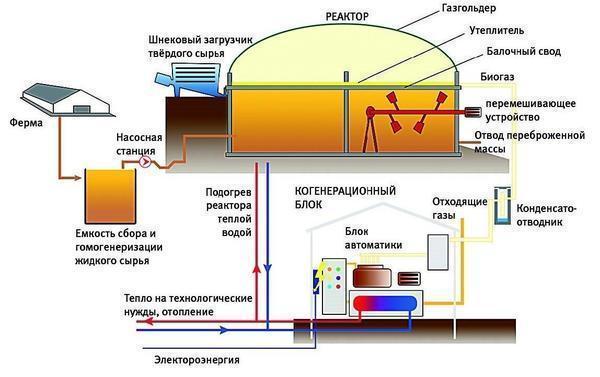

For large farms that have a constant source of a large amount of raw materials, it is advisable to build an industrial automated biogas system. In this case, it is unlikely that it will be possible to do without the involvement of specialists who will develop the project and mount the installation at a professional level.

The diagram clearly shows how the industrial automated complex for biogas production works. Construction of such a scale can be organized immediately by several farms located nearby

Today, there are dozens of companies that can offer a variety of options: from ready-made solutions to the development of an individual project. To reduce the cost of construction, you can cooperate with neighboring farms (if there are any nearby) and build one plant for all biogas production.

It should be noted that for the construction of even a small installation, it is necessary to draw up the relevant documents, make a technological scheme, a plan for the placement of equipment and ventilation (if the equipment is installed indoors), go through the procedures for coordination with the SES, fire and gas inspection.

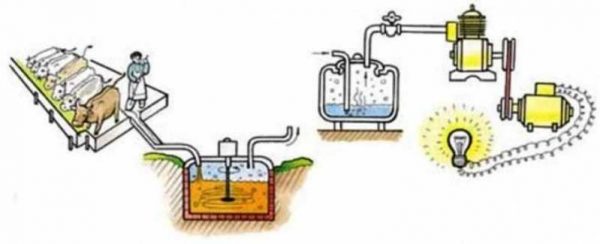

A mini-plant for the production of gas to cover the needs of a small private household can be made with your own hands, focusing on the design and specifics of the installation of installations produced on an industrial scale.

The design of plants for the processing of manure and plant organic matter into biogas is not complex. The original produced by the industry is quite suitable as a template for building your own mini-factory

Independent craftsmen who decide to start building their own installation need to stock up on a water tank, water or sewer plastic pipes, corner bends, seals and a cylinder for storing the gas obtained in the installation.

Biogas - a complete fuel from waste

Everyone knows that the new is the well-forgotten old. So, biogas is not a discovery of our time, but a gaseous biofuel, which they knew how to extract in ancient China. So what is biogas and how can you get it on your own?

Biogas is a mixture of gases obtained by overheating organic matter without air. Manure, tops of cultivated plants, grass or any waste can be used as starting material. As a rule, manure is used as a fertilizer, and few people know that it can be useful for obtaining biofuels, with which it is quite possible to heat living quarters, greenhouses, and also cook food.

The approximate composition of biogas: methane CH4, carbon dioxide CO2, impurities of other gases, for example, hydrogen sulfide H2S, and the specific gravity of methane can reach up to 70%. About 0.5 kg of biogas can be obtained from 1 kg of organic matter.

What factors affect production?

First, it is the environment. The warmer, the more active the reaction of decomposition of organic substances and the release of gas. No wonder the first installations for the production of such biofuels as biogas were involved in regions with a warm climate.Despite this, with sufficient insulation of biogas plants and the use of heated water, it is quite possible to build them in more severe climatic conditions, which is being successfully carried out at the present time.

Secondly, raw materials. It should decompose easily and contain a large amount of water in its composition, without inclusions of detergents, antibiotics and other substances that can slow down the fermentation process.

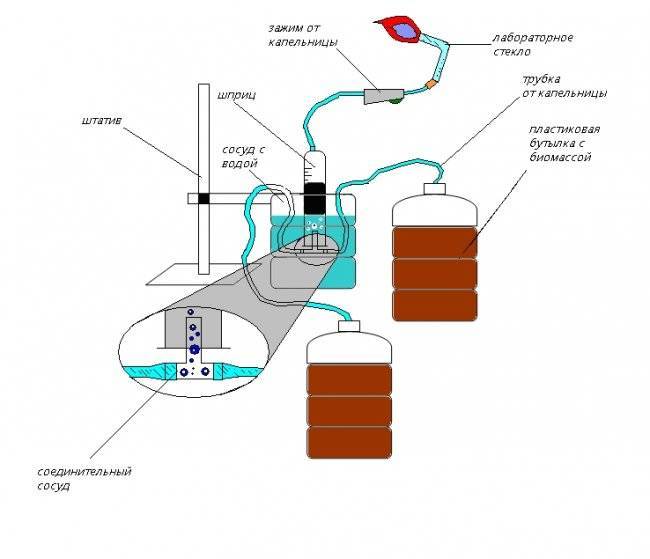

Bioinstallation by Yuri Davydov

An inventor from the Lipetsk region built with his skillful hands a device that allows you to extract "blue biofuels" at home. There was no shortage of raw materials, since he himself and his neighbors had plenty of livestock, and, of course, manure.

What did he come up with? He dug a huge hole with his own hands, laid concrete rings in it and covered it with an iron structure in the form of a dome and weighing about one ton. He brought pipes out of this container, and then filled the pit with organic matter. A few days later, he was able to cook food for cattle and heat the bathhouse on the biogas he received. Later they brought gas to the house for household needs.

Recommended composition of raw materials for processing

For this purpose, 1.5 - 2 tons of manure and 3 - 4 tons of plant waste are poured with water until 60-70% moisture content of the mixture is reached. The resulting mixture is placed in a tank and heated with a coil to 35 degrees Celsius. Under such conditions, the mixture begins to ferment without access to air and heats up to a higher temperature, which contributes to the gas evolution reaction. Gas is removed from the pit through special tubes and used for its intended purpose. The design of the installation, made by the hands of the master, is clearly visible in the diagram.

SUBSCRIBE to OUR youtube channel Econet.ru, which allows you to watch online, download from YouTube for free a video about healing, rejuvenation of a person. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing.

Homemade biogas plant:

Put LIKE, share with FRIENDS!

How to build a biomaterial reactor

If there is little biomass, instead of a concrete container, you can take an iron, for example, an ordinary barrel. But it must be strong, with high-quality welds.

The amount of gas produced directly depends on the volume of raw materials. In a small container, it will turn out a little. To get 100 cubic meters of biogas, you need to process a ton of biological mass.

To increase the strength of the installation, it is usually buried in the ground. The reactor must have an inlet pipe for loading biomass and an outlet for removing spent material. There must be a hole in the top of the tank through which the biogas is discharged. It is better to close it with a water seal.

For a correct reaction, the container must be hermetically sealed, without air access. The water seal will ensure the timely removal of gases, which will prevent the explosion of the system.

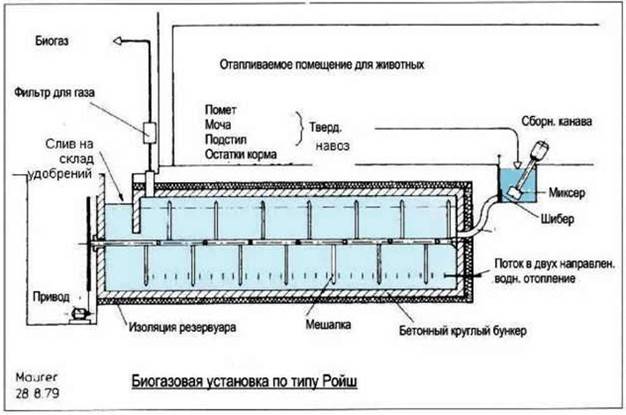

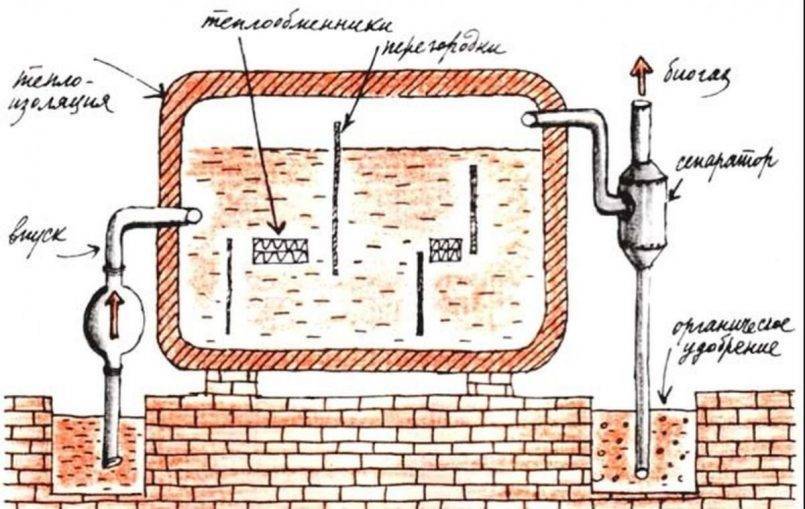

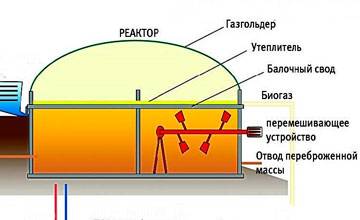

Heating system and thermal insulation

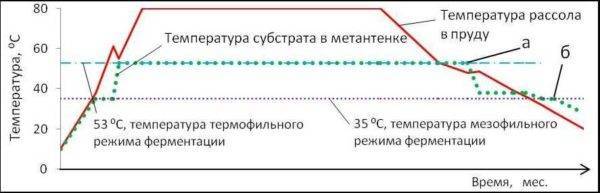

Without heating the processed slurry, psychophilic bacteria will multiply. The processing process in this case will take from 30 days, and the gas yield will be small. In summer, in the presence of thermal insulation and preheating of the load, it is possible to reach temperatures up to 40 degrees, when the development of mesophilic bacteria begins, but in winter such an installation is practically inoperable - the processes are very sluggish.At temperatures below +5°C, they practically freeze.

The dependence of the terms of manure processing into biogas on temperature

What to heat and where to place

Heat is used for best results. The most rational is water heating from the boiler. The boiler can operate on electricity, solid or liquid fuel, it can also be run on the generated biogas. The maximum temperature to which water must be heated is +60°C. Hotter pipes can cause particles to adhere to the surface, resulting in reduced heating efficiency.

You can also use direct heating - insert heating elements, but firstly, it is difficult to organize mixing, and secondly, the substrate will stick to the surface, reducing heat transfer, heating elements will quickly burn out

A biogas plant can be heated using standard heating radiators, simply pipes twisted into a coil, welded registers. It is better to use polymer pipes - metal-plastic or polypropylene. Corrugated stainless steel pipes are also suitable, they are easier to lay, especially in cylindrical vertical bioreactors, but the corrugated surface provokes sediment build-up, which is not very good for heat transfer.

To reduce the possibility of deposition of particles on the heating elements, they are placed in the stirrer zone. Only in this case it is necessary to design everything so that the mixer cannot touch the pipes. It often seems that it is better to place the heaters from below, but practice has shown that due to sediment at the bottom, such heating is inefficient. So it is more rational to place the heaters on the walls of the metatank of the biogas plant.

Water heating methods

According to the way the pipes are located, heating can be external or internal.When located indoors, heating is effective, but repair and maintenance of heaters is impossible without shutting down and pumping out the system

Therefore, special attention is paid to the selection of materials and the quality of the connections.

Heating increases the productivity of the biogas plant and reduces the processing time of raw materials

When the heaters are located outdoors, more heat is required (the cost of heating the contents of a biogas plant is much higher), since a lot of heat is spent on heating the walls. But the system is always available for repair, and the heating is more uniform, since the medium is heated from the walls. Another plus of this solution is that agitators cannot damage the heating system.

How to insulate

At the bottom of the pit, first, a leveling layer of sand is poured, then a heat-insulating layer. It can be clay mixed with straw and expanded clay, slag. All these components can be mixed, can be poured in separate layers. They are leveled into the horizon, the capacity of the biogas plant is installed.

The sides of the bioreactor can be insulated with modern materials or classic old-fashioned methods. Of the old-fashioned methods - coating with clay and straw. It is applied in several layers.

Modern materials are used to insulate bioreactors

From modern materials, you can use high-density extruded polystyrene foam, low-density aerated concrete blocks, foamed polyurethane foam. The most technologically advanced in this case is polyurethane foam (PPU), but the services for its application are not cheap. But it turns out seamless thermal insulation, which minimizes heating costs. There is another heat-insulating material - foamed glass.In plates, it is very expensive, but its battle or crumb costs quite a bit, and in terms of characteristics it is almost perfect: it does not absorb moisture, is not afraid of freezing, tolerates static loads well, and has low thermal conductivity.

Why do you need a biogas plant for farming

Some farmers, summer residents, owners of private houses do not see the need to make a biogas plant. At first glance, it is. But then, when the owners see all the benefits, the question of the need for such an installation disappears.

The first obvious reason to make a biogas plant on a farm is to get electricity, heating, which will allow you to pay less for electricity.

Another main reason for the need to create an installation is the organization of a complete cycle of non-waste production. As a raw material for the device, we use manure or droppings. After processing, we get new gas.

The third reason in favor of a biogas plant is the efficient processing and environmental impact.

3 advantages of a biogas plant:

- Getting energy to keep the family farm running;

- Organization of the completed cycle;

- Efficient use of raw materials.

Having an installation on a farm is an indicator of your efficiency and concern for the world around you. Biogenerators save a huge amount of money by making production waste-free, efficient allocation of resources and raw materials, but also your complete self-sufficiency.

Equipment

To organize the production of fuel eco-briquettes, the following minimum set of equipment is required:

- Crusher (equipment identical to pellet)

- Press

- Dryer

The above equipment can be purchased both separately and as part of a mini-factory.

If we consider a low-budget version of the organization of production, then we can stop at the proposal of the city of Krasnodar, in this company a press extruder with a capacity of 130 kilograms per hour will cost only 170 thousand rubles. And the total costs, taking into account the purchase of additional equipment (dryer, crusher) and delivery, will not exceed 300 thousand rubles.

If you plan to purchase an automatic line (mini-factory), an offer would be an excellent option. The cost of an automatic line on a turnkey basis (including additional equipment, delivery and installation), with a capacity of 500 kilograms per hour will be about 10 million rubles. Euro firewood produced on this line fully complies with the quality requirements of European countries and can be exported abroad.

You can also consider the option of purchasing a line for the production of briquettes in China. The cost of a semi-automatic line with a capacity of 200 kilograms per hour will be about 2 million rubles, and the total investment in the organization of production will be about 3 rubles.

The production of briquettes is an environmentally friendly production, the requirements for the location of the workshop are standard for conventional production (380V, water supply, sewerage, compliance with fire safety and SanPiN requirements. The workshop area depends on the selected equipment.

Benefits of biofuels

Everyone knows that any invention is a well-forgotten old one. So, biofuel is far from being a discovery of our time, since they knew how to produce it in ancient China. At that time, the tops of plants, grass, various waste and manure were used as the starting material.There are a lot of advantages of such raw materials, so it is worth familiarizing yourself with the main ones.

low cost

In today's market, biofuels are as expensive as gasoline. But it is cleaner and produces a minimum of harmful emissions. When using such fuel, it is possible to significantly reduce the maintenance costs of those units where it is used.

Renewable sources

Manure fermentation in the device

As you know, gasoline is obtained from oil, which is a non-renewable resource. And, despite the fact that oil reserves will last for more than one decade or even a century, it will end sooner or later. In turn, biofuels are made from raw materials such as:

- manure;

- waste of cultivated and wild plants;

- the plants themselves in the form of soybean, rape, corn or cane;

- wood and more.

All of them tend to be constantly renewed.

Emission reduction

During the combustion period, fossil fuels (coal, natural gas, peat) produce a significant amount of carbon dioxide, which scientists call greenhouse gas. The use of oil and coal increases the temperature of the atmosphere, which is one of the causes of the so-called global warming. To significantly reduce the greenhouse effect, biofuels should be used.

Studies have shown that biofuels significantly reduce greenhouse gas emissions by up to 65%.

Reducing dependence on imports

Refueling with biofuel

Considering that not every country has oil reserves, its imports "punch" a significant hole in the state's economy.Therefore, if the majority of people begin to lean towards the consumption of biofuels, the dependence on imports will decrease significantly. Moreover, due to the growth in the production of such raw materials, new jobs will be created. And this will have a positive impact on the economies of the countries.

Criteria for the composition of manure

The mass of manure loaded into the bioreactor should not be considered simply as a raw material suitable in any capacity. The component of the substance is of fundamental importance for the fermentation process. In practice, it has been noted that the reduction of substrate particles is accompanied by a better efficiency of the process.

The pronounced fiber content of the substrate and the increase in the area of interaction of bacteria are the main criteria that contribute to the rapid decomposition of the manure mass. In this state, raw manure, when heated and stirred, does not form sediment or film on the surface, which greatly simplifies the filtration of the gas mixture.

Preparation of manure for loading into the reactor

This procedure is given no less attention than everything else, if there is a desire to obtain a significant amount of biofuel in a short period of time. The degree of grinding of raw materials determines the duration of fermentation, which in turn affects the volume of gas produced. Thus, in order to reduce the fermentation time, it is necessary to grind the raw material well: the better the quality of grinding, the shorter the fermentation period.

Thus, in order to reduce the fermentation time, it is necessary to grind the raw material well: the better the quality of grinding, the shorter the fermentation period.

The degree of grinding of raw materials determines the duration of fermentation, which in turn affects the volume of gas produced.Thus, in order to reduce the fermentation time, it is necessary to grind the raw materials well: the better the quality of grinding, the shorter the fermentation period.

Biofuel efficiency

Biogas from manure has no color and smell. It gives as much heat as natural gas. One cubic meter of biogas provides as much energy as 1.5 kg of coal.

Most often, farms do not dispose of waste from livestock, but store it in one area. As a result, methane is released into the atmosphere, manure loses its properties as a fertilizer. Timely processed waste will bring much more benefits to the farm.

Calculating the efficiency of manure disposal in this way is easy. The average cow gives 30-40 kg of manure per day. From this mass, 1.5 cubic meters of gas is obtained. From this amount, electricity is generated 3 kW / h.

We produce fuel for biofireplaces

All kinds of oils of organic origin become the basis for liquid biofuels. Various alcohol-containing substances are added to them, and alkalis are also added to produce biodiesel. This is a rather complicated process. At home, the easiest way to make a liquid biofuel designed for the fireplace. The so-called bio-installations do not differ at all from traditional devices outwardly. However, they do not burn wood, but biofuels, which guarantees the absence of carbon monoxide, soot, soot and ash.

Biofireplaces delight their owners with ecological cleanliness and convenience, because there is no need to chop wood and clean ash from such a device. During combustion, biofuel decomposes into carbon dioxide and water, which are absolutely safe for humans. At the same time, the flame is devoid of the characteristic yellow-orange color and looks colorless.This significantly spoils the appearance of the fireplace, giving it an unnatural look. Therefore, special additives that color the flame are necessarily added to biofuels.

For the manufacture of such fuel, 96% ethanol is required. It can be purchased at a pharmacy. Highly refined gasoline can be used as a flame-coloring additive. Suitable for both high-quality household brand B-70, and branded for refueling lighters. Outwardly, such gasoline should be completely transparent, there should be no sharp specific smell. For one liter of alcohol, 50-100 g of gasoline is taken. The resulting mixture mixes very well.

Ecofireplaces are an excellent replacement for traditional appliances. For their work, environmentally friendly and safe biofuels are used, which can be produced independently.

It should be borne in mind that the composition will delaminate over time, so it is undesirable to store it. It is best to mix the ingredients just before filling the fireplace. The resulting composition can be used in rooms without hoods and chimneys, however, ventilation is nevertheless mandatory. On average, for an hour of operation of an eco-fireplace, about 400-500 ml of home-made biofuel will be required. In addition, the same composition can be used in traditional "kerosene stoves". As a result, we get a perfectly luminous lamp without soot, unpleasant odors and soot.

Getting gas from a mixture of waste

A simple plant for biogas production.

As an option, we offer no less effective technology.

Various additives are used here.

- Mix 2 tons of manure and 4 tons of any plant waste (leaves, grass, hay).

- Moisten the mixture with water to a level of 75%.

- In the tank, the liquid should be heated using a coil to about + 35⁰.

- In the process of heating, isolate the components from air access, ensuring tightness.

- Further, the heating is stopped, after which the raw material, due to the chemical reaction, will continue to heat up on its own.

- The released gas is discharged through the outlet ventilation pipes and used for its intended purpose.

What is bio-based gas made of?

To understand the composition, it is not necessary to be a professional chemist.

Enough school knowledge, which will not hurt to remember for your own good.

- Carbon dioxide (CO2).

- Methane (CH4).

- Hydrogen sulfide (H2S).

- Other impurities.

It is worth noting that 0.5 liters of gas can be obtained from 1 kg of manure or a mixture with it.