Production at home

The first and one of the main problems is where to get enough raw materials. Well, if you are a farmer and grow rapeseed or are the owner of a restaurant where vegetable fat waste remains. If you don’t have access to a source of inexpensive raw materials, then you won’t be able to make biodiesel with your own hands. Buying oils will be unprofitable, especially given the second problem - fuel quality.

To safely use home-produced biodiesel in any car or heating boiler, it is necessary to ensure the quality of the product. Otherwise, you will face endless repairs and cleanings of your engines and boiler nozzles. And for this, the technology must be organized and verified at a high, and not a handicraft level. In turn, this will lead to the same costs, whose payback is in question.

With low quality biodiesel, old cars and tractors with unpretentious engines and fuel systems can come to terms for a long time.The same applies to heating drip stoves and boilers with a Babbington burner, which are undemanding to the quality of the fuel. In this case, the simplest installation for the production of biodiesel is suitable; in other cases, the technology will have to be complicated. So, to build the installation you will need:

- 3 plastic containers, 2 of them are large and one is smaller;

- 5 ball valves;

- pipes and fittings (tees, elbows);

- electric heater with thermostat;

- pump.

To master the production of biodiesel at home, you need to place the containers on metal stands with the neck down, and make closing holes on top for pouring the components. You can also use metal barrels or homemade tanks made of steel pipes of large diameter. At the bottom of each vessel, you need to attach a fitting, and screw a tap to it, and then connect all the elements to each other with pipes, as shown in the figure:

The average capacity will serve as a reactor where the heating element needs to be built. Oil is poured into another large tank, and methyl alcohol is poured into a small one. Caustic soda is first added to the methanol to act as a catalyst. Having opened the valves in such a way that substances from the auxiliary tanks enter the reactor, the pump and the heating element are turned on, whose thermostat is set to a temperature of 60 ° C.

In the video, Top Gear host Jeremy Clarkson explains and shows how to make biodiesel at home:

Biodiesel at home

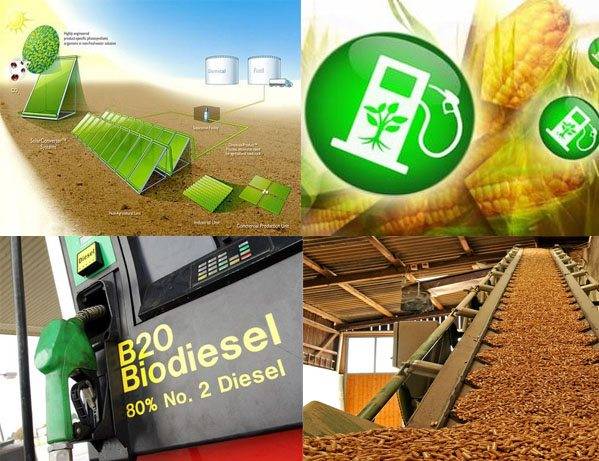

Biodiesel is a fuel obtained from any vegetable oil (sunflower, rapeseed, palm).

Brief description of the biodiesel production process:

- Vegetable oil is mixed with methanol and a catalyst.

- The mixture is heated for several hours (up to 50-60 degrees).

- During the esterification process, the mixture separates into glycerol, which settles down and biodiesel.

- Glycerin is drained.

- Diesel is cleaned (evaporated, settled and filtered).

The finished product is of suitable quality and is clear and pH neutral.

The yield of biodiesel from vegetable oil is approximately 95%.

The disadvantage of home-made biological diesel is the high cost of vegetable oil. It makes sense to produce biodiesel with your own hands only if you have your own fields for growing rapeseed or sunflower. Or having a constant source of cheap processed vegetable oil.

Biofuel fireplaces are a decorative element of the interior with live fire. The industrial production of biofireplaces offers models of various sizes and configurations. However, many people make biofireplaces with their own hands.

To make a fuel block for a biofireplace with your own hands, you need to take a metal box, put a container with bioethanol inside. Cover the box with a metal grill (you can take a simple barbecue grill). Install a wick on the grate, set it on fire and the biofireplace is ready.

In fact, this is all that is needed to make a biofireplace with your own hands. It remains to decorate it with stones or other elements to your taste.

There is very little heat from such a fireplace; it is rather just an original decoration of the house.

It is quite possible to make fuel for a biofireplace with your own hands. It contains ethanol and gasoline. Consider the process of producing bioethanol at home.

You will need the following ingredients:

Ethyl alcohol 96%, sold in a pharmacy

Aviation gasoline (it is also used to refuel lighters)

It is practically odorless, which is important for use in a residential area. Only about 70 g is needed per liter of alcohol.

gasoline. Mix well and pour into fuel container. A liter of biofuel will last from 2 to 8 hours of continuous burning, depending on the type of fireplace burner and the intensity of the flame

Only about 70 g of gasoline is needed per liter of alcohol. Mix well and pour into fuel container. A liter of biofuel will last from 2 to 8 hours of continuous burning, depending on the type of fireplace burner and the intensity of the flame.

DIY biofuel

Bioethanol is a safe type of fuel; when it is burned, only hydrogen in a gaseous state and carbon dioxide are released. However, an open fire burns oxygen, so you need to regularly ventilate the room. It will also help remove excess carbon dioxide from the air.

General provisions

Basic concepts

Let's start by defining what a biofuel is. The considered type of energy carrier is completely organic and, with the appropriate equipment, can be used for heating residential buildings, refueling cars, powering industrial plants, and so on.

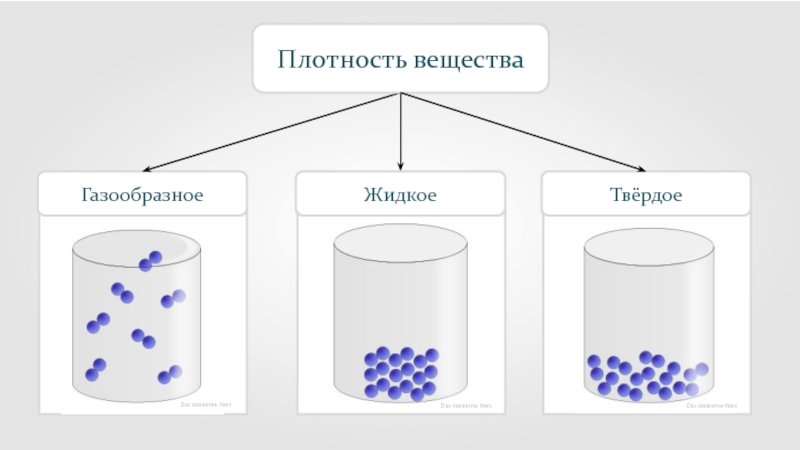

Gaseous, liquid or solid biofuels can be produced from various agricultural plants (for example, rapeseed), as well as animal and human waste products (dung biofuels). That is, the raw materials for its manufacture are, as a rule, those products that were previously sent to a landfill.

The raw material for the production of biofuels is organic matter.

In addition, the advantages of the considered type of energy carriers include their environmental friendliness.During combustion, much less harmful substances are released that affect the state of the environment. This favorably distinguishes biofuel boilers from diesel or gas heating equipment, which are famous for their carcinogenic emissions.

But biofuels also have significant disadvantages:

- low heat capacity - liquid biofuel, burning in a heat exchanger, emits less heat than a similar volume of gasoline or diesel fuel;

- high cost of production - modern technologies do not yet allow the production of biofuels - liquid, solid or gaseous - on an industrial scale, because its price is somewhat higher than traditional energy carriers;

- strong corrosive properties - vegetable oils and animal fats, which are part of organic energy carriers, have a strong destructive effect on mechanisms, which makes it difficult to use them in internal combustion engines and other similar systems.

Currently, obtaining biofuels with less aggressive properties and cheaper methods is one of the priority areas for scientific research by scientists around the world. Huge progress in this area allows us to say with confidence that most of the shortcomings of this type of energy carriers can be eliminated in the near future.

Fossil fuels are not without drawbacks

Biofuel is already widely used for greenhouses and other agricultural facilities. The gas obtained as a result of manure processing or pellets are used to create a comfortable microclimate in which various agricultural crops grow. (See also the article Heating a greenhouse in winter: features.)

Generations of biofuels

Even at the dawn of research related to the development of energy carriers from agricultural waste, scientists expressed concern that in the future, when biofuels become widespread, food problems could arise. This is possible if agricultural crops (corn, rapeseed, maize) are used not for their intended purpose, but for distillation into fuel.

To avoid this, scientists have looked for other biofuel energy sources. As a result of their research, second-generation biofuels and newer varieties of it have appeared.

These include substances obtained not from the plants themselves, but from their waste: leaves, husks, rhizomes, and so on. A prominent representative of this type of coolant is biofuel from sawdust and manure - a gas consisting of methane and carbon dioxide, which in everyday life is called "sewer".

In composition, it is absolutely identical to natural fossil methane. After unnecessary elements are removed from it, it can be used to produce ethanol for stoves that heat certain buildings.

In the photo - algae from which organic fuel is produced

The most innovative biofuel - the presentation of which took place not so long ago - is made from algae. These underwater plants can be grown in bodies of water that are not suitable for agricultural use. Moreover, they can be cultivated in so-called phytobioreactors.

As they develop, these organisms form molecular structures that resemble the structure of oil.Biofuel from algae is the most promising development, however, its practical application is still very far away.

Installation for the production of organic energy from algae

Why is it better to use biofuels?

There is such a saying “an invention is a well-forgotten old one”, and this saying can be attributed here. After all, biofuel is not a modern find, it was used in ancient China, the raw materials they had were the following products: manure, plant tops, grass and various wastes. This miracle product has a huge number of advantages, the main ones are:

low cost

In today's market, the price of biofuels is equal to gasoline. But the fuel is much cleaner and does not emit a large amount of harmful emissions. When using biofuels, it is possible to reduce the cost of maintaining those units by an order of magnitude.

Renewable sources

Biofuel has a great advantage over gasoline - it is an inexhaustible resource. After all, the main source of gasoline is oil, but at the same time it is an exhausting resource, even now oil reserves are alarming many scientists and environmentalists. And the most advanced countries throw all possible forces into research and finding alternative energy sources. In turn, biofuels are made from renewable and organic materials, such as plant remains, both wild and weedy, and fully cultivated, such as soybeans, cane and many others.

It is important that, unlike refined products, there is absolutely no harm to the atmosphere.

Biofuels slow down global change.Indeed, due to the use of coal with oil leads to an increase in atmospheric temperature, this is the cause of global warming. But biofuels reduce the greenhouse effect, thereby slowing down the global problem.

The researchers were able to prove that the use of biofuels reduced greenhouse emissions by up to 65 percent.

This shows that biofuels are much better to use, because even from the school botany course we were told that when growing a plant, CO (carbon monoxide) is partially absorbed from the atmosphere, thereby releasing oxygen into the atmosphere.

Reduced dependence on imports

After all, not all countries have oil reserves. And imports are quite expensive. In order to reduce dependence on imports, people need to switch to biofuels. In addition, due to increased demand for raw materials, workers there will be more jobswhich of course will have a positive effect on the economy.

Great gas station for your car

What properties does

That is why this type of fuel is not capable of harming human health and other organisms. The combustion of fuel for fireplaces is accompanied by a colorful fire.

Biofuel is an unsurpassed type of fuel, because it is completely safe, does not emit any harmful substances and does not smoke. Thanks to this, there is no need to install a chimney for a biofireplace. The advantages are obvious - there is no heat consumption, because it completely goes into the house. Heat dissipation 95%.

The flame obtained during the combustion of biologically pure fuel, in appearance does not differ from the usual one. Fuel in the form of a liquid gel, which is supplemented with sea salt, creates the illusion of crackling, which is reminiscent of the sound of burning wood.And when burning biofuels, flames are formed that are very similar in shape and color to the fire in a classic fireplace.

Specialist's note: this fuel is also used as an energy carrier used for lighting devices.

What types of biofuels are used for the fireplace

Large heating bills force you to look for other sources of heat. Now there are several alternative heating options. Often, thermal energy is produced by the wind or the sun. But biofuels have become very popular. It is made from various priceless raw materials.

Biofuel is made on the basis of biological and thermal processing. Biological treatment involves the work of different bacteria. So the materials for production are leaves, manure and other organic matter.

Types of biofuels:

- Liquid is represented by bioethanol, biodiesel and biobutanol;

- Solid is used in the form of briquettes and wood, coal, peat are used for production;

- Gaseous - biogas, biohydrogen.

Any kind of fuel can be made independently from biomass. But each option has its own characteristics of production. Liquid diesel fuel is made from vegetable oil. Such production requires a lot of vegetables, so it is not always profitable.

Often, products for manufacturing are toxic, so you should be more careful when working. With independent production, it should be remembered that the higher the ambient temperature, the faster the decomposition of organic matter will take place.

Application area

In a fireplace with such characteristics, an open fire is used, arising from the combustion of environmentally friendly material, usually it is specially purified ethyl alcohol. If during the combustion of firewood or coal carbon dioxide should appear, which must certainly be removed from the house, this does not happen with biofuel: it burns completely without compounds harmful to humans.

As is known from physics since school, in order to support the combustion process, oxygen is needed, which is taken from the living space: it becomes stuffy and difficult to breathe. A biofireplace is not endowed with all these features; it needs a minimum amount of air to maintain the flame in the burner.

A chimney multilevel system is an obligatory component of any natural fuel heating element. For our device, it is not needed, since smoke, as such, simply does not form.

Scope - interior decoration of large and small apartments, cottages and summer cottages, offices and a hall for receiving guests of honor.

More recently, it was used for heating purposes where, for fire safety purposes, it was forbidden to use other heating structures.

But a lot of time has passed since then, and today biofireplace is a decor item not only for an exquisite, but for the simplest interior. And many designers boldly claim that it is perfect for almost any design.

If the floor of the room is overloaded with furniture, then the wall-mounted option can correct this mistake and provide a cozy atmosphere of the hearth. One should not think that it is impossible to use it for its intended purpose - heating, although it is not so intense, it still heats the surrounding air.

There are also such designs that are equipped with wheels, and this is convenient if it is needed only for a while: push it to the middle of the apartment, sit on a carpet or a low couch, and admire the unhurried flame. It is easy to move or remove, and, if necessary, to push.

Fuel produced artificially:

Artificial fuel is called fuel obtained from natural, organic raw materials in the process of targeted processing (distillation) or as related, by-products.

Artificial fuel can be:

- compositional. To obtain, several types of fuel are mixed, including with the addition of initially non-combustible components. This group includes emulsions, suspensions, granules and briquettes;

- synthetic. To obtain it, natural resources, in particular coal, are subjected to chemical or thermochemical treatment;

- combustible waste. This group includes waste from the activities of industrial enterprises, household waste, organic matter remaining in the fields after harvesting or clearing areas for sowing, waste oils, washing fluids.

Step-by-step instruction

For self-production of fuel you need to purchase:

- Ethanol (usually sold at pharmacy outlets).

- Purified under special conditions gasoline.

For the manufacture requires ethanol with an alcohol-containing substance up to 96%, it must have a transparent consistency, not emit strong unpleasant odors. Then purchase a can of gasoline, which is used to refuel ordinary lighters, but completely cleaned.

To create a mixture, you should:

- About 70 grams of refined gasoline is poured into 1 liter of pharmacy ethanol.

- Thoroughly mix the ingredients until they stop flaking (you can do this just before refueling the burner, otherwise gasoline may float to the top).

- The finished substance is poured into the burner and set on fire.

Tip: although little carbon dioxide is released during combustion, there is still a certain percentage, and it is better to slightly open the window for better air exchange.

A self-prepared mixture will be of better quality and more economical than a store-bought counterpart; only about half a liter of fuel will be consumed per hour of burning.