- Benefits of biofireplaces

- Biofireplace elements

- Modern modifications of biofireplaces

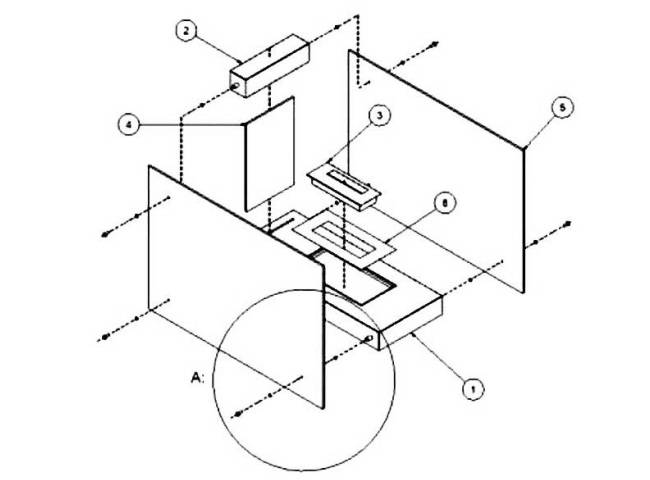

- Assembly instructions

- How to make a biofireplace with your own hands?

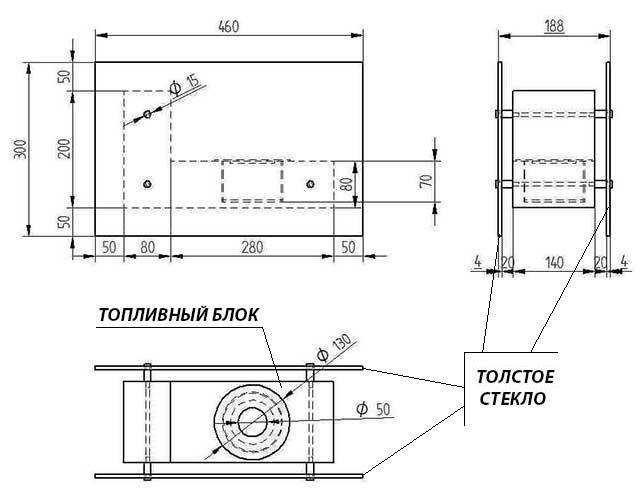

- Instructions for assembling a large bio-fireplace

- A simple do-it-yourself biofireplace: instructions for making

- Option number 2: outdoor biofireplace

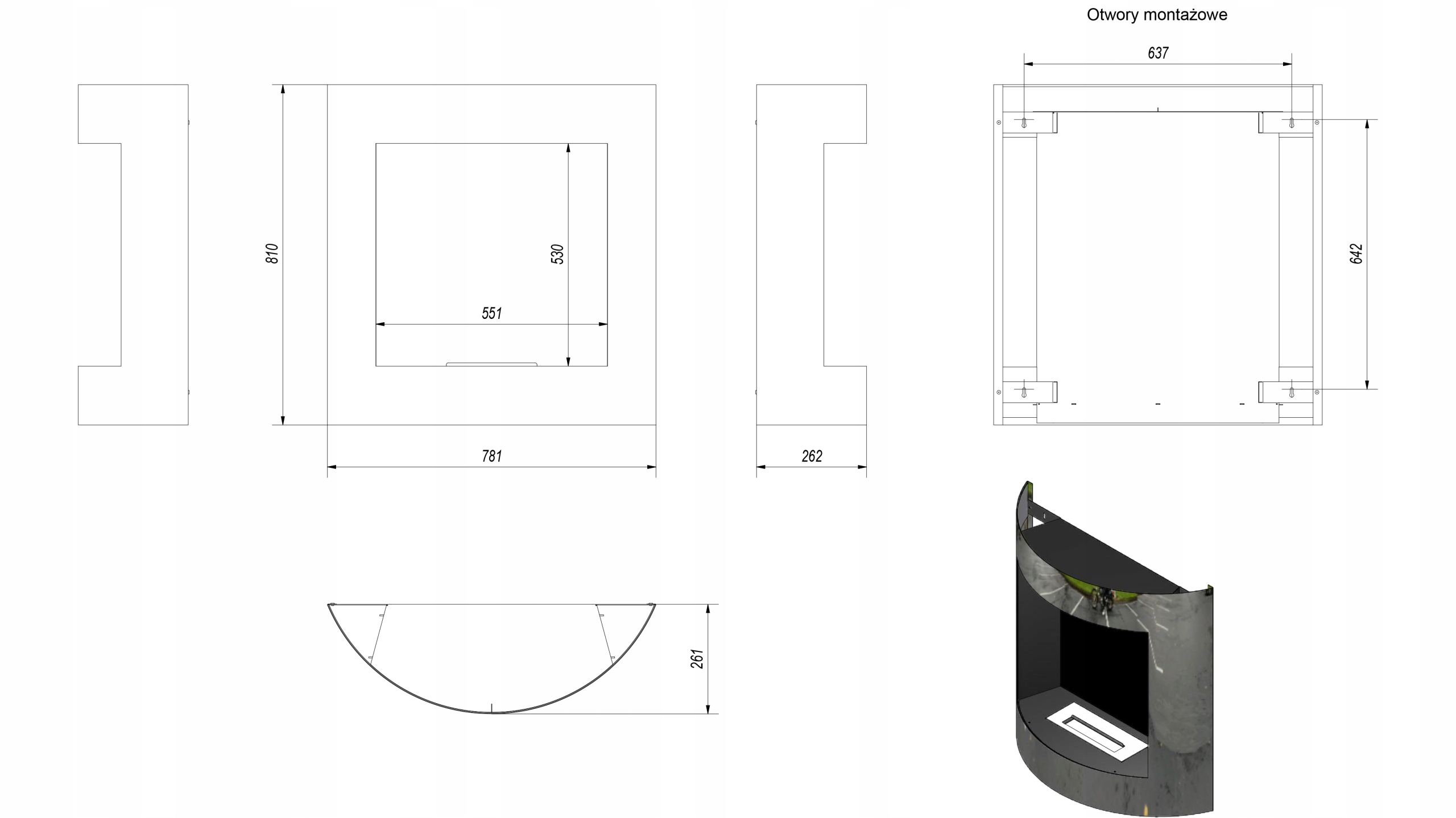

- Instructions for the manufacture of a wall-mounted biofireplace: from preparation to implementation

- No. 1. How does a biofireplace work?

Benefits of biofireplaces

But not only these factors can be considered when making a purchase, these devices have other important advantages that deserve attention:

- environmental friendliness - during the combustion of fuel there is no emission of harmful substances;

- practicality - installation does not require the preparation of a heat-resistant base and a chimney, while the variability of installation sites is limited only by reasonable fire safety measures;

- safety during operation;

- efficiency - since there are no combustion products and there is no need to remove them, all the heat produced remains in the room, which is definitely recommended to be ventilated using traditional methods;

- simple maintenance, consisting in periodic wiping of the body and burner.

An important plus can be considered wider design possibilities, as well as the fact that the cost of even complex models with automatic control competes with traditional fireplaces, the construction of which takes time and money.

But biofireplaces also have some disadvantages that must be taken into account before deciding to install this device in the house. Most models are designed for installation in rooms larger than 25 m 2, with some exceptions for miniature desktop devices.

It is also necessary to take into account the fact that the operation of a biofireplace will require regular purchase of fuel, the price of which, although not high, but with an average consumption of 0.3-0.5 l / h, can become a significant burden on the family budget.

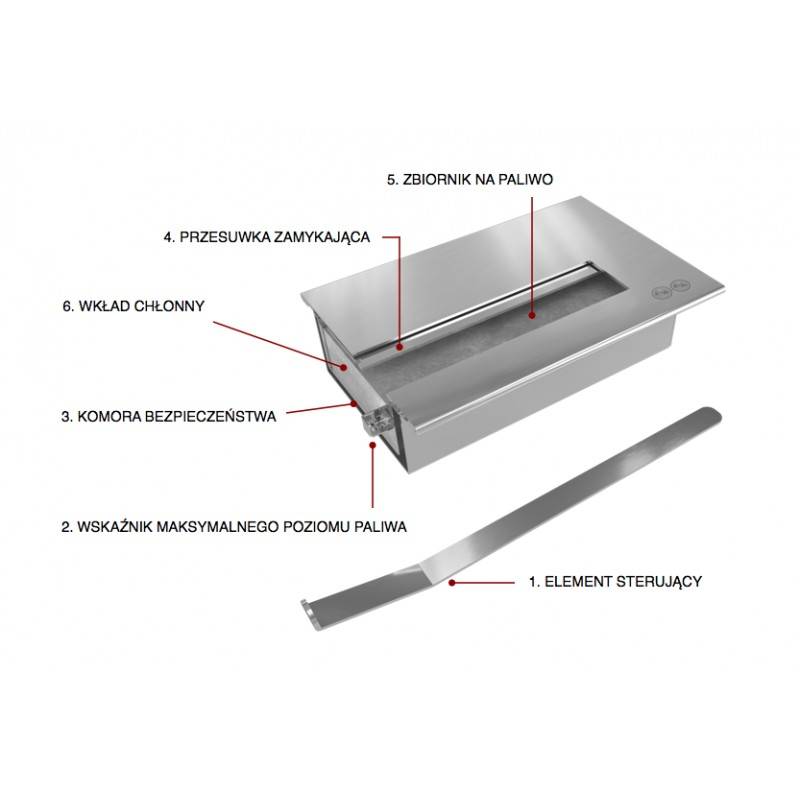

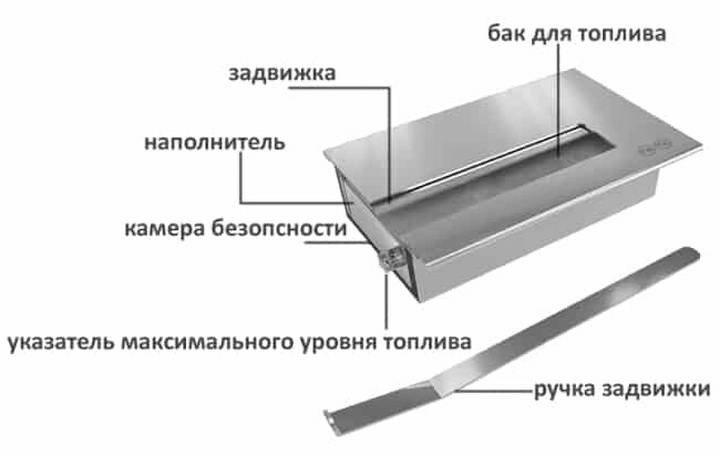

Biofireplace elements

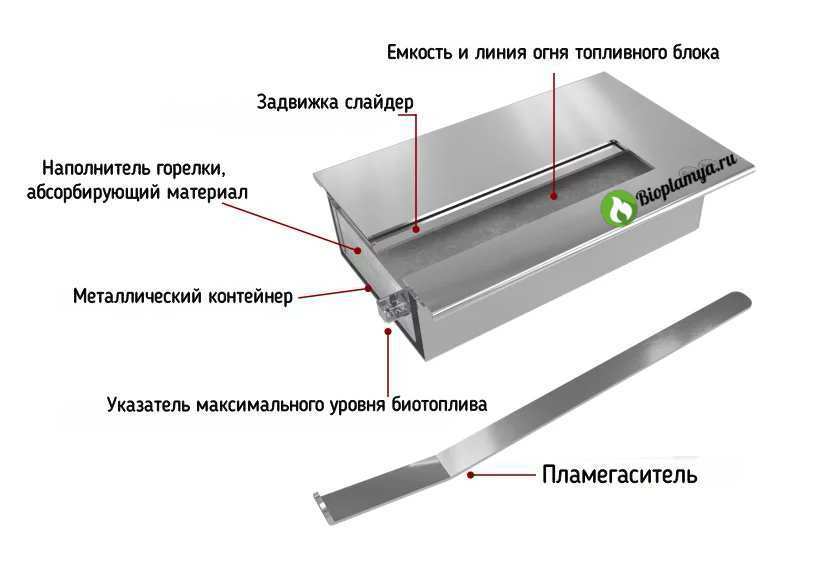

The fuel tank is part of the hearth in the form of a metal container filled with a swab. The container may have a different shape, but is always located below. In the upper part of the tank there is a hole through which alcohol vapors escape - it also serves as a nozzle. The biofireplace fuel itself deserves special mention.

Bioethanol, denatured alcohol is an alcohol obtained from organic products by distillation of fermented wort. In its original form, it is edible ethyl alcohol. To prevent its use in food, it is denatured, or simply poisoned. In this case, an indicator, usually purple, is usually added to the liquid.

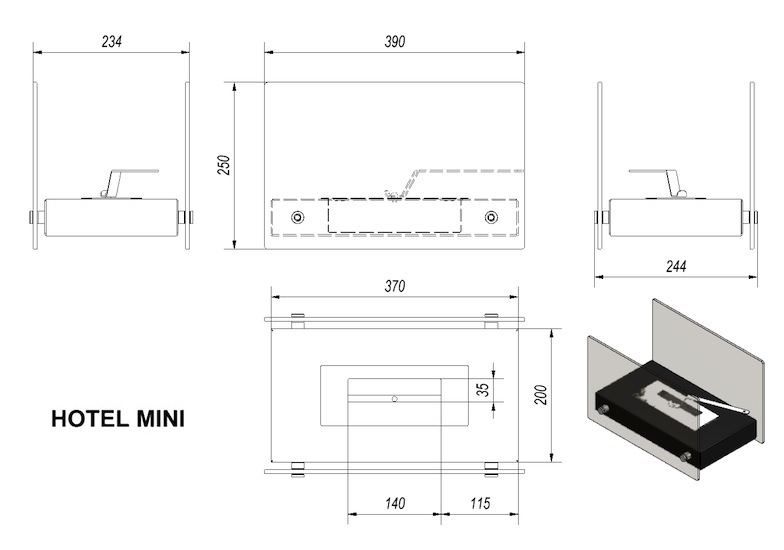

The hearth is the place where the flame burns directly. Small models - desktop, mobile, camping - combine the hearth with a fuel tank without additional parts (except for a cover for long-term storage).Large models have a metal frame in the hearth area, a valve, a control panel and a hidden piezoelectric element for ignition.

Portal - the form in which the hearth is enclosed. The portal can have a wide variety of forms, but most modern bio-fireplaces are made in an ascetic high-tech style.

Biofireplace device, video

Modern modifications of biofireplaces

Today's biofireplaces can be controlled by a remote control and any device that has Wi-Fi. Biofireplaces are manufactured in various sizes and configurations. You can choose the right model in specialized shopping centers. They are produced by various manufacturers, both domestic and foreign.

Most popular models:

- Art Flame. Its design fits perfectly into the interior, as it is made according to the patterns of a design bureau from the USA.

- The Danish manufacturing company introduced its models to the biofireplace market only a couple of years ago. The company has gained credibility with customers due to the high quality of the device, safe performance and unique design.

- Bio Blaze. Dutch devices stand out from others with mobility, they can be moved to any available place. In addition to fireplaces, the company produces liquid fuel fireplace blocks.

- GlammFire is a Portuguese manufacturer of luxury units with a wide range of models from mounted to portable. They are distinguished by the highest consumer quality and are made in accordance with European standards.

Assembly instructions

Having collected the components for the biofireplace, you can begin to assemble the device. Step-by-step instructions will allow you to assemble a biofireplace with your own hands without unnecessary difficulties:

The first thing we need to do is glue the protective glass screen. Silicone sealant dries in the region of the day, so the glass is connected in advance.

Creating a glass protective screen

Then you need to assemble, find, make a metal frame in the form of a box in which the burner will be installed and on which you will put a protective screen.

Suitable metal frame

Protective screen installation

At the next stage, the burner is placed in the frame. If the fuel was sold in a tin, then it may well play this role. If the container was plastic, you can use any tin can of a suitable size.

We place the burner in the frame

We put the wick in the jar, bring it to the grid and close it with decorative stones.

Preparation of the metal mesh

Installing the grid inside the frame on the burner

We cover the resulting structure with a protective screen, lay decorative elements and the home-made bio-fireplace is ready.

We close the grid with decorative stones

We launch a biofireplace

Ecological handicraft fireplace

As you can see, creating an alcohol fireplace with your own hands is quite simple, but this is provided that it is small in size. For large-sized systems, the construction of a special portal will be required. The easiest way to build a structure is from drywall, an easy-to-use and inexpensive material. In this case, the procedure will be as follows:

- The first step is to prepare a platform for the biofireplace. It is necessary to protect the floor from high temperatures. You can make a screed on the floor or lay a brick.

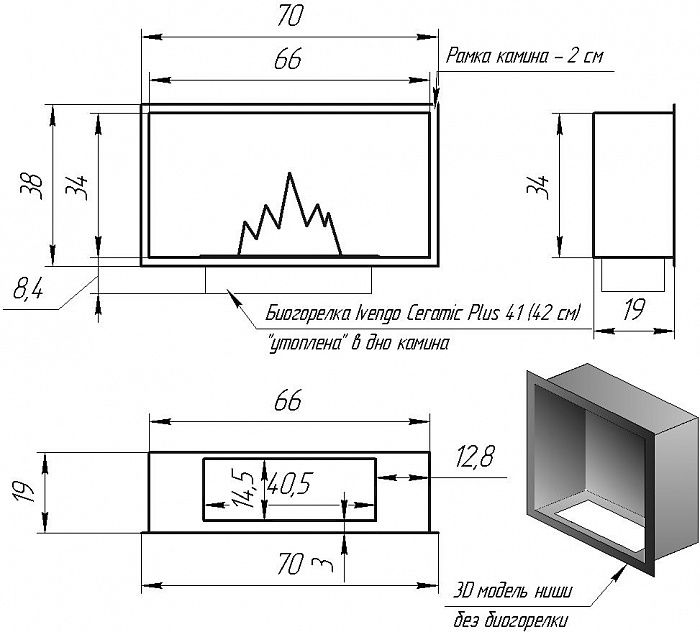

- Then, a biofireplace frame is built from a metal profile, which is securely attached to the floor and wall. Insulating material is laid inside the ceilings.

- The resulting structure is sewn up with drywall on the outside, and smoothed out with tiles or metal sheets inside. Refractory materials will protect the drywall box from the harmful effects of fire.

Construction of a portal for an eco-fireplace

- From the outside, the biofireplace box is decorated in accordance with the interior of the room. Looks great stone finish, plastic panels under the brickwork. Forged items are also welcome, especially matching accessories next to the fireplace. You can put firewood next to the portal, and throw decorative ceramic models of firewood into the firebox of a biofireplace.

- A fuel block is installed inside the resulting portal. If the system is massive, it is best to purchase a ready-made device from a store.

- To protect the environment, a protective glass screen is installed on the fuel block.

The resulting bio-fireplace will undoubtedly become the main element of the room, and a real, live fire will allow you to create a full-fledged comfort in your home.

We hope that now you understand how to make a biofireplace at home. If you are quite ready to carry out the manipulations described above, create a biofireplace with your own hands, but if such work scares you, then just buy a finished device in the store. It is noteworthy that such devices are sold assembled, so you will not have difficulties in starting the system. Read the instructions, turn on the device and enjoy the live fire.

This is interesting: Which water heater to choose for an apartment and a house - an overview of companies with reviews

How to make a biofireplace with your own hands?

This is where we come to the most interesting part, practical and to some extent creative. If you try, then such a unit can be made independently. A small bio-fireplace for an apartment, a summer residence does not require any special knowledge from you, and the result will certainly please you. The main thing is to think over its design in advance, observe the required distances between the walls, the top and the fire source, select the appropriate materials and work out all the steps.

How to make a biofireplace:

To get started, stock up on the necessary materials and tools: glass (approximate size of an A4 paper sheet), glass cutter, silicone sealant (for gluing glass). You will also need a piece of metal mesh (fine-mesh building mesh or even a steel grate from an oven will do), an iron box (it will act as a fuel compartment, so it is better to choose a steel box)

You will also need heat-resistant stones, it can even be pebbles, lace (future wick for a biofireplace), biofuel.

It is important to make correct calculations, for example, the distance from the fire source (burner) to the glass must be at least 17 cm (so that the glass does not burst from overheating). The number of burners is determined by the size of the room in which the eco-fireplace will be installed.

If the room is small (15 or 17 m²), then one burner will be enough for such an area.

The fuel compartment is a square metal box, keep in mind that the larger its dimensions, the further the fire source will be located from the glass. This box can be painted with paint of a suitable shade, but only on the outside! Inside, it must be “clean” so that the paint does not catch fire and does not begin to release toxic substances.

We take 4 glass fragments (their dimensions must correspond to the dimensions of the metal box) and glue them with silicone sealant. We should get something like an aquarium, only without a bottom. During the drying of the sealant, all sides of the “aquarium” can be supported with stable objects and left in this state until the binder mass has completely solidified (this is about 24 hours).

After the specified time, excess sealant can be carefully removed using a construction knife with a thin blade.

We take an iron can (you can use a container from under some canned product), fill it with biofuel and install it in a metal box. It is important that it has thick walls! But the best option is a stainless steel container.

Further, according to the dimensions of the fuel box, we cut out the metal mesh and install it on top of it. The net can be fixed for safety, but keep in mind that you will periodically lift it up to fill the iron can with biofuel.

We lay the pebbles or stones that you have chosen on top of the grate - they are not only a decor, but also help to evenly distribute heat.

We take a string and form a wick for a biofireplace out of it, lower one end into a jar of biofuel.

The wick impregnated with a combustible mixture can be set on fire with a thin wooden stick or a long fireplace match, or a splinter.

This is the simplest model for creating a biofireplace with your own hands, more complex analogues are made using guide profiles, drywall, tiles and other materials. The principle of creating a "burner", a casing and a fuel compartment is similar.To replenish the fuel reserves, you will need to remove the stones and raise the metal grate, but you can use a large syringe and direct a stream of flammable liquid between the cells of the grate, directly into the iron jar.

I want to pay special attention to the "heart" of the whole structure - the burner. A burner for a biofireplace is, in other words, a container for fuel

Factory burners are already manufactured according to all required standards, the most reliable material is stainless steel, such a burner will last a very long time without deformation, oxidation and corrosion. A good burner should be thick-walled so that it does not deform when heated. Also pay attention to the integrity of the burner - it should not have any cracks or any other damage! Under the influence of high temperatures, any crack increases in size. To avoid spillage of fuel and subsequent ignition, treat this nuance especially meticulously.

By the way, if you make a biofireplace yourself, you can make another version of the burner. To do this, do not fill the steel container too tightly with white glass wool, cover it from above with a grate (or mesh) cut to the size of the container. Then just pour alcohol and light the burner.

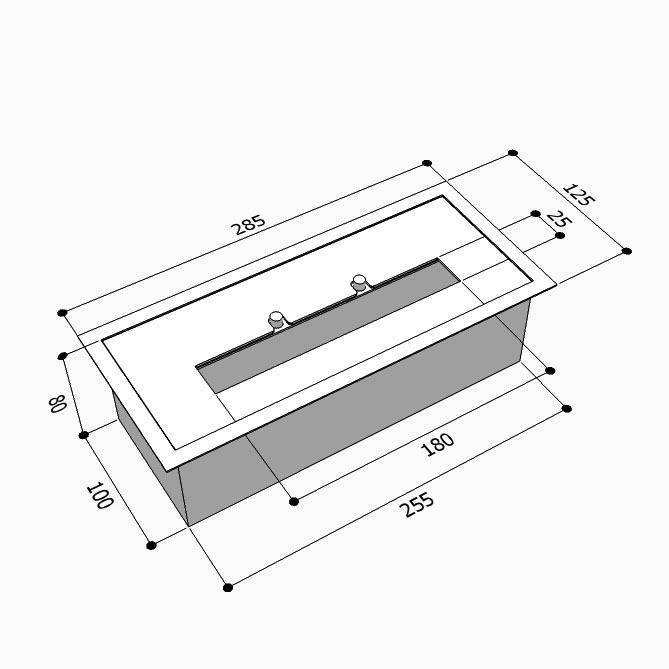

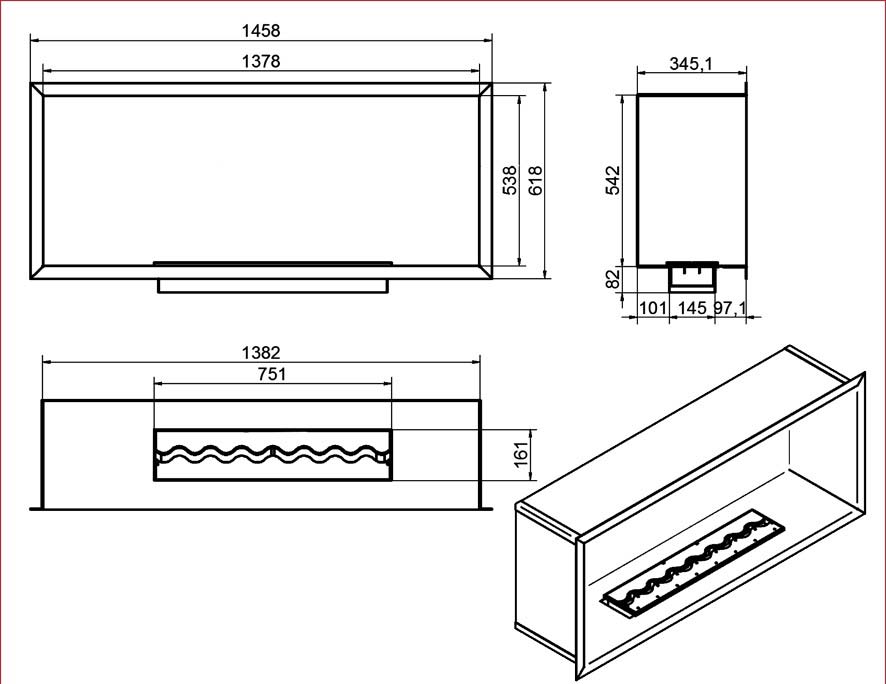

Instructions for assembling a large bio-fireplace

If you need to make a large biofireplace, the most difficult thing will be the manufacture of a fuel tank. The easiest way is to purchase a finished item in a specialized store.

If you plan to make a tank yourself, you need to take a sheet of metal with a thickness of more than 3 mm. It must be stainless steel, otherwise, during combustion, undesirable chemical reactions and even the appearance of toxic fumes are possible.

Specialized stores sell stainless steel fuel tanks for biofireplaces. They are equipped with convenient latches for extinguishing fire.

Actually the tank should consist of two compartments. The bottom one is for filling fuel. Flammable liquid vapors burn in the upper compartment. Between these compartments there must be a separating plate with holes through which the vapors enter the combustion zone. The shape of the tank may be different, it depends on the model of the fireplace.

The most popular option is a parallelepiped-shaped fuel tank with a narrow upper compartment.

It is easier to make a cylindrical tank. To do this, you can take an ordinary mug and cover it with a cut-to-size lid made of fine-mesh metal mesh. It will be possible to fill fuel through the grid, which is quite convenient.

There can be several such tank mugs in the design of a biofireplace. They can be arranged in several rows or in a circle.

It is important not to forget to remove the handles from the mugs. This must be done carefully so that a hole does not form.

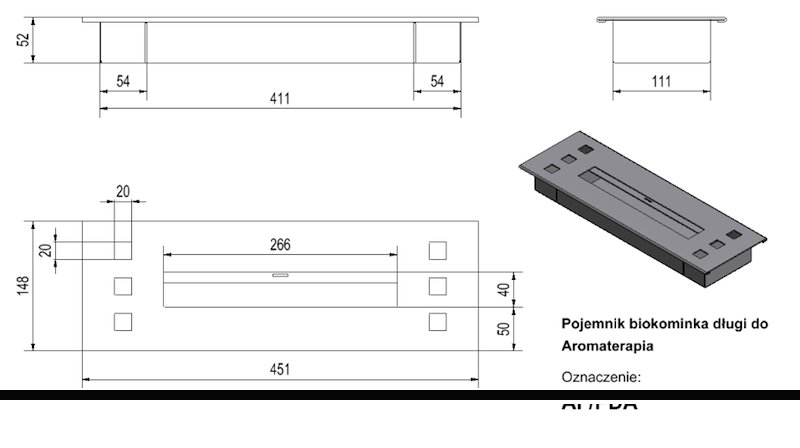

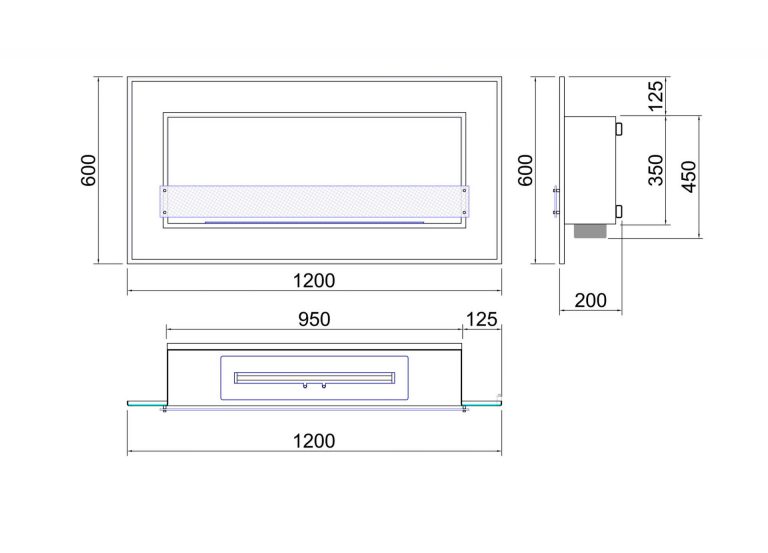

Having decided on the fuel tank, you can begin to manufacture a biofireplace. Let's make a floor model with two glass screens. For work, you need to prepare fire-resistant glass for screens, a parallelepiped-shaped fuel tank, washers, bolts and silicone gaskets for glass, plastic or metal legs.

In addition, for the manufacture of the base, we need thick plywood or drywall, self-tapping screws and wood bars 40x30 mm.

We start from the foundation. We mark out a sheet of plywood and carefully cut out the side parts of the base box and the top panel from it.We will not do the lower part of the box.

Firstly, its presence will significantly weight the structure. Secondly, without it, it will be much more convenient to fix glass sheets. We are preparing two pieces of a wooden block, on which plywood will be fixed.

Biofireplace with two glass screens can be made independently. The design of the base can be very different - in the form of a console, table, box

On the panel cut out of plywood, we outline the place where the fuel tank will be fixed. Cut out the required mounting hole for the tank. Now we assemble the frame and fix the top panel on it. The edges of the structure are well processed.

If we used not plywood, but drywall, its edges must be treated with putty. We decorate the resulting base in any suitable way: paint, varnish, etc.

Cooking glass panels. First, cut out two pieces of the desired size. In each of them you need to drill holes for decorative fasteners. This is quite difficult, because the slightest mistake can crack the glass. If there is no experience in such work, it is better to entrust the process to an experienced craftsman with a set of special tools. Holes for fasteners are also drilled on the side walls of the base.

Now we fix the glass screen on the base. To do this, we pass a bolt through the glass, do not forget to put on a silicone gasket so as not to damage the glass. We pass the bolt through the base, put on the washer and tighten the nut

This must be done with extreme caution, without applying excessive force, otherwise the glass may crack. Thus we install both glass screens

In the process of assembling the structure, silicone gaskets are necessarily used, otherwise the glass may not withstand the load and crack. It is wise to use a more durable option - tempered glass

On the bottom of the glass sheet you need to put the legs. To do this, we put rubber gaskets into the parts and put them in place. We check the correct installation of the legs. The biofireplace should stand exactly, not sway.

Using the prepared hole, we mount the fuel tank and securely fix it. The structure is almost ready. It remains to decorate it with stones or ceramic logs, if necessary.

A simple do-it-yourself biofireplace: instructions for making

First of all, you will have to make a base to secure the fuel tank with a damper, which are commercially available, and their cost is quite affordable. Yes, and the acquisition will solve a rather big problem - you do not have to do it yourself. The bars are cut to size, and fixed between sheets of plywood or drywall.

- The upper part of the base should have a rectangular hole where the fuel tank will be placed.

- Next, on the main frame, you need to fix all the other elements of the base of the biofireplace, while you need to carefully process all the edges. Moreover, if you use drywall, then you will have to carefully cover the edges with putty, otherwise they will look ugly.

- Glass panels made of heat-resistant material will have to be drilled, and this is far from easy to do at home. Therefore, it is worth contacting a real professional who will make the holes as needed, having the necessary materials, as well as special tools.

- Glass side screens should be mounted very carefully, as the glass may well burst if overloaded. Moreover, from the front, it is better to use bolts with decorative heads, which are also easy to find on the shelves of modern stores.

- When the design is completely ready, you need to install the fuel tank and burner, then the work will be fully completed.

Worth remembering

In no case should you set fire to a biofireplace with “improvised” means, such as wood chips or rolled paper, as this is fraught with burns. It is best to purchase a gas lighter with a long spout, it will be safe and inexpensive.

Thus, it turns out that you can make a biofireplace with your own hands, the video fully confirms this, you can do it on your own, and without any problems and difficulties. Moreover, beautiful stones, artificial firewood and other materials that do not burn can be laid around the burner.

Option number 2: outdoor biofireplace

You can make a beautiful outdoor biofireplace based on an aquarium. In addition to it, you will also need:

• metal mesh (according to the size of the bottom of the aquarium) - 2 pcs.;

• capacity for fuel;

• coarse sand;

• large round stones (about 10-15 cm in diameter);

• lace, which performs the function of a wick;

• fuel.

First, a metal mesh is placed in the aquarium, which is covered with sand (15-20 cm layer). Then one or more small metal containers are buried into it. At the same time, a distance of at least 15 cm must remain between the glass and the fuel tank. Then a metal mesh is laid again, the elements of which will hold the wick. The container is filled with fuel, one end of the lace (wick) is immersed at the bottom, the other is fixed over the grid.For camouflage and aesthetics, it remains to lay large stones on top of the sand, artfully covering the peeking surfaces of the fuel tank.

This option is simple. You can decorate it with any heat-resistant items, so there is an opportunity to show your own design talent. The design is mobile, easy to change location.

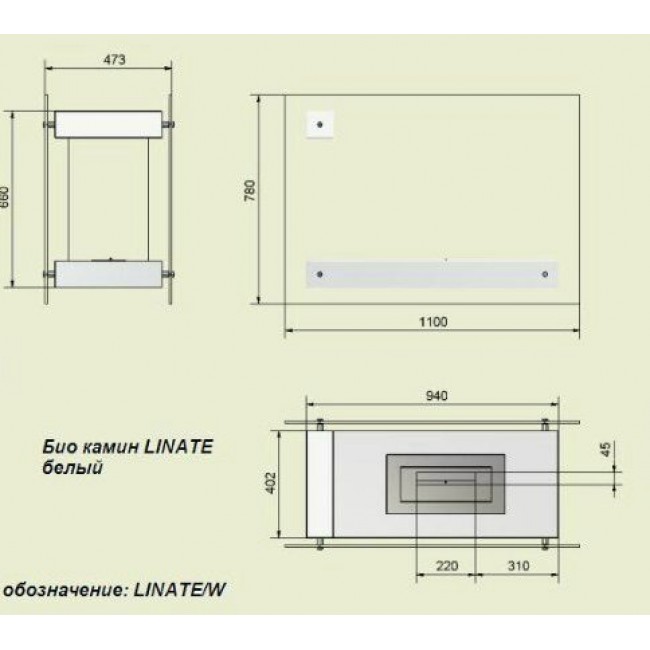

Instructions for the manufacture of a wall-mounted biofireplace: from preparation to implementation

The technology for creating a wall structure is practically the same as floor or desktop options.

The technology for creating a wall structure is practically no different from floor or desktop options. Initially, the design is thought out, the type of biofireplace is selected - straight or angular. Based on it, a drawing is developed, where fire safety is taken into account with dimensions. In other words, the distance from the hearth to the walls and the mantelpiece must be observed (at least 15 - 20 cm). Then markings are applied to the walls and construction work begins.

Please note that such a biofireplace is immediately mounted on the wall

As in previous versions, calculations should be made taking into account fire safety.

To do this, you will need materials and tools:

- drywall;

- metal profile with rack and guiding elements;

- self-tapping screws, dowel-nails;

- screwdriver;

- sheets of glass;

- heat-resistant insulating material;

- ceramic tiles for decoration;

- heat-resistant glue;

- grout;

- decor.

The process is carried out in several stages:

- Fastening guide profiles according to the markup, into which rack elements are then inserted. In this case, the structure is fixed with self-tapping screws. Thus, the entire frame is assembled.The main thing is not to forget about the arrangement of the double inner walls of the biofireplace, which will allow you to slightly reduce the temperature at the base of the hearth.

- Laying insulating material in the walls of the frame.

- Sheathing with prepared sheets of drywall, which are mounted on self-tapping screws.

- Finishing work. At this stage, you need to apply gypsum plaster, and then glue the frame, with the exception of the place under the burner, with ceramic tiles, tiles or wild stone, depending on the desires and possibilities.

- Seam grouting.

- Installation of a burner, which can serve as a purchased design, or a simple metal glass with a wick lowered into it.

- Preparation and installation of a fireplace grate or protective glass. The latter can be purchased at the store in the form of a special box without a lid, or you can make it yourself from a sheet of glass, connecting the elements with a sealant and waiting for it to dry completely.

When operating a biofireplace for the first time, the burner bowl needs to be filled only to a third of the depth, leaving a distance from the fuel to the edges (at least 2 cm). If drops or drips form outside, they must be wiped with a damp cloth. When lighting the wick, one should be prepared for the fact that a gas flash may occur at the time of ignition.

The operating time of the biofireplace depends on the capacity of the bowl. If it becomes possible to extinguish the flame in advance, you need to use special extinguishers, which you can always buy in a store or make yourself from metal. They are designs with a handle, at the end of which there is a cover for the burner.

No. 1. How does a biofireplace work?

Biofireplace is a relatively new invention. Its author is the Italian Giuseppe Lucifora, who designed the first biofireplace in 1977.Did he then think that his invention would become so popular! Today, biofireplaces are actively used in the interior design of city apartments and country houses. Often they are installed outdoors, in a summer cottage, for example. What caused such a widespread use of the device? To answer this question, it is necessary to understand the principle of operation of a biofireplace and its main components.

A biofireplace is completely different from a conventional wood-burning fireplace. To obtain a flame, a special fuel (bioethanol) is used, which is poured into the tank and ignited. Fuel burns without emitting carbon monoxide and other harmful products. This is in short. To delve into the process of biofireplace operation, it is necessary to study its structure:

- the burner is made of non-combustible materials (steel, ceramics, stone) and is decorated with sand, real stone, or imitation of firewood and coal. All elements that cover the burner must be non-combustible;

- the fuel tank, where bioethanol is poured, has a volume of 0.7 liters to 3 liters, in rare cases more. The larger the tank and the more fuel you can pour into it, the longer the process of continuous burning will be. On average, 1 liter of fuel is enough for 2-3 hours of fireplace operation. It is possible to add a new portion of fuel only after the device has cooled down. A fire is kindled by bringing a special long lighter. You can use fireplace matches, but it is dangerous to use folded pieces of paper. In automatic biofireplaces, the ignition process is easier - at the touch of a button;

- biofireplace fuel is obtained from vegetable crops rich in sugar. On combustion, it breaks down into carbon dioxide and water vapor.There is no soot, soot and smoke, so it is unnecessary to equip the chimney, but good ventilation will not hurt. Experts compare a biofireplace with a conventional candle in terms of the level and nature of emissions. Some biofireplaces burn bioethanol vapors;

- the portal is usually made of tempered glass. This material withstands heat and provides you with unhindered admiration of fire from different angles. The power and height of the flame can be adjusted thanks to a special damper, but the flames will never be higher than the glass barrier;

- the frame is the skeleton of the biofireplace. All functional parts of the product, as well as decor, are attached to it. The frame ensures the stability of the location on the floor, fastening to the wall (for wall models). The decor can be different, it completes the appearance of the fireplace and makes it a bright interior detail;

- there may be some additional components that significantly expand the functionality of the biofireplace. For example, a system of sensors that monitor work, sound design, buttons that turn on automatic fireplaces. Some appliances can be controlled with a remote control or even with a smartphone.

The intensity of the flame is regulated by flaps. When you move it, the flow of oxygen to the burner decreases or increases, which determines how large and powerful the flames will be. By blocking access to oxygen, you can completely extinguish the fireplace.

Biofireplace is bought and installed, first of all, for the beauty and feeling of comfort of the hearth. However, its benefits are not limited to this. Since there is a real fire in the fireplace, heat comes from it.A biofireplace can be compared with a heater with a power of up to 3 kW, it can easily heat the air in a relatively small room (about 30 m2), but it is not considered as a replacement for a heater, and tempered glass is not able to retain the accumulated heat for a long time.

If in a traditional fireplace heat loss due to the exhaust system reaches 60%, then in a biofireplace only 10% is lost - the remaining 90% go to space heating.

As for ventilation. A chimney for a biofireplace is not needed, but high-quality ventilation must be equipped. However, this requirement also applies to apartments where there is no biofireplace. If you feel that home ventilation is not coping, you will sometimes have to open windows and ventilate.

Biofireplaces can be very different in form, so this detail will perfectly fit into any style of interior, from classic to hi-tech.