- What are concrete rings for?

- Production and application of concrete rings

- Types of drainage

- On-mountain! or surface work

- How to save on construction?

- Calculation of capacity and choice of septic tank design

- Manufacturing procedure

- Technology and stages of construction of a well from concrete rings

- Construction of a well with alternate installation of rings

- Installation of rings in the finished shaft

- Internal waterproofing

- External waterproofing of the well

- Additional Recommendations

- Deepening a well by digging

- Carrying out preparatory work

- Deepening works

- Final work in the well

- Preliminary work

- Location selection

- Volume calculation

- Selection of materials

What are concrete rings for?

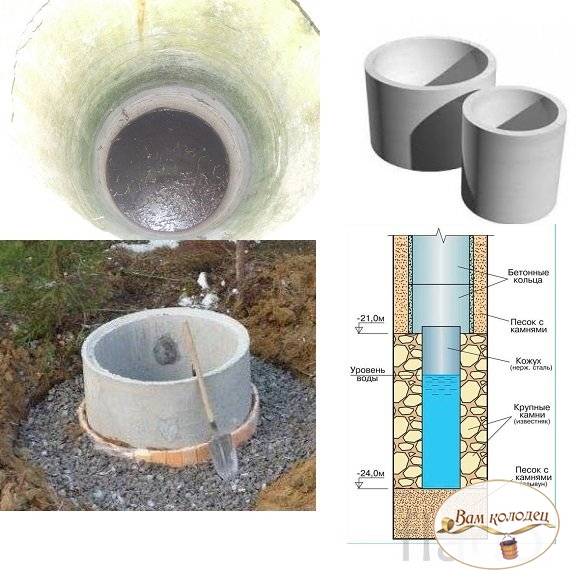

Most often, concrete rings are needed for the construction of a well, but they are also used in the construction of an autonomous sewage system - they make septic tanks or filtration wells. Another area of application is manholes in the construction of a storm and drainage system. Make out concrete rings even cellars. And there are different options - vertical, horizontal. In general, the scope is wide.

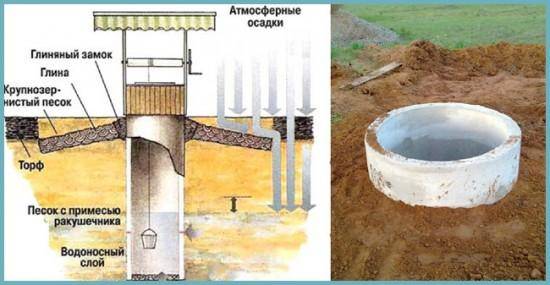

Concrete rings are used for the construction of various structures

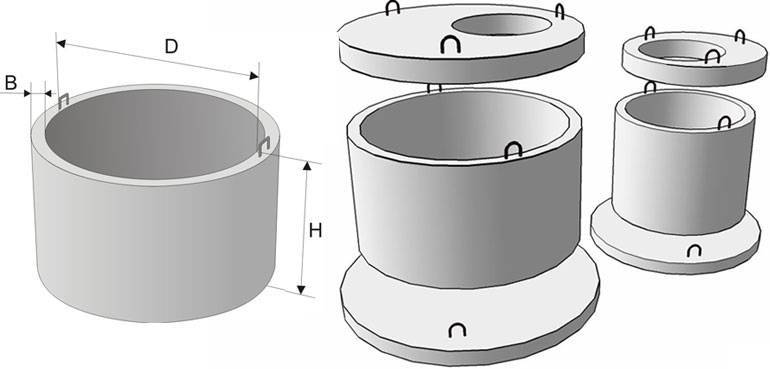

There are rings of different sizes for different needs, they also have different wall thicknesses, they can be with or without reinforcement.Despite such an abundance of choice, many are thinking about making reinforced concrete rings with their own hands. The thing is that when arranging a site, you may need more than one ring, or even ten. For some, it takes more than a dozen just to make a well. The cost of manufacturing reinforced concrete products is much lower than their retail price. Even taking into account the fact that you have to make molds for concrete rings. And if you also take into account the cost of delivery, then the savings are very solid.

Production and application of concrete rings

In construction at Kaluga facilities, concrete rings are the most commonly used material. Higher demands are placed on the quality of these building elements.

The greatest attention is paid to the high strength of the rings, which must be ensured by a competent arrangement of the reinforcing cage. The choice of brand of concrete and its quality are also decisive in the production of reinforced concrete rings.

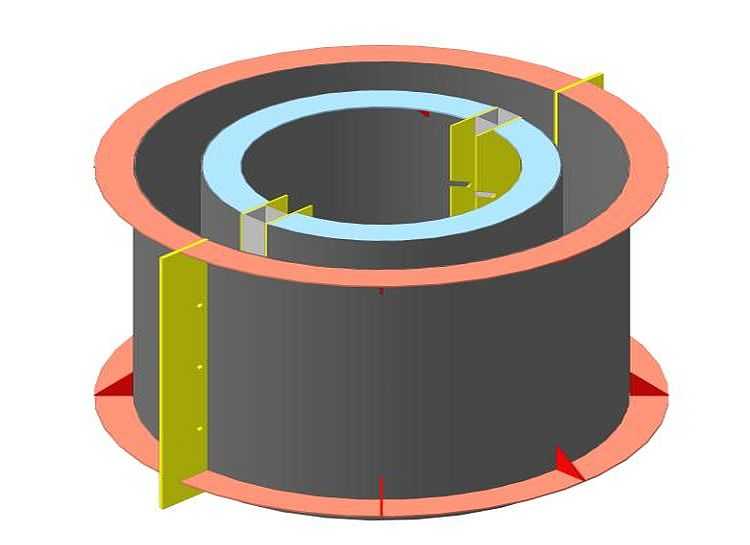

Currently, Kaluga enterprises produce concrete rings using a simple and optimal centrifugation method. Initially, a form is made that will be a container for the future product, so it is subject to a strict requirement to clearly match the desired dimensions. It is necessary to remember the quality of the manufactured product, especially the strength indicator, therefore, after creating the mold, a frame made of iron reinforcement is mounted into it. The main purpose of the rings is to strengthen the structure, their installation is a rather laborious process. Therefore, the frame of iron reinforcement, which reinforces the concrete rings, is made with great care to give the product maximum strength.Next comes the turn of the centrifugation process, based on the imposition of two forms. The modern production of reinforced concrete rings in Kaluga guarantees reliable product quality.

The manufacturing process in Kaluga consists of two superimposed one on one forms. This is followed by the process of applying concrete of the desired quality. After the material is placed, centrifugation begins, during which the centrifugal force evenly distributes the concrete. The process is not completed after a single entry, since the product may not be of sufficient quality. Therefore, at this stage, the speed is periodically changed, and the movement in the centrifuge is re-produced. A reinforced concrete ring of the required quality is formed, it is sent to the oven to dry.

A key feature of the ring manufacturing process is centrifugation. It is not simple, so it is rarely used. During this stage of production, you need to be extremely careful and accurate, observing all the subtleties of production. Subject to these conditions, the production of reinforced concrete rings in Kaluga ensures the production of high-quality and certified products that meet state standards.

Types of drainage

Although the term "drainage well for sewerage" is often used, there are actually several varieties of such structures. They differ from each other, first of all, by purpose. In addition, tanks can be made from different materials and have different sizes. But the device of the drainage well in general terms will be the same in all cases. All types of such structures are a specially equipped shaft or container, and in most cases its bottom is isolated.Drainage sewer pipes are brought into this container. The top of the well is closed with a hatch.

First of all, it is necessary to highlight the viewing wells for drainage. They are necessary in order to regularly conduct scheduled inspections of the sewer, to monitor the condition of the pipeline, carry out repairs (if necessary) and clean the pipes. A revision well (this is its second name) is arranged where there is a risk of system silting. The size of the structure must correspond to the parameters of the sewer system as a whole. If the pipeline is small, then the diameter of the manhole should be 340-460 mm.

For a large sewer system, the revision well should be larger. It can be up to one and a half meters in diameter. Often it is equipped with steps along which you can go down inside - for repair work. Cleaning of such tanks is carried out only by flushing pipes with a strong pressure of water (high pressure jet).

Another variety is a storage well, which is also called a collector or water intake. As its name implies, it is needed in order to collect water and then pump all of its volume into the gutter. The storage well is a container of large diameter and volume. Each pipe of the drainage system is connected to it. Such a reservoir must be equipped where it will not be possible to arrange a filtering well or otherwise ensure the drainage of water collected by sewerage. Usually they try to place storage wells outside the site.

In such cases, the receiving tank is equipped with an electric pump, with which the accumulated water is pumped out, in order to then water the garden with it or dump it into a reservoir.

Another type is filter wells. It is advisable to arrange them where the soil is not too wet. Usually such sites are located quite far from natural reservoirs. The filter type is suitable for those cases when the volume of water to be pumped out per day does not exceed 1 cubic meter.

On-mountain! or surface work

After the question how to dig a well of the concrete rings cleared up a bit, it's worth wondering if how to insulate a well from concrete rings.

The main function of insulation and protection of the trunk from freezing is performed by lyada. However, before proceeding with its construction, it is necessary to carry out the implementation of such an element as a concrete blind area around the well.

Concrete edging of the neck of the well shaft should be carried out with approximately 50% overlap of its section, as in the presented photo

Concrete edging of the neck of the well shaft should be carried out with approximately 50% overlap of its section, as in the presented photo

As mentioned above, the blind area fastens the mouth of the trunk and serves as the foundation for the future Lyada. However, before equipping the blind area, as mentioned above, the walls around the mouth of the trunk must be covered with clean clay and carefully seated, thoroughly rammed in several passes.

The concrete preparation for the well carried out in this way will make it possible to obtain a reliable foundation with a good hydraulic lock around the junction of the surface structure and the underground part, and to obtain a comfortable working area around the well.

Cross section showing the main structural elements

Cross section showing the main structural elements

The concrete slab is poured according to the classical technology with reinforcement with metal elements of the slab body.

Liada is built of wood, brick, wild and artificial stone.There are many options for a constructive solution, and their implementation directly depends on a number of specific objective reasons, including financial capabilities.

Inside it is placed either a manual gate for lifting water, or a pumping station. When laying a water line with a pump supply, it is necessary to provide either the possibility of discharging water from the system, or to provide measures against freezing of the pump and communications in the cold season.

As long-term practice shows, making a concrete well yourself is still half the battle, it is necessary to ensure the repair of a concrete well.

Repair of wells of this type can be current and capital. The current repair eliminates all minor shortcomings that arise during its operation, including periodic disinfection of the well shaft with bleach and special reagents.

Before disinfection, it is desirable to make a control sample on a small volume.

Before disinfection, it is desirable to make a control sample on a small volume.

A major overhaul is more extensive and is necessary when:

- The level of the water column has risen radically as a result of alluvium of sand in the lower part of the trunk.

- Displacement and separation of rings with the destruction of clay locks and seams.

- Decrease in water level and deterioration of its quality due to silting of the catchment area.

- Breakthrough of a clay cushion at the site of waterproofing in the neck of the trunk.

Some of these works have to be done manually, with the maximum possible pumping of a column of water from the trunk. It will not be superfluous to recall the observance of safety precautions during such work.

Sometimes it would be more rational to involve specialists from specialized and specialized organizations in carrying out such work.

Carrying out work on cleaning the well manually is associated not only with inconvenience, but also with a certain risk.

Carrying out work on cleaning the well manually is associated not only with inconvenience, but also with a certain risk.

Part of the work, such as sand and silt infiltration, can be carried out remotely. In this case, you need a powerful drainage pump and a supply of clean water to supply it to the well shaft.

By supplying water and washing away the deposits with pressure, and then pumping out the excess, in some cases it is possible to restore the normal flow of water without even getting your feet wet.

Remote cleaning is much safer, although it requires certain skills and additional workflow equipment.

Remote cleaning is much safer, although it requires certain skills and additional workflow equipment.

You can learn more about operations during repair work from the video in this article.

How to save on construction?

If it is not possible to use special equipment during installation and finances do not allow you to attract a team of workers, try using these methods.

Instead of the traditional digging of a pit with the subsequent immersion of the rings in them, use a technology in which the soil is extracted gradually as the ring is deepened. It is based on the fact that the ring under the influence of its weight falls down. The task of the master is to dig the soil inside the ring and under its wall.

The technology of "digging" the rings laid on the ground is used only when installing products without a bottom

The technology of "digging" the rings laid on the ground is used only when installing products without a bottom

The concrete bottom in this case will have to be poured later. And it will be located exclusively inside the ring.

A significant disadvantage of the described method is the inability to perform heat and waterproofing on the outer walls of the structure. In addition, due to the fact that the bottom is located inside the ring, the reliability of the structure is reduced.

In an effort to reduce the cost of the structure itself, the masters offer a variant of the construction of the structure, which looks like a triangle.

Storage tanks are the basis of an isosceles triangle, and their common neck is its top.

By choosing this arrangement option, you will save space for placing rings and can significantly reduce the amount of land work.

But during installation, take into account the peculiarity that the revision entrance in such a design will be one for three rings. Therefore, all overflows should be placed outside the zone of its accessibility.

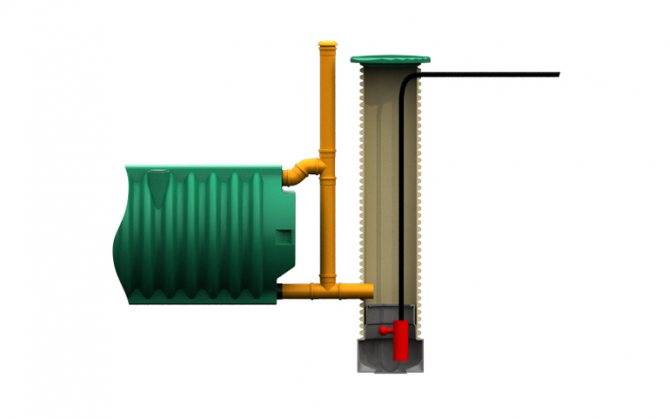

Calculation of capacity and choice of septic tank design

The volume of wastewater is the basic value taken into account when designing any treatment plant. Sanitary standards set it at the level of 200 l / day per person. In addition, the capacity of the septic tank should be equal to 3 daily volumes of sewage. Based on these two conditions, the capacity of the structure can be calculated. So, for example, a family of 4 people will need a septic tank with a volume of: 4 x 200 l / person x 3 = 2,400 liters. (2.4m3).

The second issue that needs to be resolved is the number of cleaning chambers: one, two or three. If no more than 3 people permanently live in the country house, then you can limit yourself to one camera.

With a larger number of residents (4-6 people), the sewerage system in the country house of concrete rings is made two-chamber. It copes better with a large flow of sewage. Three cleaning tanks are used in houses where several families live.

Each chamber of the septic tank performs certain tasks:

- In the first one, sedimentation of effluents and anaerobic (oxygen-free) decomposition of organic matter takes place. Heavy particles sink to the bottom here, while light particles float to the top.The clarified water flows through the pipe into the second chamber;

- In the second tank, the effluents undergo additional bacterial treatment and are discharged into a filtering trench or well. Oxygen (aerobic) decomposition of organic matter takes place here.

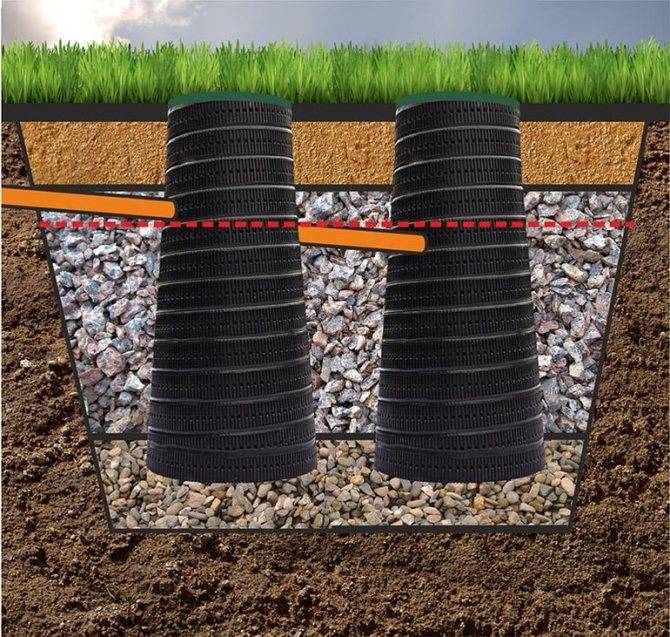

The choice of filtration method depends on the level of groundwater and the type of soil. In the absorbing well, water goes into the ground through perforated walls and a bottom covered with fine gravel.

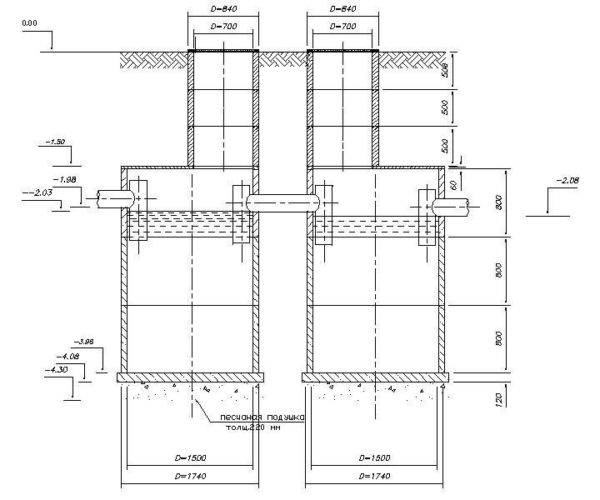

Two-chamber septic tank from reinforced concrete rings with a filter well

Two-chamber septic tank from reinforced concrete rings with a filter well

With a high level of soil water and soil that does not absorb moisture well (clay, loam), an absorbable trench is made (filtration field). A perforated pipe wrapped with geotextile is laid in it and covered with drainage material (crushed stone, gravel + sand). Due to the large length of the pipe and the presence of a filter bed, the final cleaning process proceeds normally even in heavy and wet soil.

Three-chamber septic tank with a filter trench

Three-chamber septic tank with a filter trench

Having determined the capacity, the number of chambers and the type of filtration structure, you can proceed to the choice of a place on the site. A diagram will help you with this. It indicates the minimum allowable distances from the treatment plant to water sources, trees and the road.

Sanitary breaks between septic tank, water source and other facilities

Sanitary breaks between septic tank, water source and other facilities

From this diagram it can be seen that the largest distance of the sewer facility should be from the source of drinking water (50 meters). On a summer cottage with an area of 5 acres, this requirement is not feasible. Here you will have to install a device for disinfecting drinking water with an ultraviolet lamp or use an imported bottled one.

In addition to observing sanitary breaks, the septic tank must be placed so that its chambers can be reached by the hose of the sewage truck.

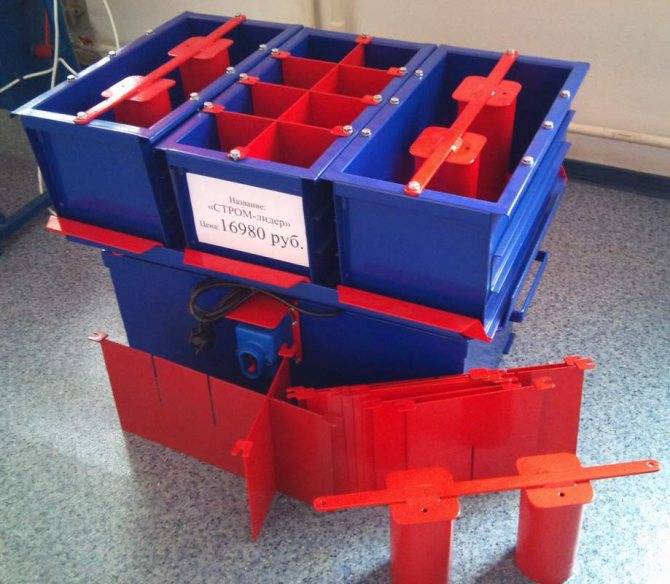

Manufacturing procedure

First you need to find the most flat area. An iron sheet is laid on it. Then you need to install the outer formwork. If it is necessary to make a tongue-and-groove ring, it is necessary to lay the groove shaper from below. After that, the installation of the reinforcing mesh is carried out.

Then carry out the installation of the internal formwork. It must be fastened to the outside. The solution is poured into the resulting form for concrete rings. For this purpose, a shovel or other device is used. As soon as the ring is completely filled, vibration should be carried out. If necessary, a ridge ring is laid on top.

At the plant, stripping is carried out almost immediately after concrete compaction. A hard solution hardens quickly enough. The formwork set is used for the following product. To remove the formwork, it is necessary to remove the fingers fastening the inner and outer parts. The void former placed under the ring is left in place until the product has completely solidified.

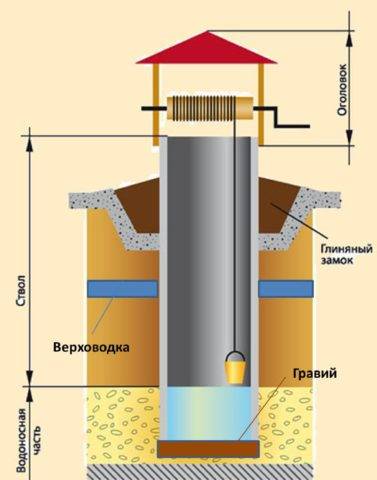

Technology and stages of construction of a well from concrete rings

It is unlikely that anyone is going to pour concrete rings on their own, because this is not only a complex and time-consuming process, but also meaningless. It is much easier to buy ready-made products in the right amount, which is easy to calculate, knowing the depth of groundwater.

Construction of a well with alternate installation of rings

The mine is always dug with a short-handled shovel by hand, with such a tool it will be much easier to manage in a limited space.When the hole of the corresponding diameter is about half a meter deep, check the evenness of the bottom and install the first ring

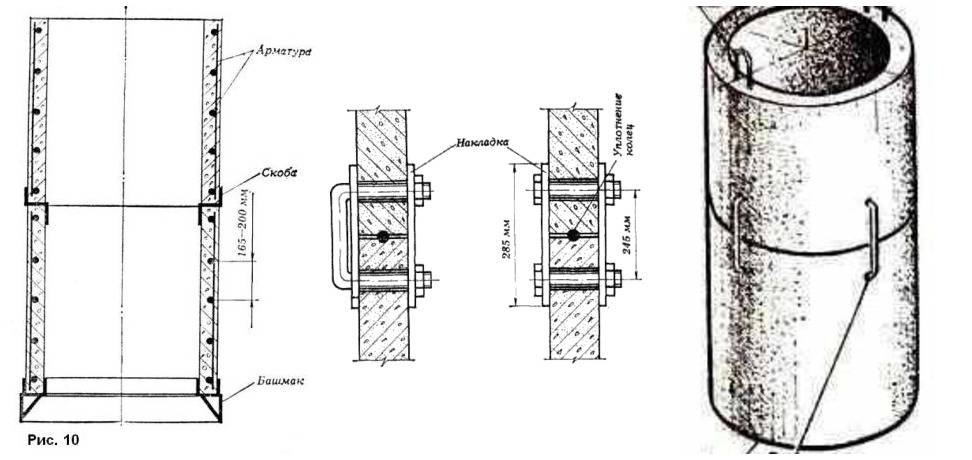

It is important that it becomes exactly in the middle of the shaft and does not rest against one of the walls. After that, they continue to dig the ground, but already inside the reinforced concrete product. As the soil is excavated, the ring will gradually deepen under its own weight, and when it reaches the upper edge of the ground level, the next ring is placed on top of it and fixed with brackets

As the soil is excavated, the ring will gradually deepen under its own weight, and when it reaches the upper edge of the ground level, the next ring is placed on top of it and fixed with brackets.

It happens that the hole is dug, but the ring does not fall. This means that it is located at a slope from the vertical axis. You can correct the position, put a shield on top and throw stones or bears from the ground on the side that needs to be besieged. When the ring starts to sag, the overweight is removed. They keep going down. And so on until the water begins to seep through the bottom of the mine. They continue to dig for some more time, pumping out the arrived water with a pump. Stop work when the mine reaches the first aquifer. The water will begin to flow very quickly. But they still continue to pump it out so that it is possible to level the bottom and lay the bottom filter, if it is necessary in a particular case.

Installation of rings in the finished shaft

There is another construction method, when the rings are lowered in turn into a mine completely dug to the aquifer. But this method is less popular and is not possible on all types of soil. It is also dangerous that at any moment, even before laying, the earth may collapse.Concrete rings are lowered into the pit with a crane, placed on top of each other and fixed with steel brackets around the circumference of the connection.

Internal waterproofing

All seams between the rings are sealed with a solution or a special ready-made composition. When lubricating them, do not forget about cracks and pits, which, under the influence of moisture, will quickly collapse and cause depressurization of the mine. It is strongly not recommended to use solutions that contain bitumen, as they can significantly spoil the taste of water.

External waterproofing of the well

The waterproofing of the well from the outside will prevent the top water from entering the mine. To do this, they make the so-called clay castle. A trench about 0.5 m wide and 1.5-2 m deep is dug around the last rings. Clay is poured into it and compacted tightly. As a result, it should lie slightly above the soil level closer to the well, and ensure that the sediments leave the slope from the mine.

The site is being concreted. Over the next 2-3 weeks, the water must be pumped out several times. It can be used for domestic needs, but for drinking purposes it is better only after a conclusion from the laboratory.

Additional Recommendations

When performing work, the following tips will be useful:

- to find out how many reinforced concrete products will be needed to build a well, you need to know the depth of the aquifer;

- in the summer, using one set of wooden formwork, you can make about 10 rings, then you need a new one;

- it is recommended to connect the block components with steel brackets, under which the corresponding holes must be prepared;

- joints are best sealed with a tarred rope, 20 mm.It is laid in a groove, previously prepared in rings. The high density of the joint will be provided under the weight of the rings themselves.

The whole range of works is available for self-study and can be successfully implemented in practice.

Making concrete well rings with your own hands using steel formwork is shown in the video:

Deepening a well by digging

This method differs from the one described above in that the well is built up with repair rings from above. Moreover, their diameter does not differ from those that have already been installed.

In fact, this is a continuation of the work begun many years ago with the initial digging of the well. The main danger in using this method is the possibility of the old column getting stuck in the ground, especially if the well is located on clay rocks.

Carrying out preparatory work

We start by fixing the rings. At each joint we fix at least 4 staples. We drill holes for them, put metal plates 0.4x4x30 cm and fix them with 12 mm anchor bolts.

Thus, the casing string will be able to withstand possible ground movements. We pump out water from the well and completely remove the bottom filter, if it was present in the structure.

Deepening works

A worker descends on the belay and begins to dig. First, he selects the soil from the middle of the bottom of the structure, then from the periphery. After that, he begins to dig under two opposite points from the edges of the lower ring with a depth of 20-25 cm.

It is no longer necessary, otherwise there is a danger of an uncontrolled descent of the element.Then the tunnel is gradually expanded to the annular area.

During operation, the column must settle under its own weight. New rings are placed on the space vacated on top. Undermining is carried out until the water begins to arrive very quickly.

It should be noted that column subsidence does not always occur, especially if the well is “older” than 1-2 years. In difficult cases, the side digging method can be used as a way to lower a stuck ring.

It looks like a spatula, which is used for lateral digging of rings. The handle, longer than 40 cm, should be bent for comfort and precision

Consider it on the example with the lower ring. We carry out the digging as already described. Then we take three hemp or strong supports from a bar and place them under the ring so that there is a distance of about 5 cm between them and the bottom edge.

These supports will subsequently take on the entire weight of the settled structure. Then, in two opposite sections, we remove the sealing solution from the annular gap.

We insert nail pullers into the resulting gaps, and two people, simultaneously acting as a lever, can try to lower the ring. If all else fails, we take a special spatula for undermining the side walls.

For its handle, fittings 10 cm long and 14 mm in diameter are used. The cutting part measuring 60x100 mm is made of 2 mm sheet iron. We insert the spatula 2-3 cm from the outer wall of the ring and proceed to hollowing out the clay.

To do this, hit the handle with a sledgehammer from the bottom up. Thus, we pass the entire ring except for the sections under which there are supports. We managed to remove the clay to a height of 10-15 cm from the lower edge of the ring.

Now you can try again the lowering attempt with the nail pullers or any other levers. If not, take the next blade. The length of its handle should be 10 cm longer. We perform similar steps.

At the end of the repair work, you should once again inspect all the seams and carefully seal them, then cover them with sealant

A small note: when the length of the shovel handle reaches 40 cm or more, it will need to be bent a little. So it will be more convenient to work. With proper lateral digging, the outer wall of the ring is gradually released, and it settles down. Similarly, work is carried out on other rings.

Final work in the well

At the end deepening works all contaminated water is removed from the facility. All seams between the rings are securely sealed and sealed. If damage to old seams is noticed, they are also eliminated.

At the bottom of the structure we lay a new bottom filter of the desired design. Then we disinfect the walls of the mine with a solution of chlorine or manganese. The well is ready for use.

Do not forget that the normal operation of the water intake mine working and the preservation of its water abundance is directly related to competent arrangement, the rules for the implementation of which will be introduced by the article we have proposed.

Preliminary work

Location selection

The installation of septic tanks from concrete rings begins with the choice of a place for this treatment plant. Of course, many people want to reduce the labor costs for laying trenches from the house to the reservoir, but still, some restrictions due to the need to maintain a sanitary condition should be taken into account without fail.

Diagram showing the main setbacks for the treatment plant

So, we have a septic tank:

- no closer than 5 m from a residential building;

- no closer than 50 m from the water intake point (well, well);

- no closer than 5 m from the road;

- no closer than 3 m from fruit trees and berry bushes.

In addition, when choosing a place, I would advise looking for a small hill (otherwise melt and rainwater will drain into the septic tank from a large area).

Don't do this, it's too close to home

It will also be useful to arrange a convenient entrance: even the most efficient septic tank needs to be pumped out when overflowing, so we leave the path for sewage equipment without fail.

Volume calculation

The next stage is the calculation of the required volume of the chambers of our treatment plant. Understanding how to calculate a septic tank is quite simple:

Two rings, as in the diagram, may not be enough

The volume is calculated by the formula:

V \u003d n x 3 x 0.2, where:

- V is the required capacity of the septic tank in cubic meters;

- n - the number of people living in a house that is connected to a septic tank;

- 3 - the average number of days for which a portion of the waste is completely processed;

- 0.2 - the average daily volume of wastewater (in cubic meters) per person.

As an example, we calculate the volume of a septic tank for 3 people:

V \u003d 3 x 3 x 0.2 \u003d 1.8 m3. This is the minimum from which you can start. It will turn out to do more - do more, less often you have to pump out.

Now let's calculate how many concrete rings of a standard size (1 m high and 1 m in diameter) are needed to equip the cells:

- The volume of one ring is 0.785 m3;

- We can use the upper ring only for 1/3 of the volume, i.e. its capacity will be approximately 0.26 m3;

- Therefore, for one container, we need a minimum of 0.785 + 0.785 + 0.26 = 1.83 m3, i.e. three rings.

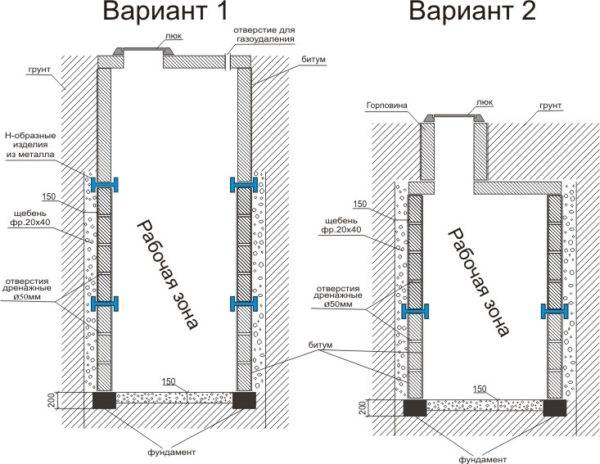

Variants with different well shapes, but with the same effective volume

Finally, we decide on the number of cameras. As a rule, a two-chamber design is sufficient for a suburban area - with a sump and a filtration well. If we are building a septic tank for a large house that uses significant volumes of water, then it is advisable to install a third chamber, or to additionally attach a pipe to the septic tank for output to the filtration field.

Selection of materials

The septic tank technology does not involve the use of expensive materials, however, taking into account the amount of work, I must note that the price in any case will be very, very significant.

This is the main element of the design

For the construction of a treatment plant, we will need:

- concrete rings for sewer wells (standard size);

- covers for sewer wells;

- sewer manholes with covers (cast iron or polymer);

- gravel for drainage;

- sand for backfilling;

- cement for sealing joints between elements and for making footings of foundations;

- waterproofing materials (roofing material, mastic, liquid glass);

- outdoor sewer pipes.

We make communications from pipes for outdoor work

In addition, for the effective functioning of the septic tank, it is desirable to purchase a special bacterial culture containing a complex of microorganisms for the efficient utilization of organic matter.

Biological product for the decomposition of organic matter