- Tools needed for cutting and processing plasterboard

- Cutting table

- Folding workbench

- Cutter narrow

- Cutter wide

- Hand saw

- Peeling planer

- Edge planer

- circular cutter

- Ballerina for GKL

- Needle roller

- Metal shears

- power tools

- Wall drywall: how to cut correctly

- Making a straight cut

- Curly cutting

- How to cut drywall or what tool exists for this

- How to use a drywall cutter

- Measuring tools for marking and dimensional control

- Roulette

- Level

- Metrostat 300

- hydraulic level

- Line laser level

- Laser rotary level

- square

- Useful Tips for Successfully Cutting Drywall Sheets

Tools needed for cutting and processing plasterboard

There are a number of tools and fixtures that are used for cutting and processing drywall sheets.

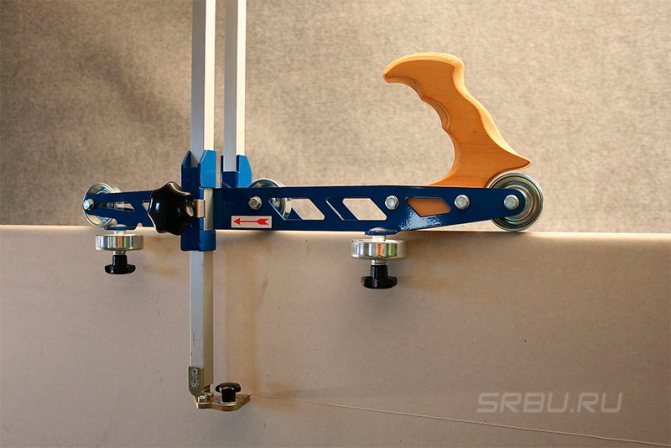

Cutting table

This device consists of two support legs with thrust elements attached to them. A lattice cover is located on top, on one side of which a clamping bar of the appropriate length is fixed by means of special clamps.

Folding workbench

An equally convenient device, the main difference of which is a removable cover, which allows, if necessary, to fold the support frame for subsequent transportation. For this, special loops are designed, which are located on the end rails.

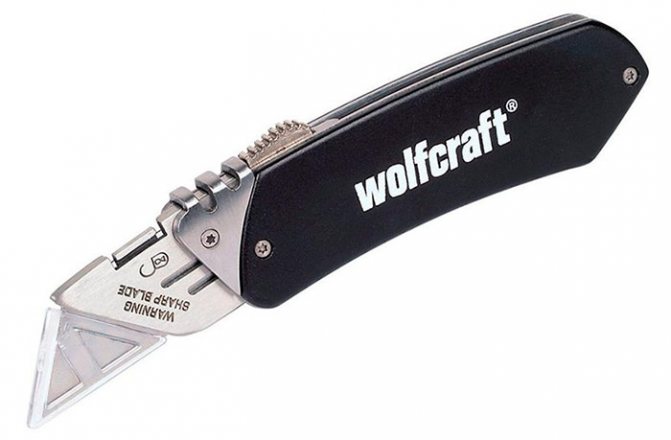

Cutting the material is carried out using a construction knife or a cutting tool designed directly for drywall.

To cut the top cardboard layer of the GKL, special knives are used.

Cutter narrow

The device is necessary in order to be able to cut a strip from a full-length sheet, the width of which does not exceed 120 mm. Such cutting is carried out due to two discs that simultaneously cut the material on both sides. Some models of such devices are equipped with an additional handle, which makes them more convenient to use.

Cutter wide

It works on the same principle, but is used to cut off larger pieces of drywall. The allowable sheet width limit in this case is 630 mm. At the same time, cutting with an ordinary knife gives almost the same results, which is the reason for the rather low demand for such devices.

Hand saw

To create rectangular holes or elements with complex shapes, you will need a hacksaw with a minimum blade width and fine teeth. Such tools are made specifically for working with GKL.

Peeling planer

The tool is a kind of rasp, with which the edges of the cut sheets are processed, which allows them to align and achieve perfect smoothness. The tool involves the use of interchangeable blades, the installation of which is carried out by loosening and tightening the tension screw.

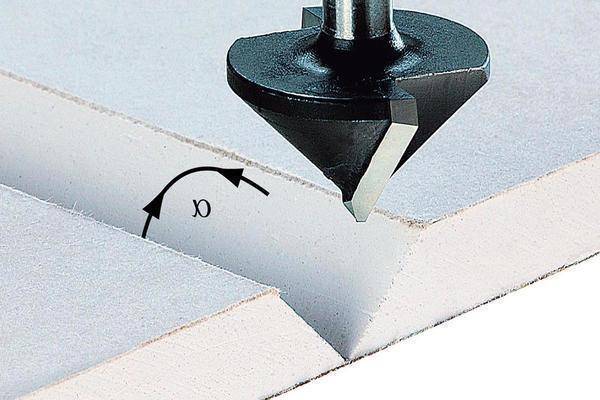

Edge planer

A bevel cutter is used to trim the edges of edges to create chamfers. In this case, the angle of inclination can be 22.5 or 45 degrees. Before using the edge cutter, the ends of the sheet must be leveled with a peeling planer.

circular cutter

A special nozzle for a drill allows you to make standard holes in drywall, which are necessary for mounting all kinds of communication elements. Such products are mainly sold in sets and have different diameters, which makes it possible to choose a cutter for a specific purpose.

Ballerina for GKL

Holes are also created with this tool. In this case, their variable diameter is assumed, which can vary in the range of 12-320 mm. The device consists of an aluminum body and a particularly durable cutting element in the form of a roller made of carbide materials.

Needle roller

This device is used exclusively in cases where it is necessary to give the material an arched shape or create another type of curved surface. Water is applied to the drywall sheet, which, during the perforation process, penetrates directly into the body of the gypsum layer. The depth of the holes is 5-7 mm, and their diameter varies between 2-3 mm. In this case, the side on which the recesses are made should be concave.

Metal shears

The tool will be needed in the process of cutting the profile. This is a great alternative to a hacksaw, which is not always convenient to work with in certain conditions.

power tools

These, first of all, include a grinder and a jigsaw, which in some cases can greatly simplify the work.Also, small electric scissors will not be superfluous, allowing you to get to hard-to-reach places.

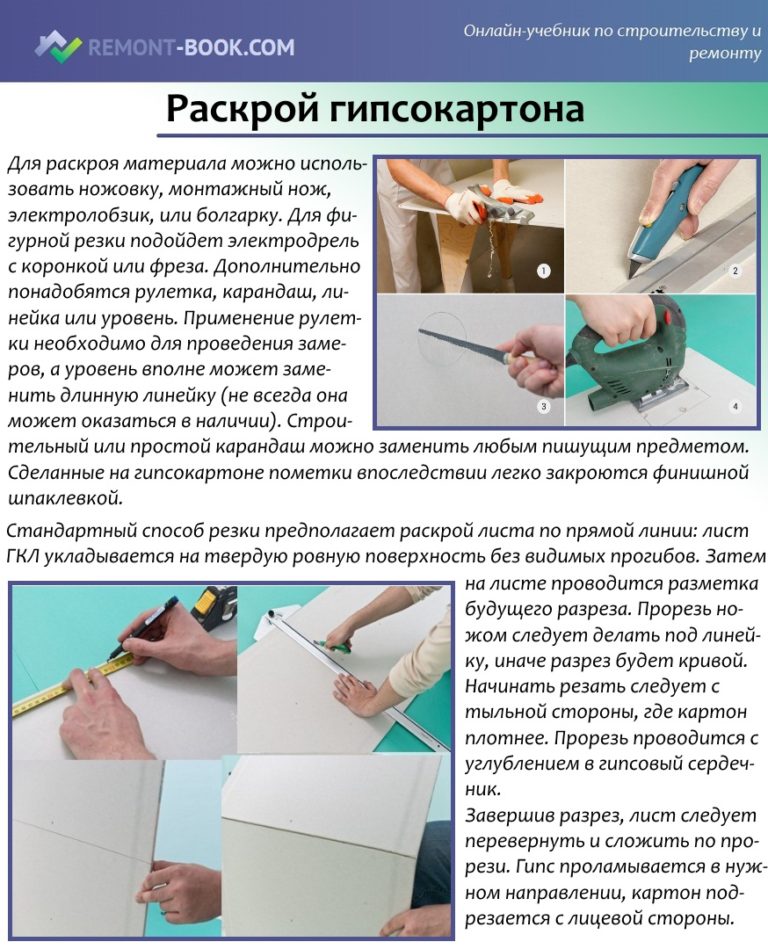

Wall drywall: how to cut correctly

Any kind of drywall has a certain structure. As a rule, this is a gypsum core or filler, glued on all sides with durable cardboard. Depending on the type of material, cardboard and filler may have a different structure, but this does not affect the cutting methods. For an even cut, it is enough to walk along the sheet with a gypsum board knife and make a break.

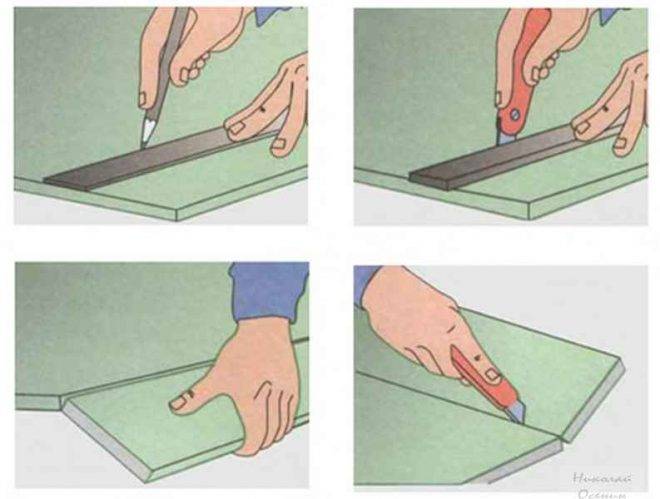

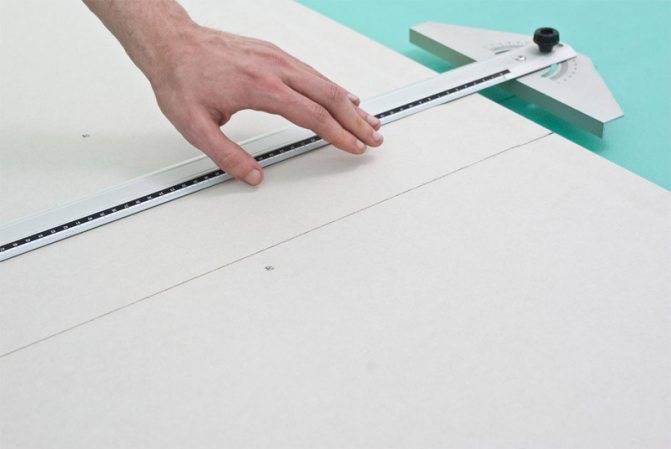

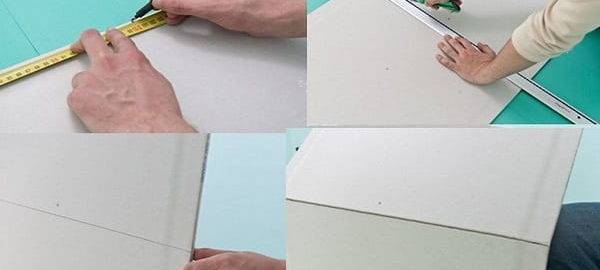

Making a straight cut

Before cutting through a sheet of drywall, you need to make an accurate markup, draw a line. Next, attach any flat object (ruler, rule or profile) along the drawn line and draw a knife along the line several times. This must be done without jerks, confidently, so that chips and notches in the material do not form.

You can cut drywall either laid out on the floor or leaning against the wall. The main condition is that the cut be perfectly even, otherwise it will not be possible to correctly break the sheet. How to make a break? To do this, turn the sheet over and bend it in half along the cut line, and then draw a knife along the resulting bend on the cardboard.

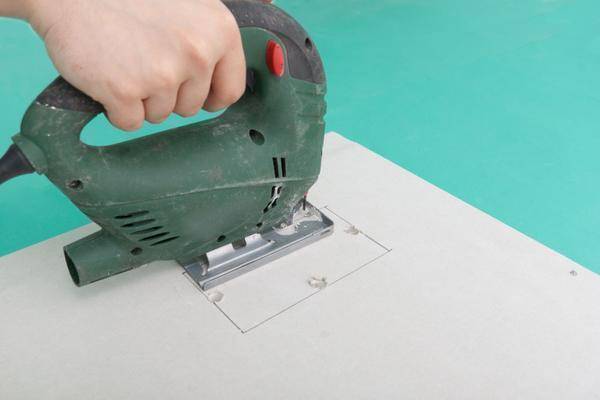

Curly cutting

If the elements of the future design involve smooth lines and bends, cutting the material is done with an electric jigsaw or a hacksaw (which is much more difficult). In order to cut out an element with rounded shapes, the sheet must be laid out on the table. The edge of the sheet should hang over the floor. After the exact marking has been made, a jigsaw is drawn along the drawn line, you need to do this from yourself, and not towards yourself, so that the power tool does not cause injury.

How to cut drywall or what tool exists for this

A professional installer will always have something to cut the sheet or cut off part of it. Even if the main purpose tool is out of order in the process. But in addition to cutting objects, an auxiliary tool is also needed.

What you need to cut drywall:

Construction knife. It is very similar to a clerical knife (both externally and in terms of the mechanism of the device), however, it is more durable. With long-term use, the only part that fails is the blade, which is easy to replace. This tool, regardless of the company and manufacturer, is very versatile, so you don’t have to select blades of a certain brand. The GKL sheet can also be cut with a clerical knife, if this is required once.

Hacksaw for drywall. This is an object with a narrow blade and serrated edges up to 18 cm long, outwardly similar to a kitchen knife-saw, since its blade is soldered into the handle. The blade is made of high-strength steel, so with a knife you can make both straight and curly cuts without much effort. It is lightweight, compact and very easy to use. This knife is universal, because in addition to the plasterboard, it can easily cope with small wooden blanks. The shape of the teeth of the drywall knife may be different, depending on the company. But this does not significantly affect the process of cutting the material.

At home, GKL can be cut with a simple hacksaw, but this is quite difficult and should be done with extreme caution.

Electric jigsaw. This tool is mostly used for cutting wood, MDF, chipboard, fiberboard, OSB, etc., however, if you install blades on metal (which has smaller teeth), then everything will work out

The blade with fine teeth does not tear the cardboard layer of the sheet and there will be fewer chips. An electric jigsaw can make both straight and curly cuts.

Plane. This tool is not used to cut a sheet or cut out a specific element of any structure being erected, but already at the final stage. With a chamfering planer or a simple peeling one, the places of cuts of a drywall sheet are processed. This is necessary for further processing of joints.

Roulette, pencil, ruler. In order to cut the sheet correctly and evenly, accurate measurement and marking is necessary. Especially when it comes to figured products for decoration. For a straight line, instead of a ruler and a pencil, you can use a chop thread, but you will have to work hard with curly markings. If you need to cut an even circle, the pencil is tied to a rope, the other end of which is fixed in the middle of the sheet, and this device is used on the principle of a compass. In the same way, semicircular bends are marked, where the length of the rope depends on the radius of the circle.

A cutter or electric drill with special nozzles is used to make holes in drywall. For example, for sockets, switches, etc. Let's consider this type of tool in more detail.

How to use a drywall cutter

For making holes of any geometric shape and grooves, as well as processing the edges of a sheet of drywall, a disk or shaped router is used.A disk milling cutter is capable of making only grooves, but the second option is better due to its versatility: in addition to grooves, it is able to cut holes of any geometric shape, as well as process the edge of the sheet.

Cutters have certain varieties. For making radius and rounded surfaces, a U-shaped tool is used, and for sharp corners, a V-shaped cutter.

Measuring tools for marking and dimensional control

High-quality installation of GKL assumes the presence of accurate markings and preliminary measurement of the material. Classical tools include tape measure, level, plumb line. However, there are also many modern devices that can significantly speed up the process and achieve better results. Consider what devices are used by experienced craftsmen today.

Roulette

This is a well-known measuring tool, the body of which is made of plastic or metal, and inside there is a measuring tape. The most commonly used tape measures are 3 m long. However, to perform various lengthy measurements, it is better to have a five-meter tape measure.

Level

This drywall tool allows you to control the slope of any vertical or horizontal surface. The product consists of a metal case with an ampoule built into it (there may be several of them), which is filled with an alcohol-containing liquid of a certain color. The angle of the base or structural element is determined by the air bubble inside. With a perfectly flat surface relative to the ground, it should occupy a middle position, without going beyond the existing marks.

Modern manufacturers offer a variety of models of levels of various sizes. Their differences may lie in the number of built-in tubular indicators, as well as their location. Some products are equipped with magnets, which is convenient when aligning elements of metal structures. Especially popular are devices with laser pointers, which allow you to make markings as quickly as possible.

Metrostat 300

Sliding tool equipped with a measuring scale and a bubble level, the length of which can reach 3 m. It can be used to control the horizontal and vertical position of the structure. In addition, there is a special nozzle designed to hold the plasterboard in a vertical position during installation work.

hydraulic level

It makes it possible to perform the breakdown of horizontal planes, as well as transfer marks from one surface to another. Mostly the hydraulic level is used in work with suspended ceilings. The marking lines are determined using a hose, the length of which, as a rule, is at least 10 m.

Line laser level

With the help of modern measuring technology, almost perfect results can be achieved. One of the devices widely used in working with drywall is a linear laser level (plane builder), which allows using mutually perpendicular beams to build projections both vertically and horizontally, which makes it possible to perform high-quality marking of absolutely any plane.

Laser rotary level

This device, operating in different modes, allows you to set vertical, horizontal and inclined planes. The laser beam in such devices constantly rotates around its axis. Thus, it is capable of projecting a plane at 3600. These devices are convenient to use when working in large rooms.

square

This tool is used primarily for marking corners. Structurally, the device is quite simple and is a ruler of a certain length, mounted in a metal base. With it, you can also control the squareness of certain elements.

Useful Tips for Successfully Cutting Drywall Sheets

In order to avoid irreparable errors when cutting the material, it is necessary to take into account some nuances and adhere to a number of the following recommendations:

- When cutting drywall, it is better not to use a grinder, because when using it, it will not only be noisy, but also a huge amount of gypsum dust will appear, which will need to be removed.

- If it is necessary to use a hammer during cutting sheets, it should be exclusively rubber, since a metal tool can cause severe damage to the material being processed. Wielding it, one should also calculate the force of blows, without making much effort.

- To reduce the number of notches along the cut line on the sides of the sheets, it is necessary to hold the knife or hacksaw at a right angle, since the lower the slope of the cutting element, the larger the gaps on the cardboard will be.

- All key cuts should be made before attaching the drywall to the crate, since if the outcome is unsuccessful, it will be necessary to replace the sheet with a new one.A damaged workpiece can be used when making inserts. An exception is the cutting of openings and sockets for sockets and switches, which are best done after installing drywall on the frame.

- It is not recommended to carry out complex patterns in material with thin partitions, for example, openwork nets, since in this case it is highly brittle.

- When cutting the sheet completely, this procedure is often performed on the floor. After making a cut along its strip, a beam should be placed under the drywall, and then you need to press on 2 parts of the canvas, easily breaking the material along the line previously passed by the cutting tool.

From all of the above, we can conclude that there is nothing complicated in working with drywall. Even a person who does not have the appropriate experience can cope with this task, and if there is any doubt, everyone can pre-train on a small workpiece, making sure that it is easy to cut. Familiarizing yourself with how how to cut drywall at home and adhering to the above technology, the use of high-quality tools will allow you to complete all the work quickly and at a high level, avoiding a variety of errors and possible damage to the sheets.

Video, how and how to cut drywall at home with your own hands:

You may be interested in:

How to make window slopes from drywall with your own hands

How to level the corner of the wall with your own hands with plaster and other materials

How to cut a drywall profile: the main options for quality work