- Devices and main components of a submersible pump

- Criterias of choice

- Revision of the pumping mechanism

- Common problems

- Device

- What could be the causes of breakdowns

- How to protect submersible pumps in a private system

- How to disassemble the unit to diagnose a breakdown

- Types of faults

- Doesn't turn on

- Turns on but does not download

- Decreased performance

- Too frequent on/off

- Pulsating water supply

- The body is leaking

- Buzzing, not pumping

- Vibrates a lot

- Doesn't turn off

- The main malfunctions of the pumping station and their elimination

- The station works for a long time without shutting down, and the pressure gauge shows a low level of pressure

- The pump often turns on, and after a little work, it turns off again

- Typical breakdowns of pumps of different brands

- Diagnostics and Troubleshooting

- Stages of disassembly and repair of the pump

- Recommendations and nuances of work

- Briefly about the device

- Operating principle

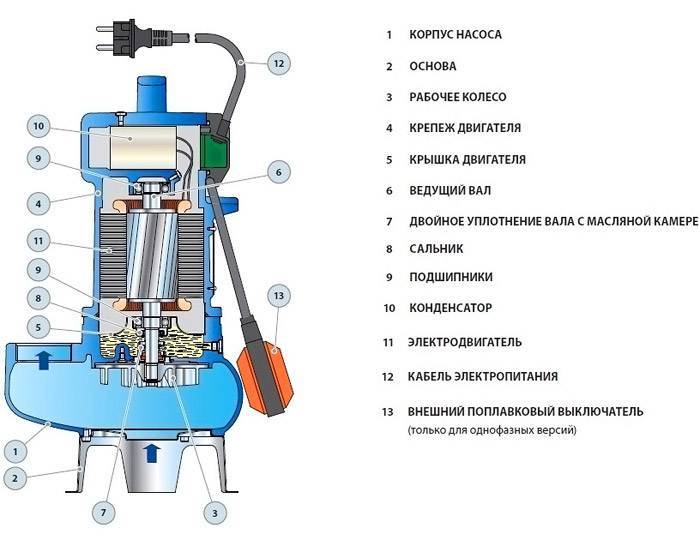

Devices and main components of a submersible pump

Currently, in Russia you can find hydraulic equipment manufactured by Italy, USA, Germany, France, Denmark: ZDS, PEDROLLO, CALPEDA, WILO, Busch, GRUNDFOS, Tapflo and others; Russian companies Dzhileks, Ampika, Pinsk OMZ, HMS Livgidromash.

Submersible pumps are designed to pump water from wells, wells or basements of buildings and, if necessary, supply it to a collapsible water supply network. At the same time, their working area is immersed in a liquid, which is why they are called so.

There are several types of these devices:

- Centrifugal, in which the main element is an impeller (impeller) or a screw. An example of them is "Water Cannon", "Aquarius", "Whirlwind", "Octopus".

- Vibrating, which are headed by a piston. An example of them is the "Kid" pump.

- Vortex, similar to centrifugal, but differ in a higher circular velocity of the liquid. An example is the vortex pump "Whirlwind".

The main components of centrifugal apparatuses include:

- impeller or screw/auger;

- electric motor;

- barbell;

- gland blocks;

- couplings;

- bearings.

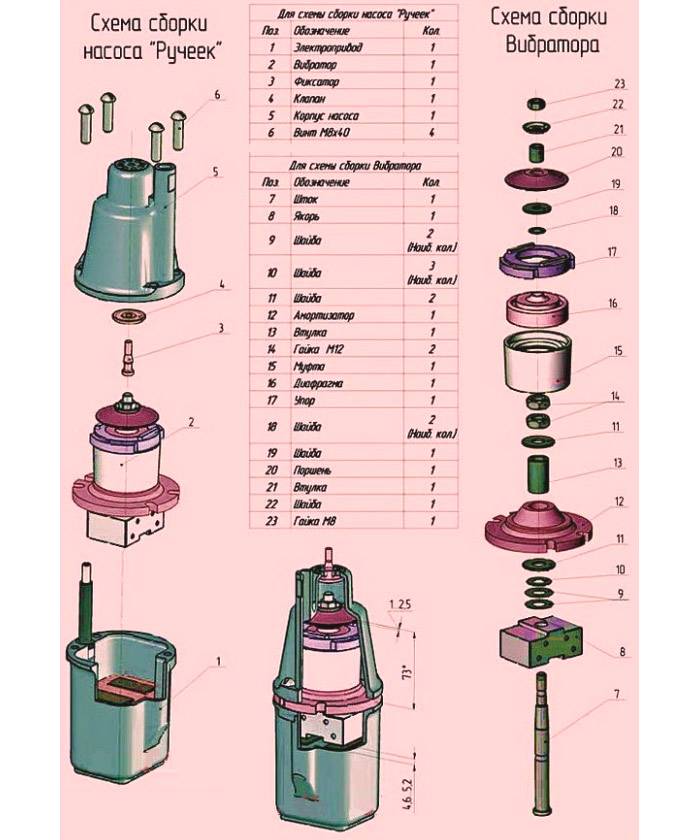

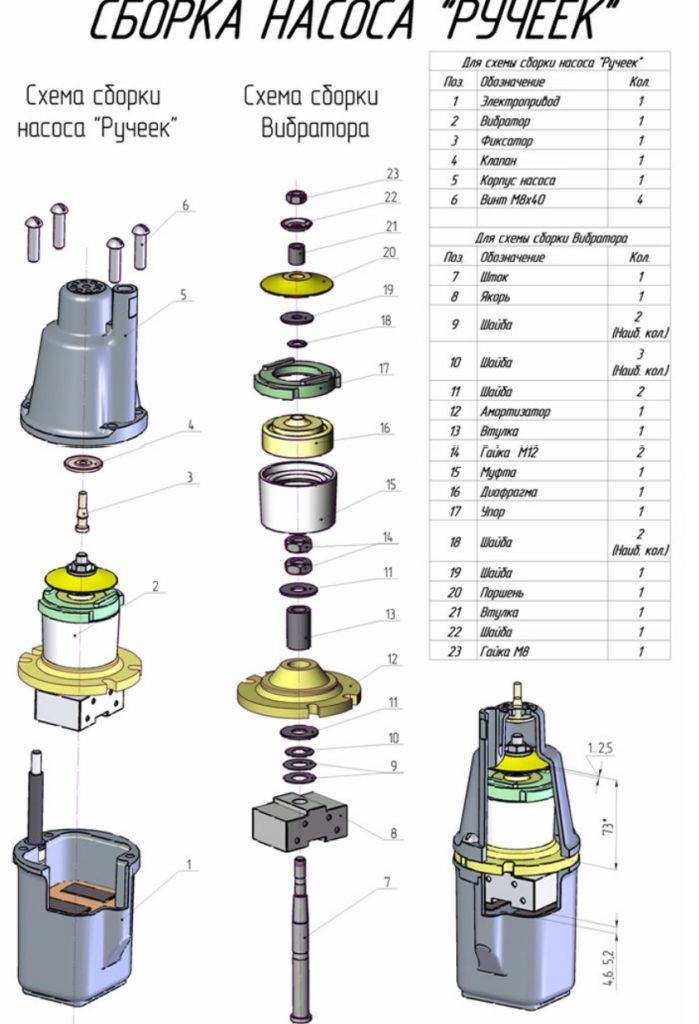

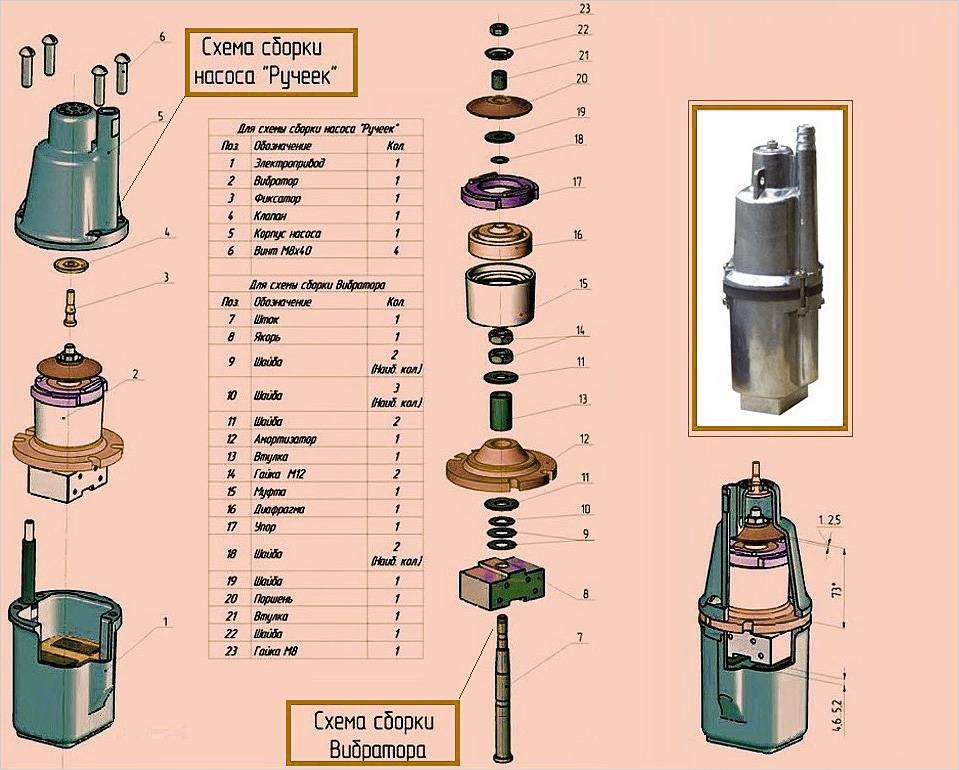

The main components of vibration apparatuses are:

- body of the working part;

- drive unit;

- electric coil;

- piston;

- diaphragm;

- valve

- shock absorber;

- emphasis;

- clutch.

Criterias of choice

There are several rules that should be followed when choosing a device:This is, first of all:

- pressure - this value for equipment of medium productivity is 7-10 meters. In some models, it reaches more than 30 meters. The data regarding the pump head depends on the distance over which the liquid is planned to be supplied;

- performance - the choice depends on the volume of the tank. For example, for a capacity of 40 "cubes" a device with 10 cubic meters per hour is enough. For industrial purposes, more efficient pumps are needed - about 100 m³ / hour or more;

- immersion depth of the device - this maximum value reaches 5 -15 meters, and the minimum - 0.3 - 0.9 meters.

In addition, you need to know on what points the duration of the pump life depends:

- the quality of the materials from which the equipment elements are made;

- temperature of pumped dirty water, it should not exceed +50°C;

- drain passage diameter;

- protection against possible overheating. Usually, a thermal switch is built into the pump (it will turn off the power if the liquid temperature becomes critical) and a float switch.

Revision of the pumping mechanism

In addition to contamination, the main reason for the breakdown of the pumping mechanism is long dry running. The blocks of centrifugal impellers, due to the lack of liquid, are very hot and sintered, so their only repair option is to replace them. The situation is similar with the auger and landing sleeves. Also, with jammed impellers, the shaft can rotate in the mounting holes, and in powerful pumps, its deformation and even destruction.

In screw pumps, screws and bushings are consumables, they are changed every 3-5 years, depending on the intensity of use. The main reasons are the natural aging of the elements and the impact of fine abrasive particles.

Screw and sleeve for screw pump

Let us draw your attention to the fact that the parts of borehole pumps have a high fitting accuracy, so that the cleaned mechanism is easy to assemble and disassemble. If during assembly the parts do not fall into place freely, then the installation order of the elements is violated

Different models of pumps have specific design differences, but the main recommendations self-repair and disassembly for the purpose of revision are always described in the user manual, often including the assembly diagram.

Submersible pumps have been enjoying great popularity among consumers for many years. And this is no coincidence, because this type of pump has many positive qualities that are simply irreplaceable when operating your own well or well. However, despite the numerous advantages, submersible pumps have one significant disadvantage - they break down quite often, and anything can cause a breakdown.

Often, the pump stops working normally due to problems with the winding or power magnet, and the cause of the malfunction can also be a valve breakthrough, a broken draft, or a short circuit. Often, submersible vibration pumps stop functioning due to a rather insignificant breakdown, which you can fix on your own without resorting to the help of specialists. Therefore, any owner of such equipment simply needs to know how to repair a submersible pump with their own hands.

Common problems

The nature of the failure and the cause of its occurrence:

- Doesn't buzz and doesn't work. The drainer is lowered into the water, the float has risen and is on the surface, the cable is connected to the circuit, but the engine does not work, there is no vibration. The cause of the breakdown is a discrepancy between the declared power of the motor and the electrical network to which the device is connected. Carefully read the characteristics of the pump, its power and efficiency. The pump is not lowered into the water deep enough, and the float does not work. Remove the device and, lifting the pillow up, turn it on again.

- Works, but does not download. The engine is on but no water is coming to the surface. There are several reasons for this.The protective mesh blocking debris and stones at the bottom of the hull clogged. Raise the machine and clean the filter. The thick fraction got into the discharge hose, and a blockage occurred. With such a breakdown, it can be knocked out of the base of the pump, if this does not happen, you need to disconnect it yourself and rinse it. Impeller broken. Her screws may break or the bearing may collapse, you can find out by disassembling the pump.

- Vibrates and overheats. The braid of the electric motor was broken, water got into the engine compartment, the shaft bearing collapsed. The unit vibrates and heats up, while the water comes in jerks or stops altogether. We urgently de-energize the equipment and pull it out to the surface. The cause of the breakdown is hidden inside. For diagnostics, you will have to disassemble the case without fail. Several impeller blades are broken. Rotation occurs by an eccentric and hits the body from one side.

- Weak pressure with a properly running engine is a consequence of a breakdown of the mechanical part of the pump. Impeller or bearing, clogged discharge hose or suction filter. Eliminated by simple rinsing in clean water or by replacing mechanical parts.

- When the unit is connected to the network, the machine works. The fuse disconnects the network if a short circuit occurs. Check all electronic parts of the pump. Pass the cable with a tester and find out where the short circuit occurred - replace it. The motor's copper braid is also at risk if the unit has been running dry. Replace the braid or install a new motor only in a repair shop.

- The device works, but turns itself off. Connected to the network and works, regularly pumping water. Suddenly it turns itself off.The reason is the mismatch between the power of the motor and the mains. Power surges can also affect the smooth operation of the unit. The solution is simple - to study in detail the instructions and characteristics of the pump, install a voltage stabilizer.

Device

Deep pump device. (Click to enlarge) Before proceeding with repair work, it is necessary to carefully consider the device structure, the principle of operation and the main malfunctions.

This will make it easy to disassemble. For the water supply of private houses, centrifugal and vibration deep pumps are often used.

The first option is often used in wells, while vibration units are used in wells.

Deep centrifugal unit consists of the following elements:

- housing, for the manufacture of which high-strength material is used;

- an electric motor that ensures the operation of the unit;

- an impeller that creates centrifugal force that pushes water into the pipeline;

- bearings;

- cooling system and o-rings.

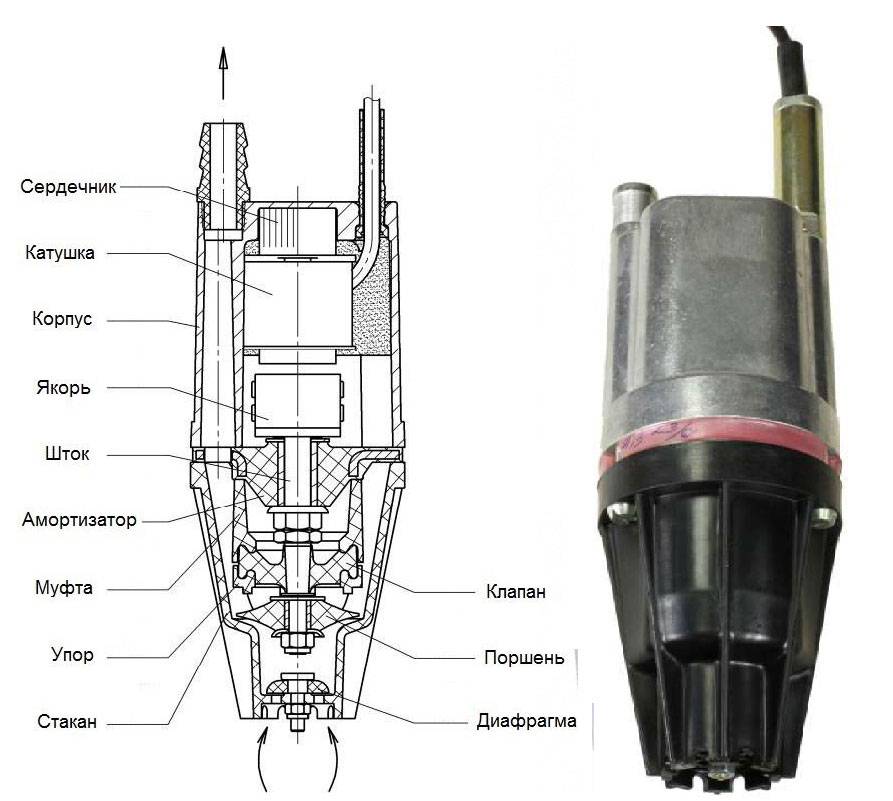

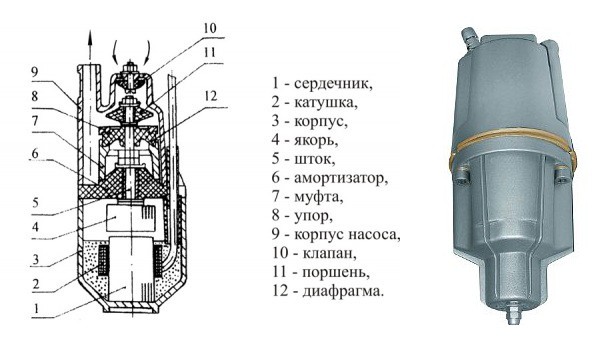

As for vibration pumps, they consist of the following structural elements:

- body made of the same durable material;

- electric motor;

- working piston;

- high power electromagnet;

- shock absorbers and other small parts.

Each of these units has its own principle of operation. Having information about the structure and principle of operation of the equipment, if necessary, it can be easily disassembled and repaired. Of course, we should not forget about the build quality. Often this parameter is of great importance in the operation and life of the equipment.

Specialist's note: It should be noted that vibration pumps are characterized by low cost and reliability in operation and are capable of pumping water of any quality.

What could be the causes of breakdowns

Submersible vibration pump device

The failure of the unit can occur for several reasons. When the pump is located directly near the water, many negative factors act on it. When carrying out repairs, the price will be significantly lower than the purchase of a new unit. The reasons for the failure of the device may be:

Output and building of the magnet. In this case, ordinary repairs will not help, you need the help of specialists.

Mechanical failure is characterized by extraneous sounds emitted by the pump. You can try to fix such a malfunction of the product yourself.

In case of mechanical failure, the cause may be too dirty water clogging the pump. Sometimes the device works in dry mode, with no oil, which must be present.

The unit may fail when the working fluid is heated to a temperature of more than 40 ° C. There can be many reasons for unit breakdowns, both in the mechanical part and in the electrical part, consisting of the engine and the automation system. Here are located:

- Time relay.

- Automatic elements that protect pumps from short circuits.

From time to time, all this can become unusable.

An incorrectly fixed underwater cable for submersible pumps can lead to breakage.

How to protect submersible pumps in a private system

Like any device, deep pumps require careful handling.Most often, manufacturers of units provide for the occurrence of possible dangerous situations during operation and produce additional devices that look like an external unit for automation and control of the product.

Deep pump connection diagram

Dry move. Occurs when the water drops below the critical level, and the unit nozzle is above it. As a result, the device fails. You can prevent this from happening:

- installation of a float system;

- lower into the water two special electrodes or level sensors that are connected to a protective device. When the lower electrode is located above the water level, the pump turns off, and when the level of the upper electrode is reached, it turns on;

- installation of a device that controls the passage of water through the pump. In its absence, this element stops the pump.

Water hammer. Occurs when the “dry pump” is turned on or when the unit is turned off. At this point, the liquid hits the impeller blades hard, which can severely damage them and lead to pump failure. You can solve the problem:

- a check valve device made of high-strength materials, which can reduce the weight of the water column acting on the impeller;

- equipment of hydraulic accumulators with pressure switches and sensors that can turn the pump on and off when there is an excess of pressure in the system.

Unstable parameters in the electrical network.

- Freezing water. Such a phenomenon in the pump housing is unacceptable. When the temperature drops below zero, the water must be drained. With year-round use of the device, it is installed in caissons.

- Turbidity of pumped liquid.The presence of abrasive particles can lead not only to jamming of the downhole pump, but also to damage to the entire tract.

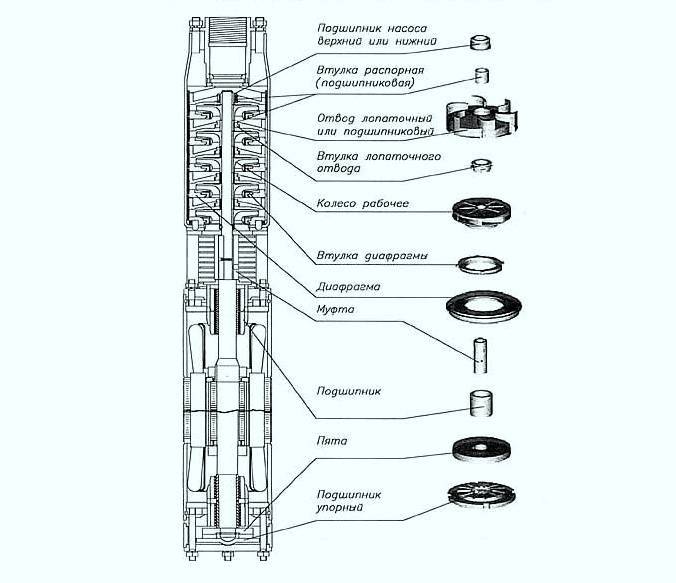

How to disassemble the unit to diagnose a breakdown

In case of pump breakdowns requiring replacement of parts located inside its housing, disassembly of the unit will be required. A submersible pump consists of a motor compartment and a compartment with one or more impellers, the purpose of which is to capture water. Below is a diagram of the device of that part of the centrifugal pump where the impellers are installed.

As can be seen from the figure, the impellers are mounted on the shaft of the unit. The more of them, the higher the pressure created by the pump. The rotary engine is located in the second compartment of the hydraulic machine. It is in a sealed case, and to open it, you need to know some of the nuances.

So, in order to move from theory to practice and disassemble the pump, follow these steps (depending on the manufacturer, the design of the unit may differ).

-

Unscrew the 2 screws holding the mesh of the device.

- Remove the mesh and turn the motor shaft by hand. If it does not spin, then the problem may be either in the engine compartment or in the pumping part of the apparatus.

- First you need to disassemble the pumping part of the device. Unscrew the 4 screws holding the power cable channel and disconnect it from the machine body.

- Next, unscrew the 4 nuts holding the pump flange.

- After unscrewing the fasteners, separate the pumping part of the apparatus from the engine. At this stage, it is possible to determine in which section the jamming occurred. If the shaft of the pump compartment does not rotate, then this assembly must be disassembled.

- Unscrew all fasteners holding the lower flange of the pump part of the unit.

- An adapter must be screwed into the fitting located at the top of the block, which will help keep the threads from damage.

- Secure the pump in a vise.

- Having picked up a suitable tool, unscrew the bottom flange.

- The impeller assembly can now be pulled out and inspected for faults.

- Next, you should check the support shaft for wear or play.

- To replace (if necessary) the impellers, it is necessary to fix the shaft in a vice and unscrew the top nut.

- At the next stage, the blocks are removed, washed and, if necessary, replaced with new ones.

- The assembly of the pumping part of the apparatus is carried out in the reverse order.

- To disassemble the electric motor, it must also be fixed in a vise.

- Next, remove the plastic flange protection by unscrewing the fasteners.

- Remove the retaining ring holding the cover with a pair of pliers.

- Remove the cover using a slotted screwdriver.

- Remove the rubber membrane from the housing.

- Remove the capacitor.

- At this stage, you can check the oil level, its quality, identify the cause of jamming, etc. The engine block is assembled in the reverse order.

Types of faults

There are several types of malfunctions that most often occur with submersible water pumps.

Doesn't turn on

There are 4 possible reasons why the machine does not respond when turned on.

- Electrical protection. Modern products have a protection function that operates on the principle of traffic jams on the electricity meter. In the event of unexpected loads or power failures, the protection operates automatically and stops the operation of the unit.It is recommended to start the mechanism again only after the reason for the operation of the machine has been determined.

- Damage to fuses. Fuses can blow due to wear and tear, but sometimes they fail for external reasons. With regular burnout, experts advise checking the integrity of the power cable, as well as the place of its connection.

- Cable damage. To check the power cable, the equipment must be removed, since most of the cord passes under water.

- Dry running protection. In addition to electrical protection, submersible devices are equipped with a device that controls the level of immersion in the liquid. If the level of the liquid medium is insufficient, the operation of the device automatically stops.

Turns on but does not download

In a situation where the included mechanism does not supply water, there may also be 4 reasons.

- Stop valve. The simplest reason for the lack of water pumping is the closed shut-off valve of the device. In this case, the pump is turned off, then the shut-off valve is turned off. Frequent start-up of the unit with the shut-off valve closed may result in damage, so it is recommended to check the valve before each start-up.

- Low water level. If the stop valve is open, the next step should be to check the dynamic water level and adjust the submersion of the machine to the desired depth.

- Check valve failure. If the check valve is clogged, it can “stick” and stop flowing water. In this case, cleaning the part or replacing it with a new one can help.

- Inlet filter clogged. A clogged filter can also interfere with the flow of water into the system, so you should check its condition and, if necessary, clean the filter screen.

Decreased performance

In the event that the equipment began to supply significantly lower volumes of water, it is recommended to check several assumptions.

- Reducing the voltage in the network. When the voltage is low, the machine is not able to work at full capacity.

- Lift pipe clogged. With a decrease in the patency of the lifting pipe, the performance of the mechanism drops noticeably.

- Clogged fittings in the water supply network. Valves and faucets in a water supply system can become clogged and prevent full flow of fluid.

- Incorrect pressure switch settings.

Too frequent on/off

The problem arises when the equipment is paired with a hydraulic accumulator. Frequent switching on and off can occur for several reasons.

- Too low pressure in the hydraulic tank.

- Rupture of rubber components of the tank.

- Incorrect pressure switch settings.

Pulsating water supply

A pulsating jet of water from a tap indicates a decrease in the water level in the well below the recommended one. In this case, the mechanism should be lowered to the estimated depth as soon as possible.

The body is leaking

When the seals are worn, the body of the unit begins to flow. The place of the leak is easy to detect by the appearance of streaks and corrosion. If the seals are not replaced in a timely manner, the product may finally become unusable.

Buzzing, not pumping

The machine may make a buzzing sound but not deliver water for the following reasons.

- The impeller stuck to the body of the device due to the long storage of the pump "dry".

- The impeller jammed due to sand, silt, dirt.

- Breakdown of the engine start capacitor.

- Low voltage in the mains.

Vibrates a lot

Strong vibration occurs predominantly in centrifugal pumps due to worn bearings or loose fittings. The problem is solved by replacing parts and strengthening elements.

Doesn't turn off

The submersible pump stops automatically shutting down if the pressure switch fails, or if the switch has incorrect settings.

The main malfunctions of the pumping station and their elimination

The device is made up of the following parts:

- A pump for taking water and supplying it to the house system.

- Membrane tank (hydraulic accumulator) to maintain the set pressure in the system.

- Pressure sensor that starts equipment when the pressure in the system decreases.

- Pressure gauge.

- Drain cock.

Each of the listed nodes performs its task, and if any of them fails, the device fails. The list of malfunctions, as well as options for their repair, is approximately the same for pumping equipment from various manufacturers. Let's analyze the most typical breakdowns of the pumping station.

The station works for a long time without shutting down, and the pressure gauge shows a low level of pressure

Possible causes of breakdowns and how to fix them:

- Lack of water in the supply well. Such a "dry" operation is fraught with the failure of the pump motor.

- Dynamic resistance inside the highway. It is possible with a large length of the intra-house network with a small diameter of water pipes. Elimination - dismantling of the main pipes and replacing them with thicker ones.

- Lack of tightness of joints or plumbing fixtures. As a result, air leakage occurs in the line, which causes a pressure drop. The solution is to find the leak and fix it.

- Filters or valves clogged with mechanical debris.They should be removed, washed and tested for performance. Defective components must be replaced.

- Incorrectly set indicators on the pressure switch. It is necessary to reduce the minimum pressure limit in the water supply network on the relay, at which the station should turn off.

- The pressure sensor does not work. To remedy the situation, you can try to clean the contacts, or replace the device.

- The pressure indicator is set to the minimum level, and the pump does not create the necessary pressure, and works continuously. Perhaps the impeller has simply worn out and the efficiency of the pump has fallen. The solution is to replace the impeller with a new one.

- Low power supply voltage. The pumping equipment is still working, but the pressure sensors do not work, or the pump speed is not enough to create the desired pressure.

The pump often turns on, and after a little work, it turns off again

Such frequent on/off cycles lead to premature wear of the equipment.

- Small volume of the accumulator tank with a large number of draw-off points. The way out is to replace the membrane tank with another, larger one, or install another, parallel hydraulic accumulator.

- The relay is set to a too small gap between the minimum and maximum head pressure. It is necessary to increase this "corridor" to the standard 1.5 atm.

- The check valve clogged, as a result of which it stopped blocking the return flow. When the pump is turned off, the water goes back into the well, and the pressure in the network drops. Clean the valve or replace it with a new one.

- Damage to the membrane of the battery tank. If its tightness is lost, water penetrates into the second, “air” half of the tank and it ceases to function in the specified mode.As a result, the entire "responsibility" for maintaining pressure in the plumbing system lies with the pump. The way out is to replace the hydraulic tank membrane.

- Also, another malfunction of the hydraulic tank can lead to frequent operation of the pump - failure of the spool. As a result, it begins to “poison” air from the air chamber of the tank, not allowing it to create the necessary pressure in it.

Unstable pressure in the water supply, as a result of which the taps of the mixers begin to “spit”. The reason is the airing of the pipeline, as a result of which plugs appear in it. The way to correct the situation is to find and seal the pipeline depressurization point. If the pump refuses to work at all, that is, it does not show signs of life when the power is turned on, the reason is a malfunction in the electrical part. To identify the exact problem, you should diagnose the electrical circuit.

When the station motor hums, but the impeller does not rotate, the reason for this may be either low voltage on the motor, or some kind of mechanical obstruction. In the first case, the terminal capacitor may burn out. In the second case, the rotor or impeller is “overgrown” with limestone deposits or oxides as a result of a long idle time of the station. Repair here consists in disassembling the station and cleaning its internal parts.

Oil seal replacement - repair of pumping stations, how to eliminate water leakage along the shaft:

Repair of the pumping station ALKO HW3500 (does not pump):

Typical breakdowns of pumps of different brands

The equipment of popular domestic and foreign brands has its own characteristic breakdowns. The devices of the Danish manufacturer Grundfos, despite their reliability and endurance, need regular replacement of mechanical seals.If this is not done in a timely manner, water will penetrate inside and damage the winding.

It is not advisable to service the unit at home. The specific design requires that repairs be carried out by a specialist with experience, ideally an employee of a company service center.

A pronounced buzz and a head that has fallen to a minimum indicate that the impeller has worn out or has shifted along the axis in the pump. The device must be disassembled, cleaned of sand, replaced damaged elements and installed new seals

Gilex units often leak fluid from the electric motor. Replacing it is possible, but only with a similar composition.

Some masters believe that it is not necessary to buy an expensive substance. You can get by with glycerin or transformer oil. However, this is not the best advice. The equipment does not tolerate filling with alternative means very well and can completely fail after such an operation.

It is better not to repair the device yourself, but to entrust this task to qualified specialists. They are guaranteed to fill the engine with the original composition and do it in strict accordance with the wishes of the manufacturer. After service, it will work as well as on the first day of purchase.

Wear of the seals is indicated by a low oil level in the pump motor. It is best to replace them as soon as possible. This will keep the motor from overheating.

In devices "Kid" of the Russian enterprise Livgidromash, coils often fail. Provokes this trouble work "dry".A strong noise heard when turned on without pumping out water indicates a break in the central axis, to which the membranes with an anchor are attached. This breakdown is easy to detect after disassembling the unit.

Replacing the axle even at home is not difficult. But finding a part for sale is really a problem.

Aquarius pumps tend to overheat. This disadvantage is especially active when the equipment works in shallow wells. Repairs are expensive and sometimes amount to about 50% of the original cost. Many users in such cases prefer to buy a new device, however, from a different manufacturer.

The same problem is typical for the Brook models. Despite the modern design and compliance with current European standards, they do not tolerate continuous operation.

The manufacturer says that the devices can continuously pump water for no longer than 7 hours. However, almost always such a load leads to overheating. In order to avoid problems, it is better to take breaks and let the equipment rest every 2-3 hours. In this way, the life of the pump can be extended.

Do not start water pumping devices when the shut-off valve is closed. In the future, this will lead to breakdown of pumping equipment. Valve must be opened before turning on.

Pumping equipment "Vodomet" is considered quite reliable and operationally stable. Most of the breakdowns here are due to misuse. Also, equipment in contact with contaminated water quickly becomes clogged with silt and sand. In this case, the pumping part of the unit needs to be replaced.

When a problem that has arisen cannot be solved at home, it is worth seeking help from professional masters of a certified service center. They will quickly determine what happened to the equipment and restore its performance. Or they will recommend purchasing and installing a new pump if the old one cannot be repaired or it is not economically viable

The pump is clogged with sand and does not pump water. How to deal with one of the most common problems of pumping equipment will tell the following video:

Diagnostics and Troubleshooting

So, let's try to determine why the pump went haywire. If it does not turn on, first of all you need to check the condition of the circuit breaker in the junction box. He may have disconnected the circuit due to overload.

If the suspicions are not confirmed, you need to turn off the unit, remove it from the well and proceed with disassembly.

Stages of disassembly and repair of the pump

First of all, near the place of work, it is necessary to spread a clean newspaper or rags on which pump parts and fasteners will be folded. We proceed in the following order:

- We disassemble the injection part of the unit.

- In a vibration-type pump, we check the condition of the valves, and in a centrifugal pump, we turn the impeller to make sure that the shaft is not jammed. If at this stage the cause of the breakdown is found in the form of a clot of dirt or a damaged part, we take appropriate measures.

Disassembled submersible pump

If all the nodes of the injection mechanism are normal, we open the electrical part. After that, you need to do the following:

- Use the indicator to check the presence of voltage at the terminals to which the power cable is connected (do not forget to plug the pump into the socket before this).

- Check the resistance of the starting winding with a tester (this must be done already with the power turned off).

- Do the same with the working winding.

If the instrument panel shows a resistance close to zero, then there is a short circuit in the winding. If, on the contrary, it is infinitely large, then a gap has occurred in the winding. In both cases, you need to rewind the engine, which requires a special machine.

Recommendations and nuances of work

- Before dismantling, the engine must be installed with the cover up, otherwise oil will leak out during its dismantling.

- Before dismantling, be sure to make sure that the unit is disconnected from the mains.

- In some models, to remove the cover, the engine must be strongly compressed in a vise.

Mounting screws on submersible pumps often turn sour due to constant contact with water.

To make it easier to maintain and repair, it is recommended immediately after purchase to replace the “native” screws with a profile for a flat screwdriver with purchased ones that have a cross-shaped profile.

Briefly about the device

By and large, the design of all pumping equipment for private use is the same. The pump consists of:

- housing in which there is a hole for water intake;

- electromagnet (dynamics);

- vibrator (electric motor).

What is a vibration pump?

For deep wells, pumps with an upper intake for water intake are used, for shallow wells - with a lower or side intake. However, the lower water intake sins with periodic captures of bottom impurities in the water from the well.

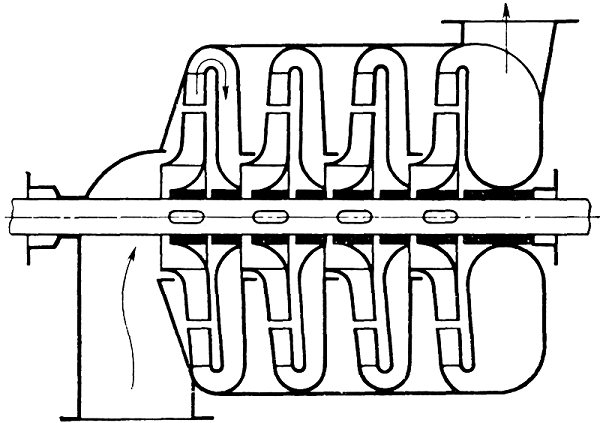

Operating principle

Since all vibration pumps operate on the basis of the principle of inertia, all work is reduced to creating vibrations in the fluid, which is driven by the diaphragm membrane and creates a difference between internal and external pressure. The pressure difference created is responsible for pumping water.

Bending the diaphragm creates vibration. The more oscillatory movements the diaphragm creates, the more intense the cooling of the motor with water should be. Therefore, it is forbidden to use pressure equipment without water entering inside.

Dynamka (as the people call an electromagnet) is:

- steel core;

- two coils of enameled copper wire.

To install the magnet, you need to fix the dynamo and coils inside the case. To do this, we fill everything with an epoxy compound, which works simultaneously as insulation and removes excess heat from the coils to the body for speedy cooling.

The composition of the compound necessarily contains epoxy, plus a hardener and plasticizer (with the addition of quartz sand). Quartz in this case serves simply as an additional heat conductor.

The electric motor consists of an armature with a rod on which a spring is installed for shock absorption and a piston (rubber). The better the quality of the rubber from which the spring and piston are made, the more reliable and economical the pump is.

The direction of the rod is provided by a rubber diaphragm. It divides the two working parts of the apparatus - (electrics and hydraulics) and is attached to the rod by a remote coupling. The most vulnerable point in the design of any pump is a rubber valve that closes the water intake holes.

The vibration of the diaphragm occurs due to the fact that when current enters the motor, the armature begins to be attracted to the magnet and is thrown back by the shock absorber at the moment of polarity change (reversal of the poles).

The hydraulic chamber of the pump is the space occupied by the valve and piston. The piston oscillates, the water springs due to the air dissolved and not dissolved in the water, either compressing or expanding, and its excess is squeezed out of the hydraulic chamber into the pressure pipe, and then into the hose. Constantly the maximum amount of working fluid in the pressure apparatus is provided by a valve that lets in and prevents water from pouring back.

Vibratory Pump with Bottom Intake

The design with an upper water intake and a bottom electric drive is a classic of the vibration pump lineup. In them, the engine cools better, and with open suction holes, it can work up to seven hours without stopping. Sometimes an overheating sensor (thermostat) is included in the kit.

By the way, pay attention to the material from which the mounting cable is made. It is better that he was from kapron. This cable, unlike the steel one, does not rub the case lugs and provides additional protection in case of damage to the current cable

This cable, unlike the steel cable, does not rub the housing lugs and provides additional protection in case of damage to the current cable.

But, before moving on to repairing vibration pumps with your own hands, you should pay attention to two more things:

- the cross section of the cable with the euro plug should not be less than the international standard 2x0.75 mm;

- hose with an internal passage diameter of at least 1.9 cm.