- What are the features of Jilex borehole pumps

- DIY pump repair and installation

- Areas of use of pumping equipment

- Water supply from a hydraulic structure

- Temporary replacement

- Filling heating systems

- Fluid pumping

- Diagnostics and Troubleshooting

- Stages of disassembly and repair of the pump

- Recommendations and nuances of work

- Detailed instructions for disassembling the pump

- The subtleties of disassembling the shaft of the pump section

- Step-by-step process of disassembling the electric motor

- Repair of the pumping station Dzhileks

- Instructions for disassembling the unit

- Model "Water cannon"

- 1 The main breakdowns of pumps and their diagnostics

- The composition of the pumping station

- How to avoid pump failure?

- A few words about adjusting the pressure switch

- How to find out the cause of a malfunction of a submersible pump?

- What do they do first?

- Where might the problem lie?

- Types of water pumping stations

- With built-in ejector

- With remote ejector

- Ejectorless designs

What are the features of Jilex borehole pumps

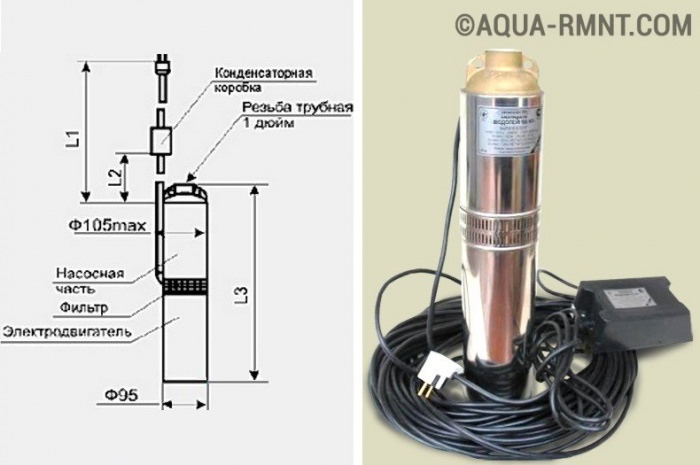

The Water Jet pump, a general view of which is shown in the photo, is a fairly popular model in the budget category. Its price is affordable for many owners of their plots, you can buy a device in almost any plumbing store. Has a large number of positive reviews.

Gillette-Vodomet pumps

Some features of the unit are as follows:

- Compared to other similar devices, Gileks water jet pumps are more responsive to the purity of the pumped water. If there is sand in the liquid, the pump will not last long.

- Not the best way to affect the durability of his work: high iron content and lime impurities in the water.

- The water cannon necessarily requires the installation of electrical protective equipment:

- voltage stabilizer;

- machine corresponding to the rated power of the pump.

- It is advisable to purchase a device for protection against "dry running".

- Do not use Gileks pumps with a capacity of 3.6 cu. m / h in weak wells, with a flow rate of 0.5 to 1 cubic meters. m/hour.

DIY pump repair and installation

To ensure the smooth operation of a well or well, special equipment is used - pumps. They are mounted near the mouth of the source or submerged under the surface of the water table, providing water supply to the surface and to the house, for outbuildings, for greenhouses, and gardens. But such equipment is subjected to a wide variety of loads, its use is quite intensive, and this causes wear of individual components and parts, breakdowns. Therefore, periodic inspection and repair of the pump is required.

Wiring diagram of the water jet pump.

All sediments differ in their design, working conditions, problems during work may be different. An example of malfunctions and repairs can be considered on the rather frequently used Vodomet pump, which has proven itself well today in the construction of wells and wells.

Areas of use of pumping equipment

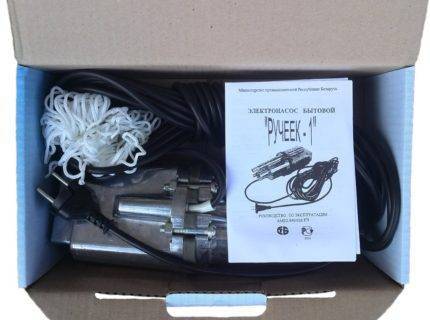

The submersible pump Strumok is widely used for domestic and household purposes:

- water supply from a hydraulic structure - a well or a well;

- temporary replacement of the main pumping equipment;

- irrigation works;

- filling heating systems before starting work;

- pumping liquid from water receivers;

- organization of an autonomous water supply system using a single water distribution point.

Water supply from a hydraulic structure

Such devices provide timely water supply for a country house, cottage or bath. True, the low performance of the pump will allow you to alternately use the water distribution point - for showering, washing dishes or washing. In this case, the water pressure is determined by the depth of the water intake column, the deeper the structure, the less pressure. You should not connect an electric pump of this type to several buildings at the same time, this can lead to a reduction in the working life and overloads of the system elements.

Temporary replacement

To provide autonomous water supply system in private households, the owners install powerful pumps. If the main equipment fails, the repair of which will take a lot of time and money, a simple Creek will become a fallback option. Even the low performance of the device will satisfy the basic needs of consumers.

Filling heating systems

In the process of building houses, the creation of autonomous heating systems is carried out earlier than the supply of water. Compact pumps are used to fill the water pipes. All work is carried out in the following order: a large volume container is filled with water, the first hose is lowered into it to supply water from pumping equipment.The second hose is connected to the tap on the radiator. When the tap is opened, the pump starts and the system is filled. A manometer is used to determine the pressure level.

Fluid pumping

Often, a vibration pump is used to pump liquid and effluent from receivers and flooded technical rooms. The equipment allows you to remove excess water automatically without the involvement of additional equipment.

Diagnostics and Troubleshooting

So, let's try to determine why the pump went haywire. If it does not turn on, first of all you need to check the condition of the circuit breaker in the junction box. He may have disconnected the circuit due to overload.

If the suspicions are not confirmed, you need to turn off the unit, remove it from the well and proceed with disassembly.

Stages of disassembly and repair of the pump

First of all, near the place of work, it is necessary to spread a clean newspaper or rags on which pump parts and fasteners will be folded. We proceed in the following order:

- We disassemble the injection part of the unit.

- In a vibration-type pump, we check the condition of the valves, and in a centrifugal pump, we turn the impeller to make sure that the shaft is not jammed. If at this stage the cause of the breakdown is found in the form of a clot of dirt or a damaged part, we take appropriate measures.

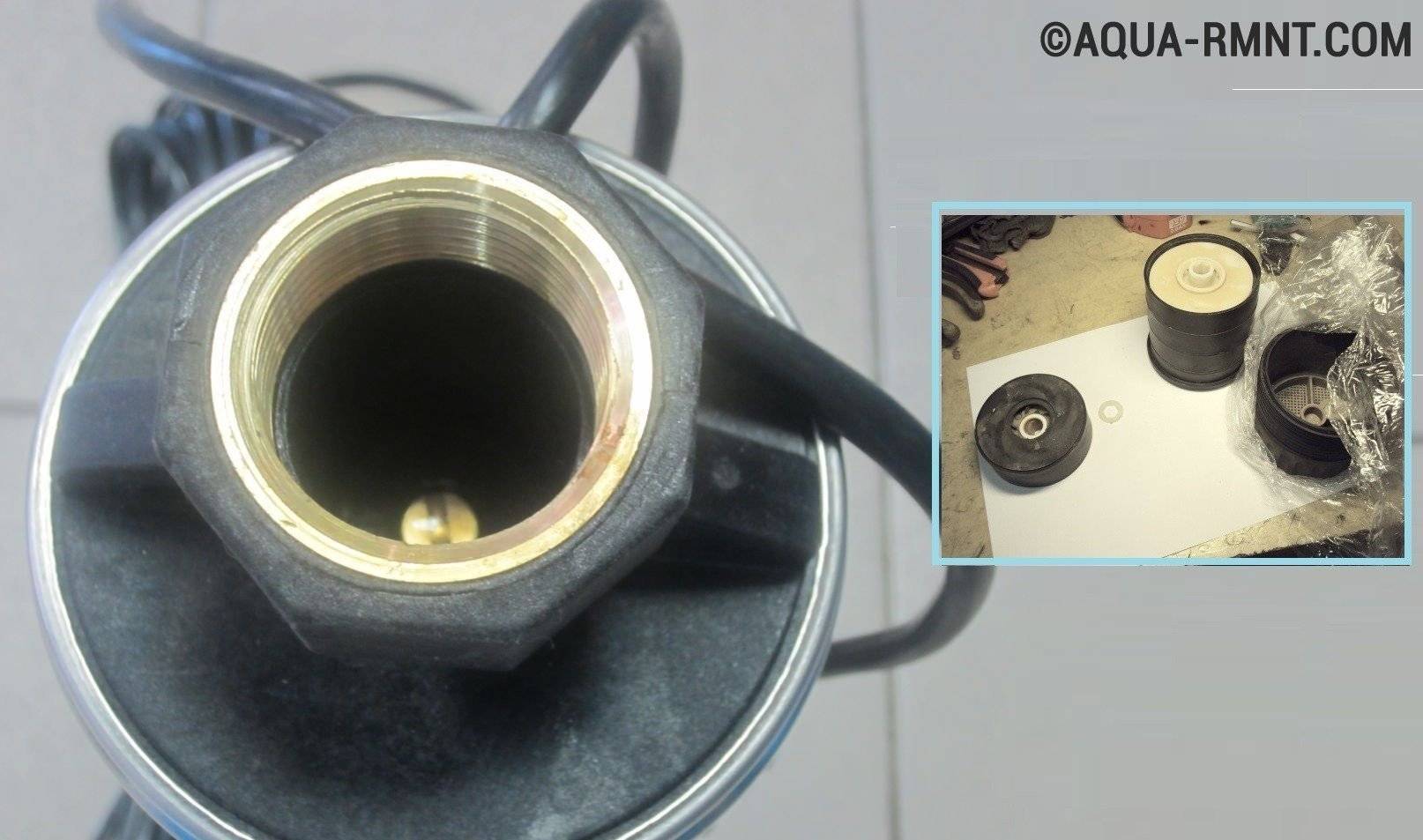

Disassembled submersible pump

If all the nodes of the injection mechanism are normal, we open the electrical part. After that, you need to do the following:

- Use the indicator to check the presence of voltage at the terminals to which the power cable is connected (do not forget to plug the pump into the socket before this).

- Check the resistance of the starting winding with a tester (this must be done already with the power turned off).

- Do the same with the working winding.

If the instrument panel shows a resistance close to zero, then there is a short circuit in the winding. If, on the contrary, it is infinitely large, then a gap has occurred in the winding. In both cases, you need to rewind the engine, which requires a special machine.

Recommendations and nuances of work

- Before dismantling, the engine must be installed with the cover up, otherwise oil will leak out during its dismantling.

- Before dismantling, be sure to make sure that the unit is disconnected from the mains.

- In some models, to remove the cover, the engine must be strongly compressed in a vise.

Mounting screws on submersible pumps often turn sour due to constant contact with water.

To make it easier to maintain and repair, it is recommended immediately after purchase to replace the “native” screws with a profile for a flat screwdriver with purchased ones that have a cross-shaped profile.

Detailed instructions for disassembling the pump

To determine and troubleshoot a submersible pump, it must be disassembled into its constituent elements. To do this, you will need a spacious workplace and a stable wide table, a vise, Phillips and flat screwdrivers, a set of keys and pliers.

The disassembly process is not difficult, but requires precision, scrupulousness and attention.

It is carried out in stages in a certain order.

Using a standard screwdriver, unscrew the screws fixing the grid of the device. Remove it and set it aside. Manually try to turn the motor shaft.If this fails, then the problem should be looked for in the pumping part of the unit or in the electric motor. To get to the pumping section, it is necessary to unscrew all the screws on which the power cable is attached and carefully disconnect it from the device case Unscrew 4 anodized nuts holding the pump flange. Separate the pump part from the electric motor Step 1 - Unscrew the screws holding the mesh Step 2 - Turn the motor shaft by hand Step 3 - Unscrew the screws holding the power cable Step 4 - Remove the nuts securing the flange

When the pumping part and the engine compartment are separated from each other, troubleshooting is much easier and more convenient.

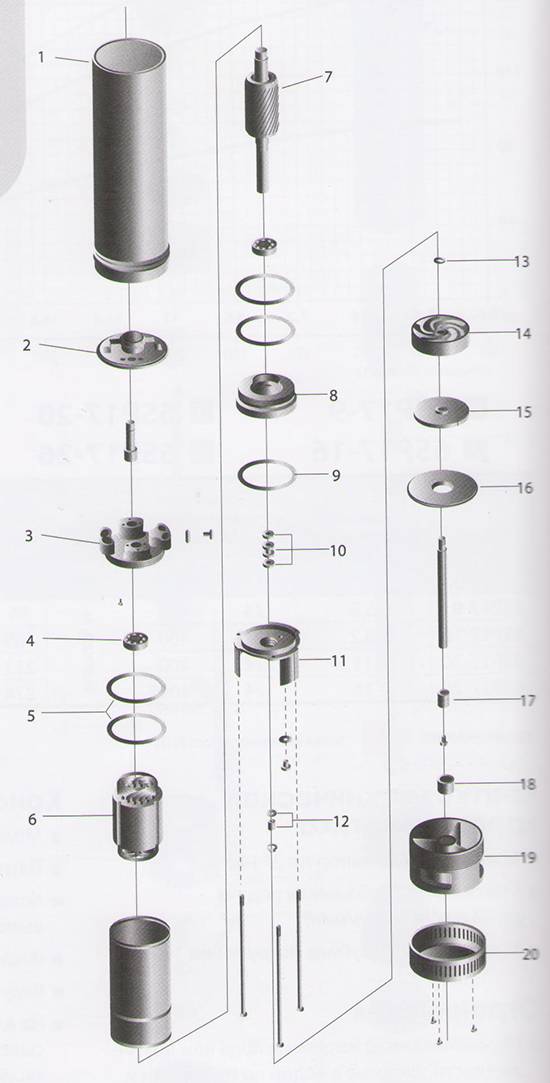

The subtleties of disassembling the shaft of the pump section

To pinpoint the exact location of the problem, try spinning the shaft of the pump section. If this is not possible, then the problem is there.

To disassemble the unit, unscrew all the fasteners that fix the lower flange of the pumping section of the module. To protect the thread from potential damage, screw the adapter into the upper fitting of the unit. Place an iron vice on the working table and firmly fix the pump part in them. remove and set aside Pull the impeller assembly out of the housing and carefully inspect for possible faults Carefully check the condition of the support shaft. Find out if there is any backlash. Determine the wear level of the part Damaged or worn impellers must be replaced. To do this, firmly fix the shaft in a vice and unscrew the upper nut. Remove the blocks with working elements, rinse in running water if contamination is found.If the parts are too worn or changed shape, replace with new ones Step 1 - Unscrew the fasteners of the bottom flange Step 2 - Install the adapter for thread protection Step 3 - Fix the pump in a vise on the table Step 4 - Remove the bottom flange of the pump Step 5 - Removing the impeller block from the housing Step 6 - Inspection for wear and play Step 7 - Unscrew the mounting nut from the impeller block Step 8 - Clean the elements of the impeller block

At the end of the measures related to the repair / replacement / maintenance of the pumping part, reassemble the equipment, carefully following the instructions. Then connect to the engine and return to the workplace.

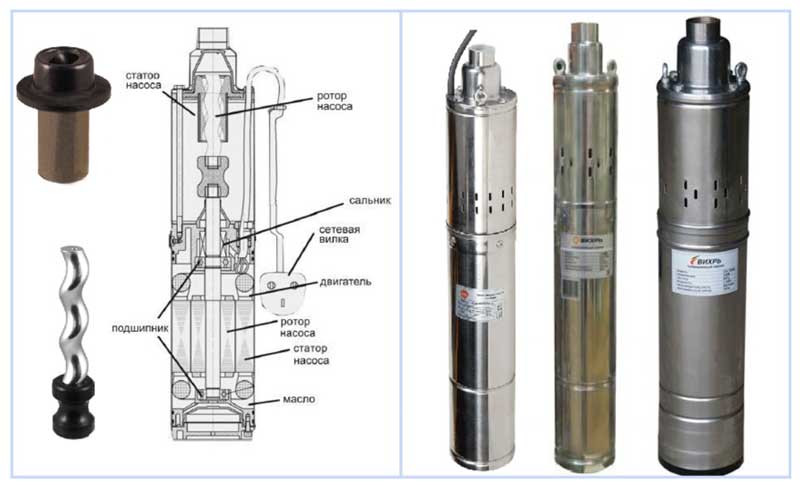

Step-by-step process of disassembling the electric motor

If the area of the problem could not be identified in the two steps described above, there is a good chance that it lies in the engine. To finally verify this, you need to do the following important steps.

from the motor disconnected from the pumping part, fix in a vice

Remove the fasteners and carefully remove the polymer protection of the flange. Take the pliers and remove the retaining ring holding the cover. Using a slotted screwdriver, pry off the cover and remove it. Carefully remove the elastic rubber membrane from the casing of the pumping equipment. Pull out the condenser. Correctly diagnose the equipment and check the oil level

Determine the cause of jamming and eliminate it Step 1 - Dismantling the submersible pump motor Step 2 - Removing the retaining ring and cover Step 3 - Removing the rubber membrane from the housing Step 4 - Removing the condenser from the submersible pump

Correctly diagnose the equipment and check the oil level.Determine the cause of jamming and eliminate it Step 1 - Dismantling the submersible pump motor Step 2 - Removing the retaining ring and cover Step 3 - Removing the rubber membrane from the housing Step 4 - Removing the condenser from the submersible pump

Assemble the engine block following the instructions. Make sure that all the details are in their original places.

Repair of the pumping station Dzhileks

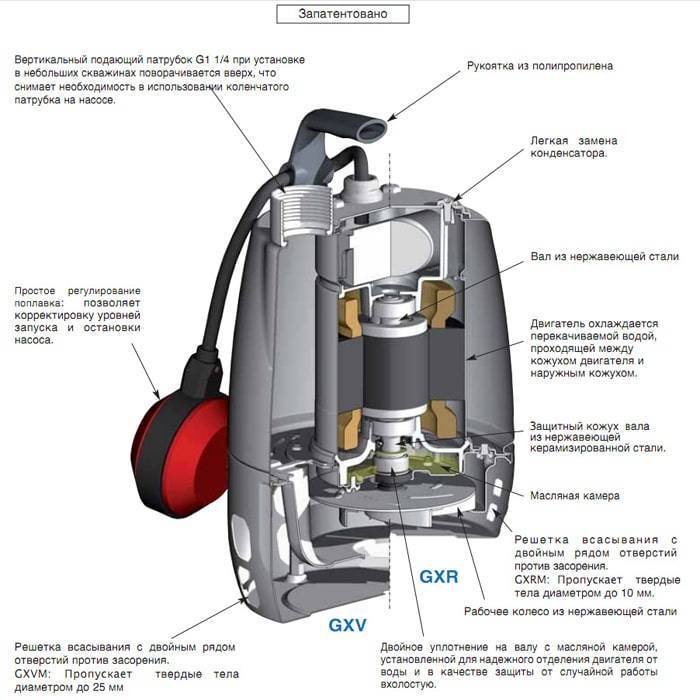

The pumping station is a self-priming surface centrifugal pressure apparatus with an ejector and a piping system. Models of this series are designed for horizontal installation and pump from 3 cubic meters of water per hour. The models differ in the level of engine noise and the presence of automation, which is needed to monitor the water level.

Partial dismantling of the pumping station Dzhleks

Partial dismantling of the pumping station Dzhleks

Let's consider an example of the repair of the Gileks Jumbo pumping station. They are equipped with a pressure switch RDM 5, a tank with membranes (hydraulic accumulator), an electric motor, a centrifugal pumping apparatus, a water intake with a filter and a piping system. You can monitor the pressure inside the installation using the arrow on the pressure gauge.

There are five main reasons why a station may fail or not work correctly:

- It hums but doesn't work. This happens if you left your device for a long time without water and movement. The impeller could just stick to the body. Twist it by hand and try to connect. If it still does not work, check the voltage level of the mains and the condition of the capacitor.

- Doesn't turn on at all. Ring the network, winding, cable with a tester. Perhaps somewhere the contacts just went away, and as soon as they are connected, everything will work again.

- Pumps water constantly and does not turn off. You need to set up the relay.You can adjust it with two mounting springs or screws (depending on which relay is installed in your station model).

- The flow of water is intermittent. The problem is the depressurization of the pipeline or joints. Also, check the water level.

- Too frequent switching on of the device with uneven water flow. It is necessary to check the relay setting and the integrity of the constituent parts of the accumulator tank. Either you have to change the unusable membrane, or the tank is cracked, or the relay itself is broken.

We disassemble the pump Gileks Vodomet

Recently, pumps for wells have become popular. As soon as they appeared on the market, they were in great demand all over the world.

Even the most common pump models often fail. The pumps will have to be repaired as soon as possible. If you do not take action, then you will have to sit for a very long time without water in your dacha or country house. For example, let's take pumps from Gileks.

Instructions for disassembling the unit

The leaders among device manufacturers are "Dzhileks" and "Aquarius". Their products are recognized as the most powerful and high quality and have already established themselves in the market. Not bad devices of the firms "Whirlwind" and "Vodomet", their performance and the ratio "price - quality" secured one of the leading positions for them.

In a situation where sand is found in the water, you need to install a filter and slightly raise the submersible pump. The main reason for the frequent occurrence of malfunctions of the deep unit is its constant presence in the water, which accelerates its wear.

Failure can be caused by the following factors:

- The device worked with insufficient water level in the well, which led to its overheating and melting of internal plastic parts.

- The unit is too powerful for this power source, and, in addition to water, it sucked dirt and sand into itself.

- Electricity fluctuations, which entails a breakdown of the capacitor and other electrical parts.

- The parts of the device are worn out.

Most often, the causes of breakdowns are clogging of the internal system, damage to moving parts, malfunction of the capacitor or accumulator. To determine the cause of the breakdown, first you should inspect the electrical cables, look for faults in the junction box, and visually inspect the device. If everything is in order, the device is disassembled, and this must be done in a certain sequence.

When disassembling the pump All items should be placed in a conspicuous place.

Stages of diagnostics and disassembly:

- Removing the distribution panel;

- Disconnecting the impeller from the engine;

- Checking the operation of the motor;

- Shaft scroll;

- Motor assembly.

If the shaft does not turn, then the engine is jammed. Then there may be particles of earth and clay inside, and the stator may burn out if the dirt is not removed in a timely manner.

When assembling, it is important to check the condition of the gaskets, as the device will again be immersed in water, and if it is not assembled correctly, water will get inside

Model "Water cannon"

In order to quickly and efficiently repair equipment, it is necessary to determine what breakdowns have occurred. There may be several reasons.

The pump does not want to turn on:

There is no voltage in the network.In this case, it is recommended to check the cable supplying electricity to the pump.

The control panel does not work. In this case, it is almost impossible to do anything with your own hands; you need to contact the service center or call the wizard.

The protection that operates in the event of an electric current leakage is constantly activated.

In this case, the attention of a professional electrician is required.

On initial startup, the pump turns on, but it does not pump water.

This situation is caused by the fact that the check valve is most likely installed incorrectly, the equipment must be lifted and inspected.

Reasons for lack of water supply may include:

Scheme of automatic water supply at home with a borehole submersible pump Vodomet.

- An air lock has formed inside the Waterjet pump. In this case, it is necessary to lower the pump to a depth greater than at the initial level. You can put the valve higher than 1 m.

- Non-return valve incorrectly mounted, blocked. It is necessary to pull it out, and then repeat the installation.

Water supply, its pressure after switching on are insufficient. This situation usually occurs after a fairly long operation of the equipment, it is caused by a clogged filter. Reasons for this failure:

- The filter mesh is clogged. It is necessary to disassemble the filter, and then clean or completely replace the mesh.

- Too much sand got into the pump while pumping water. In this case, the repair is simple, it is necessary to pump the pump, after immersing it in a container of clean water. To prevent such a breakdown in the future, you can put an additional filter to clean the sand.

- Depreciation of pumping equipment.This situation sooner or later happens with any device, there is little you can do with your own hands, it is best to immediately contact a specialized service center.

1 The main breakdowns of pumps and their diagnostics

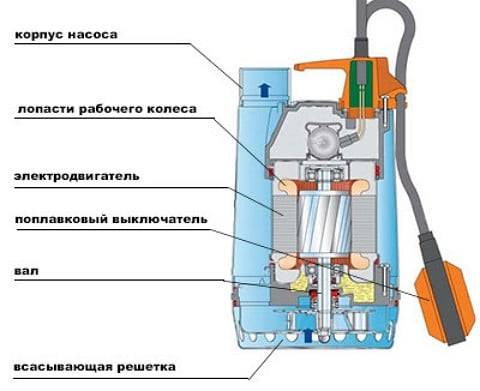

The pump is a fairly simple mechanism. Its design is not particularly complex, but this is only a comparative judgment. After all, it has an engine, contacts, an impeller, a shaft, seals, a housing, etc.

All these parts interact with each other, which leads to their gradual wear. As a result, the pump will need to be repaired.

Plus, it is worth noting that the pump works in rather difficult conditions. This does not apply to Gileks surface pumps, which are assembled together with hydraulic accumulators and installed in separate rooms. However, even such equipment often needs repair.

What can we say about submersible pumps, for example, about the representatives of the Jilex Vodomet line. Find such equipment in a well or well all the time. As a rule, it is not taken out for the winter, which only complicates the situation.

It is worth noting that due to the relative simplicity of the design, it is quite possible to repair all equipment with your own hands. This, of course, is not the best option, since if you make a mistake, you will not only not repair the pump, but will only aggravate the situation.

However, in some situations, you can do it only with your own hands. The main thing is to understand the design features of submersible and surface pumps, as well as their connection types.

There are several of the most popular and well-known pump failures that should be highlighted separately. Diagnosing them is also quite easy.For example, if electricity is connected, but the pump simply does not respond, then something has happened to the contacts or the supply wire.

Disassembled submersible pump view, the limiter is removed from the upper part of the housing

Checking this is easy enough if you have the opportunity to disassemble the device and diagnose the contacts with a tester. The absence of a signal on one of the contacts indicates its damage. It is possible that by this time it will be damp, will have an unnatural color, etc.

If all the mechanisms do not respond, then the cable is broken. This often happens with submersible water jet pumps, as their cable is suspended and poorly protected.

The rumble in the engine, uneven operation, clicks or “flooding” of the pump are all a consequence of problems with the engine or impeller. You can check the correctness of the theory if you disassemble the device and inspect it yourself. It is possible that the impeller is cracked or the bearings on the rotation shaft are out of order. These are the most common problems.

If the engine simply refuses to work, then the problem is already in it. Moreover, we already recommend not to mess with the engine. This is a rather delicate mechanism, especially for submersible models. For example, the water jet 50/25 pump engine cannot be disassembled at all, but this is typical only for some models.

Most often, the motor winding burns out, it can be replaced, but whether it will be profitable is an urgent question. It is possible that it will be easier to simply replace it with a new one. Moreover, the Gileks company supplies spare parts for its products to almost all stores in the country.

In surface pumps, for example, in Gilex Jumbo stations, the engine can generally burn out or wear out very much.All this is due to the dry running of the pump. Unlike submersible models, surface samples are very susceptible to this moment, and they suffer from a decent run.

If we are talking about Gilex Jumbo pumping stations, then it is worth noting one more widespread breakdown, which is very common. It is a problem with the pressure in the system.

There may be several reasons for this:

- Problems with the pressure switch;

- Problems with the accumulator;

- Pump problems.

Gileks Jumbo pumping station under renovation

In the first case, the relay itself goes astray. It is easiest to check it, since the relay is easy to configure and rather primitive. If problems appear during setup, then the relay is to blame.

In hydraulic accumulators, the membrane with air can burst or be damaged. This can only be checked by completely or partially disassembling the tank. The lack of sufficient air in the membrane leads to an imbalance of the entire system and, as a result, a pressure drop.

The pump can also react negatively, but this happens extremely rarely. As a rule, working elements fail, and the device simply cannot cope with swapping. But then you would notice the accompanying signs of breakdown. For example, a slight hum, low pressure, poor rotation of the impeller, etc. In all other cases, either the relay or the accumulator is to blame.

The composition of the pumping station

The complete set of the pumping station is as follows:

- Pump unit. The main parameters for selecting a separate pump or a finished pumping unit are the required water flow (in cubic meters / hour) and pressure (in meters).

- Pressure accumulator.It is a metal tank in which water pressure is constantly maintained. As soon as water is drawn, the pressure in the tank drops and the pumps turn on. When the pressure in the tank reaches the maximum setpoint (drawing stops and the pump continues to run), the pumps are switched off.

- Automation block. Without automation, it is difficult to imagine a modern pumping station. It was the pump automation system that made it possible to reach a new level of comfortable existence.

How to avoid pump failure?

By following the operating rules recommended by manufacturers, you will minimize the risk of breakdown of pumping equipment, and it will serve you for many years. Basic rules of operation:

- Do not allow the pump to run without water.

- Do not use the pump in the presence of unstable mains voltage.

- Do not operate the pump with a damaged power cord or casing.

- Do not move the unit by the power cord.

- Do not pinch the hose to increase the pressure.

- Do not pump water with dirt, impurities, debris.

When installing the pump in a well, it is necessary to put on a protective rubber ring on it, which will protect the equipment from hitting the walls.

The unit can only be switched on/off using a mains plug or a two-pole switch embedded in the fixed wiring system.

During the operation of the vibration pump "Rucheyok" it is necessary to carry out a preventive inspection in a timely manner and monitor the quality of the pumped water. If the water is dirty, then the pump must be turned off and its position relative to the bottom checked.

A few words about adjusting the pressure switch

A pressure switch is a device that automates a pumping station.The relay regulates the pressure in the water supply network, which is maintained by the accumulator. Therefore, the pressure switch and the accumulator always work in pairs.

The pressure switch unit responds when the tank is full or empty. The manufacturer performs the default setting (minimum pressure 1.5 atmospheres and 2.5 atmospheres maximum pressure).

After relay connection to the pump configure the relay for a specific object (set water pressure in the system by technologists).

Setting up the relay for an individual project:

- The relay housing is opened, where the relay control units are located. The minimum pressure is adjusted by the tension of the large spring, and the maximum pressure by the tension of the small spring.

- The adjustment of the "minimum" pressure is started on an empty drive. For what it is enough to turn off the pump and open the tap. Then loosen the big spring. Then turn on the pump and gradually tighten the spring. As soon as the pump begins to supply water, the large spring is no longer touched, the minimum pressure has become equal to the pressure of the air mass.

- Differential pressure adjustment is even easier. The pump is turned off and the pressure on the relay is measured. If the result is not satisfactory, the large or small spring is adjusted again. After that, the pump is turned on again and the value of the maximum pressure is measured.

How to find out the cause of a malfunction of a submersible pump?

To lift or not to lift equipment from the well? The simplest option is to analyze the operation of the equipment using indirect signs, without additional manipulations. After identifying all possible culprits, they act by elimination, leaving the most likely cause. But this way is not ideal.It is not always possible to count on the fact that the failure is caused by a simple reason that is easy to fix: for example, reconfiguring the accumulator - changing the operating pressure range.

Therefore, it is better to immediately assume that the malfunction is caused by more serious circumstances, which means that the “naughty” pump will have to be “extracted” from the well. In this case, the owners have a good opportunity to prevent a serious accident, which in the future may require expensive repairs. The first step is to check the power supply. If the voltage is normal (200-240 V), then interruptions in the operation of the equipment due to surges are excluded.

What do they do first?

To find out the exact cause of the device failure, proceed as follows:

- stop, turn off the water supply system, then raise the structure to the surface;

- remove the top cover from the case, then disassemble the mechanism, referring to the instructions;

- conduct a thorough inspection of each part: look for signs of wear or breakage, friction (abrasive, wet, dry), cracks, accumulation of dirt, etc .;

- the electric motor is tested in the same way, the valve, filters, HDPE pipe, and the integrity of the power cable are checked for defects.

Lastly, the sensors, relays, control unit, installed protection units are examined.

Where might the problem lie?

If the operation of the device is no longer satisfactory, then check the status of all the main nodes.

- Piston or impeller. They must be absolutely perfect, not have any damage, or even a hint of the slightest deformation.

- Distance between piston and coil magnets. Ideal - 4-5 mm. Smaller values will lead to overheating of the electric motor, larger ones will cause the coils to beat.

- Optimum distance between valve and body.It is 7-8 mm. In this case, water will flow freely without problems in the absence of pressure.

Such a check, carried out periodically, will reduce the risk of almost any malfunction of the submersible pump, and will help prevent serious equipment malfunctions.

Types of water pumping stations

With built-in ejector

The principle of operation is based on the rise of water due to the created vacuum. The ascent is carried out from a depth of 20 - 45 meters. The pumping station has a large capacity. Due to the high noise level, such a station should be located in the basement.

With remote ejector

A pump with this type of ejector is immersed in water with two pipes at once. Water, entering the ejector, leads to the appearance of a suction jet. This type of pump is prone to sand blockage and corrosion.

Ejectorless designs

In these pumps, water is lifted using a multi-stage design. They operate silently and consume little electricity.