- Filling valve threaded cartridges

- How to check tightness?

- Safety

- Required Tools

- Do-it-yourself brazier from a gas cylinder

- How to paint a brazier?

- Types and arrangement of valves

- Classification of valves for cylinders

- Gas valve device

- Transport rules

- Using the cut gas receiver

- Types of household gas cylinders

- At home

- How to get Vedashka out of the balloon?

- oxygen cylinders

- Figure 2 - Acetylene cylinder

- What will be needed?

- Safety

Filling valve threaded cartridges

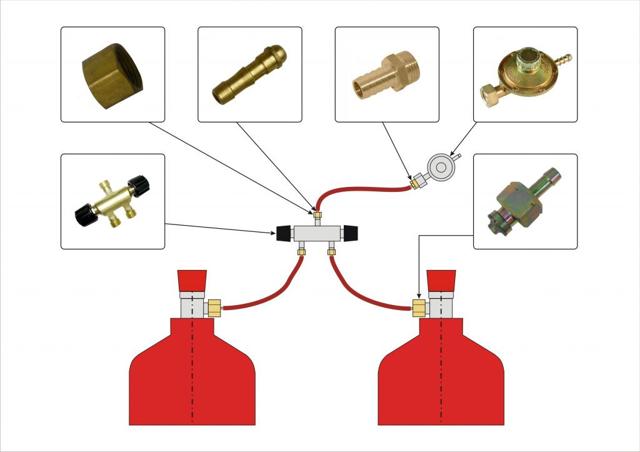

Filling valve threaded cartridges requires the following pre-prepared equipment:

- Two fittings: one, with a union nut, is connected to a household gas cylinder, and the second, threaded, is connected to a gas cartridge;

- A transparent hose with which it will be possible to trace the process of transfusion of gas. It also performs the function of an adapter and connects to two fittings;

- Valves that allow you to turn on and off the gas supply from the cylinder right at the valve;

- A filter built into the valve that prevents debris from entering and clogging the can;

- An additional valve that allows you to bleed gas without removing the adapter.

A good adapter model wins over a cheap one due to a number of advantages:

- The adapter valve ensures the safety of the household cylinder valve, which deteriorates due to regular unscrewing and tightening and due to rust or other metal particles that fall on the thread;

- Due to the fact that the valve is in the closest position to the cartridge valve, during the next refueling cycle, there is practically no leakage of excess gas, pouring it onto your hands and spraying it into the environment;

- The spherical design of the valve allows you to quickly stop the gas supply and avoid unwanted overflow and forced bleeding of excess gas;

- Thanks to the advantages described above, the refueling process is noticeably easier, safer and more economical.

An adapter is screwed onto the valve of a large household gas cylinder instead of a reducer. Refueling is best done in the company of an assistant and in the open air away from crowded places. Since there will be a strong smell of gas, people passing by may become worried and call the gas service.

The process of filling valve threaded cartridges consists of the following steps:

Step 1. First of all, you should drain the remaining condensate, bleed the residual pressure in all cartridges that you plan to fill before the adapter is connected to a large cylinder. Thanks to this, the refueling process will be a little faster.

The adapter is screwed onto the cartridge, which is turned upside down, the cartridge is slightly heated with warm hands, which increases the volume of gas and speeds up the bleed process. Drain the condensate preferably into a plastic bottle. It smells rather unpleasant and saturates the surrounding objects with the smell.

Step 2Preparation of the system consists in setting the gas cylinder in a stable position with the valve pointing downwards and opening free access to it. In no case should the cylinder rest on the valve. The ideal option is to hang the balloon upside down. Next, tighten the adapter and open the valve of the large cylinder.

Step 3. The adapter is tightly screwed to the can. Open the valve on the adapter and start pouring gas. The cessation of the noise emitted by the pouring of gas means the end of the filling.

Step 4. The next step is to release the gas in order to cool the can. The procedure is performed by opening the bleed valve on the adapter. After a few seconds, the can will be cold enough, and the pressure in it will drop to the desired level. We close the valve. If necessary, refilling is carried out.

Step 5. The most important step is to create a buffer cushion in the can to prevent possible expansion and explosion. We open the bleed valve and wait for the moment when the liquid no longer flows.

Never point the gas jet at yourself. When shaking the can, you should definitely feel the flopping. Also an effective method is weighing a filled canister on a scale.

After going through all the stages, it is important to check the tightness of all filled containers

Always point the end of the hose away from you when bleeding, draining residual condensate and creating a cushion

For safety reasons, it is not recommended to store cartridges in the sun, in damp and cold places. Cold cylinders after refueling are covered with a layer of condensate. To prevent rusting processes, it is worth wiping the containers with a dry towel.

How to check tightness?

When checking the tightness of the valve connection, it will be necessary to pump gas under pressure into the gas cylinder.

This can be done in two ways:

- Inject gas using compressor equipment or a car pump.

- Connect two cylinders with a hose, the first of which is empty (tested), and the second is filled with gas.

If soap bubbles do not inflate anywhere, then the connection is tight. But if at least slight swelling of the foam appears, then you will have to twist the valve again.

When the valve is immersed in water, it is advisable to close the side fitting with a plug so that water and suspended particles contained in it do not enter the locking mechanism.

If the balloon is small, then you can immerse its valve in a small bowl of water and look for bubbles.

After replacing the shut-off valves in the passport of gas cylinders, a corresponding mark must be put down.

It should be remembered that the methods described above for replacing a used valve are applicable only to metal tanks. If you have a composite cylinder for storing gas, this cannot be done because of the possibility of damaging the flask and breaking its tightness.

The tightness of the connections and the absence of gas leaks after connecting the reducer is checked using soapy foam, which is applied with a sponge to all connections (valve, union nut, reducer housing, to the connection between the reducer and the outgoing hose).

Fire safety scheme when working with gas cylinders: (1-Do not open the valve abruptly! The gas jet electrifies the neck of the cylinder and the gearbox, it can cause ignition and explosion; 2- Do not allow more than 1 cylinder with propane butane to be at the workplace; 3-At least once a quarter, check the safety valve by forced opening; 4- check for gas leakage)

The height of negligence is to check the tightness of the connections using matches or an electric discharge. Usually the owners of gas cylinders do not care about replacing the valve with propane cylinder, followed by checking the valve thread for leaks, since such operations are performed by gas filling station specialists using special equipment

First, under the control of a manometer, fill the test cylinder with gas with a pressure of 1.5-2 atmospheres. After that, soap suds are applied to the connection and the tap opens slightly. If soap bubbles do not inflate anywhere, then the connection is tight. But if at least slight swelling of the foam appears, then you will have to twist the valve again.

Safety

Even if you are sure that the cylinder is empty, there may be residual liquefied gas at the bottom. Therefore, in order not to risk, you need to get rid of it. To do this, leave the structure open for 12 hours. When doing this, make sure that there are no sources of ignition nearby.

After this time, it is necessary to rinse the inside of the cylinder with clean water, which will remove the remaining gas. In addition, it is allowed to use lime with water or chlorine to clean the structure. True, after such manipulations, an unpleasant odor may remain, which quickly disappears.

Required Tools

You can install HBO on a car yourself or contact a service center. In any case, in order to carry out the work efficiently, you will need to take care of the necessary tools and equipment in advance. So, you need:

- a set of gas-balloon equipment of the fourth generation;

- gas hoses with clamps, the length of which is 0.6-0.8 m, and the diameter is 4-5 mm and 12 mm for 0.5-1 m (for an engine with 4 cylinders);

- gas pipes 40-70 cm long and 6 mm in diameter;

- cooling system hose with two metal tees corresponding to the size of the inlet / outlet on the gearbox;

- thermoplastic gas tube. A product made of copper and aluminum is also suitable;

- automotive tools;

- drill;

- pliers;

- screwdriver;

- drills for metal with a diameter of 4.8 mm, crown 3 cm;

- thread tap - 6 mm;

- electrical tape, stroyfen, heat shrink tube;

- soldering iron and everything you need for soldering wires;

- multimeter;

- metal clamps or staples with self-tapping screws - you will need to fasten the lines under the bottom of the vehicle;

- car enamel or anti-corrosion treatment;

- bolts, nuts;

- intake manifold gasket

Attention! The length of all pipes, hose and clamp diameter is determined according to the car model. It is convenient to carry out work in a viewing hole or on a flyover

Instructions for installing euro equipment will help to avoid mistakes. But without a tool, this is unlikely to be done.

It is convenient to carry out work in a viewing hole or on a flyover. Instructions for installing euro equipment will help to avoid mistakes. But without a tool, this is unlikely to be done.

Do-it-yourself brazier from a gas cylinder

Another useful device can be made from a gas cylinder - a brazier, which is used during outdoor recreation in order to cook meat.

To determine the design, you will need to consider the types of barbecues that are made from cylinders.

Table number 1. Varieties of barbecues

| View, illustration | Description |

|---|---|

BBQ BBQ | This option involves the possibility of frying meat on an open fire. |

Smokehouse Smokehouse | The meat is immersed in the interior of the structure, where it is processed, with hot smoke. |

Smoker Smoker | This is a versatile design that can be used for barbecue and smoking. |

Before you start making a brazier with your own hands, again, you will need to remove the remaining gas from the cylinder. And it is better to do it away from the yard, otherwise the smell will disappear for a long time.

Table number 2. Instructions for making barbecue

| Step, No. | Description | Illustration |

|---|---|---|

| Step 1 | First you need to cut off the top ring from the cylinder. |  |

| Step 2 | Then you should go to the markup stage: - for the lid: we take the joint in the middle, from which we retreat 25 centimeters on each side; - for air supply: we retreat 12 centimeters from the joint to the sides. After that, it is necessary to make cuts in the places where there will be loops for the cover. Moreover, for the convenience of welding, no other cuts should be made yet. |  |

| Step 3 | When the hinges and fasteners for the handle are fixed, you will need to cut the structure along the remaining marks. |  |

| Step 4 | Now on each side you should make holes for air supply. |  |

| Step 5 | Now you need to install metal spacers on the cover from the back. |  |

| Step 6 | Next, use a drill and a drill of the appropriate size to make openings for skewers.It is recommended to make them wider so that any skewers can fit there. |  |

| Step 7 | Then it is necessary to weld a metal plate with holes for skewers to the edge of the structure. |  |

| Step 8 | Now you should weld the hole left from the valve with another piece of metal. |  |

| Step 9 | Next, you need to take pipes from a metal profile, cut them to size and weld a stand for a barbecue. The design should be as in the photo. |  |

| Step 10 | Then you need to make a removable table. It is made from corners, and then sheathed with boards. |  |

| Step 11 | Next, you should weld the handles to the structure and the canopy limiter. |  |

| Step 12 | It is necessary to sheathe the table with wood. |  |

How to paint a brazier?

Since the brazier is used outdoors, the structure will have to be painted without fail. The presence of a coating will protect the product from the negative effects of the environment. Of course, exterior painting is required, because it will not work inside.

You should carefully consider the choice of coverage, because it must meet the following criteria:

- the composition should contain substances that protect the metal from corrosion. You should choose a coating resistant to high temperatures (up to 480 degrees);

- since the brazier is used for cooking, the paint must be environmentally friendly. As a rule, the appropriate marking is located on the packaging.

Paints are sold both in cans and in the form of an aerosol. The second option is practical because you don't have to use brushes.

Types and arrangement of valves

The threads of valves for gas cylinders are standardized, but they themselves can have a variety of designs.The choice of valve model is influenced by the type of stored chemical, the production features of operation and the amount of money. Before buying new equipment, you should familiarize yourself with the options for the execution and internal arrangement of the valves.

Classification of valves for cylinders

The design features of gas cylinder valves are not due to the whims of engineers, but to safety considerations.

Gas valve model VB-2. This valve model has positively proved itself in Soviet times. For decades, it has been used in everyday life and industry, bringing a minimum of problems.

Depending on the material of execution, valves are divided into:

- brass;

- steel.

The choice of metal for the manufacture of the valve body is determined by the type of gases contained in the cylinder. There are the following types of stopcocks, depending on the type of stored chemicals:

- Acetylene. The body of such cylinders is painted white. Special valves are used in cylinders with acetylene, chlorine, ammonia and other aggressive substances.

- Oxygen. The cylinders are painted blue and are designed to store oxygen, argon, hydrogen, nitrogen, carbon dioxide and other inert gases.

- Propane-butane. They are painted red and are intended for the storage of substances corresponding to the name and other gaseous hydrocarbons. The most common valve type model for such a cylinder is VB-2.

Valves for acetylene cylinders are not made of brass because the substances contained in them can react chemically with copper. Usually, for the manufacture of valves of this type, carbon or alloy steel is used.

Gas valve device

A standard gas valve has the form of a tee, on each fitting of which an external thread is cut. More advanced models may have an additional protrusion - a safety valve. Its purpose is to relieve excess pressure in case of heating of a full cylinder or in case of incorrect filling.

The lower fitting of the valve is used to connect to the gas cylinder, the upper one is for fastening the flywheel, and the side one is for connecting communications for gas outlet and injection. The device of the crane for a gas cylinder is quite simple. Shut-off valves usually consist of the following common elements:

- Brass or steel body.

- Stuffing box valve or handwheel attached to the body with a union nut.

- Internal locking mechanism with valve and stem.

- Sealing gaskets.

- Plug for outlet.

You can consider in more detail the arrangement of valves on gas cylinders of each type in the presented images.

Image gallery

Photo from

Draining poisonous gases through a safety valve can be harmful to health even in open spaces.

Acetylene valves use a maximum of seals so that poisonous gases do not get outside

Gaskets in such a valve should not be made of pure rubber, because it is able to interact with oxygen.

Seals on propane tanks are simple, so they must withstand a maximum pressure of only 16 atmospheres.

Valve with safety valve

Valve for acetylene cylinder

Valve for oxygen cylinder

Valve for propane-butane cylinder

Worn valves can let a small amount of gas through, which can lead to unpredictable consequences in enclosed spaces. To prevent such situations, a plug is used on the side fitting, which serves to additionally seal the cylinder during transportation and long-term storage.

The direction of the threads on the outlets depends on the chemicals contained in the cylinders: the right one is used for non-flammable gases (oxygen, nitrogen, argon, etc.), and the left one is used for combustible gases (hydrogen, acetylene, propane, etc.)

The principle of operation of the assembled gas valve is unremarkable. To supply gas and shut it off, simply turn the handwheel slowly in the appropriate direction.

Transport rules

- Transportation is carried out by specially equipped vehicles marked with warning signs.

- For the transportation of cylinders with LPG, technical gases, a special permit is issued.

- Each gas cylinder is marked with its own color: propane-butane domestic mixture - red, oxygen - blue, acetylene - white, carbon dioxide / nitrogen - black with the designation of a chemical element / compound, argon - gray, helium - brown.

- The joint transportation of tanks with different gases, as well as empty / used up together with full ones, is strictly prohibited.

- When transported in a car, they are laid horizontally no higher than the sides, no more than three rows; in a container - standing, and it is permissible to transport tanks with oxygen, acetylene together.

- Tanks with propane-butane can be transported standing up without containers, with a gasket between them and a reliable fence.

When loading / unloading gas cylinders, it is prohibited:

- To work alone, there must be at least two loaders.

- Work in overalls, gloves contaminated with fuels and lubricants, vegetable oils.

- Load oxygen tanks into a car body that has fuel spills / stains, as well as garbage, foreign objects.

- It is categorically unacceptable to carry tanks with gases on the arms/shoulders, to roll cylinders, and also to move them, dropping them, hitting them against each other.

- Hold, feed the container with the stop valves down.

- Load/unload tanks without protective caps.

Inside buildings, steel containers with any gases must be transported on a stretcher with a secure fastening or a special cart with wheels with rubber tires; at the same time, the joint transportation of two cylinders is permissible - with oxygen, acetylene for gas welding.

Using the cut gas receiver

Due to the mass connection of all houses to the gasification system, gas receivers have lost their popularity. That is why today many craftsmen set out to make new designs from used cylinders that perform completely different functions.

The first thing that comes to mind when looking for options for using a gas receiver is a homemade potbelly stove. In this case, the propane tank is the ideal housing for the stove, since its walls are 3 mm thick, which is just enough for safe operation.

Especially popular is the barbecue grill from a gas cylinder. To make such a mobile grill, you need a simple cylinder, a burner old gas stove, grill grate and drip tray.

The internal coating of the body allows you to safely cook food in the roaster even with the lid closed. Gas brazier from of the used receiver is ideal for a spacious suburban area where you can gather a large group of friends.

From several cylinders you can build a real smokehouse with separate containers for cold and hot smoking, barbecue and grill compartments. The design can be adapted both for skewers and for the grill, which allows you to cook meat and fish in different ways. In the manufacture of such a complex structure, one should understand the principle of operation of the smokehouse, therefore it is recommended to rely on the drawing.

The process of parsing an old gas cylinder requires special care on the part of the master, since even a small amount of gas inside the container, when interacting with a spark from a grinder, can provoke an explosion. The process of sawing a gas receiver is preceded by a preparatory stage, which includes releasing gas and filling the cylinder with water

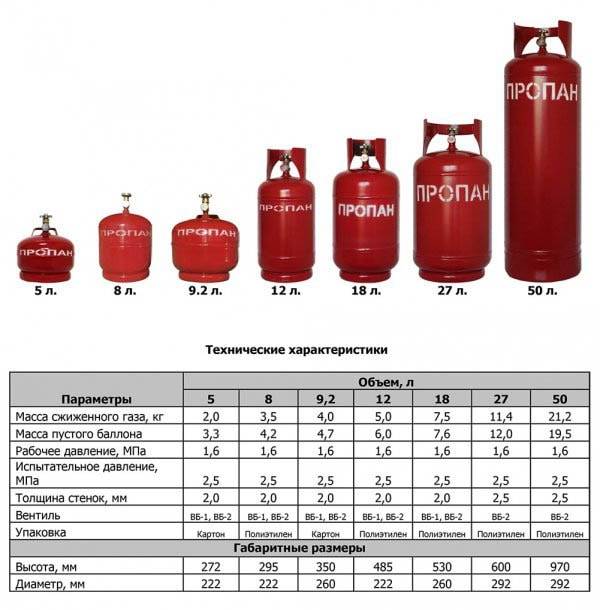

Types of household gas cylinders

In its vast majority in everyday life, gas cylinders are used to organize the operation of stoves. Therefore, this review will focus on just such a method of operation.

According to the type of material used, gas cylinders are:

- steel;

- Polymer-composite;

- Metal-composite.

The most widely used steel (metal) cylinders. It was with them that the era of mobile gasification began.

Despite numerous shortcomings (heavy weight, insecurity, susceptibility to corrosion, opacity), it is these cylinders that are in great demand due to their availability and low price.

Steel gas cylinders are distinguished by their availability and the ability to choose a tank of various capacities

Polymer-composite cylinders are 35-40% lighter than steel ones, because fiberglass filled with epoxy resin is used for their manufacture. Such cylinders are explosion-proof and impact-resistant, which are provided by a protective casing.

They are not subject to corrosion, transparent, equipped with a bypass valve. True, they have a smaller volume than steel counterparts, and their price is an order of magnitude higher.

Due to the presence of a protective casing, polymer-composite gas cylinders are characterized by high impact resistance and safety.

Metal-composite cylinders are a cross between polymer-composite and steel. In terms of safety and impact resistance, they are inferior to polymer-composite products.

At home

The rules for the use of gas cylinders, as well as their manufacture and storage, are set out in several official documents:

- “Industrial Safety Rules for Hazardous Industries Where Equipment Under Excessive Pressure is Used”, approved by Order No. 116 dated 25.03. 2014 Federal Service of Rostekhnadzor.

- PPR in the Russian Federation.

- GOST 15860-84, establishing those. conditions for cylinders with liquefied hydrocarbons pressure up to 1.6 MPa.

The recommendations of the Federal State Institution VNIIPO dated June 13, 2000 on the tactics of fire departments in the event of the possibility of an explosion of gas-balloon equipment in the fire seat provide the following information:

- Cylinders for storage and transportation of liquefied/compressed hydrocarbon gases (LHG) are widely used in various industries, as well as in everyday life.

- In accordance with GOST 15860, 25 enterprises in Russia produce welded steel cylinders for LPG storage.

- Their total number is about 40 million pieces.

- The main types with a capacity of 27.50 liters, which is up to 85% of the total.

Storage and use of gas cylinders

Considering that, according to GOST, the allowable service life of cylinders subject to compliance with the rules, technical examination once every five years is 40 years, it is easy to imagine that in recent years their number has been used both in everyday life for cooking, and at construction sites, in the workshops of industrial enterprises for conducting fire , including gas welding, works only increased; as well as the number of fires where explosions took place, loss of life.

The main requirements of the PB standards for the use of cylinders with propane, butane, their mixture when used in everyday life:

- It is forbidden to store LPG cylinders in private houses, apartments, stairwells, basements / attics, loggias / balconies of multi-storey residential buildings.

- Cookers, gas units for heating water must have an LPG supply from tanks installed outside residential buildings in annexes / cabinets made of non-combustible material located at blank external walls, at least 5 m away from the entrances to the house, basements / plinths. Exception - 1 tank up to 5 liters connected to the stove.

- Cabinets for tanks with LPG must be locked, equipped with blinds for constant ventilation, provided with inscriptions: “Flammable. Gas".

- At the entrances to private houses, townhouses, block sections, premises of buildings where tanks with LPG are used, an inscription / plate is placed: “Flammable. Cylinders with gas.

The simplest precautions are also mentioned - it is forbidden to use household appliances in case of a gas leak that has a characteristic odor; in no case do not check the tightness of any connections of the gas path from the entrance to the apartment to the appliances using an open flame. At home, you can check a gas leak with a soapy solution, but it’s better not to engage in amateur activities; but shut off the supply and, depending on the situation, call representatives of the emergency gas service or a service organization / enterprise

At home, you can check a gas leak with a soapy solution, but it’s better not to engage in amateur activities; but shut off the supply and, depending on the situation, call representatives of the emergency gas service or a service organization / enterprise.

Rules for storing gas cylinders

How to get Vedashka out of the balloon?

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

It seemed to me that such things should be pumped up with a fork pump. The atomizer head rests on parole and is unlikely to break when pumping.

So I generally also have gas for lighters, so the most technologically advanced option)

BecauseYou are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Because You are not logged in. To come in.

Because The topic is archived.

Well, I won’t offer the most interesting way, throw it into the fire, run away to a safe place and watch how everything around is lubricated

. and not plastic, but aluminum cans from the kind of beer. although there was also plastic.

Source

oxygen cylinders

Figure 2 - Acetylene cylinder

Maximum pressure of acetylene in the cylinder

is 3 MPa. The pressure of acetylene in a fully filled cylinder changes with temperature:

The pressure of filled cylinders must not exceed

at 20°C 1.9 MPa.

When opening the valve cylinder acetylene is released from acetone and in the form of gas enters through the reducer and hose into the torch or cutter. Acetone remains in the pores of the porous mass and dissolves new portions of acetylene during subsequent fillings of the balloon with gas. To reduce the loss of acetone during operation, it is necessary to keep acetylene cylinders in a vertical position. At normal atmospheric pressure and 20 ° C, 28 kg (l) of acetylene dissolves in 1 kg (l) of acetone. The solubility of acetylene in acetone increases approximately in direct proportion with increasing pressure and decreases with decreasing temperature.

To fully utilize the capacity of the cylinder empty acetylene cylinders are recommended to be stored in a horizontal position

, as this contributes to the uniform distribution of acetone throughout the volume, and with tightly closed valves. When taking acetylene from a cylinder, it carries away part of the acetone in the form of vapors. This reduces the amount of acetylene in the cylinder during the next fillings. To reduce the loss of acetone from the cylinder, acetylene must be taken at a rate of not more than 1700 dm 3 /h.

To determine the amount of acetylene

the cylinder is weighed before and after filling with gas and the amount of acetylene in the cylinder in kg is determined by the difference.

Weight of empty acetylene cylinder

consists of the mass of the cylinder itself, the porous mass and acetone. When taking acetylene from a cylinder, 30-40 g of acetone per 1 m 3 of acetylene is consumed together with gas. When taking acetylene from a cylinder, it is necessary to ensure that the residual pressure in the cylinder is at least 0.05-0.1 MPa.

Use of acetylene cylinders

instead of acetylene generators gives a number of advantages

: compactness and ease of maintenance of the welding installation, safety and improvement of working conditions, increase in labor productivity of gas welders. In addition, dissolved acetylene contains less impurities than acetylene obtained from acetylene generators.

The reasons for the explosion of acetylene cylinders can be sharp shocks and blows, strong heating (over 40 ° C).

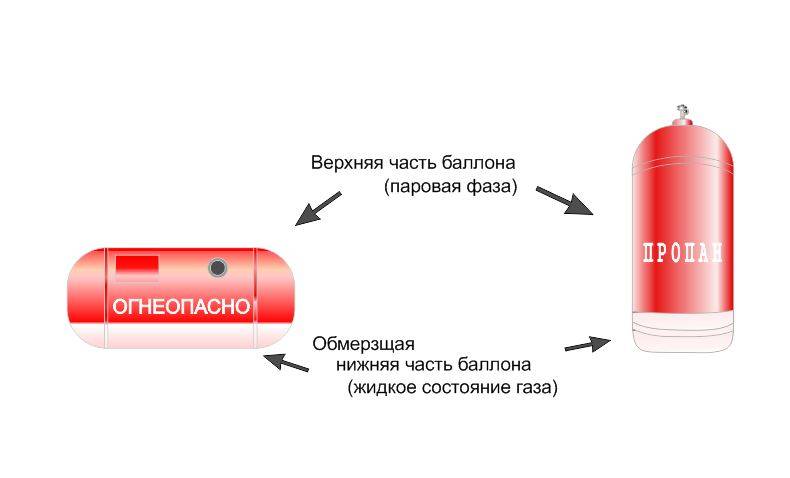

Cylinders for propane-butane are made

according to -84 welded from carbon steel sheet. The main application was found in cylinders with a capacity of 40 and 50 dm 3. Cylinders for propane-butane are painted

in red with a white inscription "propane".

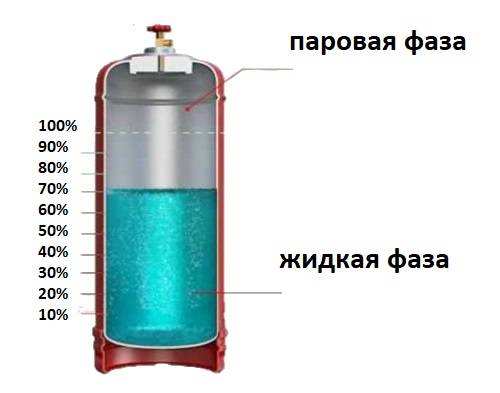

The propane-butane cylinder is

a cylindrical vessel 1, to the upper part of which a neck 5 is welded, and to the bottom - a bottom 2 and a shoe 3. A brass valve 6 is screwed into the neck. Backing rings 4 are pressed onto the cylinder body. A cap 7 serves to protect the cylinder valve.

Cylinders are designed for a maximum pressure of 1.6 MPa. Due to the high coefficient of volume expansion, cylinders for liquefied gases are filled to 85-90% of the total volume. Cylinder filling rate

for propane - 0.425 kg of liquefied gas per 1 dm3 of cylinder capacity. AT cylinder with a capacity of 55 dm3 3 24 kg of liquid propane-butane is poured. The maximum gas withdrawal should not exceed 1.25 m 3 /h.

What will be needed?

To carry out the work in question, a certain set of tools is required. As a rule, cutting is carried out by a grinder. Other required tools are as follows:

Gas and open-end wrench for working with the valve. In order to remove all the gas from the tank, the valve must be fully opened.

A hacksaw is also used for cutting, for example, in the case of cutting off the neck

It is worth paying attention to the correct choice of a suitable cutting blade, as too soft metal leads to rapid grinding of the teeth.

Water is used to clean the surface. It is usually poured into a container.

When working with a grinder, you should be careful, as the circle is in contact with a small area. In addition, goggles should be used at the time of cutting, as a large number of fragments and burning abrasive are formed.

Cutting a gas cylinder with a grinder

For an angle grinder, it is important to choose the most suitable circle. This is because the wrong abrasive wheel can wear off quickly.

Before each cutting, check the integrity of the nozzle, its reliability of fastening. Cutting without a protective cover is not allowed.

Safety

Even if you are sure that the cylinder is empty, there may be residual liquefied gas at the bottom. Therefore, in order not to risk, you need to get rid of it. To do this, leave the structure open for 12 hours. When doing this, make sure that there are no sources of ignition nearby.

Before flushing the structure, it is necessary to unscrew the valve

Before flushing the structure, it is necessary to unscrew the valve

After this time, it is necessary to rinse the inside of the cylinder with clean water, which will remove the remaining gas. In addition, it is allowed to use lime with water or chlorine to clean the structure. True, after such manipulations, an unpleasant odor may remain, which quickly disappears.