- Pressure in the heating system

- How to correctly calculate the volume of the tank for heating systems?

- Calculation formula

- Do-it-yourself open tank

- To what level to inflate the air chamber

- Types, device and principle of operation of expansion tanks

- Expansion tank for open type heating

- Expansion tank for closed type heating

- How and where is the expansion tank placed

- open system

- closed system

- Right choice

- Device and principle of operation

- How to calculate the volume of a box in M 3

- Formulas

Pressure in the heating system

Pressure in the network arises as a result of the influence of several factors. It characterizes the effect of the coolant on the walls of the system elements. Before filling with water, the pressure in the pipes is 1 atm. However, as soon as the process of filling the coolant begins, this indicator changes. Even with a cold coolant, there is pressure in the pipeline. The reason for this is the different arrangement of the elements of the system - with an increase in height by 1 m, 0.1 atm is added. This type of impact is called static, and this parameter is used when designing heating networks with natural circulation. In a closed heating system, the coolant expands during heating, and excess pressure is formed in the pipes.Depending on the design of the line, it can change in different sections, and if stabilizing devices are not provided at the design stage, then there is a risk of system failure.

There are no pressure standards for autonomous heating systems. Its value is calculated depending on the parameters of the equipment, the characteristics of the pipes, and the number of storeys of the house is also taken into account. In this case, it is necessary to follow the rule that the pressure value in the network must correspond to its minimum value in the weakest link in the system. It is necessary to remember about the mandatory difference of 0.3-0.5 atm. between the pressure in the direct and return pipes of the boiler, which is one of the mechanisms for maintaining the normal circulation of the coolant. Taking into account all this, the pressure should be in the range from i .5 to 2.5 atm. To control the pressure at various points in the network, pressure gauges are inserted that record low and excess values. In the event that the meter must not only serve for visual control, but also work with the automation system, electrocontact or other types of sensors are used.

- The density of heated water is less than the density of cold water. The difference between these values leads to the fact that a hydrostatic head is created, which promotes hot water to the radiators.

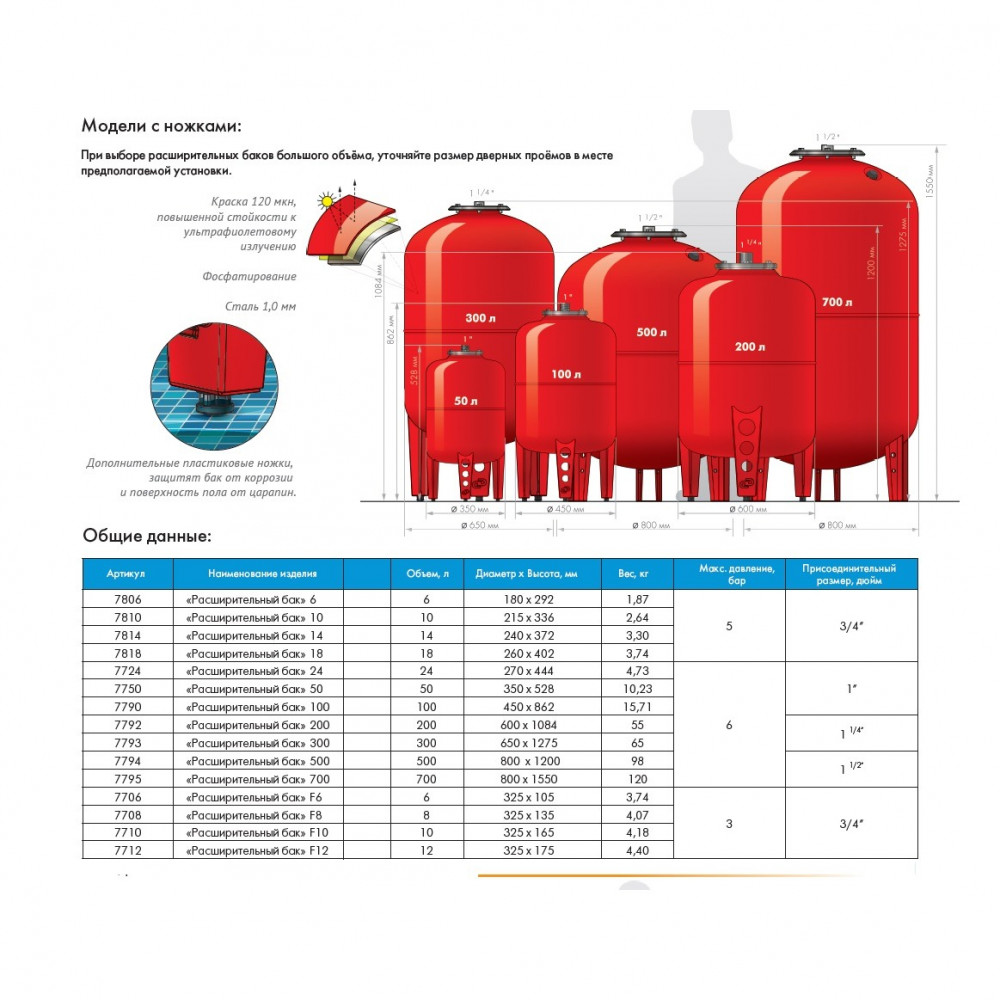

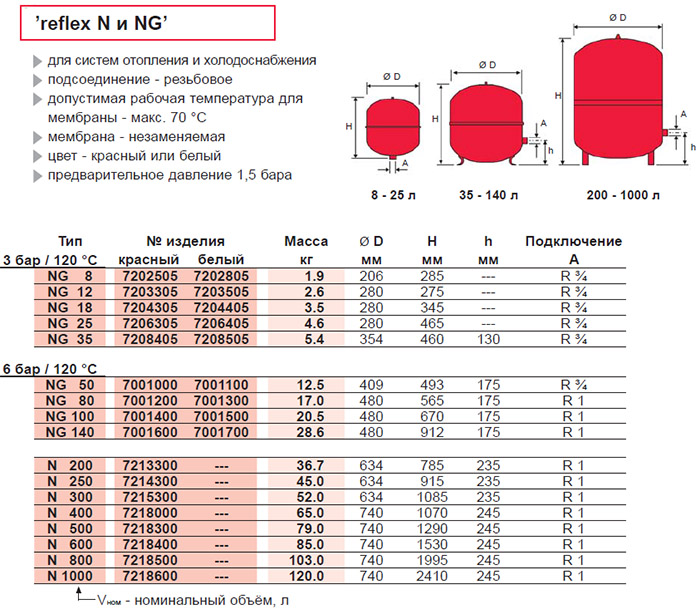

- For expansion tanks, the most informative are the maximum allowable values of temperature and pressure.

- According to manufacturers, in modern tanks the coolant temperature can reach 120 ° C, and the operating pressure is up to 4 atm. at peak values up to 10 bar

How to correctly calculate the volume of the tank for heating systems?

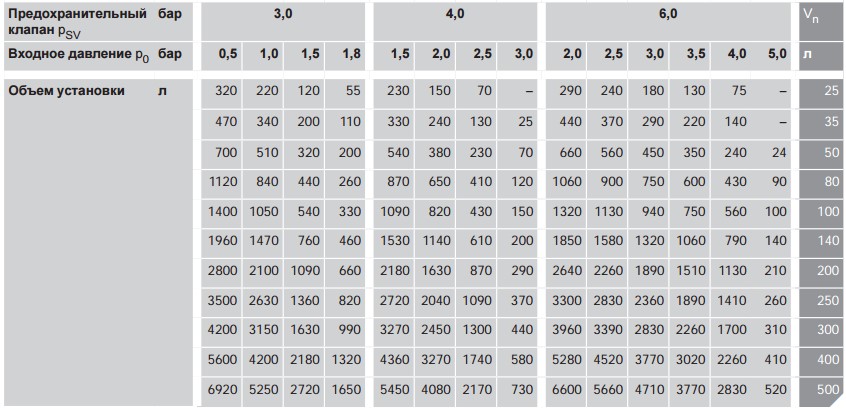

In order to correctly calculate the volume of the expansion tank, several factors that affect this indicator are taken into account:

- The capacity of the expandomat directly depends on the amount of water in the heating system.

- The higher the allowable pressure in the system, the smaller the tank size you will need.

- The higher the temperature to which the coolant is heated, the larger the volume of the device should be.

Reference. If you choose an expansion tank that is too large, it will not provide the necessary pressure in the system. A small tank will not be able to accommodate all the excess coolant.

Calculation formula

Vb \u003d (Vc * Z) / N, in which:

Vc is the volume of water in the heating system. To calculate this indicator, multiply the boiler power by 15. For example, if the boiler power is 30 kW, then the amount of coolant will be 12 * 15 \u003d 450 liters. For systems where heat accumulators are used, the capacity of each of them in liters must be added to the figure obtained.

Z is the expansion index of the coolant. This coefficient for water is 4%, respectively, when calculating, we take the number 0.04.

Attention! If another substance is used as a coolant, then the expansion coefficient corresponding to it is taken. For example, for 10% ethylene glycol, it is 4.4%

N is an indicator of the efficiency of tank expansion. Since the walls of the device are made of metal, it can slightly increase or decrease in volume under the influence of pressure. To calculate N, you need the following formula:

N= (Nmax—N)/(Nmax+1), where:

Nmax is the maximum pressure in the system. This number is from 2.5 to 3 atmospheres, to find out the exact figure, look at what threshold value the safety valve in the safety group is set to.

N is the initial pressure in the expansion tank. This value is 0.5 atm.for every 5 m height of the heating system.

Continuing the example with a 30 kW boiler, let's assume that Nmax is 3 atm., the height of the system does not exceed 5 m. Then:

N=(3-0.5)/(3+1)=0.625;

Vb \u003d (450 * 0.04) / 0.625 \u003d 28.8 l.

Important! The volumes of commercially available expansion tanks meet certain standards. Therefore, it is not always possible to buy a tank with a capacity that exactly matches the calculated value.

In such a situation, purchase a device with rounding up, because if the volume is slightly less than necessary, it may harm the system.

Do-it-yourself open tank

open tank

Another thing is the expansion tank for heating an open house. Previously, when only the opening of the system was assembled in private homes, there was even no question of buying a tank. As a rule, an expansion tank in the heating system, the scheme of which consists of five main elements, was made right at the installation site. It is not known whether it was possible, in general, to buy it at that time. Today it is easier, as you can do it in a specialized store. Now in the predominant majority of housing is heated by sealed systems, although there are still many houses where there are opening circuits. And as you know, tanks tend to rot and it may be necessary to replace it.

A store-bought heating expansion tank device may not meet the requirements of your circuit. There is a possibility that it won't fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask.Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose. Since the first tank is rotten, then you need to make sure that this does not happen to the second. Therefore it is better to use stainless steel. It is not necessary to take a thick one, but also too thin. Such metal is more expensive than usual. In principle, you can do with what is.

Now let's take a step-by-step look at how to make a tank with your own hands:

action first.

Metal sheet marking. Already at this stage, you should know the dimensions, since the volume of the tank also depends on them. A heating system without an expansion tank of the required size will not work correctly. Measure the old one or count it yourself, the main thing is that it has enough space for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another piece and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open. To do this, it must be welded onto the curtains to the second, immovable, part;

third act.

Welding blanks in one design. Make a hole in the bottom and weld a pipe there through which the coolant from the system will enter. The branch pipe must be connected to the entire circuit;

action four.

Expansion tank insulation. Not always, but often enough, the tank is in the attic, since the peak point is located there. The attic is an unheated room, respectively, it is cold there in winter. The water in the tank may freeze.To prevent this from happening, cover it with basalt wool, or some other heat-resistant insulation.

As you can see, there is nothing difficult in making a tank with your own hands. The simplest design is described above. At the same time, in addition to the branch pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the scheme of the expansion tank for heating:

- through which the system is fed;

- through which the excess coolant is drained into the sewer.

Scheme of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The withdrawal of water through the drain is called an emergency release, and the main task of this pipe is to prevent the coolant from overflowing through the top. Make-up can be inserted anywhere:

- so that the water is above the level of the nozzle;

- so that the water is below the level of the nozzle.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is above the water level, will murmur. This is more good than bad. Since make-up is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water from the water supply enters the expansion tank, then you already understand that there is a possibility of some kind of malfunction in the circuit.

As a result, to the question: “Do I need an expansion tank in the heating system?” - you can definitely answer that it is necessary and mandatory.It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

To what level to inflate the air chamber

It is important to correctly adjust the expansion tank for closed heating. The capacity calculation is, of course, a serious aspect, but even if it is done correctly, the tank may still not work properly. To understand this, let's briefly dwell on its design.

It consists of two compartments, between which there is a rubber gasket. There is no communication between cameras. There is a nipple in the air compartment.

During operation, water fills the volume of the tank chamber, while the membrane is stretched. If the pressure in the air chamber is too high, it will simply prevent the elastic from deforming. As a result, the tank does not work. The air chamber should be two tenths of an atmosphere less than the operating pressure of the boiler. Or, use the manufacturer's recommendations for adjustment.

Types, device and principle of operation of expansion tanks

Expansion tank for open type heating

In open heating systems, the role of the RB can be performed by any container located at the highest point in relation to all other elements. In low-rise housing construction, the regular location of the tank is an attic or attic room.

In order to minimize the loss of liquid during evaporation into the environment, a cover is mounted on the tank. In case the temperature drops to negative values and prevents the liquid from freezing, the tank is insulated from all sides.To prevent the heat transfer fluid in the tank from boiling, the container is connected to a pipe leading to the return circuit. To prevent liquid from overflowing and being discharged into the sewer, most designs provide a hose or pipe.

A significant disadvantage of open circuits is the need to periodically top up the liquid evaporated into the atmosphere. The problem is solved by installing an automated control mechanism with automatic replenishment, however, the supply of water to the tank complicates the design and leads to its rise in price.

In an open circuit, communication with the atmosphere is carried out through the RB and the air formed as a result of the boiling of the liquid is removed. In this case, no increased pressure is created in the heating mains, and water circulation is due to convection. In this case, there is a process of natural convection, in which the cold layers of the coolant go down, and the hot ones rise up.

A simple example of natural convection is the heating of water in a kettle placed on a lit kitchen stove. When installing an open expansion tank between it and the system, the installation of shut-off valves is not provided. Structurally, an open-type tank can be either cylindrical or rectangular in shape. In standard designs, a viewing window is located on the tank cover to control the liquid level. The disadvantages of open systems include:

- increased heat loss through the expansion tank;

- increased level of corrosion of system elements due to direct contact of the liquid with air;

- obligatory location of the RB over all elements of the contour.

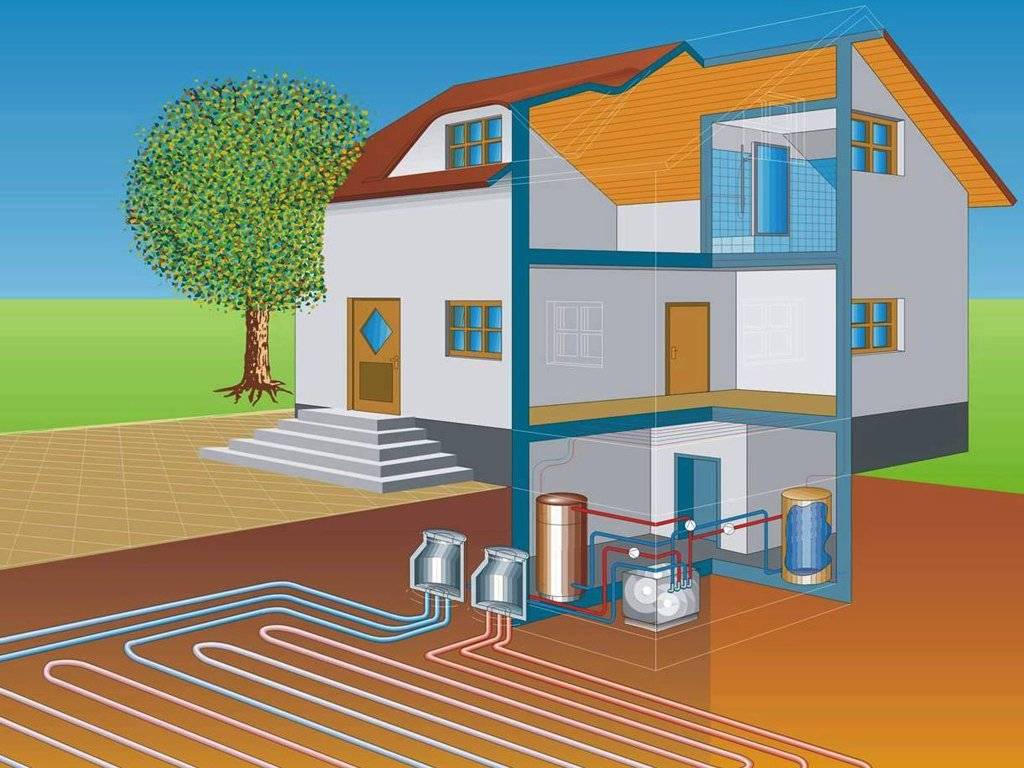

Expansion tank for closed type heating

A sealed heating circuit with forced circulation of water or antifreeze is devoid of the disadvantages inherent in open circuits. There is no air penetration into sealed systems, and compensation for changes in the state of the thermal energy carrier occurs through the use of sealed membrane tanks.

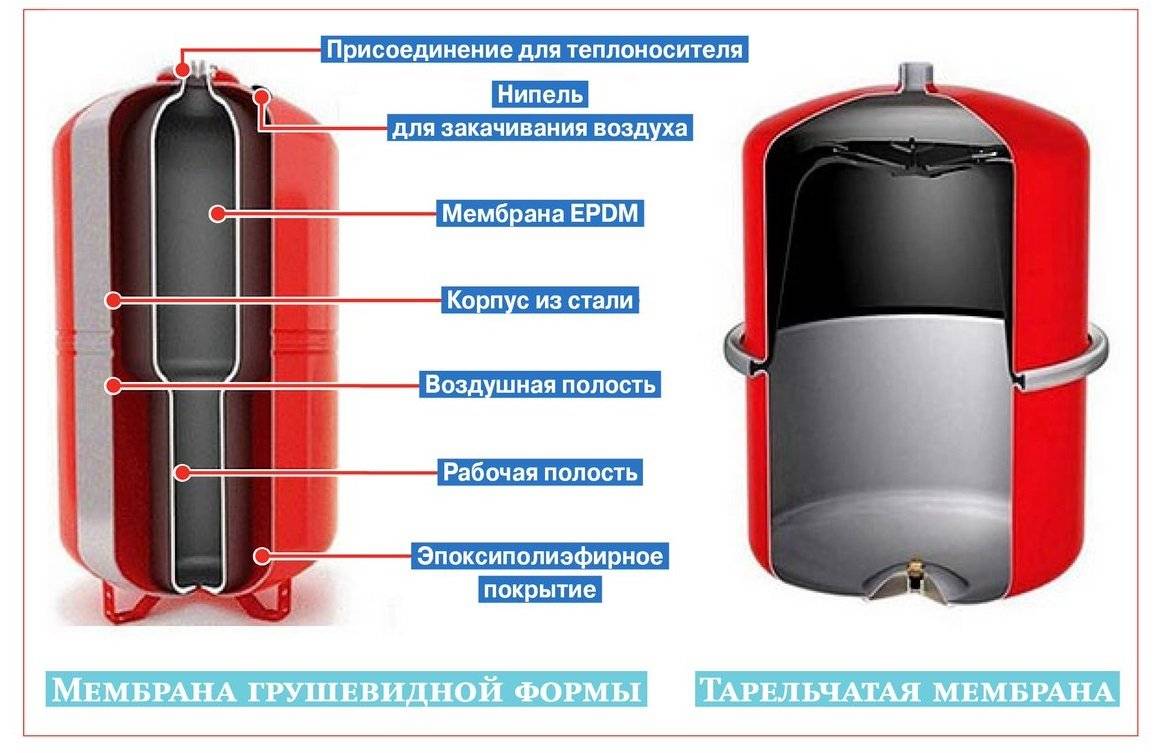

Technically membrane expansion tank made in the form of a vessel, the inner part of which is divided by an elastic partition into two sections: liquid and gas. The gas chamber is supplied with a spool for pressure regulation. The spool is usually fitted with a protective plastic cap or cap to prevent contamination.

In the liquid part, a branch pipe for supplying and discharging liquid is mounted. Most often, membrane tanks are in the form of a cylinder, but for small thermal systems, round containers in the form of tablets are used. In appearance, RBs are similar to pumped storage tanks (HA) for water supply systems.

As a rule, GAs are painted blue, and expansion tanks are red. GA and membrane RPs are not interchangeable and their purpose is different. In HA, the membrane has the shape of a “pear” and is made of a material that allows safe contact with drinking water. Contact with metal parts is excluded. In the Republic of Belarus, the partition is made of technical rubber and coated with an anti-corrosion compound, which increases its service life.

How and where is the expansion tank placed

So, we are going to design and assemble a heating system with our own hands. If she also earns - our joy will not be the limit. Are there any instructions for installing the expansion tank?

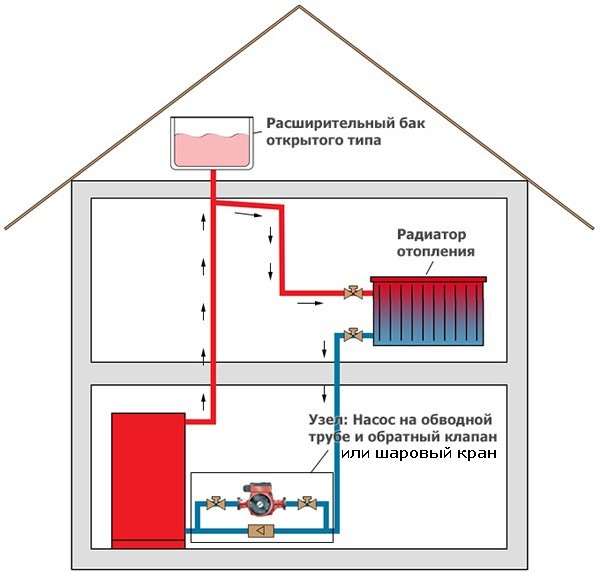

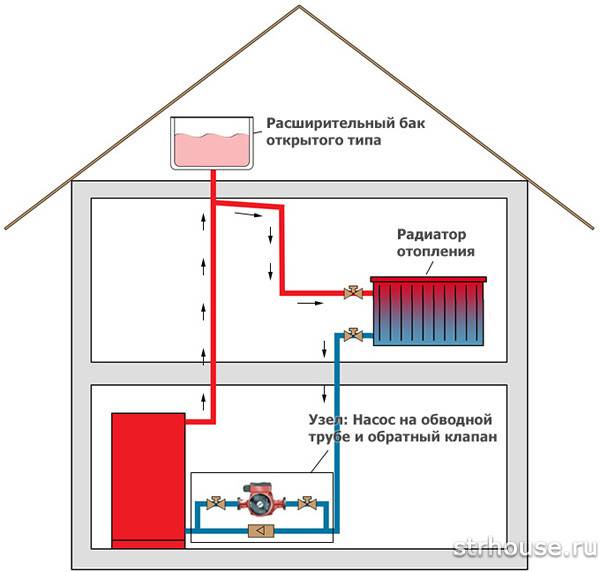

open system

In this case, simple common sense will prompt the answer.

An open heating system is, in essence, one large vessel of complex shape with specific convection currents in it.

The installation of the boiler and heating appliances in it, as well as the installation of pipelines, must ensure two things:

- Rapid rise of the water heated by the boiler to the upper point of the heating system and its discharge through the heating devices by gravity;

- The unimpeded movement of air bubbles to wherever they rush in any vessel with any liquid. Up.

- The installation of a heating expansion tank in an open system is always carried out at its highest point. Most often - at the top of the accelerating manifold of a single-pipe system. In the case of top filling houses (although you hardly have to design them), at the top filling point in the attic.

- The tank itself for an open system does not need shutoff valves, a rubber membrane, and even a lid (except to protect it from debris). This is a simple water tank open on top, into which you can always add a bucket of water to replace the evaporated one. The price of such a product is equal to the cost of several welding electrodes and a square meter of steel sheet 3-4 mm thick.

It looks like an expansion tank for an open heating system. If desired, a water tap from the water supply can be brought into the hatch in it. But much more often, as the water evaporates, it is topped up with an ordinary bucket.

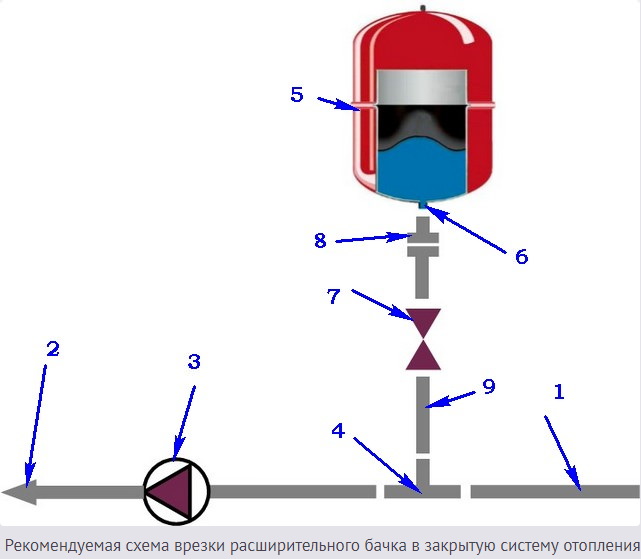

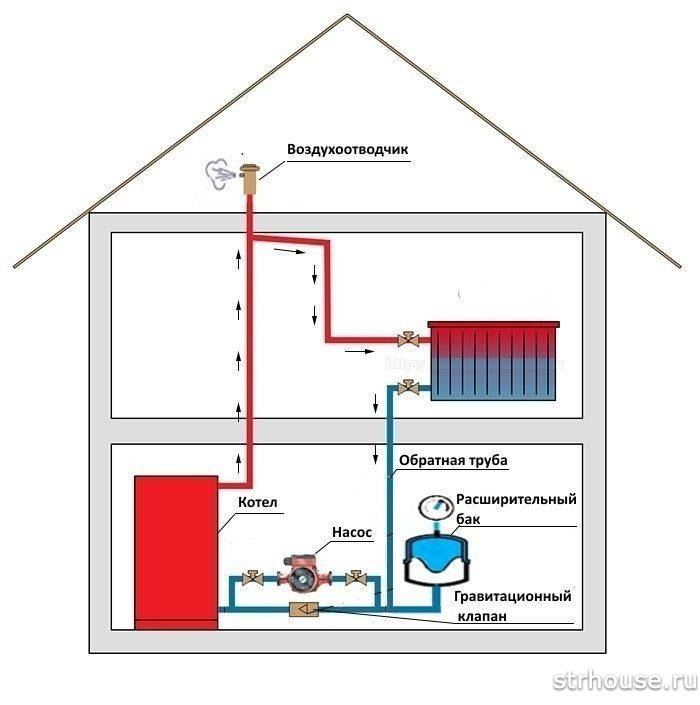

closed system

Here, both the choice of the tank and its installation will have to be taken quite seriously.

Let's collect and systematize the basic information available on thematic resources.

The installation of the expansion tank of the heating system is optimal in the place where the water flow is closest to laminar, where there is a minimum of turbulence in the heating system. The most obvious solution is to place it in a straight filling area in front of the circulation pump. At the same time, the height relative to the floor or the boiler does not matter: the purpose of the tank is to compensate for thermal expansion and dampen water hammer, and we perfectly bleed air through air valves.

A typical tank setup. Its location in a single-pipe system will be the same - in front of the pump along the water course.

- Tanks in the factory are sometimes supplied with a safety valve that relieves excess pressure. However, it is better to play it safe and make sure that your product has it. If not, buy and mount next to the tank.

- Electric and gas boilers with electronic thermostats are often supplied with a built-in circulation pump and a heating expansion tank. Before you go shopping, make sure you need them.

- The fundamental difference between membrane expansion tanks and those used in open systems is their orientation in space. Ideally, the coolant should enter the tank from above. This subtlety of installation is designed to completely remove air from the compartment of the tank that is intended for liquid.

- The minimum volume of the expansion tank for a water heating system is taken approximately equal to 1/10 of the volume of the coolant in the system. More is acceptable. Less is dangerous. The volume of water in the heating system can be roughly calculated based on the heat output of the boiler: as a rule, 15 liters of coolant per kilowatt are taken.

- A pressure gauge mounted next to the expansion tank and the make-up valve (connecting the heating to the water supply) can provide you with an invaluable service. The situation with a stuck spool of the safety valve, alas, is not so rare.

- If the valve relieves pressure too often, this is a clear sign that you miscalculated with the volume of the expansion tank. It is not necessary to change it at all. It is enough to purchase another one and connect it in parallel.

- Water has a relatively low coefficient of thermal expansion. If you switch from it to a non-freezing coolant (for example, ethylene glycol), you will again need to increase the volume of the expansion tank or install an additional one.

The expansion tank in the photo is mounted in accordance with all the rules: the coolant is connected from above, the tank is equipped with a pressure gauge and a safety valve.

Right choice

You can choose the right device based on the available heating equipment, your own capabilities, preferences.

Open expansion devices do an excellent job of compensating for pressure drops in a heating structure, but have too many disadvantages for most people.

Membrane tanks will be an excellent solution for the stable operation of the heating system

When purchasing a product, it is important to consider some of the nuances. The first, most important characteristic of the unit is the internal membrane

This separator must calmly endure high temperatures, increasing internal pressure. Violation of the integrity of the membrane web is rare and occurs only when the system is not started correctly.In other situations, heating, air compression occur gradually, without having a destructive effect. But temperature indicators can reach high values, so the membrane must endure them.

It is important not to confuse products with a hydraulic accumulator, with which there is so much in common. Often illiterate or cunning sellers inspire the buyer that the only difference lies in the color of the equipment

In fact, the purpose of the devices is completely different, so the water reservoir is made from materials with a different composition, and the membrane is prepared for cold water supply. Such characteristics are completely unsuitable for heat supply equipment.

Hydraulic accumulator

The choice of expansion apparatus is based on its resistance to hot liquids, so the average heat resistance should be 90 degrees, and more modern models of the rack tolerate 110 degrees.

You can see a good example of how to choose the right expander tank in the following video:

average rating

ratings over 0

Share link

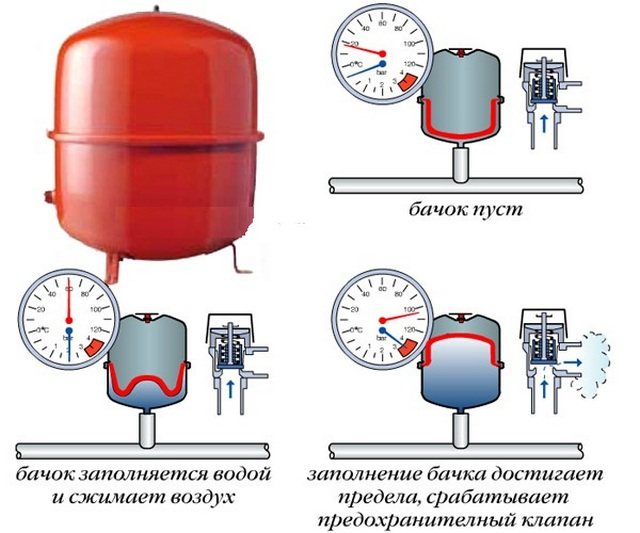

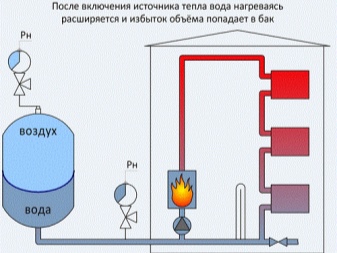

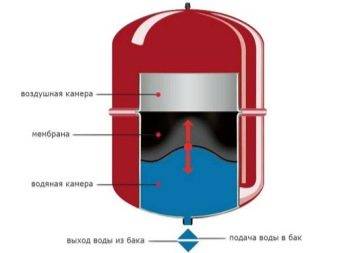

Device and principle of operation

And now we should consider in detail what elements the expansion tanks consist of, and how they work. First, let's find out how such an element works.

As a rule, the design of the expansion tank as a whole is placed in a stamped steel casing. It has the shape of a cylinder. A little less often there are cases in the form of a kind of "pills". Typically, high-quality metals coated with an anti-corrosion protective compound are used for the production of these elements. The outer side of the tanks is covered with enamel.

For heating, expansion tanks with a red body are used. There are also blue options, but usually this color is worn by water batteries, which are integral parts of the water supply system.

On one side of the tank there is a threaded pipe. It is required to enable insertion into the heating system. There are times when the package also includes items such as fittings. They greatly simplify installation work.

On the other hand, there is a special nipple valve. This element serves to form the desired pressure level in the inside of the air chamber.

In the inner cavity, the expansion tank is divided by a membrane into 2 separate parts. Closer to the nozzle is a chamber designed for a thermal carrier, and on the opposite side there is an air chamber. Typically, tank membranes are made of a very flexible material that has minimal diffusion values.

The principle of operation of the expansion tank in the heating system is very simple and straightforward. Let's analyze it in detail.

- In the initial state, at the moment the tank is connected to the system and it is filled with a heat carrier, a specific volume of water passes through the pipe into the water compartment. The pressure indicator in both compartments is gradually equalized. Further, such an uncomplicated system becomes static.

- With an increase in the temperature value, a direct expansion of the heat carrier in volumes in the heating system is carried out. This process is accompanied by an increase in pressure indicators. Excess fluid is sent to the tank itself, and then pressure bends the membrane part.At this moment, the volume of the chamber for the coolant becomes larger, and the air compartment, on the contrary, decreases (at this moment, the air pressure in it increases).

- When the temperature drops and the total volume of the heat carrier decreases, excessive pressure in the air chamber causes the membrane to move back. The heat carrier at this time returns back to the pipeline.

If the pressure parameters in the heating system reach critical levels, the valve should start, which belongs to the "safety group". In such a situation, he will be responsible for the release of excess fluid. Certain models of expansion tanks have their own individual safety valve.

Of course, it should be borne in mind that the design of the tank mainly depends on the variety of the specific model purchased. For example, they are non-separable or with the possibility of replacing the membrane element. Included with such products may be parts such as clamps for wall mounting or special stands - small legs with which it is easier to place the outdoor unit on a flat plane.

Expansion tanks with a membrane-diaphragm are usually non-separable. In many cases, they contain a balloon membrane part - it is made from pliable and elastic raw materials. At its core, this membrane is a conventional water chamber. As pressure increases, it expands and increases in volume. Such types of tanks are usually supplemented with a collapsible flange, which makes it possible to independently change the membrane if it breaks.

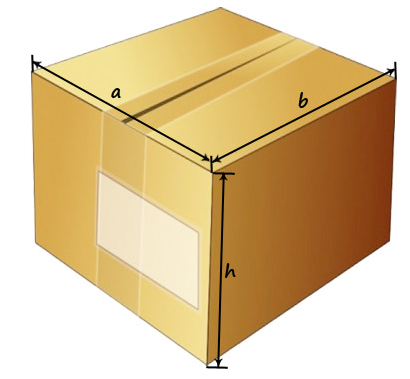

How to calculate the volume of a box in M 3

During the packing and transportation of goods, entrepreneurs are wondering how to do it right in order to save time and money. The calculation of the volume of containers is an important point in the delivery. Having studied all the nuances, you will be able to choose the box you need in size.

How to calculate the volume of a box? In order for the cargo to fit into the box without problems, its volume must be calculated using the internal dimensions.

Use the online calculator to calculate the volume of a box in the form of a cube or parallelepiped. It will help speed up the calculation process.

The cargo to be placed in a container can be of a simple or complex configuration. The dimensions of the box should be 8-10 mm larger than the most protruding points of the load. This is necessary so that the item fits into the container without difficulty.

External dimensions are used when calculating the volume of boxes in order to correctly fill the space in the back of the vehicle for transportation. They are also needed to calculate the area and volume of the warehouse required for their storage.

First, we measure the length (a) and width (b) of the box. To do this, we will use a tape measure or a ruler. The result can be recorded and converted to meters. We will use the international measurement system SI. According to it, the volume of the container is calculated in cubic meters (m 3). For containers whose sides are less than a meter, it is more convenient to take measurements in centimeters or millimeters. It must be taken into account that the dimensions of the cargo and the box must be in the same units of measurement. For square boxes, the length equals the width.

Then we will measure the height (h) of the existing container ─ the distance from the bottom valve of the box to the top one.

If you made measurements in millimeters, and the result must be obtained in m 3, we translate each number into m. For example, there is data:

Considering that 1 m = 1000 m, we will translate these values into meters, and then substitute them into the formula.

Formulas

- V=a*b*h, where:

- a – base length (m),

- b - base width (m),

- h - height (m),

- V is the volume (m3).

Using the formula for calculating the volume of a box, we get:

V \u003d a * b * h \u003d 0.3 * 0.25 * 0.15 \u003d 0.0112 m 3.

This method can be used when calculating the volume of a parallelepiped, that is, for rectangular and square boxes.