- Determination of annual gas consumption

- Volume flow

- The value of pressure and velocity in the flow

- Types of gas, liquid and steam flow

- Calculation of main gas consumption

- Heat meters

- Vane meters

- Instruments with differential recorder

- Consumption of natural gas at home

- Gas … and other gas

- Method of calculation for natural gas

- We calculate the gas consumption by heat loss

- Heat loss calculation example

- Boiler power calculation

- By quadrature

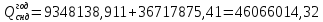

Determination of annual gas consumption

annual

gas costs Qyear,

m3/year,

for household needs is determined by the number

population of the city (district) and norms

gas consumption per person,

and for public utilities - depending on

from the throughput of the enterprise

and gas consumption rates according to the formula:

(3.1)

Where:

q

- norm heat consumption for one settlement

unit, MJ/year;

N

– number of accounting units;

– lower calorific value of gas on dry

mass, MJ/m3.

Table

3.1 Annual gas consumption for domestic

and household needs

| Purpose | Index | Quantity | Norm | Annual | results, |

| Quarters with gas stoves and centralized | |||||

| On the | On the | population | 2800 | 6923067,49 | |

| Hospitals | On the | 1637,131 | 367911,5 | ||

| Polyclinics | On the | 3547,117 | 5335,796 | ||

| Canteens | On the | 14938822 | 1705670,755 | ||

| TOTAL: | 9348138,911 | ||||

| Quarters (2nd | |||||

| On the | On the | population | 8000 | 31787588,63 | |

| Hospitals | On the | 2630,9376 | 591249,1485 | ||

| Polyclinics | On the | 5700,3648 | 8574,702 | ||

| Canteens | On the | 24007305 | 2741083,502 | ||

| TOTAL: | 36717875,41 | ||||

| annual | |||||

| Baths | On the | 3698992,9 | 2681524,637 | ||

| Laundries | On the | 25964,085 | 8846452,913 | ||

| bakery | On the | 90874,298 | 8975855,815 |

annual

gas costs for technological and

energy needs of industrial,

household and agricultural

enterprises determined by specific

fuel consumption standards, the volume of produced

products and the value of the actual

fuel consumption. Gas consumption

determined separately for each

enterprises.

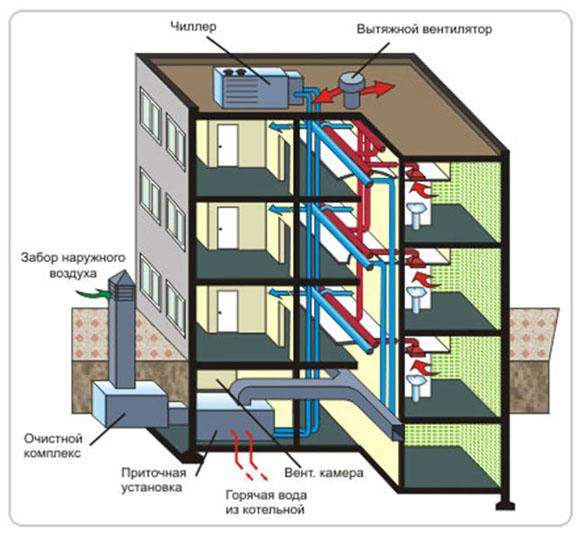

Annual

gas consumption for the boiler room is added up

from gas expenses for heating, hot

water supply and forced ventilation

buildings throughout the area.

Annual

gas consumption for heating

, m3/year,

residential and public buildings are calculated

according to the formula:

(3.1)

Where:

a

= 1.17 - correction factor is accepted

depending on the outside temperature

air;

qa–

specific heating characteristic

buildings are accepted 1.26-1.67 for residential

buildings depending on the number of storeys,

kJ/(m3×h×aboutFROM);

tin

– temperature

internal air, C;

tcpfrom

– average outdoor temperature

air during the heating season, °С;

Pfrom

\u003d 120 - the duration of the heating

period, days ;

VH–

external building volume of heated

buildings, m3;

–inferior

calorific value of gas on a dry basis,

kJ/m3;

ή

– efficiency of the heat-using plant,

0.8-0.9 is accepted for heating

boiler room.

Outer

construction volume of heated buildings

can be determined

how

(3.2)

Where:

V–

volume of residential buildings per person, accepted

equal to 60 m3/person,

if there is no other data;

Np—

number of inhabitants in the region, people

Table

3.2 Correction factor values

a

temperature dependent

outdoor

air

| ,°C | -10 | -15 | -20 | -25 | -30 | -35 | -40 | -50 |

| a | 1,45 | 1,20 | 1,17 | 1,08 | 1,00 | 0,95 | 0,85 | 0,82 |

Annual

gas consumption for centralized hot

water supply (DHW)

,

m3/year,

boiler houses determined by the formula:

(3.3)

Where:

qDHW

\u003d 1050 kJ / (person-h) - an aggregated indicator

hourly average heat consumption for DHW on

1 person;

N

– number

residents using the centralized

DHW;

tchl,txs–

cold water temperature in summer and

winter period, °С, accepted tchl

\u003d 15 ° С,tx=5

°C;

–inferior

calorific value of gas on a dry basis,

kJ/m3;

–

reduction factor

hot water consumption in summer

depending on the climate zone

taken from 0.8 to 1.

m3/year

Annual

gas consumption for forced ventilation

public buildings

,

m3/year,

can be determined from the expression

(3.4)

Where:

qin–

specific ventilation characteristic

building, 0.837 kJ/(m3×h×°С);

fcp.in.–

average outdoor temperature

for calculation of ventilation, °С, (permissible

accepttcp

in.=tcpom).

By

area annual gas consumption consumed

low pressure networks

,

m3/year,

equals

(3.5)

m3/year

m3/year

Annual

gas consumption by large household

consumers

, m3/year,

equals:

(3.6)

m3/year

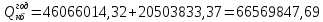

Total

for utilities and household

needs spent

,

m3/year,

gas

(3.7)

m3/year

m3/year

General

annual gas consumption by the region

,

m3/year,

without industrial consumers is:

(3.8)

m3/year.

Volume flow

Volumetric flow is the amount of liquid, gas or steam passing through a given point in a certain period of time, measured in units of volume such as m3/min.

The value of pressure and velocity in the flow

Pressure, which is usually defined as force per unit area, is an important characteristic of flow. The figure above shows two directions in which the flow of liquid, gas or vapor, moving, exerts pressure in the pipeline in the direction of the flow itself and on the walls of the pipeline. It is the pressure in the second direction that is most often used in flow meters, in which, based on the reading of the pressure drop in the pipeline, the flow is determined

It is the pressure in the second direction that is most often used in flow meters, in which, based on the reading of the pressure drop in the pipeline, the flow is determined

The figure above shows two directions in which the flow of liquid, gas or vapor, moving, exerts pressure in the pipeline in the direction of the flow itself and on the walls of the pipeline. It is the pressure in the second direction that is most often used in flow meters, in which the flow is determined based on the indication of the pressure drop in the pipeline.

The speed at which a liquid, gas or vapor flows has a significant effect on the amount of pressure exerted by the liquid, gas or steam pipeline walls; as a result of a change in speed, the pressure on the walls of the pipeline will change. The figure below graphically depicts the relationship between the flow rate of a liquid, gas or steam and the pressure that the liquid flow exerts on the pipeline walls.

As can be seen from the figure, the diameter of the pipe at point "A" is larger than the diameter of the pipe at point "B". Since the amount of liquid entering the pipeline at point "A" must equal the amount of liquid leaving the pipeline at point "B", the rate at which the liquid flows through the narrower part of the pipe must increase. As the fluid velocity increases, the pressure exerted by the fluid on the pipe walls will decrease.

In order to show how an increase in the flow rate of a fluid can lead to a decrease in the amount of pressure exerted by the flow of fluid on the walls of the pipeline, a mathematical formula can be used. This formula takes into account only velocity and pressure. Other indicators such as: friction or viscosity are not taken into account

If these indicators are not taken into account, then the simplified formula is written as follows: PA + K (VA) 2 = PB + K (VB) 2

The pressure exerted by the fluid on the pipe walls is denoted by the letter P. PA is the pressure on the pipeline walls at point "A" and PB is the pressure at point "B". The fluid velocity is denoted by the letter V. VA is the velocity of the fluid through the pipeline at point "A" and VB is the velocity at point "B". K is a mathematical constant.

As already formulated above, in order for the amount of gas, liquid or steam that passed through the pipeline at point "B" to be equal to the amount of gas, liquid or steam that entered the pipeline at point "A", the velocity of the liquid, gas or steam at point " B" should increase.Therefore, if PA + K (VA)2 should equal PB + K (VB)2, then as the speed VB increases, the pressure PB should decrease. Thus, an increase in speed leads to a decrease in the pressure parameter.

Types of gas, liquid and steam flow

The speed of the medium also affects the type of flow generated in the pipe. Two basic terms are used to describe the flow of a liquid, gas, or vapor: laminar and turbulent.

laminar flow

Laminar flow is the flow of a gas, liquid, or vapor without turbulence, which occurs at relatively low overall fluid velocities. In laminar flow, a liquid, gas, or vapor moves in even layers. The speed of the layers moving in the center of the flow is higher than the speed of the outer (flowing near the pipeline walls) layers of the flow. The decrease in the speed of movement of the outer layers of the flow occurs due to the presence of friction between the current outer layers of the flow and the walls of the pipeline.

turbulent flow

Turbulent flow is a swirling flow of gas, liquid, or vapor that occurs at higher velocities. In turbulent flow, the layers of the flow move with eddies, and do not tend to a rectilinear direction in their flow. Turbulence can adversely affect the accuracy of flow measurements by causing different pressures on the pipeline walls at any given point.

Calculation of main gas consumption

The calculation of the required power is carried out on the assumption that the height of the rooms does not exceed 3 m, its area is 150 m2, the condition of the building is satisfactory, there is insulation. Then, for heating 10 m2 of area, an average of 1 kW of energy is consumed at a temperature lower than -10 0С.Since such a temperature lasts on average only half of the heating season, we can take as a base value - 50 W * m / h.

AT depending on the thickness wall insulation gas consumption is significantly reduced

Gas consumption for heating a house of 150 m2 will be determined by the ratio

A \u003d Q / q * ɳ

- Q

in the selected example, it is calculated as 150*50 = 7.5 kW and is the required power needed to heat this room.

- q

is responsible for the brand of gas and provides specific heat. For example, q = 9.45 kW (gas G 20).

- ɳ

shows the efficiency of the boiler, expressed in relation to the unit. If efficiency = 95% then ɳ = 0.95.

Let's do the calculations, we get that the flow gas for home an area of 150 m2 will be equal to 0.836 m3 per hour, for a house with a size of 100 m2 - 0.57 m3 per hour. To obtain the average daily amount, the result is multiplied by 24, for the average monthly it is multiplied by another 30.

If the boiler efficiency is changed to 85%, 0.93 m3 will be consumed per hour.

Heat meters

Now let's find out what information is needed in order to calculate the heating. It is easy to guess what this information is.

1. The temperature of the working fluid at the outlet / inlet of a particular section of the line.

2. The flow rate of the working fluid that passes through the heating devices.

The flow rate is determined through the use of thermal metering devices, that is, meters. These can be of two types, let's get acquainted with them.

Vane meters

Such devices are intended not only for heating systems, but also for hot water supply. Their only difference from those meters that are used for cold water is the material from which the impeller is made - in this case it is more resistant to elevated temperatures.

As for the mechanism of work, it is almost the same:

- due to the circulation of the working fluid, the impeller begins to rotate;

- the rotation of the impeller is transferred to the accounting mechanism;

- the transfer is carried out without direct interaction, but with the help of a permanent magnet.

Despite the fact that the design of such counters is extremely simple, their response threshold is quite low, moreover, there is reliable protection against distortion of readings: the slightest attempt to brake the impeller by means of an external magnetic field is stopped thanks to the antimagnetic screen.

Instruments with differential recorder

Such devices operate on the basis of Bernoulli's law, which states that the speed of a gas or liquid flow is inversely proportional to its static movement. But how is this hydrodynamic property applicable to the calculation of the flow rate of the working fluid? Very simple - you just need to block her path with a retaining washer. In this case, the rate of pressure drop on this washer will be inversely proportional to the speed of the moving flow. And if the pressure is recorded by two sensors at once, then you can easily determine the flow rate, and in real time.

Note! The design of the counter implies the presence of electronics. The overwhelming majority of such modern models provide not only dry information (temperature of the working fluid, its consumption), but also determine the actual use of thermal energy. The control module here is equipped with a port for connecting to a PC and can be configured manually

The control module here is equipped with a port for connecting to a PC and can be configured manually.

Many readers will probably have a logical question: what if we are not talking about a closed heating system, but about an open one, in which selection for hot water supply is possible? How, in this case, to calculate Gcal for heating? The answer is quite obvious: here pressure sensors (as well as retaining washers) are placed simultaneously on both the supply and the “return”. And the difference in the flow rate of the working fluid will indicate the amount of heated water that was used for domestic needs.

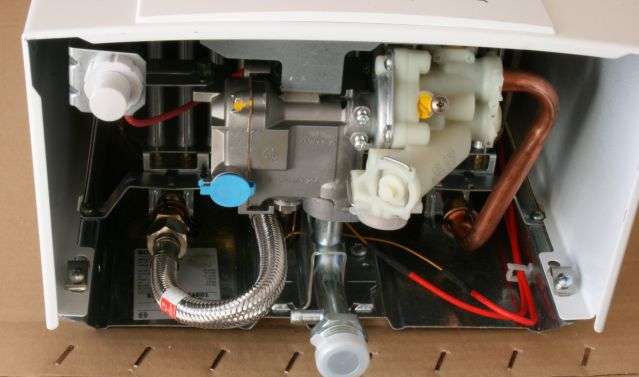

Consumption of natural gas at home

The owners of all apartments and houses, many enterprises need to calculate the volumes of gas consumed. Data on the need for fuel resources are included in the projects of individual houses and their parts. To pay according to real numbers, gas meters are used.

The level of consumption depends on the equipment, thermal insulation of the building, season. In apartments without centralized heating and hot water supply, the load goes to the water heater. The device consumes up to 3-8 times more gas than a stove.

Gas water heaters (boilers, boilers) are wall-mounted and floor-standing: they are used simultaneously for heating and for heating water, and less functional models are mainly for heating only

Gas water heaters (boilers, boilers) are wall-mounted and floor-standing: they are used simultaneously for heating and for heating water, and less functional models are mainly for heating only

The maximum consumption of the stove depends on the number of burners and the power of each of them:

- reduced - less than 0.6 kW;

- normal - about 1.7 kW;

- increased - more than 2.6 kW.

According to another classification, low power for burners corresponds to 0.21-1.05 kW, normal - 1.05-2.09, increased - 2.09-3.14, and high - more than 3.14 kW.

A typical modern stove uses at least 40 liters of gas per hour when turned on. The stove usually consumes about 4 m³ per month for 1 tenant, and the consumer will see approximately the same figure if he uses the meter. Compressed gas in cylinders in terms of volume requires much less. For a family of 3, a 50-liter container will last about 3 months.

In an apartment with a stove for 4 burners and without a water heater, you can put a counter marking G1.6. A device with a size G2.5 is used if there is also a boiler. To measure the gas flow, large gas meters are also installed, on G4, G6, G10 and G16. The meter with parameter G4 will cope with the calculation of the gas consumption of 2 stoves.

Water heaters are 1- and 2-circuit. For a boiler with 2 branches and a powerful gas stove, it makes sense to install 2 counters. One of the reasons is that household gas meters do not cope well with the large difference between the power of the equipment. A weak stove at minimum speed uses many times less fuel than a water heater at maximum.

The classic stove has 1 large burner, 2 medium and 1 small, using the largest one is the most cost-effective

The classic stove has 1 large burner, 2 medium and 1 small, using the largest one is the most cost-effective

Subscribers without meters pay for volume based on consumption per inhabitant multiplied by their number and consumption per 1 m² multiplied by the heated area. The standards are valid all year round - they laid the average figure for different periods.

Norm for 1 person:

- Gas consumption for cooking and heating water using a stove in the presence of centralized hot water supply (DHW) and central heating is about 10 m³ / month per person.

- The use of only one stove without a boiler, centralized hot water supply and heating - approximately 11 m³ / month per person.

- The use of a stove and a water heater without centralized heating and hot water is about 23 m³/month per person.

- Heating water with a water heater - about 13 m³ / month per person.

In different regions, the exact consumption parameters do not match. Individual heating with a water heater costs about 7 m³/m² for heated living spaces and about 26 m³/m² for technical ones.

On notice from a meter installation company you can see how much the consumption figures differ with and without a gas meter

The dependence in gas consumption was indicated in SNiP 2.04.08-87. Proportions and indicators are different there:

- stove, central hot water supply - 660 thousand kcal per person per year;

- there is a stove, no hot water supply - 1100 thousand kcal per person per year;

- there is a stove, a water heater and no hot water supply - 1900 thousand kcal per person per year.

Consumption according to the standards is affected by the area, the number of residents, the level of well-being with household communications, the presence of livestock and its livestock.

The parameters are differentiated based on the year of construction (before 1985 and after), the involvement of energy-saving measures, including the insulation of facades and other external walls.

More about consumption norms gas per person can be read in this article.

Gas … and other gas

Blue fuel has been the most popular and cheapest energy source for many years. Most often, two types of gas are used for heating and, accordingly, two connection methods:

- Trunk

. It is pure methane with a trace amount of perfume added to make leak detection easier. Such gas is transported through gas transmission systems to consumers.

- Liquefied mixture

propane with butane, which is pumped into the gas tank and provides independent heating.When this liquid changes to a gaseous state, the pressure in the tank increases. Under the action of high pressure, the gas mixture rises through pipes to the point of consumption.

Both types have their pros and cons:

- there is always a risk of pipeline breakage during main connection, pressure reduction

in him. The gas holder gives complete autonomy, it is only necessary to monitor the presence of gas;

- gas tank equipment and its maintenance costly

. But this is the only possibility of gas heating if there is no mains in the vicinity;

- to calculate the gas consumption for heating a house of 100 sq m, perform fuel calorie comparison

from the line and the liquefied mixture in the cylinder. The calorie content of the propane-butane mixture is three times greater than that of methane: when burning 1 m3 of the mixture, 28 kW is released, and the combustion of the same amount of methane produces 9 kW. Accordingly, the amount of heating of the same area will be spent differently.

A liquefied mixture is often pumped into small-capacity cylinders for autonomous heating.

For autonomous heating, liquefied gas in cylinders is also used.

Method of calculation for natural gas

The approximate gas consumption for heating is calculated based on half the capacity of the installed boiler. The thing is that when determining the power of a gas boiler, the lowest temperature is laid. This is understandable - even when it is very cold outside, the house should be warm.

Calculate gas consumption for heating you can do it yourself

But it is completely wrong to calculate the gas consumption for heating according to this maximum figure - after all, in general, the temperature is much higher, which means that much less fuel is burned. Therefore, it is customary to consider the average fuel consumption for heating - about 50% from heat loss or boiler power.

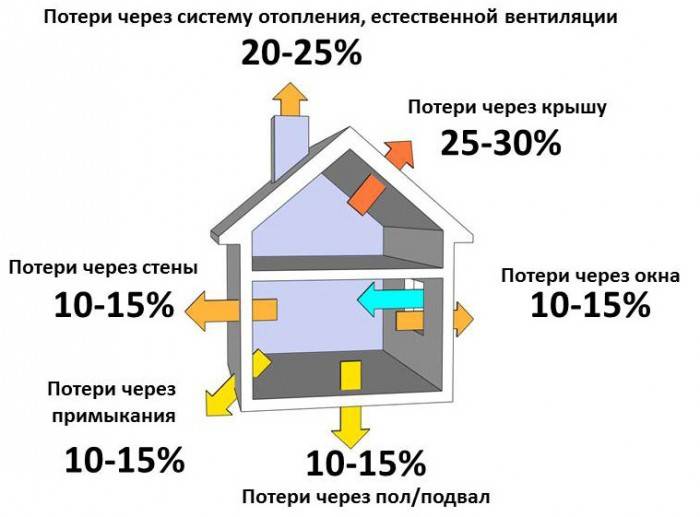

We calculate the gas consumption by heat loss

If there is no boiler yet, and you estimate the cost of heating in different ways, you can calculate from the total heat loss of the building. They are most likely familiar to you. The methodology here is as follows: they take 50% of the total heat loss, add 10% to provide hot water supply and 10% to heat outflow during ventilation. As a result, we get the average consumption in kilowatts per hour.

Then you can find out the fuel consumption per day (multiply by 24 hours), per month (by 30 days), if desired - for the entire heating season (multiply for the number of months, during which it works heating). All these figures can be converted into cubic meters (knowing the specific heat of combustion of gas), and then multiply cubic meters by the price of gas and, thus, find out the cost of heating.

| The name of the crowd | unit of measurement | Specific heat of combustion in kcal | Specific heating value in kW | Specific calorific value in MJ |

|---|---|---|---|---|

| Natural gas | 1 m 3 | 8000 kcal | 9.2 kW | 33.5 MJ |

| Liquefied gas | 1 kg | 10800 kcal | 12.5 kW | 45.2 MJ |

| Hard coal (W=10%) | 1 kg | 6450 kcal | 7.5 kW | 27 MJ |

| wood pellet | 1 kg | 4100 kcal | 4.7 kW | 17.17 MJ |

| Dried wood (W=20%) | 1 kg | 3400 kcal | 3.9 kW | 14.24 MJ |

Heat loss calculation example

Let the heat loss of the house be 16 kW / h. Let's start counting:

- average heat demand per hour - 8 kW / h + 1.6 kW / h + 1.6 kW / h = 11.2 kW / h;

- per day - 11.2 kW * 24 hours = 268.8 kW;

-

per month - 268.8 kW * 30 days = 8064 kW.

Convert to cubic meters.If we use natural gas, we divide the gas consumption for heating per hour: 11.2 kW / h / 9.3 kW = 1.2 m3 / h. In calculations, the figure 9.3 kW is the specific heat capacity of natural gas combustion (available in the table).

Since the boiler has not 100% efficiency, but 88-92%, you will have to make more adjustments for this - add about 10% of the figure obtained. In total, we get the gas consumption for heating per hour - 1.32 cubic meters per hour. You can then calculate:

- consumption per day: 1.32 m3 * 24 hours = 28.8 m3/day

- demand per month: 28.8 m3 / day * 30 days = 864 m3 / month.

The average consumption for the heating season depends on its duration - we multiply it by the number of months that the heating season lasts.

This calculation is approximate. In some month, gas consumption will be much less, in the coldest - more, but on average the figure will be about the same.

Boiler power calculation

Calculations will be a little easier if there is a calculated boiler capacity - all the necessary reserves (for hot water supply and ventilation) are already taken into account. Therefore, we simply take 50% of the calculated capacity and then calculate the consumption per day, month, per season.

For example, the design capacity of the boiler is 24 kW. For gas consumption calculation we take half for heating: 12 k / W. This will be the average need for heat per hour. To determine the fuel consumption per hour, we divide by the calorific value, we get 12 kW / h / 9.3 k / W = 1.3 m3. Further, everything is considered as in the example above:

- per day: 12 kW / h * 24 hours = 288 kW in terms of the amount of gas - 1.3 m3 * 24 = 31.2 m3

-

per month: 288 kW * 30 days = 8640 m3, consumption in cubic meters 31.2 m3 * 30 = 936 m3.

Next, we add 10% for the imperfection of the boiler, we get that for this case the flow rate will be slightly more than 1000 cubic meters per month (1029.3 cubic meters).As you can see, in this case everything is even simpler - fewer numbers, but the principle is the same.

By quadrature

Even more approximate calculations can be obtained by the quadrature of the house. There are two ways:

- It can be calculated according to SNiP standards - for heating one square meter in Central Russia, an average of 80 W / m2 is required. This figure can be applied if your house is built according to all requirements and has good insulation.

- You can estimate according to the average data:

- with good house insulation, 2.5-3 cubic meters / m2 are required;

-

with average insulation, gas consumption is 4-5 cubic meters / m2.

Each owner can assess the degree of insulation of his house, respectively, you can estimate what gas consumption will be in this case. For example, for a house of 100 sq. m. with average insulation, 400-500 cubic meters of gas will be required for heating, 600-750 cubic meters per month for a house of 150 square meters, 800-100 cubic meters of blue fuel for heating a house of 200 m2. All this is very approximate, but the figures are based on many factual data.