- Advantages and disadvantages

- Calculation of heating registers

- Calculation of the required heat output for space heating

- Calculation of the thermal power of the register

- Heat transfer of registers from smooth pipes. Table

- How to calculate the required number of register sections

- What other parameters should be taken into account

- Varieties of heating registers

- Materials for manufacturing

- Design

- Types of registers

- Stationary and mobile registers

- Calculation of heating registers

- Calculation of the required heat output for space heating

- Calculation of the thermal power of the register

- Heat transfer of registers from smooth pipes. Table

- How to calculate the required number of register sections

- What other parameters should be taken into account

- Selecting the heater configuration

- Heat exchanger installation

- How to make a register with your own hands

- How to weld a heating register

Advantages and disadvantages

Before undertaking the manufacture of heating registers, it is necessary to evaluate all the pros and cons of these heaters, so as not to be deceived in expectations later. So, first about the advantages:

- low cost and ease of manufacture;

- low hydraulic resistance: thanks to this, the heater can be used in the "tail" of any system;

- reliability and durability: a register welded from ordinary pipes with high quality will easily last at least 20 years;

- resistance to pressure drops and water hammer;

- smooth surface facilitates easy removal of dust when cleaning rooms.

Unfortunately, a do-it-yourself heating register also has a lot of drawbacks. The main one is low heat transfer with a significant mass of the device. That is, in order to ensure a comfortable temperature in a medium-sized room, the register must have a decent size. Here is a simple example taken from the technical literature. If the temperature difference between the coolant and the room is 65 ºС (DT), a register welded from 4 DN32 pipes 1 m long will give out only 453 W, and from 4 DN100 pipes - 855 W. It turns out that, based on heat transfer per 1 m of length, any panel or sectional radiator is at least twice as powerful.

Other negative aspects of smooth-tube registers are not so critical, although they are significant:

- holds a large volume of water: the disadvantage does not play a big role if there are 1-2 pieces for the entire system of such heating devices;

- during operation, it is very difficult to increase or decrease the power of registers from smooth pipes. You can not do without dismantling and welding machine;

- subject to corrosion and require periodic maintenance with painting;

- have an unpresentable appearance: the defect is reparable, if necessary, the heater is hidden behind a decorative screen.

After analyzing the advantages and disadvantages of smooth-tube devices, we can conclude that their scope in private housing construction is very limited. As already mentioned, the registers can be used for heating various rooms with low requirements for comfort and interior.

When selecting materials, it is necessary to resolve the question - what diameters of pipes to take and what should be their total length. All these parameters are arbitrary, you can make a heater from any pipes, and take its length convenient for placement in the room. But in order to supply the required amount of heat, it is necessary to provide a sufficient heat exchange area. To do this, it is recommended to perform an approximate calculation of the register by surface area.

To make such a calculation is quite simple. It is necessary to calculate the area of the outer surface of all sections in m2 and multiply the resulting value by 330 W. Proposing this method, we proceed from the statement that 1 m2 of the surface of the register will give off 330 W of heat at a coolant temperature of 60 ºС, and indoor air - 18 ºС.

For a person with skills in welding, it will not be difficult to independently weld the register according to the available drawings. It is necessary to prepare and cut pipes into sections and jumpers, cut out plugs from a steel sheet. The assembly sequence is arbitrary; after welding, the heater should be checked for tightness. When manufacturing and installing registers, consider the following recommendations:

- you should not take pipes with too thin or thick walls: the former will cool faster and last less, while the latter will warm up for a long time and are difficult to adjust;

- do not forget to build a Mayevsky crane into the end of the upper section to release air;

- when welding coils, a rotary section can be made from two finished elbows if it is not possible to use a pipe bender;

- put a tap at the coolant inlet, a valve at the outlet;

- remember that the installation of the registers is carried out with an imperceptible bias towards the connection of the supply pipe.Then Mayevsky's crane will be at the highest point.

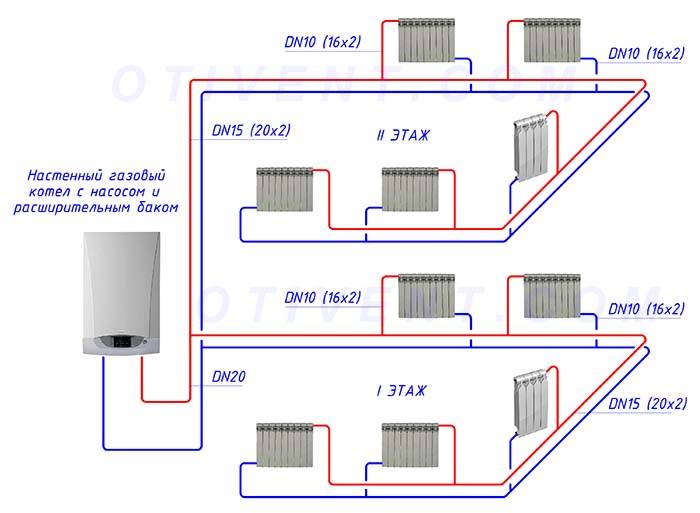

Calculation of heating registers

So that the house is not cold and the heating evenly warms up all the rooms, it is important to calculate the number of registers for each room. For purchased devices, their power is looked at in the passport and the number of devices is calculated; for home-made tubular heaters, the length of the pipes will have to be determined by yourself

Calculation of the required heat output for space heating

If your house was built according to the project, then the data on the required power of heating devices are available in the documents - you need to find and use them.

If there is no engineering systems project, then traditional approximate data on heat losses are used:

- 100 W per 1 m² of room area with one outer wall and one window.

- 120 W per 1 m² of room area with two external walls and one window.

- 130 W per 1 m² of room area with two external walls and two windows.

The total heat loss is calculated, the received power is increased by 20% (multiplied by 1.2) and the total power of all heating devices is obtained. In the northern regions of Russia, it is desirable to increase the resulting capacity by another 20 percent.

The power of the appliances in each room is calculated based on the above data (multiply the heat loss of the room by 1.2).

The exact way to calculate the heat loss of a house is very complicated and is used by design organizations.

Calculation of the thermal power of the register

The amount of heat (W) supplied from the pipe to the room is determined by the formula:

where:

- K is the heat transfer coefficient, W / (m2 0С), is taken depending on the pipe material and the parameters of the coolant.

- F is the surface area, m2, calculated as the product of π·d·l.

- where π = 3.14, and d and l are the diameter and length of the pipe, respectively, m.

∆t is the temperature difference, 0С, determined in turn by the formula:

- Where: t1 and t2 are the temperatures at the boiler inlet and outlet, respectively.

- tk is the temperature in the heated room.

- 0.9 - reduction factor for a multi-row device.

For a steel structure, the heat transfer coefficient to air is 11.3 W/(m2 0C). For a multi-row register, a reduction factor of 0.9 is accepted for each row.

For calculations, you can use a calculation calculator - there are many of them on the Internet, but manually is more reliable.

Heat transfer of registers from smooth pipes. Table

The values of heat transfer coefficients for steel smooth-tube registers are given in the table.

In private houses, the temperature difference is usually 60-70 °C.

How to calculate the required number of register sections

The number of purchased registers is determined by dividing the required power by the nameplate power of the device.

For self-made registers, the required power in each room is divided by the heat transfer of one linear meter of the pipes used. It turns out the required total length of the pipes. Then this length is distributed between the devices, dividing by the number of pipes - their length is obtained. Options are possible here - there may be several short devices or one long one.

What other parameters should be taken into account

If it becomes necessary to increase the power of the device, then it is necessary to increase the length of the pipes, and not their diameter. The efficiency of the system decreases with increasing pipe diameter.

If oil or antifreeze is used in the system, it should be noted that they have a lower heat capacity than water.When using them, heating devices must have a larger area than devices in a water system.

Varieties of heating registers

Heating registers are a group of pipelines located parallel to each other and communicating with each other. They may differ in material, shape and design.

Materials for manufacturing

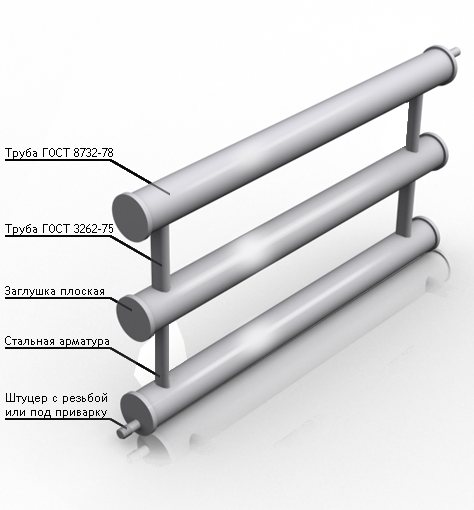

Most often heating registers are made of smooth steel pipes according to GOST 3262-75 or GOST 10704-91. The use of electric-welded pipes is preferable because of the ability to withstand higher pressure. However, in practice, water and gas pipes are also quite common, which are operated no less successfully. Such heaters can easily withstand all kinds of mechanical damage and stress, as well as work with any coolant.

There are also stainless steel models. They are installed in rooms with increased requirements for aesthetics and durability. Due to the increased cost, the use of stainless steel registers is most justified in bathrooms. High resistance to corrosion and a variety of configurations of stainless steel heated towel rails allow them to be used even in the most modern bathroom interiors.

Aluminum and bimetallic registers are more efficient in terms of heat transfer. They are distinguished by lightness and aesthetics, they work perfectly in individual heating systems with well-organized water treatment. In other cases, the low quality of the coolant leads to a quick failure of the devices.

Sometimes you can find registers made of copper. Usually they are used in systems where the main wiring is copper.It is convenient to work with them, they are very nice and durable. In addition, the thermal conductivity of copper is about 8 times higher than that of steel, which makes it possible to significantly reduce the size of the heating surface. A common drawback of all devices made of non-ferrous metals - sensitivity to operating conditions - limits the scope of copper registers.

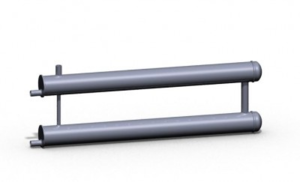

Design

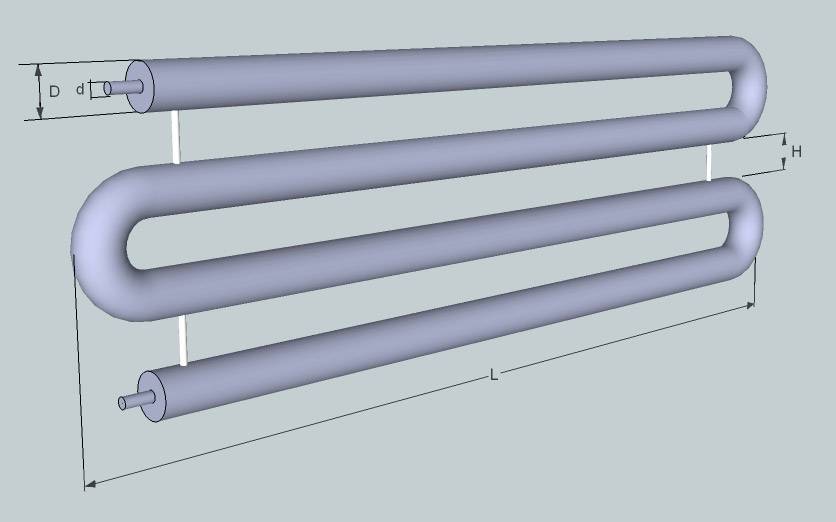

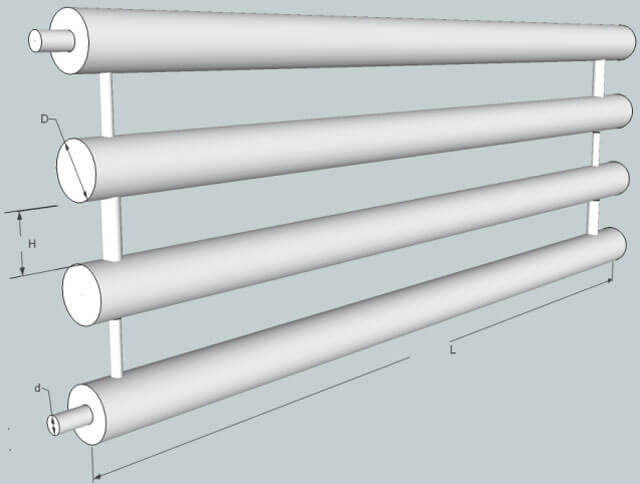

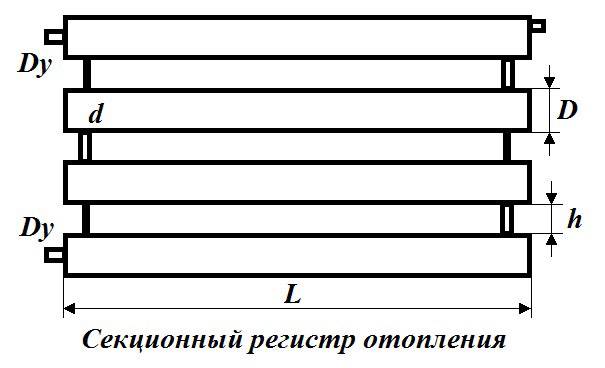

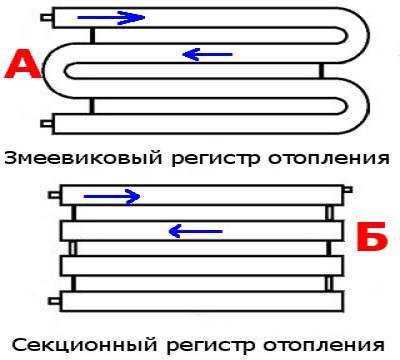

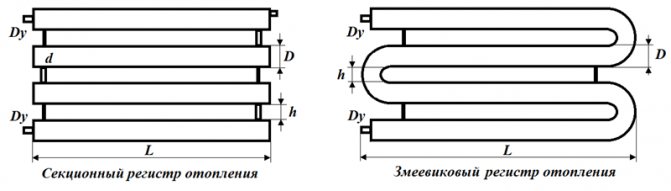

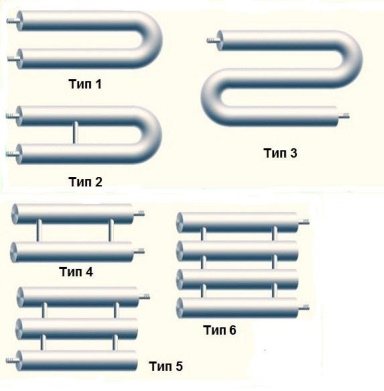

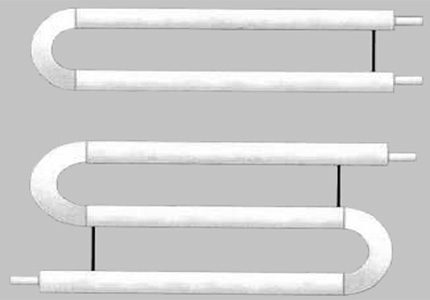

The most characteristic designs of traditional steel registers can be divided into 2 types:

- Sectional;

- Serpentine.

The first is characterized by a horizontal arrangement of pipelines and the use of vertical narrow jumpers between them. The second involves the use of straight and arcuate elements of the same diameter, which are connected by a snake by welding. When using stainless steel or non-ferrous metals, the pipes are simply bent to give the desired configuration.

There are three options for the execution of connecting pipes:

- Threaded;

- Flanged;

- For welding.

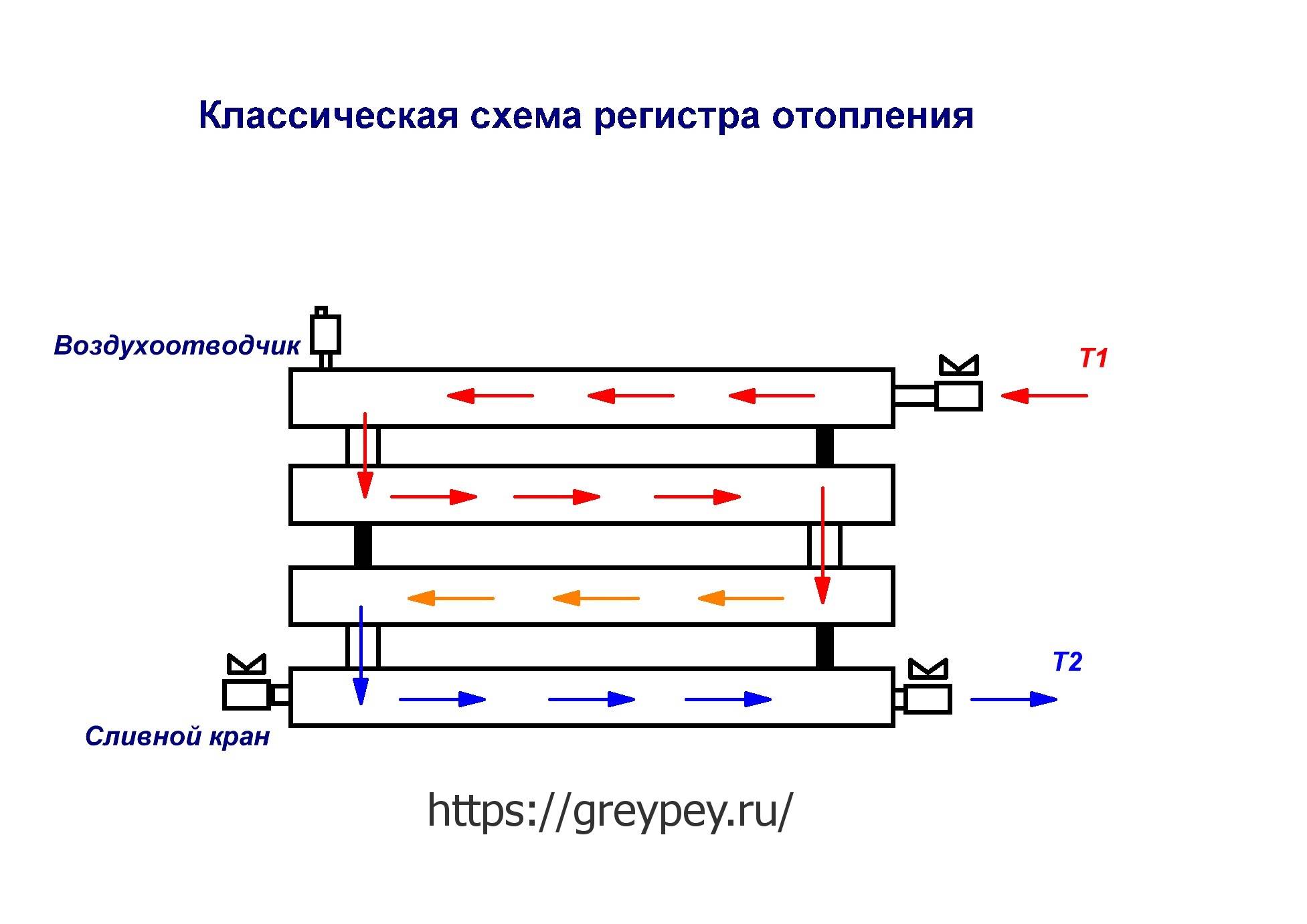

They can be located both on one side of the device, and on different sides. The coolant outlet is provided under the supply or diagonally from it. Sometimes there is a lower connection of highways, but in this case heat transfer is significantly reduced.

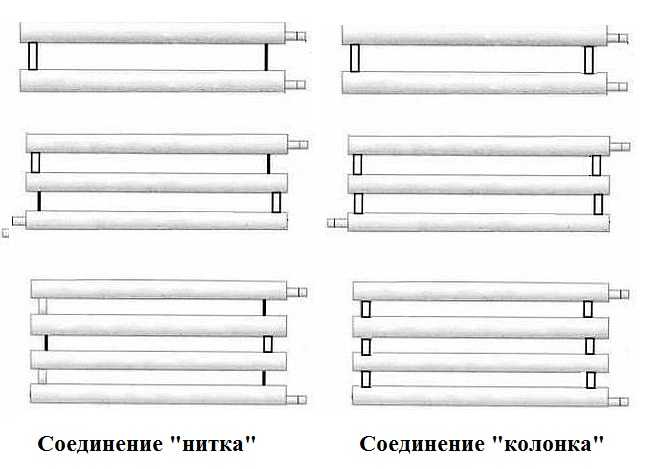

In sectional registers, 2 types of connections are distinguished depending on the way the jumpers are placed:

- "Thread";

- "Column".

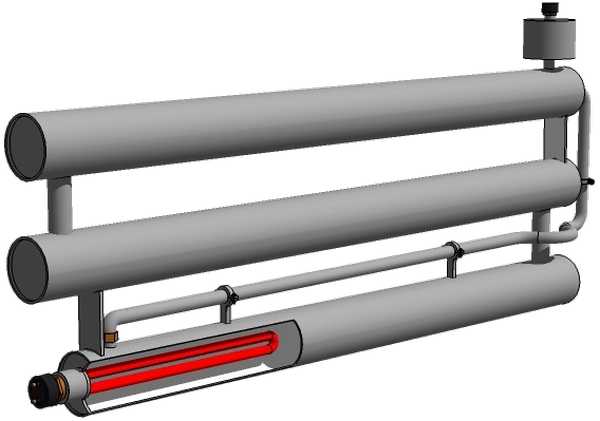

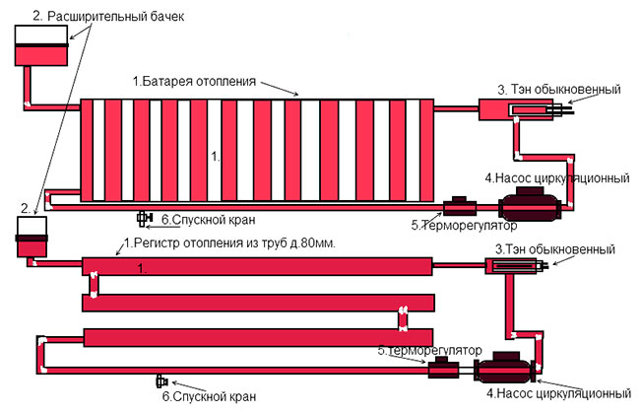

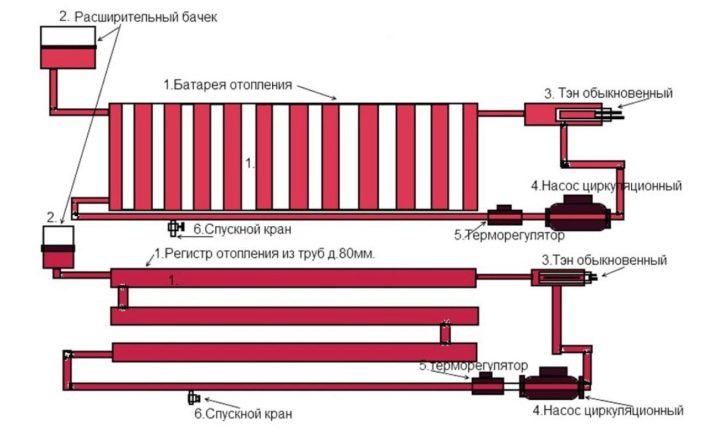

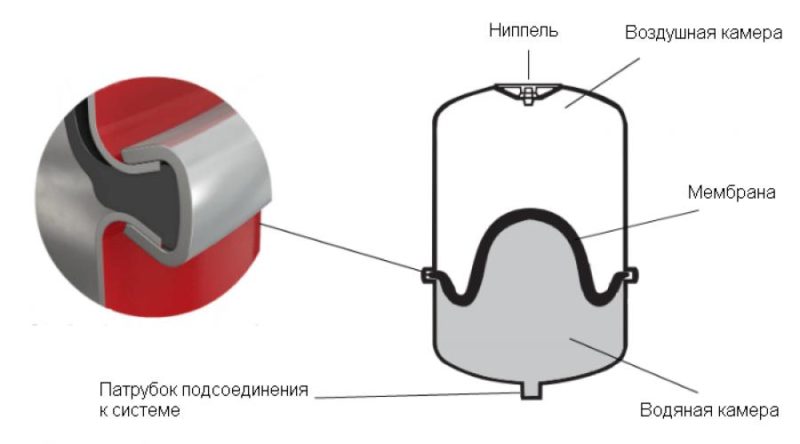

Smooth pipe registers can be used as registers of the main heating system or as separate heaters. For autonomous operation, a heating element of the required power is installed inside the device and connected to the network. As a coolant for portable electric registers made of steel, antifreeze or oil is often used, because.it does not freeze during storage or an emergency power outage.

When used separately from the general heating system, an additional expansion tank must be placed in the upper part of the device. This avoids the increase in pressure due to the increase in volume when heated. The size of the container is selected based on the ability to accommodate about 10% of the total amount of liquid in the heater.

For autonomous use of the register made of steel pipes, legs 200 - 250 mm high are welded to it. If the device is part of the heating circuit, it is not planned to move and the walls are strong enough, then a stationary mount using brackets is used. Sometimes, for very massive registers, a combined installation option is used, i.e. the device is placed on racks and additionally fixed on the wall.

Types of registers

Heating registers are divided into three types:

- aluminum;

- cast iron;

- steel.

Aluminum registers are in high demand due to their low specific weight, good heat dissipation, excellent corrosion resistance, long service life, lack of joints and welds.

Aluminum registers are in high demand due to their low specific weight, good heat dissipation, excellent corrosion resistance, long service life, lack of joints and welds.

Aluminum pipes are produced by monolithic casting. Aluminum registers are used in residential and administrative premises. The main disadvantage of aluminum devices is the high price.

Cast iron registers are easy to install, because they have a flanged monolithic connection. During installation, a second flange is welded to the heating pipeline, and then using bolts, a strong connection is made.

Steel registers are installed in the heating system by welding. Qualitatively carried out welding is the guarantor of the long service life of the entire heating system.

Stationary and mobile registers

To heat the coolant in stationary registers, heating boilers are needed. To heat the coolant in mobile registers, an electric heating element is used, operating from a network with a voltage of 220 V. This type of registers is used for workers' houses of builders, premises where finishing work is carried out.

Installing registers indoors has a number of undeniable advantages over installing batteries in a heating system:

- long service life, pipes made of steel do not need repair, at least 25 years;

- the heating system is distinguished by a high degree of reliability, the main requirement for ensuring such reliability is the high-quality execution of welding seams;

- an open heating system can be installed in large areas, low resistance to the movement of the coolant ensures the large diameter of the pipes used for the register.

Recently, registers have been installed much less frequently, choosing more alternative modern heating devices. The disadvantages of this type of device include:

- not the most attractive appearance of the register, a thick steel pipe is laid along the wall throughout the room;

- a small area of contact with the air in the room leads to a low heat transfer rate, zero use of convection;

- the supply of the heating system with registers is characterized by high cost and complexity of installation, large-diameter steel pipes on the construction market are quite expensive, the need to use welding during installation.

Calculation of heating registers

So that the house is not cold and the heating evenly warms up all the rooms, it is important to calculate the number of registers for each room. For purchased devices, their power is looked at in the passport and the number of devices is calculated; for home-made tubular heaters, the length of the pipes will have to be determined by yourself

Calculation of the required heat output for space heating

If your house was built according to the project, then the data on the required power of heating devices are available in the documents - you need to find and use them.

If there is no engineering systems project, then traditional approximate data on heat losses are used:

- 100 W per 1 m² of room area with one outer wall and one window.

- 120 W per 1 m² of room area with two external walls and one window.

- 130 W per 1 m² of room area with two external walls and two windows.

The total heat loss is calculated, the received power is increased by 20% (multiplied by 1.2) and the total power of all heating devices is obtained. In the northern regions of Russia, it is desirable to increase the resulting capacity by another 20 percent.

The power of the appliances in each room is calculated based on the above data (multiply the heat loss of the room by 1.2).

The exact way to calculate the heat loss of a house is very complicated and is used by design organizations.

Calculation of the thermal power of the register

The amount of heat (W) supplied from the pipe to the room is determined by the formula:

where:

- K is the heat transfer coefficient, W / (m2 0С), is taken depending on the pipe material and the parameters of the coolant.

- F is the surface area, m2, calculated as the product of π·d·l.

- where π = 3.14, and d and l are the diameter and length of the pipe, respectively, m.

∆t is the temperature difference, 0С, determined in turn by the formula:

- Where: t1 and t2 are the temperatures at the boiler inlet and outlet, respectively.

- tk is the temperature in the heated room.

- 0.9 - reduction factor for a multi-row device.

For a steel structure, the heat transfer coefficient to air is 11.3 W/(m2 0C). For a multi-row register, a reduction factor of 0.9 is accepted for each row.

For calculations, you can use a calculation calculator - there are many of them on the Internet, but manually is more reliable.

Heat transfer of registers from smooth pipes. Table

The values of heat transfer coefficients for steel smooth-tube registers are given in the table.

In private houses, the temperature difference is usually 60-70 °C.

How to calculate the required number of register sections

The number of purchased registers is determined by dividing the required power by the nameplate power of the device.

For self-made registers, the required power in each room is divided by the heat transfer of one linear meter of the pipes used. It turns out the required total length of the pipes. Then this length is distributed between the devices, dividing by the number of pipes - their length is obtained. Options are possible here - there may be several short devices or one long one.

What other parameters should be taken into account

If it becomes necessary to increase the power of the device, then it is necessary to increase the length of the pipes, and not their diameter. The efficiency of the system decreases with increasing pipe diameter.

If oil or antifreeze is used in the system, it should be noted that they have a lower heat capacity than water. When using them, heating devices must have a larger area than devices in a water system.

Selecting the heater configuration

Home-made radiator designs are mainly made on the basis of metal pipes with a diameter of 80 - 150 mm.

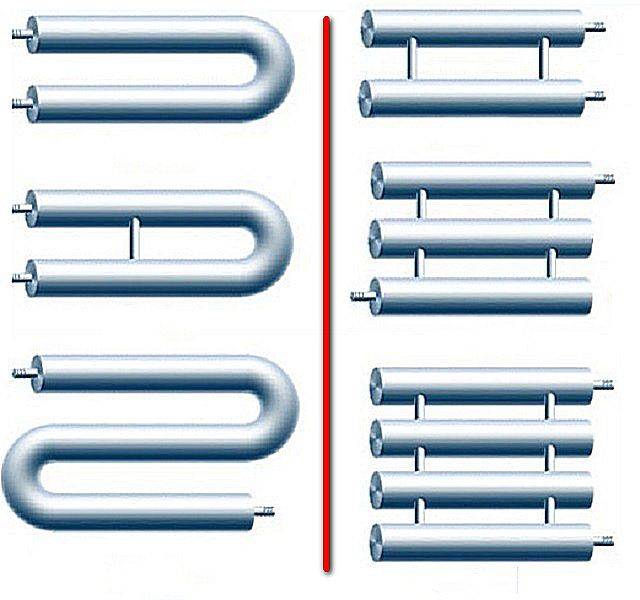

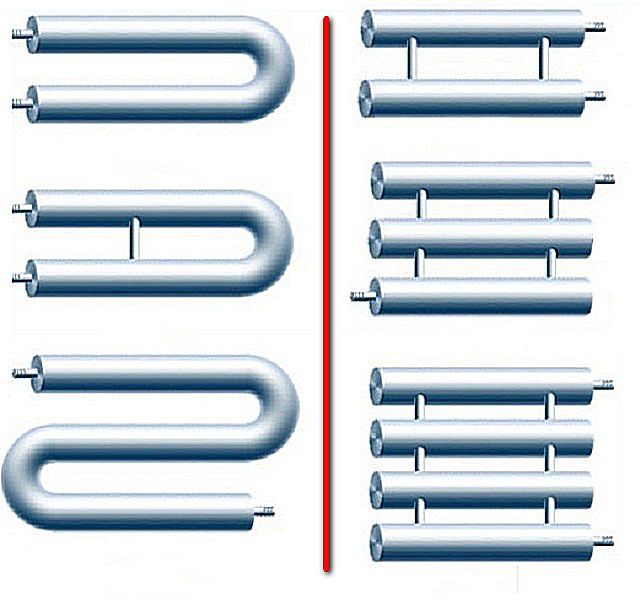

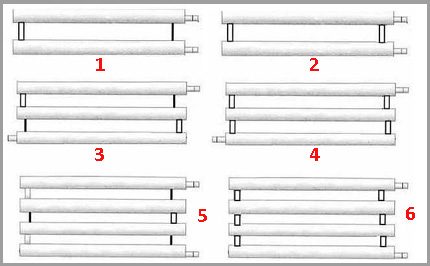

Design features are limited to two versions:

- Lattice.

- snake.

The lattice version of the heating battery differs from the “snake” in a slightly different circuit construction, and, depending on the variations in such batteries, the distribution of the coolant may be different.

Options for circuit construction of heating registers for their own production: 1 - one jumper and one-way power supply; 2 - two jumpers and one-sided power supply; 3 - two-way power supply and 2 jumpers; 4 - two-way power supply and 4 jumpers; 5, 6 - multipipe

Coil structures actually have a uniform design, assuming a strictly sequential movement of the coolant.

Lattice registers are built according to different schemes:

- with one or two jumpers and one-way power supply;

- with one or two jumpers and versatile power supply;

- parallel connection of pipes;

- series connection of pipes.

Number of pipes one assembly can be from two up to four or more. Rarely, but there is also the practice of manufacturing single-tube registers.

The coil assembly usually contains at least two pipes connected on one side by a blind jumper, on the other - by a through jumper, which are made of two pipe bends (2x45º). It should be noted that the design of heating registers in the form of a coil is used much less frequently than the design of the "lattice".

Options for the possible manufacture of registers of the "snake" type.For serpentine structures of registered batteries, the choice of manufacturing options is limited in comparison with lattice-type structures.

Both manufacturing options - lattice and coil - can be made not only on the basis of classic round pipes, but also on the basis of shaped pipes.

Profile pipes are seen as a somewhat specific material, as they require a slightly different approach when assembling heating radiators. However, registers from a profile pipe are more compact and take up less usable space, and this factor is also important.

Heat exchanger installation

Given the large weight of the heating register, you need to use appropriate brackets for fastening, but it is better to put it on the floor. As you understand, there are two installation methods:

- hang on the wall;

- put on the floor.

The main thing is that the structure is very strong. The distance to the walls, which is 20–25 cm, is also important. The same distance should be to the floor, while maintaining the intended slope angle for circulation. The distance between the pipes of the heating register must be at least five centimeters. It does not matter whether it is a stand-alone heat exchanger or connected to a network.

Radiators of any type are installed around the perimeter of the room on the outer walls. That is why in apartments the battery is always under the window. The heat exchanger not only heats the air, it also heats the walls

It is very important to paint the registers so that they do not rust.

How to make a register with your own hands

It will be easiest to assemble such a heating device on your own using the following technology:

- pipes are cut into segments, according to the calculation;

- at the ends of the segments, closer to the edge, marks are made for the location of the jumpers;

- from a pipe with a diameter equal to the feed, the jumpers themselves are cut out;

- pipes are laid out on a flat horizontal surface parallel to each other;

- with the help of welding in three places, all jumpers-pieces are attached;

- jumpers are welded to the sections.

When assembling the heating radiator, install jumpers as close as possible to the edge of the horizontal sections. In this case, the heat transfer of the register in the future will be higher. At the final stage:

- plugs for sections are cut out of sheet metal;

- all plugs are attached to the ends pointwise or diagonally;

- elements are welded into place.

The plugs should be cut in such a way that when they are installed, a small “chamfer” remains along the edge of each section. This "chamfer" is subsequently filled with a weld.

Registers welded in this way are preferably additionally equipped with air vents. Simply put, in each upper section of such a device it is worth installing a standard Mayevsky crane.

How to weld a heating register

The assembly of individual structural elements together is carried out by welding the metal. This can be done in any way convenient for you. How to weld heating register? In fact, it all depends on what kind of welding machine you have:

- electric arc (manual, semi-automatic);

- gas.

The most widespread are electric arc manual welding machines, as they are the cheapest and simplest. Such an apparatus can both connect metal parts and cut them. On large parts, you need to cut holes for pipes. This should be done near the edge, stepping back one diameter of the pipe.There will be four holes on the middle section, two on the first and outer sections.

Holes for connecting pipes

After that, on a flat horizontal surface, we lay out all the elements in one structure and make tacks at the base of the nozzles. You need to make either two tacks along the equator of the pipe, or three evenly around the entire circumference, as in the Mercedes badge. If the location of the tacks is incorrect, then the part may lead during welding. After making sure that the geometry of the register is correct, you can proceed to welding.

While working in the melting bath, it is necessary to maintain a high temperature and distribute the molten metal. The electrode must constantly move along a certain trajectory. How to weld a heating register, the simplest electrode movement trajectories:

- left - right (herringbone);

- forward - backward (with an influx).

The most important moment is the formation of the root of the seam on the tack and the exit from the tack. The process is carried out with a break, as the welder needs to change the position of the electrode. Although with proper skill you can cook without interruption. After the seam has cooled, you need to knock down the sludge with a hammer. So, it remains only to weld the ends with plugs, which must first be cut out of metal of the same thickness.

As a result, we got a blank in which holes for supply and return, as well as an air vent, will be cut in the future. The air vent, the same Mayevsky crane, removes air pockets that reduce the efficiency of the heat exchanger. You can also read more about the air in the heating system. Connecting the registers to the heating system is the last stage, after which it is possible to carry out a hydraulic test and put the equipment into operation.

In addition, this blank can be used for the manufacture of a register with an electric heating element. A hole for a heating element is cut out in the lower end, and an open-type expansion tank is installed in the upper part.