- Boiler types

- Solid fuel boilers

- gas boilers

- Electric boilers

- Conclusion

- How to calculate the power of a gas heating boiler for the area of \u200b\u200bthe house?

- How to calculate the power of the heating boiler by the volume of the house?

- How to calculate the power of a boiler with a hot water circuit?

- What is the best way to calculate - by area or by volume?

- How much is the "extra" kilowatt?

- We also recommend seeing:

- How to calculate the optimal number and volumes of heat exchangers

- Video description

- Conclusion

- What is room heat loss?

- Calculation of the power of a gas boiler depending on the area

- Calculation of a single-circuit heating boiler

- How to calculate the power of a double-circuit boiler

- Calculation of the power of an indirect heating boiler

- What should be guided

- gas boilers

- Electric boilers

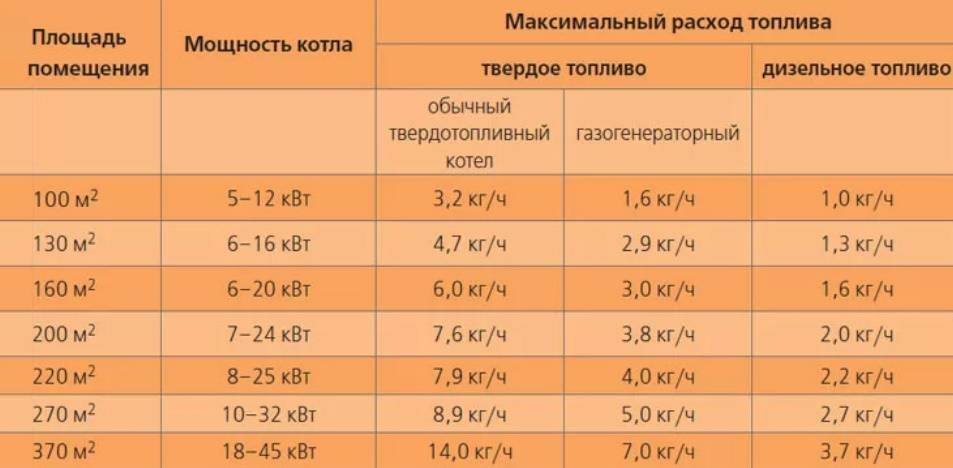

- Solid fuel boilers

- Oil boilers

- 3 Correcting the calculations - additional points

- Solving the problem of excess power

Boiler types

When choosing a boiler, you need to consider what type of heater it works on.

Solid fuel boilers

Boilers have the following advantages:

- profitability;

- autonomy;

- simplicity of design and control.

- it is necessary to prepare and store fuel;

- periodic loading of fuel and cleaning from combustion products is necessary;

- daily temperature fluctuations within 5ºС.

The system is far from the best, but in the absence of other sources of fuel, this is the only possible option.

Disadvantages can be reduced by using a bulb or water accumulators. The thermal bulb regulates the air supply to the furnace, thereby increasing the duration of fuel combustion. This increases efficiency and reduces the number of refills. Heat accumulators are designed to increase the inertia of the heating system. A container that is thermally insulated from the outside crashes into the heating circuit. The installation of a thermostatic valve installed at the inlet of the registers limits the supply of cold water from the heat accumulator at its inlet.

Due to this, the coolant heats up quickly, and then the heat accumulator begins to heat up. Heat transfer to the heating system takes much longer. Thus, temperature fluctuations in the house are reduced.

The heating elements built into the heat accumulator with automatic control make it possible to turn it on for electric heating at night, when the cost of electricity is minimal. In fact, the heat accumulator performs the function of an electric boiler. The efficiency of a solid fuel boiler is 71-79%. The creation of pyrolysis boilers allows you to raise it up to 85%. It is necessary for everyone to know that this type of boilers works only on wood.

gas boilers

The use of a gas boiler is the best option for home heating. It is simple and safe to operate, has cheap fuel that does not need to be stored and loaded.

It needs a chimney. The boiler room is required only for boilers with an open combustion chamber. The efficiency of gas boilers is 89-91%, but there are even more efficient boilers. Therefore, this indicator is given in the characteristics of each model.

Electric boilers

An electric boiler is the most environmentally friendly source of heat. It can be used to heat hot water through a boiler or as a backup source.

For private houses, models are sold with a power of up to 20 kW. The large power of the boiler may not be pulled by electricity meters that the electrical service installs at the entrance. Despite the high cost electricity from electric boilers the highest efficiency of 99%. Step power adjustment ensures their more economical operation.

Conclusion

If you calculate the power of the heating boiler using the above simple methods, you can select the required unit for heating the house. The calculation option through the heat losses of the enclosing structures makes it possible to more accurately determine the required boiler power.

If the house is provided with sufficient insulation, then the boiler will be needed with less power, and the cost of heating the premises will significantly decrease due to the reduction in heat loss.

This is interesting: How to choose a gas boiler - we understand which unit is the best

How to calculate the power of a gas heating boiler for the area of \u200b\u200bthe house?

To do this, you will have to use the formula:

In this case, Mk is understood as the desired thermal power in kilowatts. Accordingly, S is the area of \u200b\u200byour home in square meters, and K is the specific power of the boiler - the “dose” of energy spent on heating 10 m2.

Calculation of the power of a gas boiler

How to calculate area? First of all, according to the plan of the dwelling. This parameter is indicated in the documents for the house.Don't want to search for documents? Then you will have to multiply the length and width of each room (including the kitchen, heated garage, bathroom, toilet, corridors, and so on) summing up all the obtained values.

Where can I get the value of the specific power of the boiler? Of course, in the reference literature.

If you don’t want to “dig” in directories, take into account the following values of this coefficient:

- If in your area the winter temperature does not fall below -15 degrees Celsius, the specific power factor will be 0.9-1 kW/m2.

- If in winter you observe frosts down to -25 ° C, then your coefficient is 1.2-1.5 kW / m2.

- If in winter the temperature drops to -35 ° C and lower, then in the calculations of thermal power you will have to operate with a value of 1.5-2.0 kW / m2.

As a result, the power of a boiler that heats a building of 200 "squares", located in the Moscow or Leningrad region, is 30 kW (200 x 1.5 / 10).

How to calculate the power of the heating boiler by the volume of the house?

In this case, we will have to rely on the thermal losses of the structure, calculated by the formula:

By Q in this case we mean the calculated heat loss. In turn, V is the volume, and ∆T is the temperature difference between inside and outside the building. Under k is understood the coefficient of thermal dissipation, which depends on the inertia of building materials, door leaf and window sashes.

We calculate the volume of the cottage

How to determine the volume? Of course, according to the building plan. Or by simply multiplying the area by the height of the ceilings. The temperature difference is understood as the "gap" between the generally accepted "room" value - 22-24 ° C - and the average readings of a thermometer in winter.

The coefficient of thermal dissipation depends on the heat resistance of the structure.

Therefore, depending on the building materials and technologies used, this coefficient takes the following values:

- From 3.0 to 4.0 - for frameless warehouses or frame storages without wall and roof insulation.

- From 2.0 to 2.9 - for technical buildings made of concrete and brick, supplemented with minimal thermal insulation.

- From 1.0 to 1.9 - for old houses built before the era of energy-saving technologies.

- From 0.5 to 0.9 - for modern houses built in accordance with modern energy-saving standards.

As a result, the power of the boiler heating a modern, energy-saving building with an area of 200 square meters and a 3-meter ceiling, located in a climatic zone with 25-degree frosts, reaches 29.5 kW (200x3x (22 + 25) x0.9 / 860).

How to calculate the power of a boiler with a hot water circuit?

Why do you need a 25% headroom? First of all, to replenish energy costs due to the "outflow" of heat to the hot water heat exchanger during the operation of two circuits. Simply put: so that you do not freeze after taking a shower.

Solid fuel boiler Spark KOTV - 18V with a hot water circuit

As a result, a double-circuit boiler serving the heating and hot water systems in a house of 200 "squares", which is located north of Moscow, south of St. Petersburg, should generate at least 37.5 kW of thermal power (30 x 125%).

What is the best way to calculate - by area or by volume?

In this case, we can only give the following advice:

- If you have a standard layout with a ceiling height of up to 3 meters, then count by area.

- If the ceiling height exceeds the 3-meter mark, or if the building area is more than 200 square meters - count by volume.

How much is the "extra" kilowatt?

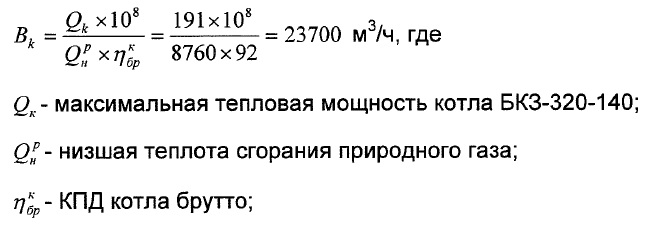

Taking into account the 90% efficiency of an ordinary boiler, for the production of 1 kW of thermal power, it is necessary to consume at least 0.09 cubic meters of natural gas with a calorific value of 35,000 kJ/m3. Or about 0.075 cubic meters of fuel with a maximum calorific value of 43,000 kJ/m3.

As a result, during the heating period, an error in calculations per 1 kW will cost the owner 688-905 rubles. Therefore, be careful in your calculations, buy boilers with adjustable power and do not strive to "bloat" the heat generating capacity of your heater.

We also recommend seeing:

- LPG gas boilers

- Double-circuit solid fuel boilers for long burning

- Steam heating in a private house

- Chimney for solid fuel heating boiler

How to calculate the optimal number and volumes of heat exchangers

When calculating the number of required radiators, one should take into account what material they are made of. The market now offers three types of metal radiators:

- Cast iron,

- Aluminum,

- bimetallic alloy,

All of them have their own characteristics. Cast iron and aluminum have the same heat transfer rate, but aluminum cools quickly, and cast iron heats up slowly, but retains heat for a long time. Bimetallic radiators heat up quickly, but cool down much slower than aluminum ones.

When calculating the number of radiators, other nuances should also be taken into account:

- thermal insulation of the floor and walls helps to save up to 35% of heat,

- the corner room is cooler than the others and needs more radiators,

- the use of double-glazed windows on windows saves 15% of heat energy,

- up to 25% of heat energy “leaves” through the roof.

The number of heating radiators and sections in them depends on many factors.

In accordance with the norms of SNiP, heating 1 m³ requires 100 W of heat. Therefore, 50 m³ will require 5000 watts. On average, one section of a bimetallic radiator emits 150 W at a coolant temperature of 50 ° C, and a device for 8 sections emits 150 * 8 = 1200 W. Using a simple calculator, we calculate: 5000: 1200 = 4.16. That is, approximately 4-5 radiators are needed to heat this area.

However, in a private house, the temperature is regulated independently and it is usually believed that one battery emits 1500-1800 W of heat. We recalculate the average value and get 5000: 1650 = 3.03. That is, three radiators should be enough. Of course, this is a general principle, and more accurate calculations are made based on the expected temperature of the coolant and the heat dissipation of the radiators to be installed.

You can use the approximate formula for calculating radiator sections:

N*= S/P *100

The symbol (*) shows that the fractional part is rounded according to general mathematical rules, N is the number of sections, S is the area of the room in m2, and P is the heat output of 1 section in W.

Video description

An example of how to calculate heating in a private house using an online calculator in this video:

Conclusion

Installation and calculation of the heating system in a private house is the main component of the conditions for comfortable living in it. Therefore, the calculation of heating in a private house should be approached with great care, taking into account many related nuances and factors.

The calculator will help if you need to quickly and averagely compare various construction technologies with each other.In other cases, it is better to contact a specialist who will correctly carry out the calculations, correctly process the results and take into account all the errors.

Not a single program can cope with this task, because it contains only general formulas, and the heating calculators for a private house and tables offered on the Internet serve only to facilitate calculations and cannot guarantee accuracy. For accurate, correct calculations, it is worth entrusting this work to specialists who can take into account all the wishes, capabilities and technical indicators of the selected materials and devices.

What is room heat loss?

Any room has a certain heat loss. Heat comes out of walls, windows, floors, doors, ceilings, so the task of a gas boiler is to compensate for the amount of outgoing heat and provide a certain temperature in the room. This requires a certain thermal power.

It has been experimentally established that the greatest amount of heat escapes through the walls (up to 70%). Up to 30% of thermal energy can escape through the roof and windows, and up to 40% through the ventilation system. The lowest heat loss at the door (up to 6%) and the floor (up to 15%)

The following factors affect the heat loss of the house.

The location of the house. Each city has its own climatic features. When calculating heat losses, it is necessary to take into account the critical negative temperature characteristic of the region, as well as the average temperature and duration of the heating season (for accurate calculations using the program).

The location of the walls relative to the cardinal points. It is known that the wind rose is located on the north side, so the heat loss of the wall located in this area will be the largest.In winter, a cold wind blows with great force from the western, northern and eastern sides, so the heat loss of these walls will be higher.

The area of the heated room. The amount of outgoing heat depends on the size of the room, the area of \u200b\u200bwalls, ceilings, windows, doors.

Heat engineering of building structures. Any material has its own coefficient of thermal resistance and heat transfer coefficient - the ability to pass a certain amount of heat through itself. To find out, you need to use tabular data, as well as apply certain formulas. Information on the composition of walls, ceilings, floors, their thickness can be found in the technical plan of housing.

Window and door openings. Size, modification of the door and double-glazed windows. The larger the area of window and door openings, the higher the heat loss.

It is important to take into account the characteristics of the installed doors and double-glazed windows when calculating.

Accounting for ventilation. Ventilation always exists in the house, regardless of the presence of an artificial hood

The room is ventilated through open windows, air movement is created when the entrance doors are closed and opened, people walk from room to room, which contributes to the escape of warm air from the room, its circulation.

Knowing the above parameters, you can not only calculate the heat loss of the house and determine the power of the boiler, but also identify places that need additional insulation.

Calculation of the power of a gas boiler depending on the area

In most cases, an approximate calculation of the thermal power of the boiler unit is used for heating areas, for example, for a private house:

- 10 kW per 100 sq.m;

- 15 kW per 150 sq.m;

- 20 kW per 200 sq.m.

Such calculations may be suitable for a not very large building with an insulated attic floor, low ceilings, good thermal insulation, double-glazed windows, but no more.

According to the old calculations, it is better not to do it. Source

Unfortunately, only a few buildings meet these conditions. In order to carry out the most detailed calculation of the boiler power indicator, it is necessary to take into account a full package of interrelated quantities, including:

- atmospheric conditions in the area;

- the size of the residential building;

- coefficient of thermal conductivity of the wall;

- the actual thermal insulation of the building;

- gas boiler power control system;

- the amount of heat required for DHW.

Calculation of a single-circuit heating boiler

Calculation of the power of a single-circuit boiler unit of wall or floor modification of the boiler using the ratio: 10 kW per 100 m2, must be increased by 15-20%.

For example, it is necessary to heat a building with an area of 80 m2.

Calculation of the power of a gas heating boiler:

10*80/100*1.2 = 9.60 kW.

In the case when the required type of device does not exist in the distribution network, a modification with a larger kW size is purchased. A similar method will go for single-circuit heating sources, without a load on hot water supply, and can be used as the basis for calculating gas consumption for a season. Sometimes, instead of living space, the calculation is performed taking into account the volume of the residential building of the apartment and the degree of insulation.

For individual premises built according to a standard project, with a ceiling height of 3 m, the calculation formula is quite simple.

Another way to calculate the OK boiler

In this option, the built-up area (P) and the specific power factor of the boiler unit (UMC) are taken into account, depending on the climatic location of the facility.

It varies in kW:

- 0.7 to 0.9 southern territories of the Russian Federation;

- 1.0 to 1.2 central regions of the Russian Federation;

- 1.2 to 1.5 Moscow region;

- 1.5 to 2.0 northern regions of the Russian Federation.

Therefore, the formula for the calculation looks like this:

Mo=P*UMK/10

For example, the required power of a heating source for a building of 80 m2, located in the northern region:

Mo \u003d 80 * 2/10 \u003d 16 kW

If the owner will install a double-circuit boiler unit for heating and hot water, professionals advise adding another 20% of the power for water heating to the result.

How to calculate the power of a double-circuit boiler

The calculation of the heat output of a double-circuit boiler unit is carried out on the basis of the following proportion:

10 m2 = 1,000 W + 20% (heat loss) + 20% (DHW heating).

If the building has an area of 200 m2, then the required size will be: 20.0 kW + 40.0% = 28.0 kW

This is an estimated calculation, it is better to clarify it according to the rate of water use of hot water supply per person. Such data are given in SNIP:

- bathroom - 8.0-9.0 l / min;

- shower installation - 9 l / min;

- toilet bowl - 4.0 l / min;

- mixer in the sink - 4 l / min.

The technical documentation for the water heater indicates what heating output of the boiler is required to guarantee high-quality water heating.

For a 200 l heat exchanger, a heater with a load of approximately 30.0 kW will suffice. After that, the performance sufficient for heating is calculated, and at the end the results are summarized.

Calculation of the power of an indirect heating boiler

In order to balance the required power of a single-circuit gas-fired unit with an indirect heating boiler, it is necessary to establish how much heat exchanger is required to provide hot water to the residents of the house. Using the data on the norms of hot water consumption, it is easy to establish that the consumption per day for a family of 4 will be 500 liters.

The performance of an indirect heating water heater directly depends on the area of \u200b\u200bthe internal heat exchanger, the larger the coil, the more heat energy it transfers to water per hour. You can detail such information by examining the characteristics of the passport for the equipment.

Source

There are optimal ratios of these values for the average power range of indirect heating boilers and the time to obtain the desired temperature:

- 100 l, Mo - 24 kW, 14 min;

- 120 l, Mo - 24 kW, 17 min;

- 200 l, Mo - 24 kW, 28 min.

When choosing a water heater, it is recommended that it heats the water in about half an hour. Based on these requirements, the 3rd option of the BKN is preferable.

What should be guided

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we distinguish several types of boilers.

gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive, it is available to a wide range of consumers. What are gas heating boilers? They differ from each other depending on what type of burner - atmospheric or inflatable.In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products leave through a special pipe with the help of a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall mounted gas boiler

As for the method of placing the boilers, the choice of a heating boiler assumes the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to conduct hot water, then you can install modern wall-mounted heating boilers. So you will not need to install a boiler for heating water, and this is a financial savings. Also, in the case of wall-mounted models, combustion products can be removed directly to the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall models is their dependence on electrical energy.

Electric boilers

Next, consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. Such types of heating boilers are small in size, so they can be used in small houses, as well as in cottages from 100 sq.m. All combustion products will be harmless from an environmental point of view. And the installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and prices for it are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as spare appliances for heating.

Solid fuel boilers

Now it's time to consider what solid fuel heating boilers are. Such boilers are considered the most ancient, such a system has been used for space heating for a long time. And the reason for this is simple - fuel for such devices is available, it can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to work offline.

Gas generating solid fuel boiler

Modification of such boilers are gas generating devices. Such a boiler differs in that it is possible to control the combustion process, and the performance is regulated within 30-100 percent. When you think about how to choose a heating boiler, you should know that the fuel used by such boilers is firewood, their humidity should not be less than 30%. Gas-fired boilers depend on the supply of electrical energy. But they also have advantages in comparison with solid propellant ones. They have a high efficiency, which is twice as high as solid fuel appliances. And from the point of view of environmental pollution, they are environmentally friendly, since the combustion products will not enter the chimney, but will serve to form gas.

The rating of heating boilers shows that single-circuit gas-generating boilers cannot be used to heat water. And if we consider automation, then it is great. You can often find programmers on such devices - they regulate the temperature of the heat carrier and give signals if there is an emergency danger.

Gas-fired boilers in a private house are an expensive pleasure. After all, the cost of a heating boiler is high.

Oil boilers

Now let's look at liquid fuel boilers.As a working resource, such devices use diesel fuel. For the operation of such boilers, additional components will be needed - fuel tanks and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this, replaceable burners or special burners are used, which are capable of operating on two types of fuel.

Oil boiler

3 Correcting the calculations - additional points

In practice, housing with average indicators is not so common, so additional parameters are taken into account when calculating the system. One determining factor - the climatic zone, the region where the boiler will be used, has already been discussed. We give the values of the coefficient Woud for all areas:

- the middle band serves as a standard, the specific power is 1–1.1;

- Moscow and Moscow region - we multiply the result by 1.2–1.5;

- for the southern regions - from 0.7 to 0.9;

- for the northern regions, it rises to 1.5–2.0.

In each zone, we observe a certain scatter of values. We act simply - the further south the area in the climatic zone, the lower the coefficient; the further north, the higher.

Here is an example of adjustment by region. Suppose that the house for which the calculations were made earlier is located in Siberia with frosts up to 35 °. We take Woud equal to 1.8. Then we multiply the resulting number 12 by 1.8, we get 21.6.We round off towards a larger value, it turns out 22 kilowatts. The difference with the initial result is almost twice, and after all, only one amendment was taken into account. So the calculations need to be corrected.

In addition to the climatic conditions of the regions, other corrections are taken into account for accurate calculations: the height of the ceiling and the heat loss of the building. The average ceiling height is 2.6 m. If the height is significantly different, we calculate the coefficient value - we divide the actual height by the average. Suppose the ceiling height in the building from the example considered earlier is 3.2 m. We consider: 3.2 / 2.6 \u003d 1.23, round it up, it turns out 1.3. It turns out that to heat a house in Siberia with an area of 120 m2 with ceilings of 3.2 m, a boiler of 22 kW × 1.3 = 28.6 is required, i.e. 29 kilowatts.

It is also very important for correct calculations to take into account the heat loss of the building. Heat is lost in any home, regardless of its design and type of fuel. Through poorly insulated walls, 35% of warm air can escape, through windows - 10% or more

An uninsulated floor will take 15%, and a roof - all 25%. Even one of these factors, if present, should be taken into account. Use a special value by which the received power is multiplied. It has the following stats:

Through poorly insulated walls, 35% of warm air can escape, through windows - 10% or more. An uninsulated floor will take 15%, and a roof - all 25%. Even one of these factors, if present, should be taken into account. Use a special value by which the received power is multiplied. It has the following stats:

- for a brick, wooden or foam block house, which is more than 15 years old, with good insulation, K = 1;

- for other houses with non-insulated walls K=1.5;

- if the house, in addition to non-insulated walls, does not have an insulated roof K = 1.8;

- for a modern insulated house K=0.6.

Let's return to our example for calculations - a house in Siberia, for which, according to our calculations, a heating device with a capacity of 29 kilowatts is needed. Suppose that this is a modern house with insulation, then K = 0.6. We calculate: 29 × 0.6 \u003d 17.4. We add 15-20% to have a reserve in case of extreme frosts.

So, we calculated the required power of the heat generator using the following algorithm:

- 1. We find out the total area of the heated room and divide by 10. The number of specific power is ignored, we need average initial data.

- 2. We take into account the climatic zone where the house is located. We multiply the previously obtained result by the coefficient index of the region.

- 3. If the ceiling height differs from 2.6 m, take this into account as well. We find out the coefficient number by dividing the actual height by the standard one. The power of the boiler, obtained taking into account the climatic zone, is multiplied by this number.

- 4. We make a correction for heat loss. We multiply the previous result by the coefficient of heat loss.

Placement of boilers for heating in the house

Above, it was only about boilers that are used exclusively for heating. If the appliance is used to heat water, the rated power should be increased by 25%

Please note that the reserve for heating is calculated after adjusting for climatic conditions. The result obtained after all calculations is quite accurate, it can be used to select any boiler: gas, liquid fuel, solid fuel, electric

Solving the problem of excess power

Due to the high cost of the method, the budget option of multi-stage burners in inexpensive gas and LT boilers is considered. With the onset of the specified period, a stepwise transition to reduced combustion reduces the boiler power. A variant of smooth transition is modulation or smooth adjustment, commonly used in wall-mounted gas appliances. This possibility is almost not used in the designs of LT boilers, although a modulating burner is a more advanced option than a mixing valve. Modern pellet boilers are already equipped with a power control system and automatic fuel supply.

For an inexperienced consumer, the presence of a modulating burner system may seem like a sufficient reason to abandon the calculation of heat losses at home, or at least limit themselves to an approximate definition. By no means, the presence of such a function cannot solve all the problems that arise: if, when the boiler is turned on, it starts working at maximum power, then after a while the machine reduces it to the optimum.

At the same time, a powerful boiler in a small system has time to heat the water and turn off even before the modulating burner passes to the desired level of combustion. The water cools down quickly enough, the situation will repeat itself “to a blot”. As a result, the operation of the boiler takes place in impulses as with a single-stage powerful burner. The change in power can reach no more than 30%, which will eventually lead to failures with a further increase in the external temperature. It is worth remembering that we are talking about relatively cheap devices.

In more expensive condensing boilers, the modulation limits are wider. ZhT boilers can cause noticeable difficulties when trying to use in small and well-insulated houses. In such a house, about 150 sq.m, 10 kW of power is enough to cover heat losses. In the line of ZhT boilers offered by manufacturers, the minimum power is twice as much. And here an attempt to use such a boiler can lead to a situation even worse than that described above.

ZhT (diesel fuel) is burning in the furnace, everyone saw a black plume behind an unheated and unregulated diesel engine. And here in the products of incomplete combustion, soot falls abundantly, it and unburned products thoroughly clog the combustion chamber. And now the brand new boiler needs to be urgently cleaned so as not to reduce the efficiency and restore heat transfer. And after all, if you first select the correct power of the boiler, there would not be all the problems described.

In practice, you should choose the boiler power slightly lower than the heat losses of the house. Popularity and practical use have gained boilers with TsOGVS, i.e. double-circuit, heating water for heating and hot water supply. And among these two functions, the required capacity for CH is less than for DHW. Of course, this approach made the choice of boiler power more difficult.

The method of obtaining hot water in a 2-circuit boiler is through-flow heating. Since the time of contact (heating) of running water is insignificant, the power of the boiler heater must be high. Even for low-power double-circuit boilers, the DHW system has 18 kW of power and this is only the minimum, which makes it possible to take a normal shower. The presence of a modulating burner in such a device will make it possible to work with a minimum power of 6 kW, almost equal to the heat loss in a 100-meter house with high-quality thermal insulation.

This scheme allows you to reduce the power of the boiler, combined with a water heater. As a result, the task is completed and the boiler power is sufficient to compensate for heat losses (CH) and hot water (boiler).At first glance, as a result, during the operation of the boiler to the boiler, hot water will not go into the heating system and the temperature in the house will drop. In fact, for this to happen, the boiler must turn off for 3 to 4 hours. The process of replacing heated water from the boiler with cold water occurs gradually. The practice of using heated water says that even draining half the volume, which is 50 liters at a temperature of about 85 degrees Celsius and the same amount of cold to use, leads to the remainder in the tank of half the volume of hot and the same amount of cold. The heating time will be no more than 25 minutes. Since such a volume is not consumed at a time in the family, the heating time of the boiler will be much less.