- Well pumping methods

- Cleaning a well with a bailer or pipe

- Cleaning the well with a vibration pump

- Cleaning with two pumps

- Deep pump cleaning

- Causes of silting and how to eliminate it

- Compressor pumping of the well

- Fight against silt and quicksand

- Description of the work technology

- Cleaning work in the well

- Video description

- Cleaning work with a bailer

- Cleaning work with a vibration pump

- Cleaning work with two pumps

- Preparing for a long downtime and pumping after it

- Briefly about the main

- Pumping a well after drilling: the basis of the process

- Flushing and pumping wells

- Cleaning work in the well

- Video description

- Cleaning work with a bailer

- Cleaning work with a vibration pump

- Cleaning work with two pumps

- Preparing for a long downtime and pumping after it

- How to pump a well after drilling from sand, silt and clay

- Why you need to pump a well

- How to pump a well after drilling

- Causes of silting and how to fix it

- How to pump a well after drilling?

- Technological features of the well pumping process

- How to properly pump a well after drilling

- Description of the work technology

- Choosing the Right Pump

- Suspension of the pump

- Time required for buildup

- Mistakes to avoid

- The most typical are:

- Ways to deal with silting

- Ways to deal with silting

- Features of the buildup of the well

- With a small debit

- on clay

Well pumping methods

Cleaning a clogged well can be done in several ways:

- Cleaning the well from clay with a pipe.

- Using a vibratory pump with a nozzle.

- The process is carried out simultaneously by two pumps. Usually it is deep and rotary.

Such methods can be used separately, or alternately, depending on the depth of the mine and the degree of clogging.

Cleaning a well with a bailer or pipe

Sectional bailer

Before cleaning water from a well from clay using a bailer, you need to:

- Remove the deep pump and free the shaft completely from foreign objects.

- Fix the bailer on a rope or a sufficiently strong metal cable and smoothly lower it to the bottom.

- After reaching the bottom, the bailer rises 50 centimeters and then drops sharply under its own weight.

- From a sharp blow to the bottom, the clay begins to move, and the free space is filled with its particles.

- From a sharp fall, the intake channel opens a metal ball, and water with clay goes inside the bailer.

- When lifting, the channel closes the ball, and dirty water is retained in the cylinder.

- Such movements must be repeated 2-3 times, then the cylinder slowly rises to the surface.

Each such procedure lifts up from 250 to 500 grams of clay. This cleaning process is lengthy, but in practice it turns out to be quite effective.

Cleaning the well with a vibration pump

The easiest and fastest cleaning option is to use a vibration pump.It is used in all types of structures, especially in mines where the receiver is narrowed, and cleaning with a deep unit is not possible.

Further, the cleaning process occurs in the following order:

- A durable rubber or durite hose is put on the water intake and securely fastened with metal brackets.

- The length of the hose depends on the size of the constricted section.

- The hose must have sufficient rigidity so that it does not bend when it hits the ground.

- The pump descends to the bottom of the shaft, then rises by 5-10 centimeters and turns on.

- The hose collects and pushes the sludge deposit to the surface, but with such a heavy load and clogged valves, the pump will quickly break down. Therefore, it is recommended to periodically remove it from the shaft for washing with clean water.

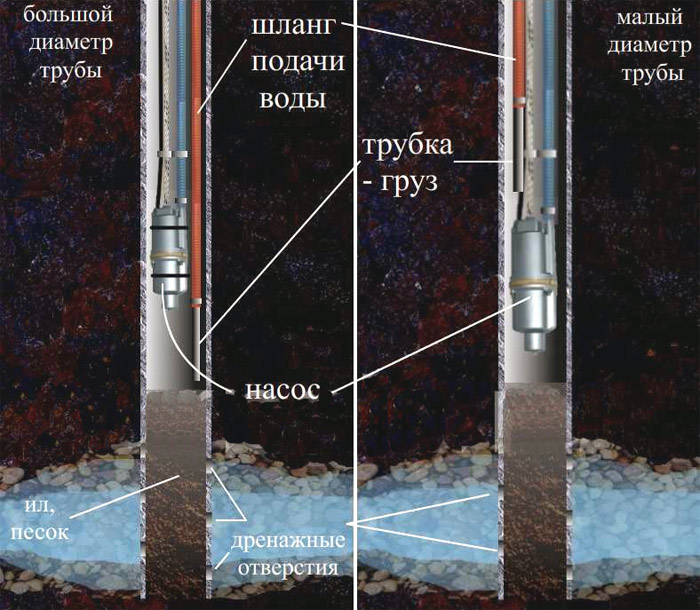

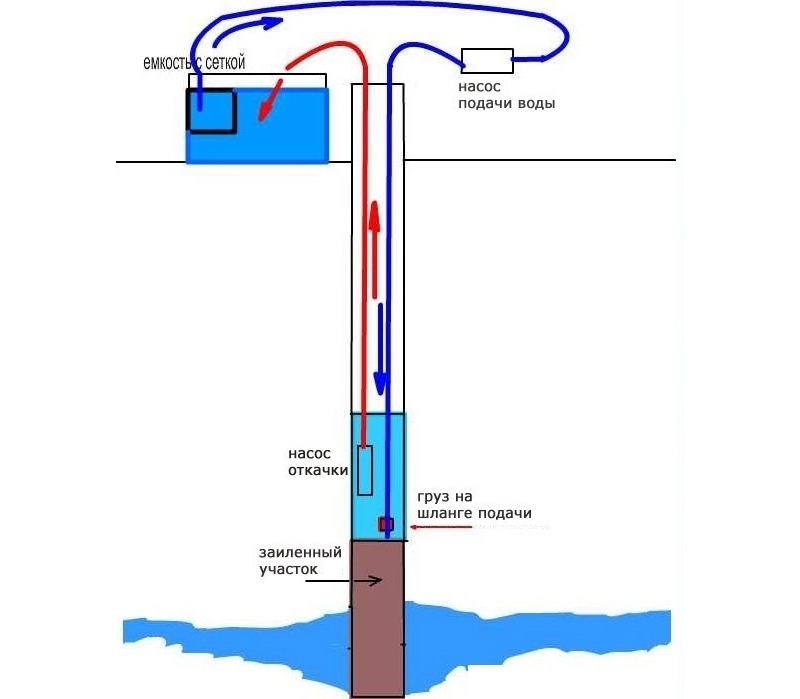

Cleaning with two pumps

The method is characterized by a long duration, but at the same time a person may not participate in the process.

Before you clean the well from clay by this method, you need to prepare in advance:

- Up to 300 liters capacity for liquid.

- Centrifugal pump for pumping water.

Centrifugal pump

Deep pump cleaning

Deep pump

This method is as follows:

- From the tank, a centrifugal pump will supply water under pressure through a hose to the bottom of the well, while washing away the clay deposit.

- A deep pump will pump water back into the tank with washed clay. This forms a closed flushing system.

- The deep pump rises from the bottom of the well by 15 centimeters.

- A weight is attached to the end of the injection hose immersed in water or a metal tube is put on to prevent twisting of the end and direct it clearly to the bottom of the shaft.

- It is better to put a filter on the suction hose of a centrifugal pump so that small pebbles or sand do not accidentally enter the pump.

How bentonite clay is used for drilling wells can be found in the video. This article gives the most common methods for cleaning clay from wells.

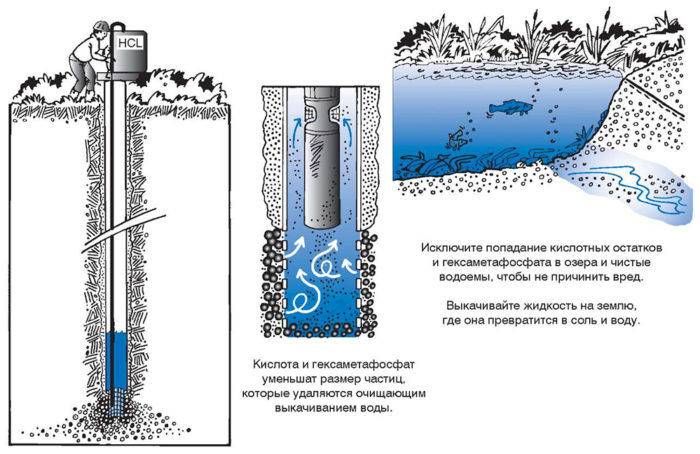

Causes of silting and how to eliminate it

When silting or sanding, cleaning the well can be carried out by various methods. As a preventive measure, after some downtime or if a slight silting is detected, it is enough to turn on the pump for several hours and pump out water with accumulated sludge. The problems are evidenced by a slight decrease in the debit of the well.

Finding out how to drill a new well, you can find various recommendations, some of which are applicable to cleaning already finished and commissioned facilities. For example, there is a method of cleaning a well with a fire truck.

At the same time, a large amount of water under pressure is supplied inside the well, which makes it possible to break up the contaminants accumulated there, partially wash them out and facilitate further cleaning of the water source.

The idea is interesting, but it refers to structures that are already in operation and for some reason need to be cleaned again. It is difficult to pump a well immediately after completion of drilling operations in this way.

The same can be said about the work with the bailer. This is a manual method of cleaning, in which a special bailer (a heavy metal product) is thrown to the bottom of the well so that it breaks and scoops up dirt and sand accumulated at the bottom. The bailer is taken out, freed from sediment and again thrown to the bottom of the well.

Wells are also pumped with the help of a motor pump: Caiman, Hitachi, Honda, etc. The cost of such a unit can be about a thousand dollars, or even two or three thousand, depending on the model.

This method, like those described above, will come in handy in the future if you need to reanimate the finished well and clean it of dirt, sand or silt. But at the end of drilling, pumping equipment should be used.

Compressor pumping of the well

How to properly pump with compressed air is known to any driller. This method is used when there is no electricity at the work site. Mobile compressors with internal combustion engines are used, capable of supplying water intake from 2 cubic meters of air per hour.

Air is supplied to the bottom of the pit through a perforated metal tube with a plugged end. The air rises through the well pipe, dragging the cuttings particles with it and carrying them out.

With a casing diameter of more than 5 inches, it is correct to use an airlift system. It consists of two tubes. One of them pours air into the mixer. The second sucks in the sludge and passes it up along with the air.

How long it takes to clean the water intake in this way depends on its depth and the height of the dynamic level.

The ease of use of the method determines the possibility of doing the washing with your own hands.

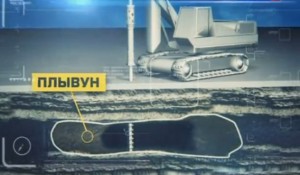

Fight against silt and quicksand

No matter how long and how many times you rock the well, silt will still appear in the mine. After all, mesh filters superimposed for intake holes at the end of the casing, are simply not designed for such a small "caliber" of contaminants

Quicksand is water-saturated sands or sandy loam

As a result, the owner of the well must allocate time for preventive work carried out immediately after the recession of the flood (seasonal increase in the level of groundwater). After all, mud plugs are formed during an unexpected increase in pressure in the aquifers of the soil.

Moreover, there are two ways to deal with traffic jams, namely:

- If the moment has not yet been missed, and there is still no plug in the well, then you just need to increase the intensity of operation, pumping out water not as needed, but for 2-3 hours in a row. As a result of such an overload, coarse sand will be washed around the filtering elbow of the casing pipe, and silt deposits will be removed from the mine before the next flood. But after such a tough operation, it is necessary to inspect and repair the pump.

- If the moment is missed and a plug has formed in the well, then it will have to be washed out with a jet of water supplied to the bottom of the well under pressure. Moreover, for blurring, you need a special injection pump, a hose, the length of which is equal to the depth of the well, and a hydraulic nozzle. After blurring, the silty suspension is simply pumped out of the well without any residue.

As you can see, both technologies do not require exorbitant efforts, and most of the work related to well maintenance is carried out remotely. Therefore, just do not be lazy, service the well at the right frequency, and enjoy clean water all year round.

Published: 11.09.2014

Description of the work technology

Well drilling is of two types. During internal pumping, the pores of the reservoir are cleaned for thorough washing. External involves the removal of the crust from the wall surface of the reservoir.

First, an external flushing of the well after drilling is done, and then an internal one.

For proper pumping, you will need the following tools and equipment:

- Centrifugal and vibration pumps;

- timer regulator;

- construction drill;

- outlet pipe.

Vibration equipment is used first. It pumps out water, which contains solid particles. Vibration affects large particles. They become mobile.

If after two days the pumped out water contains sand, then the unit can no longer be used.

Then the centrifugal unit is installed.

During pumping, it is impossible to take all the water and drain the filter devices. The disappearance of water contributes to the clogging of pores.

To shake the well after drilling, the following activities are performed.

- The pump is placed in the well and fluid is taken. After the appearance of air bubbles, the unit turns off.

- Measurements are made of the height of the water, which forms after a while.

- To program the timer, you need to know the debit of the source. The volume of water is divided by the time it enters the reservoir. If the pump performance is higher, then the time is determined at which the device will operate without draining the well.

- If there is no timer, then holes are drilled in the outlet pipe so that part of the water flows back into the reservoir. In this case, the power of the unit is compensated

Flushing of the well after drilling is carried out until the water is completely clean.

Rocking the well should be carried out before clean water flows.

The procedure should begin immediately after the creation of the reservoir. Otherwise, additional cleaning methods will be required for declaying.

You need to rock the well after installing the last element of the casing.

Proper mounting of the pump is important. Pumps for pumping the well after drilling are mounted at a distance of 80 cm from the surface of the bottom of the reservoir.

For high-quality operation of the unit, it is periodically lifted up and washed.

Pumping equipment operates in intermittent mode.

When performing this procedure, the following errors are most often encountered:

- If the pump is placed low, then it becomes clogged with silt. There are cases when the devices are pulled into quicksand.

- With a high location of the unit, the upper layer of the well will be processed, and the deposits will settle to the bottom. There will be a need for re-treatment of water.

- The selected water is poured out next to the reservoir. As a result, the liquid penetrates through the soil layer into the well and erodes the soil.

The pump unit is located in line with the filter unit.

It is not recommended to use the cords that come with the device. They are not durable.

It is worth choosing a cable made of durable material. The unit is lowered on it.

Cleaning work in the well

If the location of the well is at the cottage, used only for the weekend in the summer, then it is not worth it. Too laborious and costly. It will be quite enough to have imported (brought) water for a couple of days.

It is quite another matter if agricultural work on growing vegetables is carried out on the site, there is an orchard or a flower garden. Or it is used for long-term residence. In this case, the presence of a constant source of fresh water is simply necessary, because. it is supposed to water the beds, cook food and use it for hygienic purposes.

Own well allows the owner to:

- do not depend on the central water supply;

- always have an uninterrupted supply of water in the required volume;

- use clean water that has passed through natural filters and is saturated with essential trace elements.

Video description

Which option of a well for water to choose can be found here:

However, the presence of these advantages will require the owner of the site to carry out periodic preventive maintenance to clean the clogged device. As a rule, this cleaning is carried out in several ways:

- with the help of a bailer;

- pumping the well with a vibration pump;

- using two pumps (deep and rotary).

The use of these methods presupposes both their separate use and their joint use in turn. It all depends on the weediness and depth of the well.

Cleaning work with a bailer

The bailer (metal pipe) is fixed with a strong iron cable or rope and smoothly lowers to the bottom. When it reaches the bottom, it rises (up to half a meter) and drops sharply. The blow of the bailer under the influence of its weight is able to lift up to half a kilogram of clay rock. Such a well cleaning technique is quite laborious and long-term, but inexpensive and effective.

Cleaning the well with a bailer

Cleaning work with a vibration pump

This option for cleaning the well will be the simplest and fastest. That is why it is considered the most common and has found application even in mines with a narrowed receiver, which is why the use of a conventional deep pump is not possible.

Vibration pump cleaning

Cleaning work with two pumps

This method is characterized by the fact that it does not actually require human participation in the process.The flushing of the well takes place using two pumps that do all the work themselves, but the time spent on this is simply enormous.

Preparing for a long downtime and pumping after it

If a visit to the summer cottage in the winter (or for another long period) is not expected, and the well will not be used either, then you should take care of this in advance. It is necessary to consider preparing the device for inactivity and how to pump the well after a winter or a long downtime.

Preparation comes down to installing a heating cable inside or using any materials at hand to insulate the device.

Well pumping after winter is carried out by standard methods, which are described above, and are used only if necessary.

An example of well insulation for the winter

Briefly about the main

A private well on your own site is a useful and absolutely necessary thing. However, it will require some periodic maintenance work on cleaning and buildup. The above describes what buildup is, why it is used, which pump to pump the well after drilling, how to do it correctly and in what way, and what are the features of using one or another option. The issues of preparing the device for a long downtime (wintering) and restoring performance after this period are also mentioned.

Source

Pumping a well after drilling: the basis of the process

Many people think that the aquifer is the layer that flows from the tap, but this is not so. In nature, the aquifer is a sand-clay mixture, which is compressed between a sandy loam and a clay lens. It is from this mixture that water is extracted, which is purified using mechanical filters.But, unfortunately, mesh filters are not able to clean the smallest particles. And besides the fact that the filter does not clean fine particles, they also penetrate into the middle of the filter and clog it from the inside.

In the end, the owner of a newly drilled and equipped well must pump this mixture to the bottom, thereby increasing the efficiency of the filters and the quality of the water.

Also, during the buildup, sand and silt are washed out not only from the pipe, but from the environment of the layer. And that is why the rocked well is surrounded not by a muddy suspension, but by a layer of pure water, but to achieve such a result, it is necessary to make an effort.

For successful pumping, you need to know 3 basic rules:

- The first is waiting for the time required for the buildup of the well;

- The second rule that you need to know is which pump should do it;

- And the third rule is how to organize the pumping process: when to start pumping, where it is better to fix the pump, and so on.

Experts point out that if the buildup of the well is done correctly, it will make it possible to remove all the smallest particles from the aquifer, which is located directly next to the pipe. An increase in a new well with a small debit is the dream of every summer resident, this can be done in a vibrational way, the most important thing is not to make mistakes, especially during winter. After the well has been drilled, the next step is to flush the water that is being pumped. This can be done without any problems with your own hands, a detailed description of how to get rid of sand in the water, pump out silt, as well as increase the flow of clean water, can be found in the video.

Flushing and pumping wells

Cleaning, flushing and pumping wells are different concepts. Flushing is performed by the drilling crew immediately after drilling and casing the well with pipes. Flushing is also used in case of well silting after a long downtime.

Flushing is the release of the internal space of the casing pipes and the annulus of the well from the drilling fluid after drilling or accumulated sludge after the downtime of the well.

When flushing inside the casing of pipes, a fire hose is lowered and water is supplied under pressure. This water rises along the wellbore, pushing the entire drilling fluid in front of it, washing it out. After the inside of the string is washed, a special cap with a fire hose screwed to it is put on the head of the casing string of pipes, and again water is supplied under pressure. By pressurizing the casing pipe, the water looks for a way out and finds it in the filter part of the casing string. Now the water rises through the annulus, flushing it. Now, after the entire pipe and wellbore are washed, the drilling crew made a test pumping out and showed that there is water in the well with a sufficient flow rate, they start pumping the well with a pump.

Pumping is mainly needed for wells drilled in sandy soils and clay. The purpose of pumping a well is to completely clean the aquifer from the remnants of the drilling fluid carried along the aquifer during drilling and the opening of aquifers smeared during drilling if the aquifer is on clay.

Cleaning work in the well

If the location of the well is supposed to be in a summer cottage, used only for weekends in the summer, then it is not worth it. Too laborious and costly.It will be quite enough to have imported (brought) water for a couple of days.

It is quite another matter if agricultural work on growing vegetables is carried out on the site, there is an orchard or a flower garden. Or it is used for long-term residence. In this case, the presence of a constant source of fresh water is simply necessary, because. it is supposed to water the beds, cook food and use it for hygienic purposes.

Own well allows the owner to:

- do not depend on the central water supply;

- always have an uninterrupted supply of water in the required volume;

- use clean water that has passed through natural filters and is saturated with essential trace elements.

Video description

Which option of a well for water to choose can be found here:

However, the presence of these advantages will require the owner of the site to carry out periodic preventive maintenance to clean the clogged device. As a rule, this cleaning is carried out in several ways:

- with the help of a bailer;

- pumping the well with a vibration pump;

- using two pumps (deep and rotary).

The use of these methods presupposes both their separate use and their joint use in turn. It all depends on the weediness and depth of the well.

Cleaning work with a bailer

The bailer (metal pipe) is fixed with a strong iron cable or rope and smoothly lowers to the bottom. When it reaches the bottom, it rises (up to half a meter) and drops sharply. The blow of the bailer under the influence of its weight is able to lift up to half a kilogram of clay rock. Such a well cleaning technique is quite laborious and long-term, but inexpensive and effective.

Cleaning the well with a bailer

Cleaning work with a vibration pump

This option for cleaning the well will be the simplest and fastest. That is why it is considered the most common and has found application even in mines with a narrowed receiver, which is why the use of a conventional deep pump is not possible.

Vibration pump cleaning

Cleaning work with two pumps

This method is characterized by the fact that it does not actually require human participation in the process. The flushing of the well takes place using two pumps that do all the work themselves, but the time spent on this is simply enormous.

Preparing for a long downtime and pumping after it

If a visit to the summer cottage in the winter (or for another long period) is not expected, and the well will not be used either, then you should take care of this in advance. It is necessary to consider preparing the device for inactivity and how to pump the well after a winter or a long downtime.

Preparation comes down to installing a heating cable inside or using any materials at hand to insulate the device.

Well pumping after winter is carried out by standard methods, which are described above, and are used only if necessary.

An example of well insulation for the winter

A private well on your own site is a useful and absolutely necessary thing. However, it will require some periodic maintenance work on cleaning and buildup. The above describes what buildup is, why it is used, which pump to pump the well after drilling, how to do it correctly and in what way, and what are the features of using one or another option.The issues of preparing the device for a long downtime (wintering) and restoring performance after this period are also mentioned.

How to pump a well after drilling from sand, silt and clay

You need to pump the well immediately after drilling, you need to do this according to the instructions, and to clean water. Well pumping is also relevant during operation, as it silts up over time. In order for the aquifer to work correctly, it must be monitored and swayed in a timely manner!

Why you need to pump a well

Well drilling is the most important step organization of autonomous water supplywhich cannot be ignored. Groundwater contains many contaminants, impurities and insoluble inclusions, which is why it is forbidden to use it for drinking or other domestic purposes. To eliminate the problem and effectively clean the liquid, a complex buildup of the well will be required.

In most cases, heavy mud is only present after the completion of drilling activities. But the problem may arise in the future.

Small particles of clay or larger inclusions collect in the lower part of the trunk, which leads to silting. The problem is exacerbated by the rare operation of the well. So, if the water was not used during the cold period, when spring returns, many deposits can appear that will create problems.

How to pump a well after drilling

To independently figure out how to rock a well after drilling, you need to study the step-by-step guide and familiarize yourself with each step of the procedure. If it is performed by a team of professionals, and not by amateurs with budget equipment, the pumping service should be included in the contract.

In other cases, you will have to solve the problem yourself.

Causes of silting and how to fix it

To know how to properly pump dirty water, it is important not only to purchase a suitable pump for pumping a well with a low debit, but also to study the causes of pollution. If the liquid is constantly filled with sand, as a preventive measure, you can use the downtime method or run the pump for a couple of hours and pump out the liquid

When figuring out how to properly pump a well, you should take into account the recommendations of specialists that are suitable for most cases.

So, someone builds a well with their own hands using a fire hose.

This technology allows you to supply large volumes of water inside and break down the main contaminants or partially wash them out to facilitate further cleaning.

The method is quite interesting, but it is only suitable for those structures that have been in operation for a long time, but for some reason require re-treatment.

You can understand how to pump a well from clay right on the site after completing the drilling procedures.

For example, in addition to pumping the well with a compressor, you can apply the technology of manual processing with a bailer.

It is a heavy metal object that sinks to the bottom of the structure in order to break up dirt and sand. Then the bailer is taken out, released and thrown back.

Knowing how to rock a well on clay or sand, you can safely reanimate the hydraulic structure and protect the inhabitants of the house from the use of dirty, silty and unsafe liquids.

How to pump a well after drilling?

Very often, a well is considered the only source that provides water to the owners of country houses and cottages. Drilling is not so difficult, especially if finances allow.

It should be understood that when organizing a water supply system, a number of actions are carried out. An extremely important question in this matter: "How to pump a well after drilling?".

Technological features of the well pumping process

Experts mean by the concept of “pumping” the process of cleaning a water source after drilling is completed. It is impossible to drink water from an uncleaned well: sand, small particles, impurities can be found in such a liquid, even large stones can be caught. Such water is also not recommended for irrigation. Therefore, it is desirable to properly pump the individual source.

If this is neglected, then sand, silt and smaller particles will settle to the bottom of the well, after which the source will clog. And this will make it impossible to further exploit water resources.

The purpose of the well buildup is to remove this harmful layer, which is located near the pipe. The first portions of the water will be quite cloudy, then it will become clearer until it reaches crystal clearness.

The timing of pumping differs depending on the type of soil. For sandstone, the process can barely exceed 12 hours, and for clay soil, it can take several weeks or even months. It should be understood that deep wells swing longer than shallow ones.

How to properly pump a well after drilling

Recommendations:

Do not use expensive innovative equipment. An advanced pump of foreign or domestic production will come in handy a little later for clean water. And for buildup, an old inexpensive copy is suitable, which is not a pity.Such equipment is not so demanding on the purity of water, therefore it will not react to pollution in the form of silt or sand and will not burn;

It is necessary to select the correct suspension position of the pump. It is recommended to place the device close to the day of the source. A height of 50-70 cm should be enough. This is an approximate gravel pack level;

It is necessary to monitor the cleanliness of the pump and flush it as it becomes dirty.

This will significantly extend its service life;

It is extremely important to monitor the drain of pumped water. To prevent the dirty substance from entering the source again, it is necessary to divert the water as far as possible

If you do not follow such a simple rule, then you can swing the well to infinity;

It is worth taking care that the pump is lowered into the source not on the cord that comes with the kit, but on a strong cable. This will make it easier to get the equipment if it gets stuck in the pipe or dragged into the silt.

Description of the work technology

Actually pumping a well is an ordinary pumping of water

However, there are several aspects to which special attention should be paid.

Choosing the Right Pump

Even if the owner has prepared a powerful water supply device, you should not lower it into the well. Experience shows that high-quality expensive equipment will come in handy later, for pumping clean water. Whereas, especially for the buildup process, it is advisable to purchase an inexpensive submersible pump. Most likely, he will regularly fail, pumping a muddy suspension, but he will bring his work to an end. At the same time, the more expensive “permanent” option will remain unscathed and will be able to work perfectly on clean water.Another caveat: the “temporary” pump must be a submersible centrifugal pump, since vibration models simply cannot cope with such a load.

Suspension of the pump

When thinking about how to pump a well after drilling, you should pay special attention to the height of the pump. It should be close to the line of the bottom of the well, 70-80 cm above its mark, practically on the same level with the gravel pack

In this case, the sludge will be captured and actively removed to the outside. In order for the pump to work in this mode for as long as possible, it must be periodically stopped, removed and washed, passing clean water through it.

Time required for buildup

It is difficult to determine immediately how much time it will take to build up the well.

The process should continue until clean water appears. The intensity of the swing directly affects the result. The more water is pumped out, the more sand and other small particles go with it. Coarse sand that has not passed through the filter settles to the bottom, forming an additional filter layer.

The duration of the buildup process depends on the composition of the soil on which the well is equipped

Experts say that in order to completely clean the well, more than a dozen tons of water must be pumped out of it. On average, with a structure depth of 50 to 500 m, the process should take at least 48 hours, with a smaller depth, respectively, less.

Mistakes to avoid

In the behavior of the buildup of a new well, errors occur that disrupt the cleaning process.

The most typical are:

- Pump too high. It should not be placed near the surface of the water.Otherwise, the use of the equipment will be useless: it will not be able to capture fine particles, which are most abundant in the bottom part of the well. In this case, despite the measures taken to build up, the well will quickly silt up and stop producing water.

- Pump set too low. A buried device will not be able to function properly. It will very quickly clog with suspension and stop. In addition, the pump can "burrow" in the silt. It is very difficult to extract the apparatus pulled into the ground to the surface.

- Illiterate water disposal. Pumped out dirty water should be discharged as far as possible. Otherwise, it can again fall into the well, and then the buildup process can last almost indefinitely.

- Descent of the pump on an insufficiently strong cord supplied with it. It's better not to. The device can get stuck in the well or be sucked into the silt. In this case, pulling it out by the cord is unlikely to succeed. It is worth buying a strong thin cable and using it to lower the pump for buildup.

Ways to deal with silting

The water in the well will always be clear and clean if preventive maintenance is carried out from time to time.

Each owner of the structure needs to know how to pump the well in order to prevent re-silting. To do this, during periods when water intake is reduced, you should regularly turn on the pump for two to three hours. If, nevertheless, despite all efforts, a plug of silt has formed at the bottom, you can try to wash it out. A hose is lowered into the well to the pump, through which clean water is supplied under pressure. It will wash away unwanted bottom sediments, rise up through the annular space and splash out of the well.The procedure should be carried out until gravel from the bottom filter begins to come to the surface along with water. Next, carry out the usual buildup.

The well is quite easy to operate

It is important to competently carry out drilling work and equip the structure, which subsequently will not cause much trouble. It is very important to know how to properly pump a well so that it produces a large volume of crystal clear water.

High-quality rocking work is the key to a long and trouble-free operation of the structure.

Ways to deal with silting

The water in the well will always be clear and clean if preventive maintenance is carried out from time to time.

Each owner of the structure needs to know how to pump the well in order to prevent re-silting. To do this, during periods when water intake is reduced, you should regularly turn on the pump for two to three hours. If, nevertheless, despite all efforts, a plug of silt has formed at the bottom, you can try to wash it out. A hose is lowered into the well to the pump, through which clean water is supplied under pressure. It will wash away unwanted bottom sediments, rise up through the annular space and splash out of the well. The procedure should be carried out until gravel from the bottom filter begins to come to the surface along with water. Next, carry out the usual buildup.

Features of the buildup of the well

There are different types of wells, and this will depend on some nuances of work.

With a small debit

There are situations when a well already exists, but its resource, or, as they say, debit, is very low. This characteristic refers to the amount of water received from the well for a certain period.Most often it is measured in liters per unit of time.

Many site owners want to increase the productivity of the well, and sometimes they succeed. To do this, buildup is used with simultaneous erosion of the lower layer with a strong jet of water. Use two pumps running at the same time. You can also try to increase the debit of the well mechanically using special devices (bailers) that select silt and sand from the bottom. In most cases, a positive result can be achieved, but if nothing helps, then a new source has to be drilled.

on clay

If a sand well can be cleaned in 12-24 hours, then with a clay bottom, this process can drag on for several days or even weeks. If clean water cannot be reached quickly, then it makes sense to use bailers or a second pump, as in the case of increasing debit. Constant pumping of the clay mixture will eventually lead to a positive result.