- Stages of work

- flushing

- Peculiarities

- Cork removal

- Recommendations for the fight against silting and sanding

- Step-by-step instructions for pumping a well

- Well flushing after drilling

- The task of pumping a well after drilling

- Well pumping methods

- Cleaning a well with a bailer or pipe

- Cleaning the well with a vibration pump

- Cleaning with two pumps

- Deep pump cleaning

- How to pump a well after drilling?

- Appointment of the buildup of the well after drilling

- Technology of well stimulation at the exhibition

- Preparing for a long downtime and pumping after it

- Work performance technology

- Description of the work technology

- Choosing the Right Pump

- Suspension of the pump

- Time required for buildup

- Mistakes to avoid

- The most typical are:

- Ways to deal with silting

- How long does it take to pump a well after drilling, and what to do if the process drags on?

- How to download?

Stages of work

The main question that the owners of artificial sources ask themselves is how to pump the well after drilling. In fact, everything is quite simple. The main thing is to follow simple rules and avoid common mistakes.

First, you need to prepare the necessary tool:

- centrifugal pump;

- steel rope;

- hose;

- carrying.

Everything is simple here

However, it is important to purchase a strong metal cable on which the pump will be suspended. Do not use a rope for these purposes - it can fray and break. And if the device falls into the well, this will create additional problems.

And if the device falls into the well, this will create additional problems.

flushing

Before rocking the well after drilling, it is advisable to take care that dirty water does not get back into the casing. This is especially true for shallow sources. If the discharge is carried out next to the casing, the dirt will very quickly penetrate into the aquifer, and then into the casing. Therefore, the process can be endless.

To avoid this, you need to stock up on a long hose and organize water drainage as far as possible from the source. It can be a pit or just a wasteland - the main thing is that the area allows you to take large volumes of water.

On this, the preparation can be considered completed. Now it's time to move on to the main work. How to flush a well after digging, the sequence of actions:

the pump is fixed in the well. It must be installed at a height of 50-70 centimeters from the bottom - this is the optimal depth that allows you to pump out the dirt. If you lower it lower, the liquid may be too thick and the pump will not be able to handle it. And if the pump is located higher, the cleaning efficiency will decrease significantly;

after that, the pump is connected and the cleaning process begins

It is important not to forget to periodically get it to the surface and rinse with clean water.

Now, you need to wait until clean water comes out of the well. On average, the work will take 1-2 days.But, a lot depends on the specific conditions.

Peculiarities

Considering that after drilling a well, a considerable amount of water will have to be pumped out of it, you need to prepare for this. The main problem is created by the pollution in it - silt, sand and clay. If you pour the liquid directly onto the soil, it can be spoiled, so it makes sense to make the simplest filter installation.

One of the available options is to use an old barrel or other similar container for this purpose. And to make an installation out of it is quite simple:

- closer to the top, you need to make a hole in the side of the container;

- install a mesh filter on it - gauze or old tights are suitable for this;

- if there is no hole at the top, you will need to make one.

Everything, now the hose is connected to the top, and dirty water will be poured into the barrel. Due to the fact that it will flow out through the top, it will have time to settle. Of course, periodically it will have to be cleaned of deposits, but then the dirt will not fall on the upper layers of the soil.

Cork removal

Sometimes a situation occurs when a plug of sediments forms at the bottom. In this case, a simple pumping will not work. To eliminate it you will need:

- additional pressure pump and long hose;

- it sinks to the bottom of the casing string and a jet of water is fed through it from the surface;

- it erodes the cork and lifts deposits;

- at the same time, they are raised to the surface by a submersible pump.

Cork removal with two pumps

If deposits are too dense, they may need to be worked out mechanically. For example, with the help of a bailer.

Recommendations for the fight against silting and sanding

The processes of silting and sanding, as already noted, are completely natural. Underground water does not flow through pipes and is not in an isolated state. It is constantly in contact with various particles, mixes with them and, in the absence of proper arrangement, is removed from the dirty well. In order for the water to constantly come out clean and transparent, the well owner must periodically carry out preventive maintenance to avoid re-silting.

To do this, during periods of reduced water intake, you need to regularly turn on the pump for at least a few hours. If a silt plug still collects at the bottom, try to wash it out. To do this, take a hose, lower it into the well to the pump and supply clean water under pressure. It should wash away deposits. As a result, all the dirt will rise and come out of the well along with the water. Continue the procedure until gravel from the filtration backfill begins to come to the surface. After that, do the usual buildup discussed earlier.

Step-by-step instructions for pumping a well

Directly pumping a well comes down to ordinary pumping of water from a source

But there are a number of important features that must be taken into account. You need to choose the right pump for pumping

Even if you have already bought a powerful water supply unit, do not rush to lower it into the well. In practice, it has been repeatedly established that it is better to save high-quality expensive pumps for further pumping clean water, and not spoil them during the pumping process.

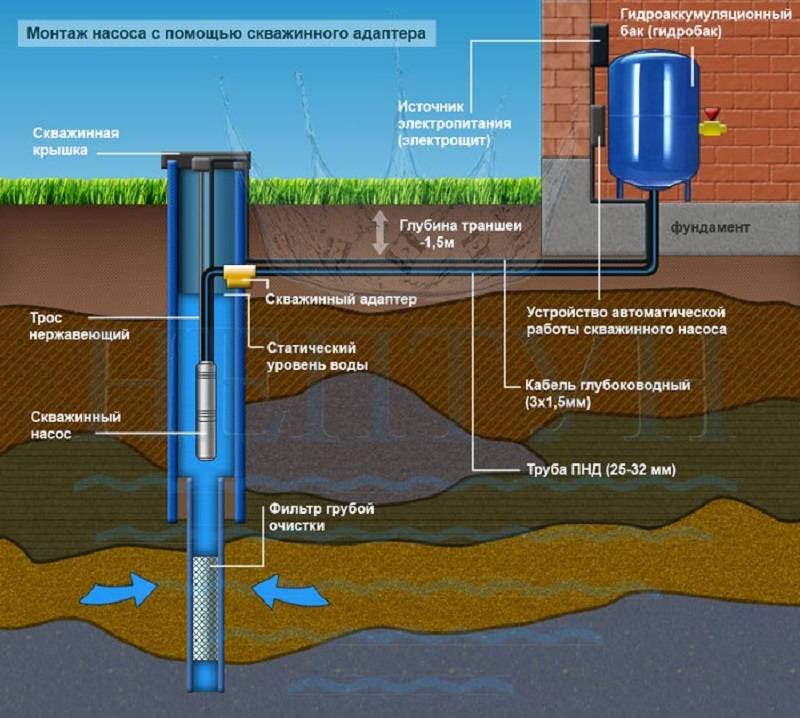

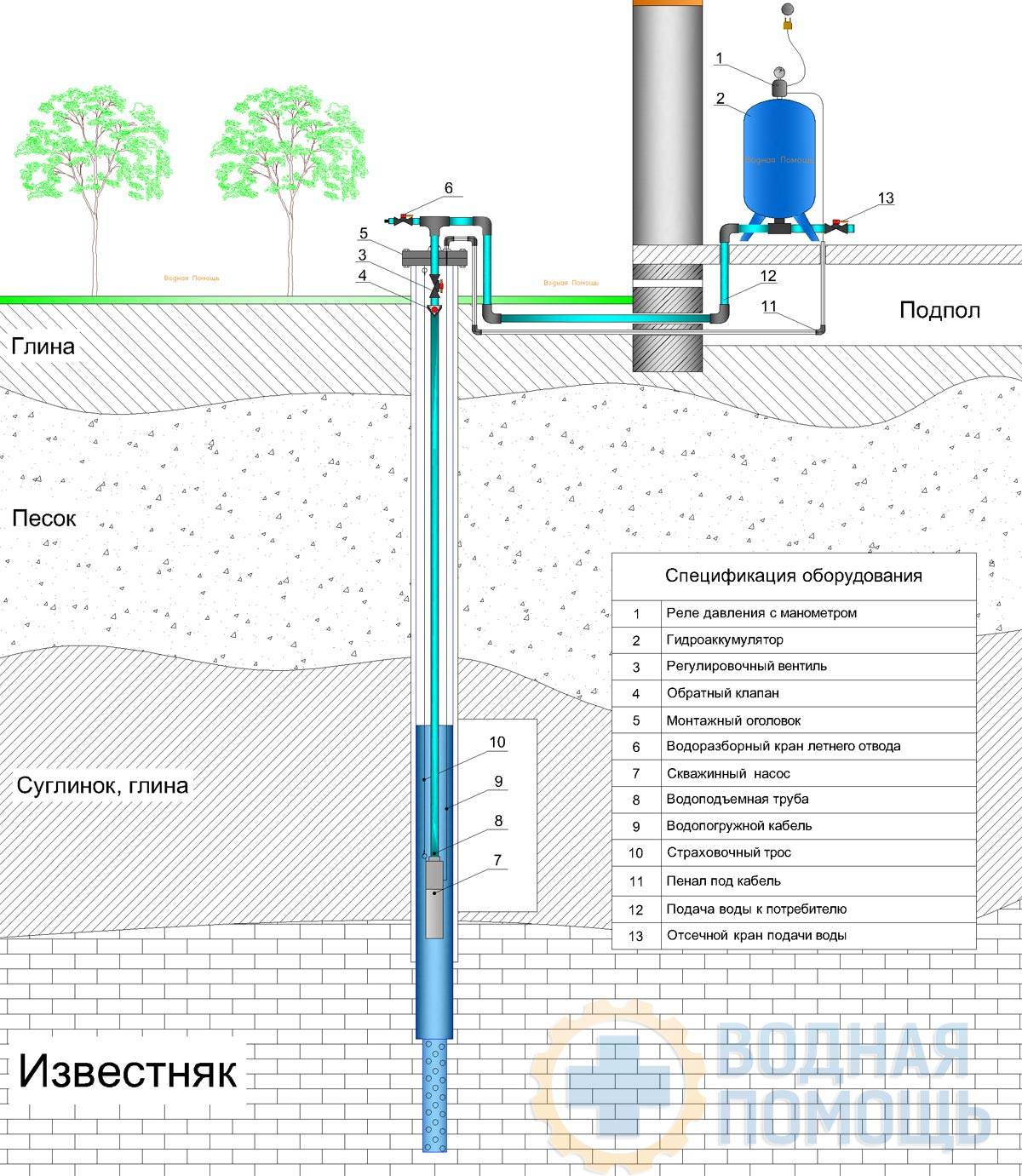

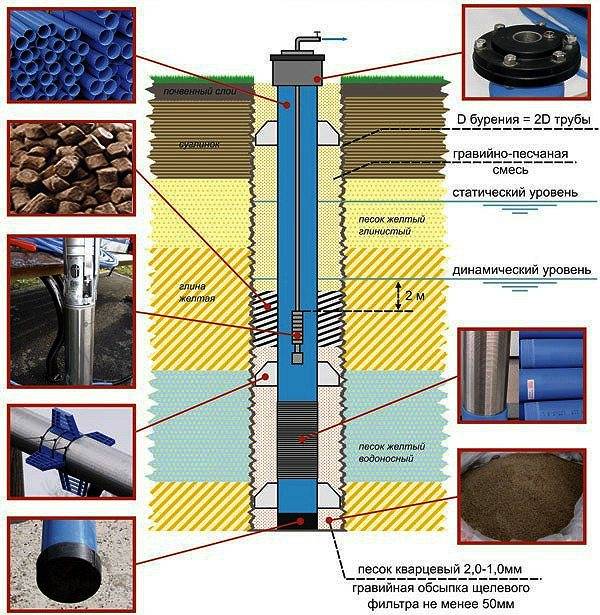

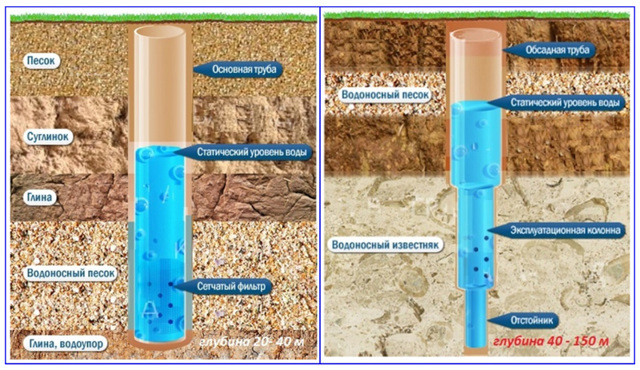

An example of a typical well scheme.

To build up the source, an ordinary inexpensive submersible type model is sufficient.When doing work, be prepared for the fact that the pump may break, and more than once. It will have to be repaired or replaced with a new one. That is why it is not recommended to buy too expensive units.

It is important that such a "temporary" pump is just submersible and centrifugal. A vibration-type unit simply cannot bear this load.

It will break very quickly, which will entail additional costs.

The next step is the correct suspension of the pump. The main point in this procedure is the determination of the height of the device. The pump should be located near the bottom line of the source, about 70-80 cm above it, almost at the same level as the gravel filtration backfill. With this arrangement, the silt will be successfully caught and quickly removed from the source.

In order for the pump to work as long as possible in such conditions, periodically stop it, lift it up and flush it by passing a clean liquid through it.

Submersible pump device.

It is very difficult to establish a specific time for pumping a well before starting work. The process can be completed only when clean water begins to flow from the source. The result directly depends on the intensity of rocking. The more water is pumped out of the well, the faster the sand and other particles will leave. Large sand that has not passed through the filter will gradually settle to the bottom and create an additional filtration layer.

According to professional well drillers, during the pumping process, more than one ton of water has to be removed from the source. On average, at a depth of 50-500 m, it takes 2 days.If the depth is less, then the time spent is reduced. The owners of sites on clay and limestone soils will have to deal with pumping for the longest time.

Well flushing after drilling

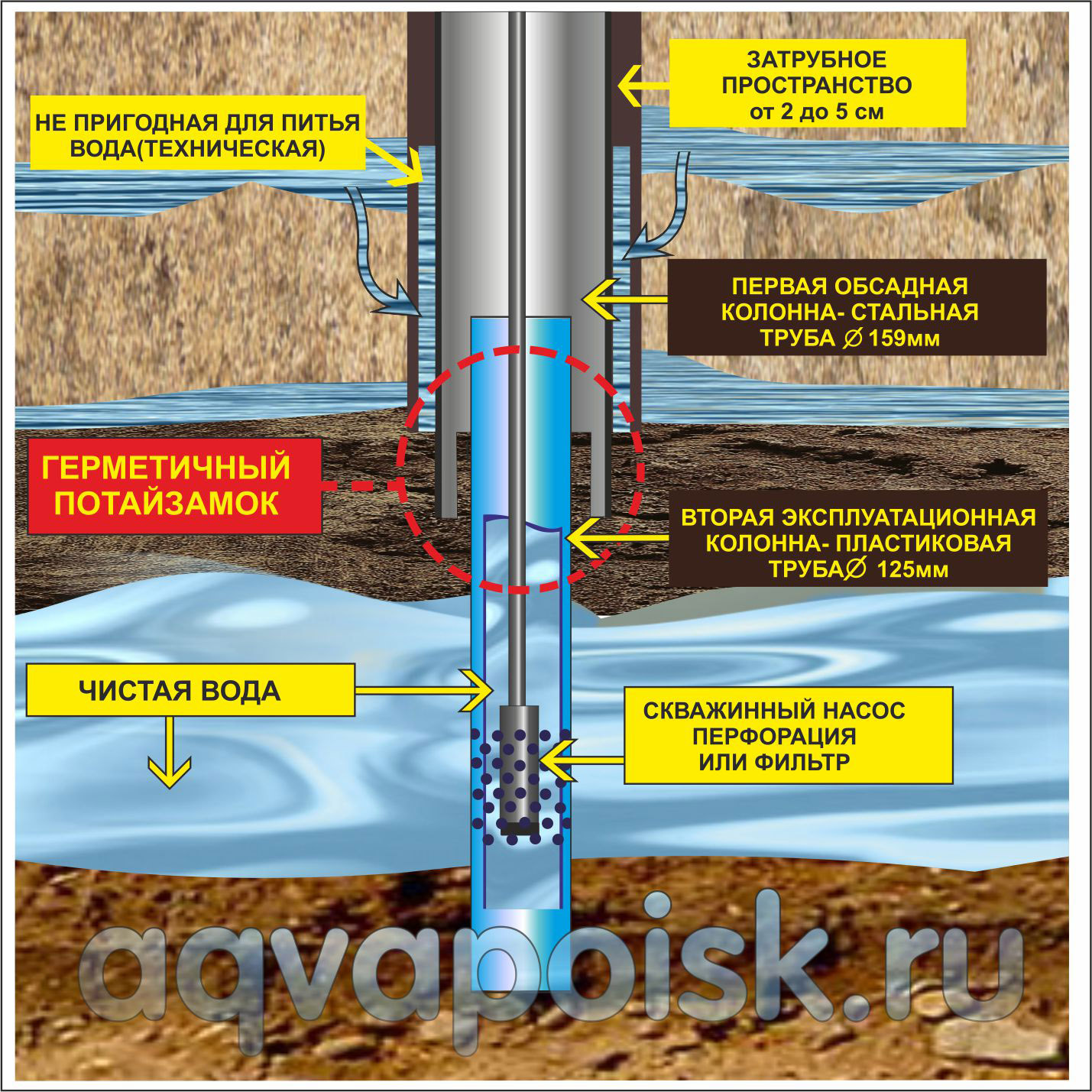

Well flushing is carried out using pipes that sink to the bottom and supply water at the highest possible pressure. The pressure of the water washes out the silt and all the dirt that has accumulated during the operation of the well. When flushing, the accumulated dirt particles rise through the pipes and are removed to the outside.

When flushing a clogged well while drilling, it is very important to be careful to avoid damaging the filter.

It is not recommended to flush the well before starting the casing procedure, as rock collapse may begin, and this will lead to clogging of the mouths.

For the tightness of the cleaning process, it is necessary to fix the pump on the upper part of the pipe by putting an adapter on it, and this adapter is fixed with pipes with self-tapping screws in the amount of 4 pieces. The volume of water used will depend entirely on the size and characteristics of the well, as well as the degree of contamination.

The task of pumping a well after drilling

When the well is pumped after drilling, all particles and inclusions, even the smallest ones, are removed from the wellbore and from the nearby aquifer, and this is reflected in the fact that at the first stage of pumping, a very dirty liquid will flow from the well. However, in the future, as it is pumped, it will begin to brighten, and the more water is pumped out, the lighter the result will be.

Sometimes pumping requires really big efforts - so, if we talk about deep objects created in limestone or clay soil, then here it can take several weeks to pump, and only in this case it will be possible to get a quality result.

If we consider not too deep sandy wells, then pumping here usually takes about 12 hours. Long-term work on alumina is associated with the fact that in the process of drilling on such soils a clay solution is formed, which makes the water cloudy, and it is equally successfully formed both during drilling and during washing.

Clay breaks up into small particles, which are washed out with great difficulty, and therefore it takes a very long time to pump the well. Nevertheless, properly carried out pumping will allow you to end up with high-quality and clean water that will meet all the requirements, and this process will also allow you to operate the well for a long time.

Thus, in the case of water drilling there are no trifles, and each of the stages is significant. Understanding all aspects of such a craft can be difficult, and even professionals sometimes have difficulty with some things - for example, with access to new technologies and the study of the latest modern equipment.

Well pumping methods

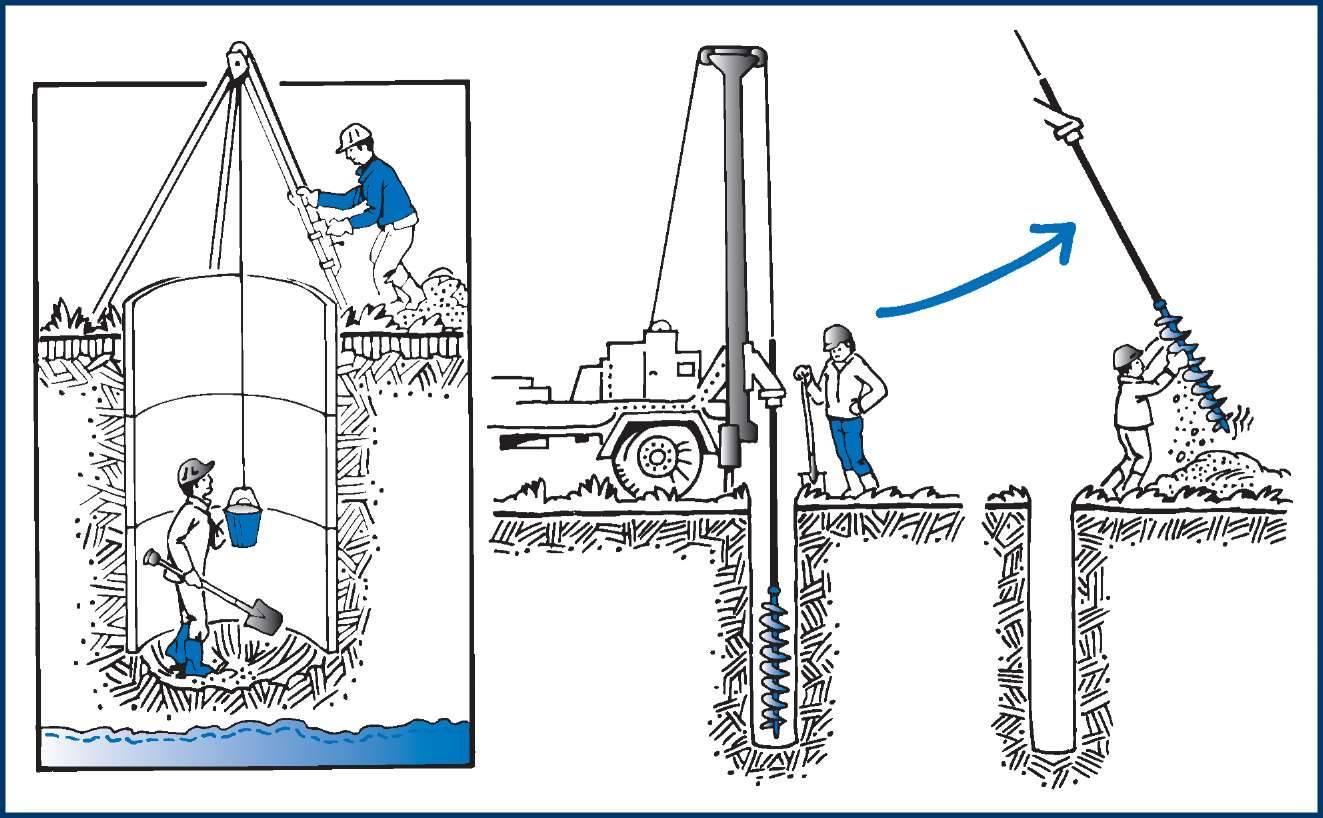

Cleaning a clogged well can be done in several ways:

- Cleaning the well from clay with a pipe.

- Using a vibratory pump with a nozzle.

- The process is carried out simultaneously by two pumps. Usually it is deep and rotary.

Such methods can be used separately, or alternately, depending on the depth of the mine and the degree of clogging.

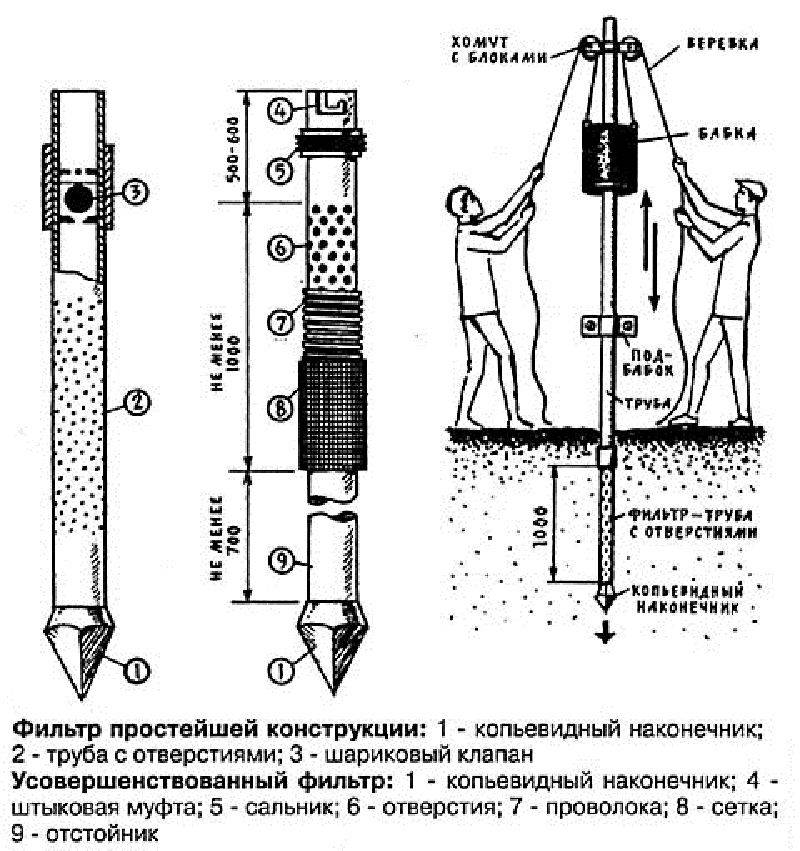

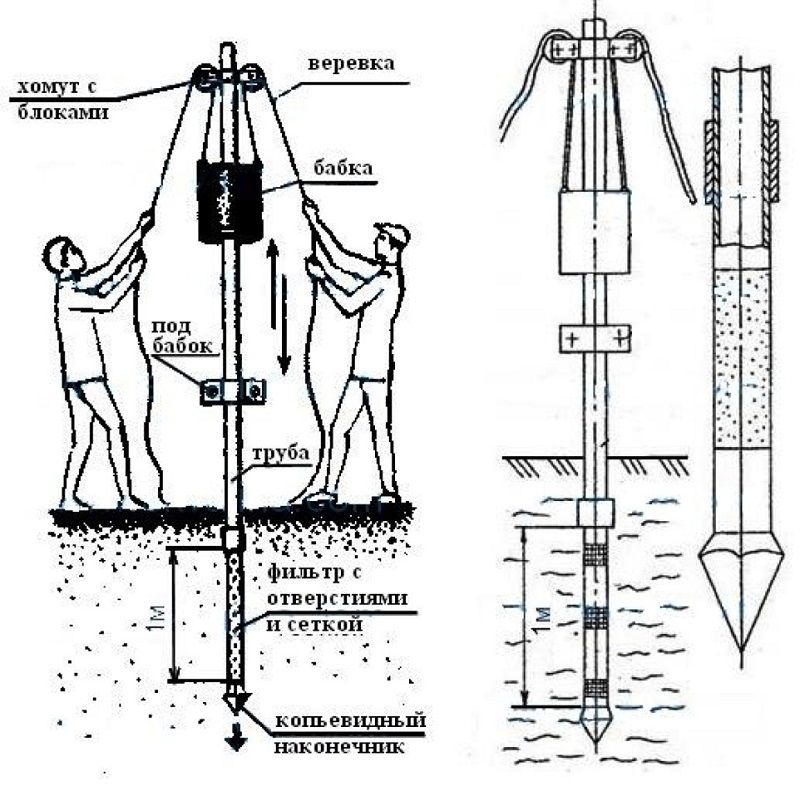

Cleaning a well with a bailer or pipe

Sectional bailer

Before cleaning water from a well from clay using a bailer, you need to:

- Remove the deep pump and free the shaft completely from foreign objects.

- Fix the bailer on a rope or a sufficiently strong metal cable and smoothly lower it to the bottom.

- After reaching the bottom, the bailer rises 50 centimeters and then drops sharply under its own weight.

- From a sharp blow to the bottom, the clay begins to move, and the free space is filled with its particles.

- From a sharp fall, the intake channel opens a metal ball, and water with clay goes inside the bailer.

- When lifting, the channel closes the ball, and dirty water is retained in the cylinder.

- Such movements must be repeated 2-3 times, then the cylinder slowly rises to the surface.

Each such procedure lifts up from 250 to 500 grams of clay. This cleaning process is lengthy, but in practice it turns out to be quite effective.

Cleaning the well with a vibration pump

The easiest and fastest cleaning option is to use a vibration pump. It is used in all types of structures, especially in mines where the receiver is narrowed, and cleaning with a deep unit is not possible.

Further, the cleaning process occurs in the following order:

- A durable rubber or durite hose is put on the water intake and securely fastened with metal brackets.

- The length of the hose depends on the size of the constricted section.

- The hose must have sufficient rigidity so that it does not bend when it hits the ground.

- The pump descends to the bottom of the shaft, then rises by 5-10 centimeters and turns on.

- The hose collects and pushes the sludge deposit to the surface, but with such a heavy load and clogged valves, the pump will quickly break down.Therefore, it is recommended to periodically remove it from the shaft for washing with clean water.

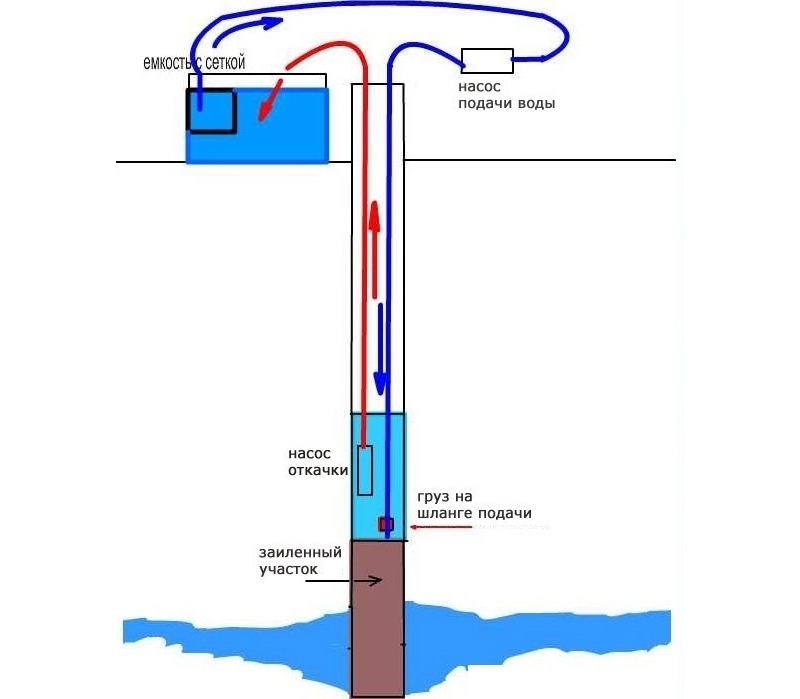

Cleaning with two pumps

The method is characterized by a long duration, but at the same time a person may not participate in the process.

Before you clean the well from clay by this method, you need to prepare in advance:

- Up to 300 liters capacity for liquid.

- Centrifugal pump for pumping water.

Centrifugal pump

Deep pump cleaning

Deep pump

This method is as follows:

- From the tank, a centrifugal pump will supply water under pressure through a hose to the bottom of the well, while washing away the clay deposit.

- A deep pump will pump water back into the tank with washed clay. This forms a closed flushing system.

- The deep pump rises from the bottom of the well by 15 centimeters.

- A weight is attached to the end of the injection hose immersed in water or a metal tube is put on to prevent twisting of the end and direct it clearly to the bottom of the shaft.

- It is better to put a filter on the suction hose of a centrifugal pump so that small pebbles or sand do not accidentally enter the pump.

How bentonite clay is used for drilling wells can be found in the video. This article gives the most common methods for cleaning clay from wells.

How to pump a well after drilling?

Well construction work requires certain knowledge and qualifications, but the question is: “How to pump the well after drilling?” - not only specialists can decide.

Appointment of the buildup of the well after drilling

Swinging is a special process designed to clean the well from the soil after it has been drilled.If this process is not carried out, then soon the well will silt up to such an extent that it will interfere with its work. This is a natural process that will happen over time. Therefore, well maintenance and cleaning should be done regularly.

The smallest grains of sand that are not captured by filters are present in any aquifer. Grains of sand or other small particles, when they enter the well, accumulate over time and occupy its area, which significantly impairs productivity.

With a properly performed buildup, all small elements rise from the well and the nearby water layer. In this case, the liquid supplied from the well will be cloudy, which is a confirmation of the effectiveness of the work performed. Gradually, the water will become more and more pure.

Before swinging the well after drilling, it is necessary to make sure that the equipment is properly set up and the power supply is available, as this process can take up to 12 hours in sandy soil.

As for wells drilled in limestone or clay soil, their buildup can take from several weeks to several months.

Technology of well stimulation at the exhibition

This process, in fact, is a simple pumping of water. However, there are several points that require attention from those who produce it. First of all, this is a competent choice of a pump that can build up.

At the same time, you should not choose expensive powerful models. It is better to opt for a simple submersible pump.In the process of buildup, it can even fail several times, since it is rather difficult to pump a turbid suspension, but at the same time it will be able to complete the task.

It is worth paying attention to the height of the pump before starting work. It should not be too close to the water surface

Otherwise, he will not be able to capture fine particles from the bottom of the well, and his work will be useless. Burying the apparatus is also not worth it due to the fact that it itself can become clogged with silt and stop functioning. A "buried" pump is also difficult to remove to the surface for cleaning.

Technologies and rules for well swaying after drilling are covered at many forums and congresses, including at the largest industry exhibition "Neftegaz", which will be held at the Central Exhibition Complex "Expocentre". Among other topics, it also covers this issue, as well as new technologies related to it.

Research carried out by industry experts in this area provides, first of all, an increase in the efficiency of the buildup process, as well as its acceleration.

Exhibition "Neftegaz" in the Central Exhibition Complex "Expocentre" – a great opportunity to evaluate the latest developments in this area, as well as get acquainted with samples of modern equipment designed for well stimulation.

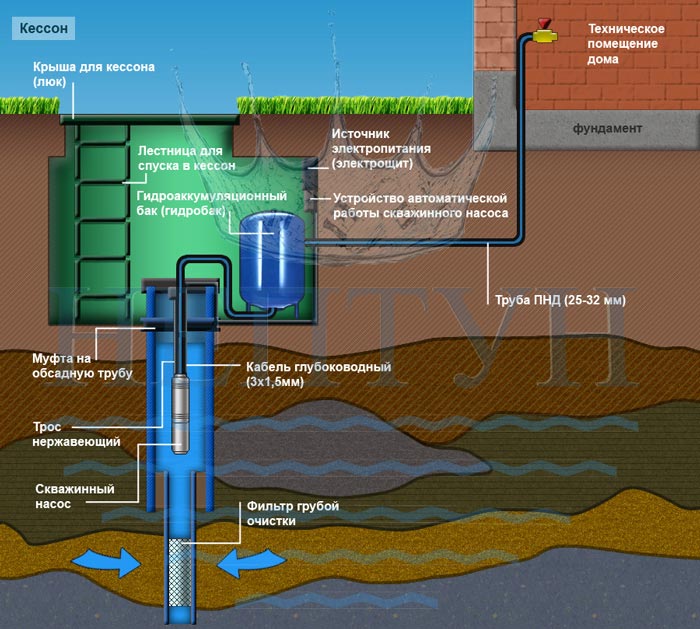

Preparing for a long downtime and pumping after it

If a visit to the summer cottage in the winter (or for another long period) is not expected, and the well will not be used either, then you should take care of this in advance. It is necessary to consider preparing the device for inactivity and how to pump the well after a winter or a long downtime.

Preparation comes down to installing a heating cable inside or using any materials at hand to insulate the device.

Well pumping after winter is carried out by standard methods, which are described above, and are used only if necessary.

An example of well insulation for the winter

Work performance technology

The main thing when starting a well with a pump is to install it correctly. You need to lower the equipment almost to the very bottom. The distance from the bottom of the well to the inlet of the unit should be 40-70 cm. If you raise the device higher, this will not give the expected effect. If you lower the pump to the very bottom, it will pump only rocks (sand, clay) and will quickly fail. In addition, with a low installation of the unit, there is a high risk that it will simply become mired in sludge masses. It will be extremely difficult to lift it from there.

Water with an admixture of mud is diverted either to the nearest ravines or to country roads. The main thing is that it does not bother anyone. Yes, and it is undesirable to drain muddy slurry close to the well, since the mud can again ooze into shallow aquifers.

The principle of flushing a well looks like this:

- Pumping equipment is lowered into the source shaft to the desired mark.

- The equipment is connected to the network and pumping of dirty water begins. You need to work continuously to get ahead of the water supply of the source.

- The unit is regularly lifted, washed and lowered into the well again.

- Work is carried out until the appearance of completely clean water.

Description of the work technology

Actually pumping a well is an ordinary pumping of water

However, there are several aspects to which special attention should be paid.

Choosing the Right Pump

Even if the owner has prepared a powerful water supply device, you should not lower it into the well. Experience shows that high-quality expensive equipment will come in handy later, for pumping clean water. Whereas, especially for the buildup process, it is advisable to purchase an inexpensive submersible pump. Most likely, he will regularly fail, pumping a muddy suspension, but he will bring his work to an end. At the same time, the more expensive “permanent” option will remain unscathed and will be able to work perfectly on clean water. Another caveat: the “temporary” pump must be a submersible centrifugal pump, since vibration models simply cannot cope with such a load.

Suspension of the pump

When thinking about how to pump a well after drilling, you should pay special attention to the height of the pump. It should be close to the line of the bottom of the well, 70-80 cm above its mark, practically on the same level with the gravel pack

In this case, the sludge will be captured and actively removed to the outside. In order for the pump to work in this mode for as long as possible, it must be periodically stopped, removed and washed, passing clean water through it.

Time required for buildup

It is difficult to determine immediately how much time it will take to build up the well.

The process should continue until clean water appears. The intensity of the swing directly affects the result. The more water is pumped out, the more sand and other small particles go with it. Coarse sand that has not passed through the filter settles to the bottom, forming an additional filter layer.

The duration of the buildup process depends on the composition of the soil on which the well is equipped

Experts say that in order to completely clean the well, more than a dozen tons of water must be pumped out of it. On average, with a structure depth of 50 to 500 m, the process should take at least 48 hours, with a smaller depth, respectively, less.

Mistakes to avoid

In the behavior of the buildup of a new well, errors occur that disrupt the cleaning process.

The most typical are:

- Pump too high. It should not be placed near the surface of the water. Otherwise, the use of the equipment will be useless: it will not be able to capture fine particles, which are most abundant in the bottom part of the well. In this case, despite the measures taken to build up, the well will quickly silt up and stop producing water.

- Pump set too low. A buried device will not be able to function properly. It will very quickly clog with suspension and stop. In addition, the pump can "burrow" in the silt. It is very difficult to extract the apparatus pulled into the ground to the surface.

- Illiterate water disposal. Pumped out dirty water should be discharged as far as possible. Otherwise, it can again fall into the well, and then the buildup process can last almost indefinitely.

- Descent of the pump on an insufficiently strong cord supplied with it. It's better not to. The device can get stuck in the well or be sucked into the silt. In this case, pulling it out by the cord is unlikely to succeed. It is worth buying a strong thin cable and using it to lower the pump for buildup.

Ways to deal with silting

The water in the well will always be clear and clean if preventive maintenance is carried out from time to time.

Each owner of the structure needs to know how to pump the well in order to prevent re-silting. To do this, during periods when water intake is reduced, you should regularly turn on the pump for two to three hours. If, nevertheless, despite all efforts, a plug of silt has formed at the bottom, you can try to wash it out. A hose is lowered into the well to the pump, through which clean water is supplied under pressure. It will wash away unwanted bottom sediments, rise up through the annular space and splash out of the well. The procedure should be carried out until gravel from the bottom filter begins to come to the surface along with water. Next, carry out the usual buildup.

The well is quite easy to operate

It is important to competently carry out drilling work and equip the structure, which subsequently will not cause much trouble. It is very important to know how to properly pump a well so that it produces a large volume of crystal clear water.

High-quality rocking work is the key to a long and trouble-free operation of the structure.

How long does it take to pump a well after drilling, and what to do if the process drags on?

From deep artesian wells, water mixed with silt or clay can be pumped out for months

When pumping work goes on and on, but there is no result, you should pay attention to whether such mistakes are made:

- The submersible pump hangs very high from the bottom, and the water that rises from the very bottom of the shaft simply does not pump.

- The submersible pump is almost drowned in silt or sand because it is lowered too low. In this case, the device will simply burn out or sink completely in the bottom layers of the soil, and the well cannot be used.

- The pumped water pours out too close to the mouth of the mine, because of which it again descends into the well and pollutes it.

Before pumping a well after drilling, it is important to find out its exact depth and check yourself or the invited masters on the three above points.

How to download?

Powerful submersible pump

Let's start with the question: Was the well made by a company, or covens? Further actions depend on the answer, since in the first case this service is included in the terms of the contract (if you, out of ignorance, did not refuse it). This is done using a powerful submersible centrifugal pump capable of pumping from 3 to 6 m³ / h of water containing a large amount of impurities. Such a pump sinks almost to the bottom of the well, and with a powerful suction stream it will pull out all the rubbish.

If you “saved” on pumping by hiring shabashnikov, the cost of which is less than that of professional drillers, but at the same time they are not responsible for anything, then you will have to pump the well yourself. To do this, you will need to purchase an inexpensive pump of domestic production.

Do not rush to say that you do not need it, since an imported one specially purchased for this purpose is already available. What kind of water will we pump out? Almost a swamp with sand and various rubbish! So if you are in a hurry to install your expensive branded priming pump, then get ready to say goodbye to it, as it is simply not designed for such work.

Let's get back to an inexpensive domestic pump, which may not even “survive” until the end of the flush:

- Attach a stainless steel cable to it, and lower it to the bottom of the well.

- Then lift centimeters by 30-40 and secure in this position. Now you can turn it on.Seeing how the water went, you yourself will be glad that you did not put an expensive pump.

- In order for your "Kid" (or "Brook") to serve as longer, you need to pull it out from time to time, and give it the opportunity to clean itself with clean water, and then lower it back into the well.

The pump must not be in the same position. It must be slowly raised and lowered by 4-6 cm, while not making sudden movements. This is necessary so that the sand from the cork rises in parts and does not clog the hose.

The pump must be gradually lowered lower and lower in order to clean the bottom of the well from all that is superfluous. If suddenly water stops flowing from the hose, then most likely the pump has sucked. In this case, it must be immediately disconnected from the power supply and pulled out, and this would not have happened without an attached cable, since the silt firmly holds everything that gets into it.