- Filling gas cylinders

- The design of cylinders for gaseous oxygen, the marking of cylinders, the causes of their explosion.

- An alternative way is a warm room

- How to warm up a gas cylinder?

- Why are the cylinders covered with frost?

- How to make thermal wraps at home

- How often can procedures be performed

- Efficiency

- Possible harm

- Power consumption

- Disposal of cylinders with a gas mixture

- Gas for heating: pros and cons

- The situation on the street

Filling gas cylinders

In some villages there are teams with auxiliary workers and equipment for their delivery. If there is no such service, then you have to buy cylinders on your own, or look for GZS to fill them with liquefied gas (read: “Liquefied gas boiler: fuel consumption for heating“).

Heating from gas cylinders is cheaper if they are refueled. However, it should be borne in mind that at some GZS they seek to save money and fill only half of them. At the same time, the station employees say that the gas boils at only 40 degrees, so it is unreasonable to fill a full cylinder - it can burst. At the same time, purchased products are almost completely filled with gas. Therefore, such proposals should not be accepted.Heating the house with bottled gas is quite economical. One cylinder with a capacity of 50 liters is enough to ensure the normal operation of the heating system with a capacity of 10-20 kW. It is recommended to buy automatic devices - they do not work all day, but about a third of the day, starting gas heating of a private house with cylinders only when the temperature drops below the specified one. The functioning of conventional systems has to be regulated independently. Thus, if you specify the required room temperature at 20 degrees, the boiler will consume approximately 5 m³.

Regardless of whether there is automation or not, in order to save money, it is advisable to turn off the boiler at night.

The design of cylinders for gaseous oxygen, the marking of cylinders, the causes of their explosion.

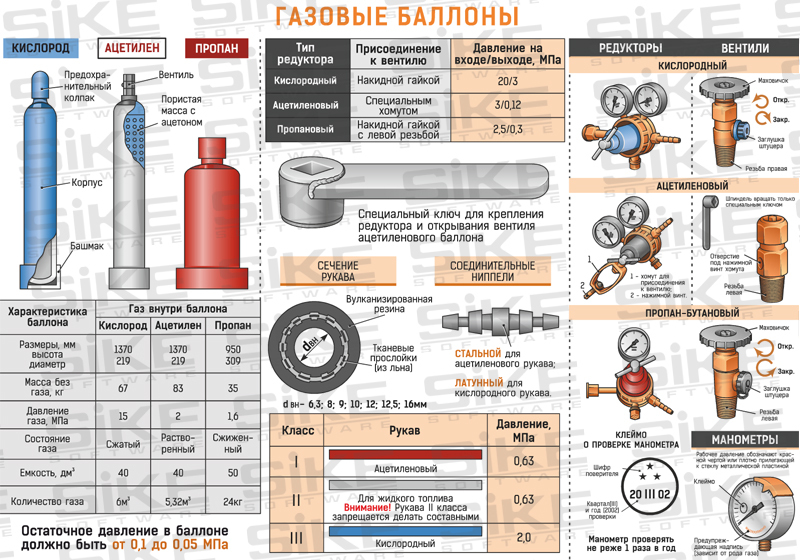

Cylinders for compressed gases

Steel cylinders are used for storage and transportation of compressed, liquefied and dissolved gases under pressure. Cylinders have different capacities - from 0.4 to 55 dm3.

Cylinders are steel cylindrical vessels, in the neck of which there is a conical threaded hole, into which a shut-off valve is screwed. Each gas has its own design of valves, which excludes the installation of oxygen valves on an acetylene cylinder and vice versa. A ring with an external thread is tightly fitted onto the neck to screw on a safety cap, which serves to protect the cylinder valve from possible shocks during transportation.

Cylinders for compressed, liquefied and dissolved gases are made from seamless pipes of carbon and alloy steel. For liquefied gases at a working pressure of not more than 3 MPa, the use of welded cylinders is allowed.

Depending on the type of gas in the cylinder, the cylinders are painted on the outside in conventional colors, and the name of the gas is applied with the paint corresponding to each gas. For example, oxygen cylinders are painted in blue, and the inscription is made in black paint, acetylene - in white and red paint, hydrogen - in dark green and red paint, propane - in red and white paint. Part of the upper spherical part of the cylinder is not painted and the passport data of the cylinder is stamped on it: the type and serial number of the cylinder, the trademark of the manufacturer, the mass of the empty cylinder, capacity, working and test pressure, the date of manufacture, the stamp of the OTK and the stamp of the Gosgortekhnadzor inspection, the date of the next tests. Cylinders are periodically, every five years, subjected to inspection and testing.

The main types of cylinders used for the storage and transportation of oxygen, nitrogen, hydrogen and other gases are shown in the table.

oxygen cylinders

For gas welding and cutting, oxygen is delivered in steel oxygen cylinders of the type 150 and 150 L. The oxygen cylinder is a seamless steel cylindrical vessel 3, having a convex bottom 1, on which a shoe 2 is pressed; at the top, the cylinder ends with a neck 4. There is a conical hole in the neck, where a shut-off valve 5 is screwed in. A safety cap 6 is screwed onto the neck to protect the valve.

The most widely used in gas welding and cutting are cylinders with a capacity of 40 dm3. These cylinders have dimensions: outer diameter - 219 mm, wall thickness - 7 mm, height - 1390 mm. The mass of the cylinder without gas is 67 kg. They are designed for a working pressure of 15 MPa, and a test pressure of 22.5 MPa.

To determine the amount of oxygen in the cylinder, you need to multiply the capacity of the cylinder (dm3) by the pressure (MPa). For example, if the capacity of the cylinder is 40 dm3 (0.04 m3), pressure is 15 MPa, then the amount of oxygen in the cylinder is 0.04x15=6 m3.

Figure 1 - Oxygen cylinder

At the welding station, the oxygen cylinder is installed in a vertical position and secured with a chain or clamp

To prepare the oxygen cylinder for operation, unscrew the cap and the plug of the fitting, inspect the valve to determine if there is any fat or oil on it, carefully open the cylinder valve and purge its fitting, then close the valve, inspect the union nut of the reducer, attach the reducer to the cylinder valve , set the working pressure of oxygen with the adjusting screw of the reducer. At the end of gas extraction from the cylinder, it is necessary to ensure that the residual pressure in it is not less than 0.05-0.1 MPa

When handling oxygen cylinders, it is necessary to strictly follow the rules of operation and safety, due to the high chemical activity of oxygen and high pressure. When transporting cylinders to the welding site, it must be firmly remembered that it is forbidden to transport oxygen cylinders together with combustible gas cylinders. If the valve of the oxygen cylinder freezes, it must be warmed up with a rag soaked in hot water.

The reasons for the explosion of oxygen cylinders can be fat or oil getting on the valve, falling or hitting cylinders, the appearance of a spark when the gas is taken too much (the neck of the cylinder is electrified), heating the cylinder by some heat source, as a result of which the gas pressure in the cylinder will become higher than the permissible one.

Table 1 - Types of cylinders for liquefied gases

| Cylinder type | Pressure, MPa | Tensile strength, MN/m2 | Relative extension, % | ||

| conditional | hydraulic | pneumatic | |||

| 100 | 10 | 15,0 | 10 | 650 | 15 |

| 150 | 15 | 22,5 | 15 | 650 | 15 |

| 200 | 20 | 30,0 | 20 | 650 | 15 |

| 150L | 15 | 22,5 | 15 | 900 | 10 |

| 200L | 20 | 30,0 | 20 | 900 |

An alternative way is a warm room

In order not to look for ways to insulate tanks installed on the street, you can do it easier - move the cylinders to a heated room. In comfortable conditions, the cylinders “give away” almost the entire volume of fuel, so refueling needs to be done less often, and there are no problems with the movement of gas inside the supply system.

The main thing is to follow the installation and operation rules:

- the balloon is installed vertically;

- the vessel must be accessible for maintenance, inspection or replacement;

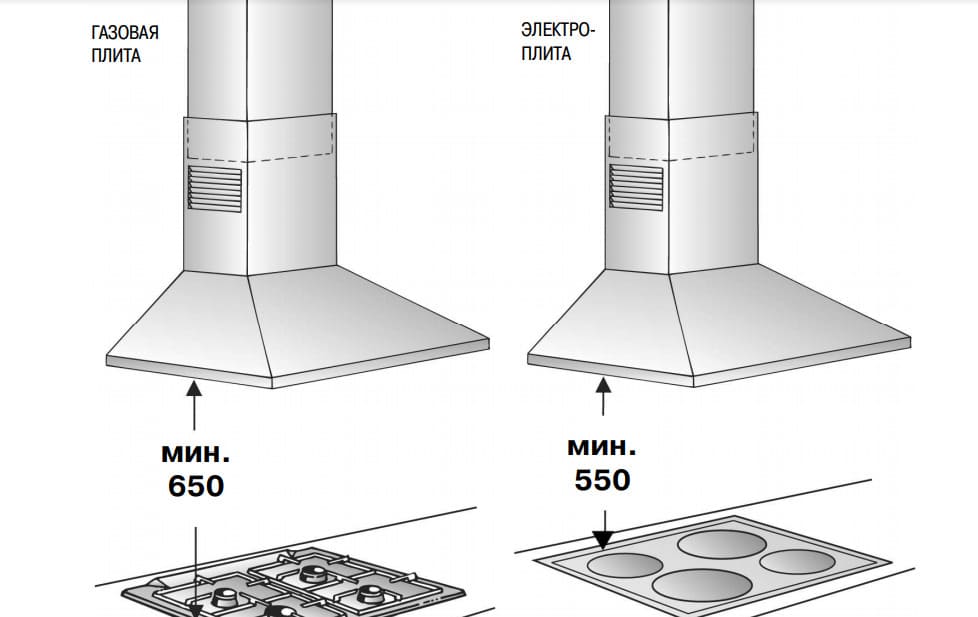

- the distance from the tank to the stove - at least half a meter, to the radiator or stove - at least 1 m;

- if a firebox is located opposite, the distance is increased to at least 2 m.

One of the main requirements concerns the choice of room for installation.

Do not install in the bedroom, living room or other living rooms. The cylinder is installed in the room where the gas-consuming equipment is located - a stove, that is, in the kitchen

Do not install in the bedroom, living room or other living rooms. The cylinder is installed in the room where the gas-consuming equipment is located - a stove, that is, in the kitchen

A liquefied gas tank is usually installed either right next to the stove, or in a neighboring non-residential premises, by throwing the fuel supply hose through a hole in the wall.

Cylinders must not be kept in basements, basements and any other premises that are not equipped with ventilation or a ventilation system.

And remember an important condition: if your house has more than 2 floors, placing any gas containers inside the building is prohibited!

How to warm up a gas cylinder?

And now let's look at how to ensure the correct operation of gas equipment at low air temperatures, and what can be done so that the gas does not freeze. To resolve this issue, there are several options.

First of all, try to transfer the gas cylinder to a warm room, after a while the frost from the surface will gradually evaporate, and the conditions necessary for converting liquefied gas into a vapor state are formed inside the cylinder. After that, the gas supply will be restored, and the gas appliance can be used for its intended purpose.

But, if it is not possible to transfer the equipment, then it is necessary to heat the tank on site so that the gas inside does not cool. Very often, owners of gas appliances resort to heating the cylinder by direct exposure to fire. It is strictly forbidden to perform such actions, as this contributes to the rapid conversion of gas into a vapor state, respectively, the pressure in the container is growing rapidly and can cause an explosion.

To reduce the likelihood of fuel cooling, you can insulate the cylinder with special materials that prevent the penetration of cold. But this method is suitable for small temperature changes in the environment.

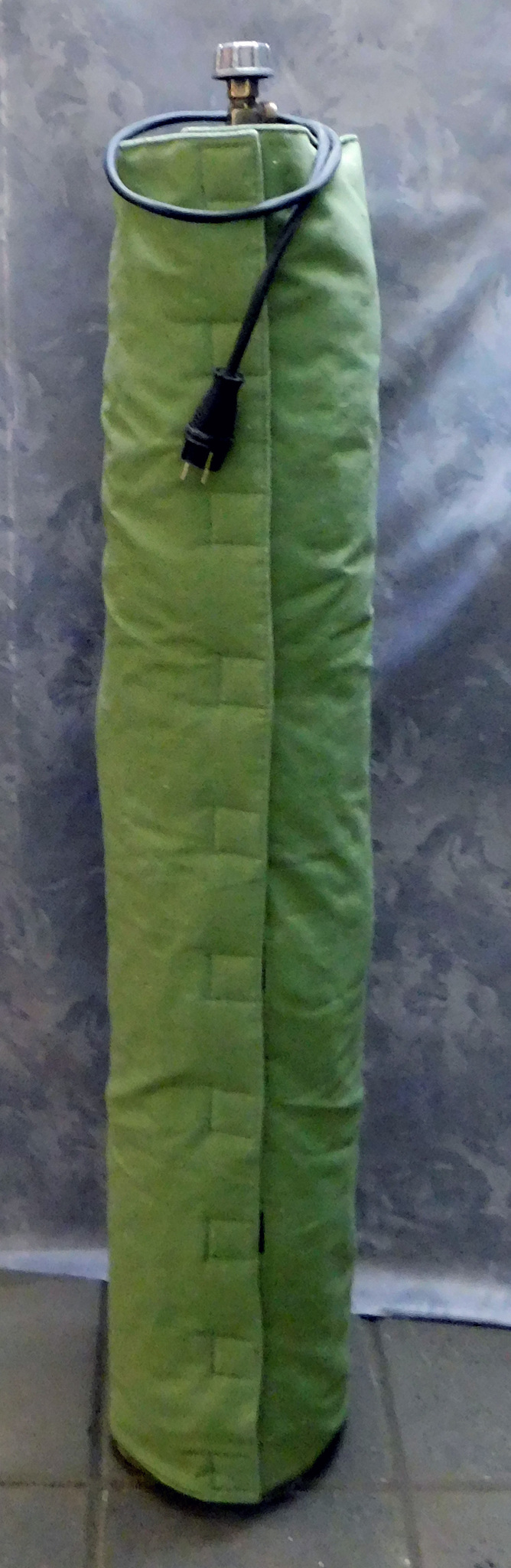

If the temperature is colder outside, then you can use special heating equipment.An electric heater is able not only to warm the gas cylinder, but also to provide a constant temperature at which the device will perform its functions with the greatest efficiency.

Thus, fuel consumption is reduced by up to 30 percent.

Why are the cylinders covered with frost?

Here you can also debunk one of the most common misconceptions. It is generally accepted that if such a device "freezes", then it becomes covered with frost. Some even argue that it is necessary to insulate such equipment with blankets, old coats and other improvised devices. So, the frost will disappear faster if the gas container is left as it is, without helping it to “thaw” with warm clothes.

The bottom of the gas cylinder, which is covered with frost

The appearance of frost can be explained by a number of physical processes that occur inside the structure when it is connected to furnaces or burners. At such moments, active fuel consumption is observed, therefore, large volumes of gas liquid turn into a vapor fraction. And such a phenomenon is always accompanied by a large consumption of heat, it is for this reason that the surface of the cylinder becomes much colder than the temperature in the surrounding space. Moisture in the air space begins to appear in the form of condensate on the walls of the installation, subsequently turning into frost. This is a completely natural phenomenon, with which nothing needs to be done.

Moreover, all attempts to use artificial "insulation" violate safety standards during operation, and also affect the deterioration of the heat exchange of the device with the environment and affect the conditions of gas supply.If your burner did not please with a grandiose flame, then after your “maneuvers” with a blanket, it may stop working altogether.

Do not insulate gas cylinders with anything!

In general, when connecting gas devices with high power, you need to be aware that the gas cylinder has limitations in terms of recoil speed. This means that the liquid fuel is converted into the steam stage gradually. For example, a 50 liter tank can provide about 500 grams of gas in 60 minutes. This is equivalent to a power of 6-7 kW. In the cold season, this figure is halved if the equipment is located outside. In summer, the situation is reversed: the maximum flow rate increases.

In any case, it can be concluded that frost is evidence that the cylinder cannot cope with high fuel consumption. This can cause a temporary drop in gas pressure and equipment failure. If this happens, it is better to stop consumption and wait until a sufficient vapor head has formed.

How to make thermal wraps at home

Thermal wraps are a spa treatment that allows you not only to get benefits for your body, but also to relax and unwind. You can also have a session at home, the main thing is to follow the precautions. The use of a thermal blanket for wrapping increases the effectiveness of the procedure by 2 times

Models with infrared heating function increase the therapeutic effect. The main area of application is weight loss.

It is worth alternating different wraps in one course so that the epidermis does not get fed up. Before the procedure, you need to prepare the body.Cleansing and massaging will help the substances in the mixture work better.

How often can procedures be performed

The course consists of 12 procedures. A visible result is achieved after the fifth wrap. Between courses it is worth taking a break of at least 2 months. At this time, it is necessary to continue the usual care of the body. Supportive thermal wrapping procedures are allowed once a month.

The interval between sessions depends on the activity of the substance used. Wraps should not be carried out more often than twice a week: the body must recover.

Efficiency

Thermal wrapping has a cumulative cosmetic effect in the form of smoothing the skin relief, making it smooth.

It lasts for a long time with proper care and proper nutrition. But if the goal is to lose weight, body wraps and massage treatments alone are indispensable. It is necessary to give the body physical activity in order to maintain in good shape not only the skin, but also the muscles.

Possible harm

When thermal wrapping, an allergy to the components of the active mixture is possible. The vessels dilate, which can be detrimental to varicose veins. Acceleration of blood circulation will also be harmful during the menstrual cycle. Contraindications should be clarified with a specialist during the examination.

Precautionary measures

At home or in the salon, you need to monitor the quality of the ingredients applied to the skin. The individual tolerance of the substance also plays a role, so it is worthwhile to conduct an allergy test in advance on a small area of \u200b\u200bthe skin. Do not warm up the abdomen, chest. This measure is necessary to avoid an undesirable effect if there are hidden contraindications. You need to follow the instructions for using the electric blanket.

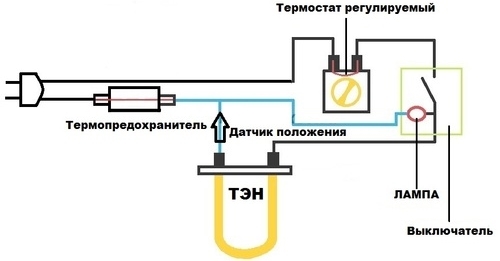

Power consumption

One double electric blanket consumes 70-110 watts. This is less than the average desktop computer. A single blanket is comparable to an incandescent lamp - almost 60 watts.

Disposal of cylinders with a gas mixture

Compliance with the rules of safe disposal is mandatory for gas cylinders with any composition. They must be handed over to specialized points of reception / exchange. Despite the fact that propane-butane gas is contained in the tank at a lower pressure than methane, the possibility of an explosion remains. The reason for this is the high residual pressure of propane.

Some companies offer a profitable exchange of old containers for new ones or make significant discounts on the purchase of new cylinders when returning used containers.

The main motives for self-opening old containers are the use of empty containers for household purposes and scrapping. Experts advise to abandon such ideas or take the help of professionals. The main thing is to remember that a whole cylinder is never completely free of a gas mixture.

An excellent solution is to hand over the cylinder to a private service company. As a rule, their prices significantly exceed the benefits of scrapping the container. An additional bonus is self-delivery, when representatives of the organization go to pick up equipment at the specified address.

Gas for heating: pros and cons

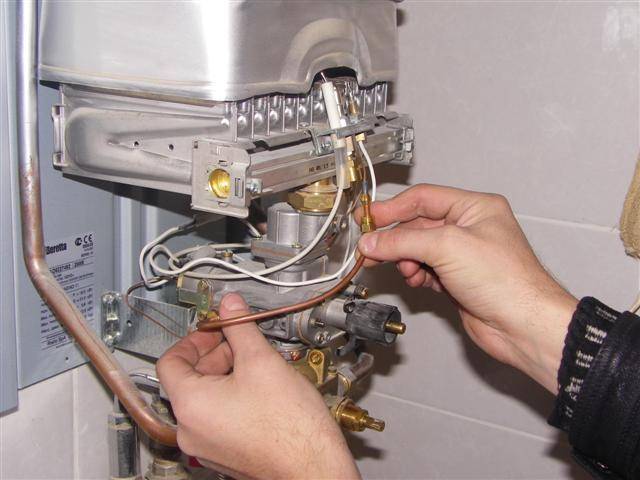

Gas boiler connected to cylinders

Gas boilers are now used everywhere because they are simpler and more convenient than solid fuel boilers, and cheaper to operate than electric ones. But this is where there is a centralized gas supply. But what about in our case?

The main questions that arise for any summer resident who is thinking about a liquefied gas heating system:

- Is it possible to effectively heat a house by powering the boiler from a cylinder?

- How long can the boiler work on one cylinder?

Let's figure it out.

So, how much gas is in the tank?

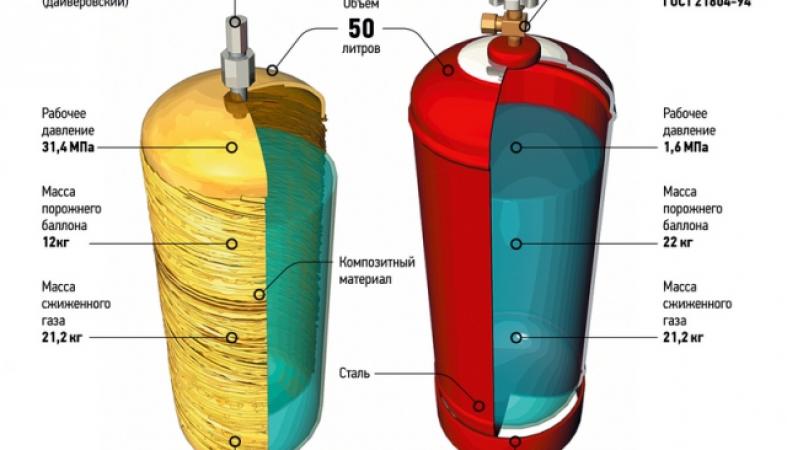

- Cylinder with a volume of 50 liters. The cylinder contains 21.5 kg of gas*.

- 27 liters - 11.4 kg*.

- 12 liters - 5.3 kg*.

- 5 liters - 2.3 kg*.

*Data taken from the markings on the cylinders. In reality, the numbers may differ.

How many cylinders will be required for continuous stable operation of a gas boiler?

- The average gas consumption for the boiler is 15 liters per day per 100 sq.m. heated area.

- About 22 kilograms of gas is placed in one 50 liter tank, which corresponds to about 35-42 liters.

- That is, one such tank is enough for two days.

Constantly using liquefied gas for heating makes sense only if you have a gas station nearby or have several filled containers in stock.

For long-term uninterrupted operation of the heating boiler, you will need a whole battery of gas cylinders

In addition, in any case, the cylinders will have to be transported to the gas station, and these are additional costs for gasoline plus the time spent.

Therefore, heating with liquefied gas may make sense in the following cases:

- A small heated area of the house and the house is well insulated, which will reduce gas consumption to a minimum

- In the near future, your holiday village is planned to be gasified, so the use of liquefied gas is a temporary measure.

- Gas heating is used for a small amount of time and works in conjunction with other heating equipment

- You have access to very cheap, or even better, free gas, which, of course, is extremely unlikely

By and large, it makes sense to use bottled gas for heating only occasionally: you arrived at the dacha, it’s cold in the house, it’s stabbing firewood no time or just laziness, and the room needs to be warmed up. But in this case, the installation of a gas boiler is impractical.

If during the cold season, arrivals at the dacha occur infrequently, you can purchase and install gas heaters in the room. You can warm up in just a couple of minutes. At the same time, save on the installation of the heating system and fuel.

If your trips to the country are irregular, and, in addition, you have an unheated garage, buy a portable (mobile) gas heater. It can be easily moved around the house, transported by car, installed in any room and quickly raise the air temperature in it to a comfortable one. The gas cylinder is placed inside such a heater and covered with a protective cover.

Making a greenhouse with your own hands from a profile pipe and polycarbonate: a complete description of the process, drawings with dimensions, watering and heating (Photo & Video)

The situation on the street

Warming a gas cylinder in winter is a particularly sensitive issue. It is very relevant for fishermen and tourists. He also worries the owners of private houses and buildings, the cylinders of which are on the street.

It is also important here at what temperature propane gas freezes in cylinders. Already at -15, the liquid substance in the cylinder freezes slightly

Gas production slows down. And the operation of gas appliances is disrupted. For example, when hiking or fishing, there may be problems with burners, in the country - with a portable stove.

And the next question arises - is it possible to heat the propane cylinder so that gas units work better. As part of liquefied gas, a pair of hydrocarbons: propane and butane.Evaporation of the former occurs at extremely low temperatures. Evaporation of the second - already from -14-15 degrees.

In order for the cylinder to function well in winter, the composition should be about 70% propane.

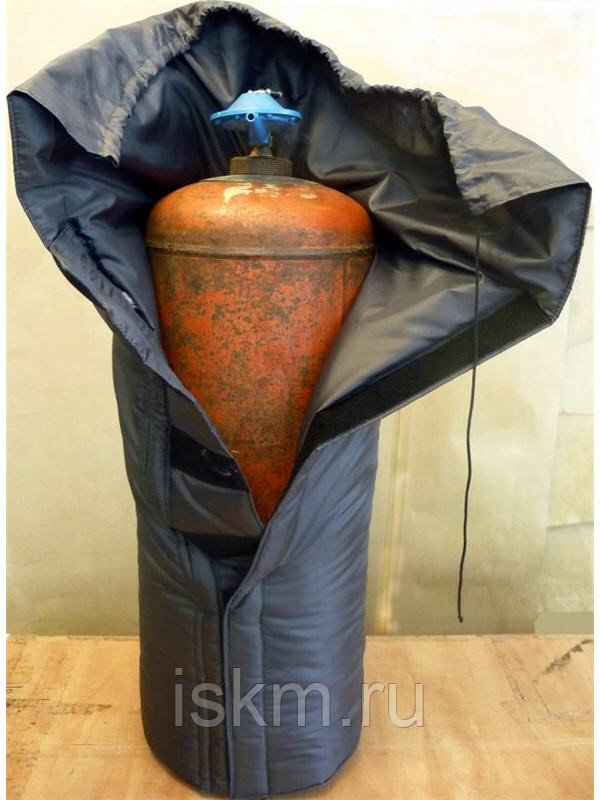

How to insulate a gas cylinder on the street? How to warm a gas cylinder on the street? There are different solutions to these sensitive questions. The following are some popular methods:

- The use of disposable chemical heating pads. They heat up to 35-40 °C. This is the maximum allowable rate for cylinders. The duration of such heating pads is 6-7 hours.

- Use of reusable salt pads. But their norm is about 50 ° C. It is somewhat dangerous to heat the cylinder with them.

In principle, a gas cylinder heater can be anything. The main thing is that its functional temperature does not exceed that of the cylinder. This rate is displayed on the label. The balloon needs constant monitoring. It should be checked periodically. If it is a little warm, you need to reduce the thermal effect on it. If it gets too hot, stop heating it right away.

Often, at dachas, the owners place the cylinders in special devices, these can be boxes, lockers, etc. And here a logical question arises - how to insulate such a cabinet for gas cylinders?

Here the most effective way is to apply the BH Thermal system. It costs between 7000-8000 rubles. You can use the domestic analogue of TEO-GB1 for about 5000 rubles. This is a lightweight non-flammable stocking that provides heating. It completely covers the surface.

How to warm up a gas cylinder when it freezes? If your gas cylinder is freezing up, then you need to apply any of the following actions (or all):

- Gently pour hot water over the bottle.You can act on it with hot steam. The cylinder valve is closed. This is partial heating. In order for the part to warm up completely, it must be removed, transferred to a warm room for 20-40 minutes. In no case should heating be carried out with an open flame.

After the procedure, the moisture concentrated there is removed from the gearbox by blowing. Before purging, its hose is removed.

- Transfer the entire container to a warm room. This must be done immediately when the gas cylinder is covered with frost. The cylinder must be kept indoors, preferably near the battery, until it warms up. You can connect a special electric heater.

- Apply saline or chemical heating pad. That is, hiking methods of heating.

And in order to avoid such troubles, the cylinders need to be concentrated in warm rooms or heated with high quality.

In the first case, a heated floor technology should be installed under the cylinders on the basis of the existing heating system.

In the second - to use efficient heaters.

- Management will improve significantly.

- Reduced consumption of liquefied gas

- Pressure develops inside the balloon - this is a consequence of the formation of convection heat.

- A pure liquefied fraction will be produced. So gas is saved up to 30%.

And for tourists, special devices are optimal, for example, a nozzle-heater for a Pyramid gas cylinder

It is suitable for many burners, tiles and stoves. It is often used to heat not only tents, but also small buildings. It is made from chrome steel. Its weight is 120 grams.

Price tag - 650 rubles.