- Steam heating type

- How to improve system reliability

- How to choose a water pump for home heating

- performance and pressure

- Rotor type

- Power consumption

- Control type

- Heat carrier temperature

- Other characteristics

- Pump device

- How to choose the best pump for a private house heating system

- Common parameters

- Choice based on performance

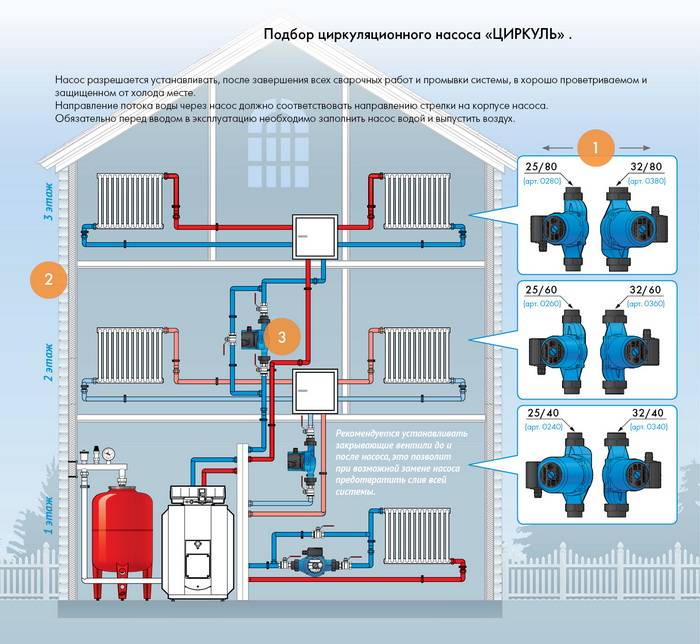

- Pressure in one-story and two-story houses

- External conditions

- How to choose a device based on consumption patterns

- TECHNICAL DATA OF THE CIRCULATION PUMP

- Which pumps are suitable for residential installations

- Where to put the circulation pump?

- Power connection

- Heating with water as heat carrier

Steam heating type

Some consumers confuse steam heating with water heating. In essence, these systems are very similar, except that the coolant is steam rather than water.

Inside the heating boiler of the natural circulation system, water is heated to boiling point and converted to steam, which then moves to the pipeline and is further supplied to each radiator in the circuit.

into construction steam heating system with natural circulation of the coolant includes the following components:

- a special heating boiler, inside which water is heated to the boiling point, and steam is accumulated;

- valve for releasing steam into the heating system;

- pipeline;

- heating radiators.

The classification of steam-type heating according to wiring diagrams and other criteria is exactly the same as that of water heating systems. Recently, a boiler has also been used to heat a private house, which also has its advantages.

How to improve system reliability

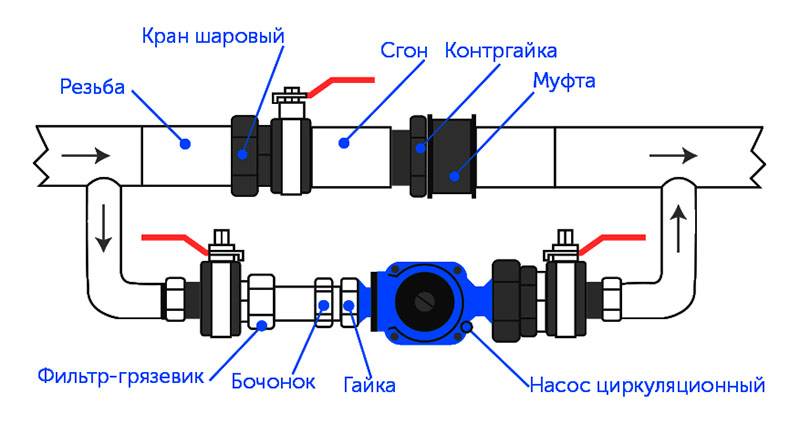

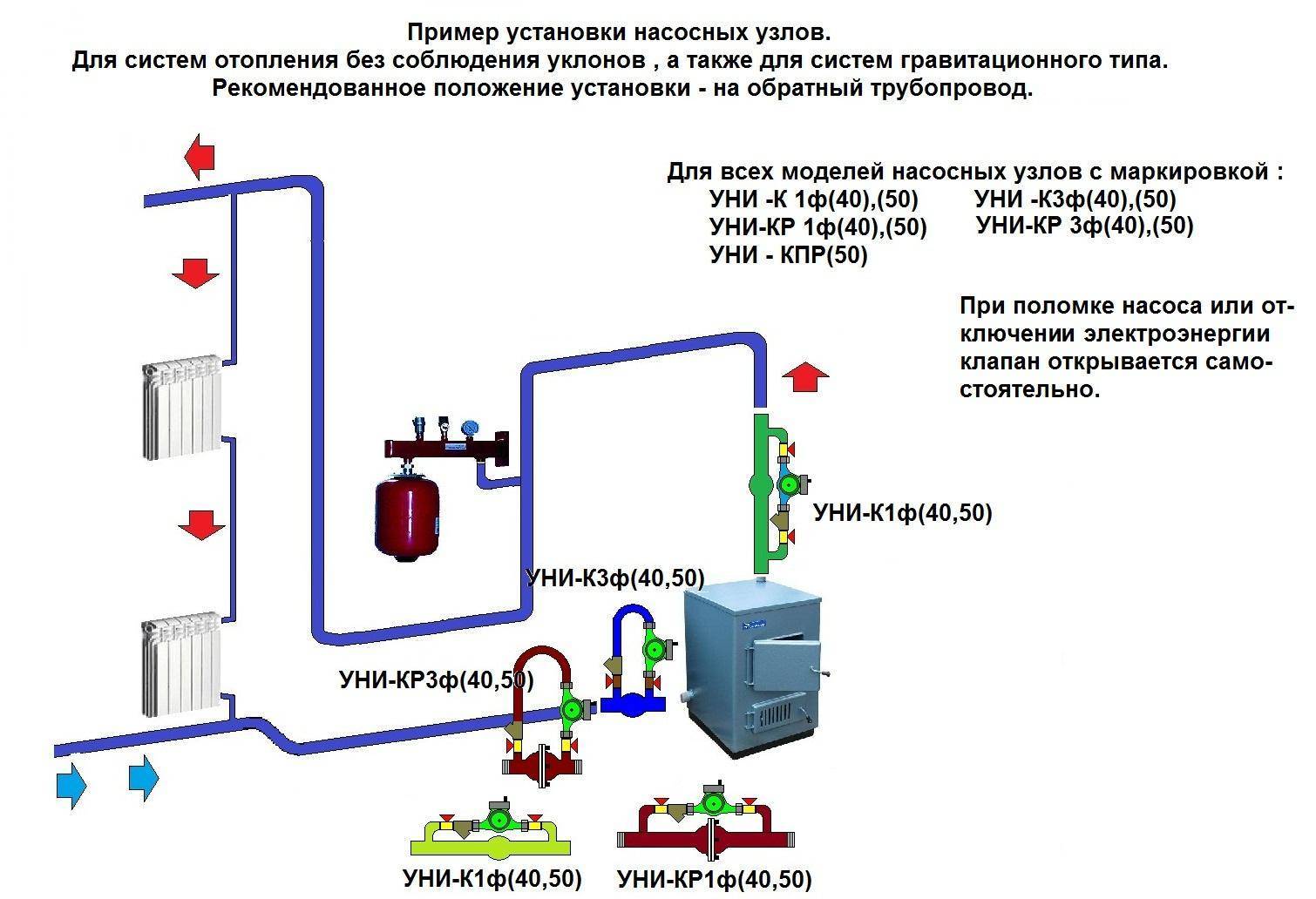

As a rule, the circulation pump does not require high performance, like drainage pumps, nor the need to lift liquid to a great height, like, say, downhole equipment. But they must work for a long time - throughout the entire heating season, and, of course, the heating should in no case fail during this period. Therefore, it is not worth saving, and to ensure absolute reliability, it is better to install a pair of pumps - the main and additional ones - on the bypass branch of the pipeline through which the coolant is pumped.

If the main pump suddenly fails, the homeowner can very quickly switch the heating medium supply to the bypass branch, and the heating process will not be interrupted. It is curious that with the current level of automation, this switching can also be done remotely, for which pumps and ball valves must be connected to the Internet. The cost of such automation (the price of a set of ball valves and a remote-controlled socket) is approximately 5–6 thousand rubles.

ShutterStock

Installing a pump in a hot water system with underfloor heating.

Grundfos

circulation pumps. Model ALPHA3 with data transfer function and support for mobile applications.

Grundfos

ALPHA1 L pumps are used for the circulation of water or glycol-containing liquids in controlled heating systems and in heating systems with variable flow. The pumps can also be used in DHW systems.

Leroy Merlin

Oasis circulation pumps, three power switching modes, cast iron housing, model 25/2 180 mm (2,270 rubles).

How to choose a water pump for home heating

Pump for heating in private The house is selected according to several main parameters:

- performance and pressure;

- rotor type;

- Power consumption;

- Control type;

- Heat carrier temperature.

Let's see how water pumps are chosen for heating a private house.

performance and pressure

Correctly made calculations will help you choose the unit that best meets your needs, which means it will help save the family budget.

The performance of an electric water pump is its ability to move a certain amount of water per minute. The following formula is used for calculation - G=W/(∆t*C). Here C is the thermal capacity of the coolant, expressed in W * h / (kg * ° C), ∆t is the temperature difference in the return and supply pipes, W is the required heat output for your home.

The recommended temperature difference when using radiators is 20 degrees. Since water is usually used as a heat carrier, its heat capacity is 1.16 W * h / (kg * ° C). Thermal power is calculated for each household individually and is expressed in kilowatts. Substitute these values into the formula and get the results.

The head is calculated according to the pressure loss in the system and is expressed in meters.Losses are calculated as follows - losses in pipes (150 Pa / m), as well as in other elements (boiler, water purification filters, radiators) are considered. All this is added and multiplied by a factor of 1.3 (provides a small margin of 30% for losses in fittings, bends, etc.). There are 9807 Pa in one meter, therefore, we divide the value obtained by summing up by 9807 and we get the necessary pressure.

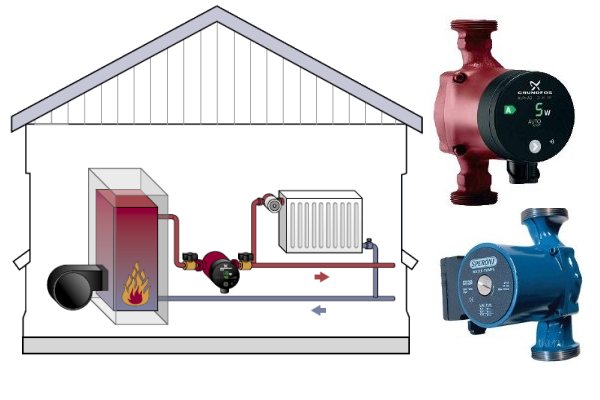

Rotor type

Domestic heating uses wet rotor water pumps. They are characterized by a simple design, minimal noise and maintenance-free operation. They are also characterized by small dimensions. Lubrication and cooling in them is carried out using a coolant.

As for dry-type water pumps, they are not used in home heating. They are bulky, noisy, require cooling and periodic lubrication. They also need periodic replacement of seals. But their throughput is large - for this reason they are used in heating systems of multi-storey buildings and large industrial, administrative and utility buildings.

Power consumption

The most modern water pumps with energy efficiency class "A" have the lowest power consumption. Their disadvantage is the high cost, but it is better to invest once in order to get reasonable energy savings. In addition, expensive electric pumps have a lower noise level and a long service life.

Control type

Through a special application, you can get information about the operation of the device wherever you are.

Typically, the adjustment of rotation speed, performance and pressure is performed by a three-position switch.More advanced pumps are endowed with electronic control systems. They control the parameters of heating systems and save energy. The most advanced models are controlled wirelessly, directly from your smartphone.

Heat carrier temperature

Water pumps for heating a private house differ in their operating temperature range. Some models can withstand heating up to + 130-140 degrees, this is exactly what should be preferred - they will cope with any thermal loads.

As practice shows, operation at the maximum temperature is possible only for the shortest time, so having a solid supply will be a plus.

Other characteristics

When choosing a water pump for heating, it is necessary to pay attention to the maximum operating pressure for the selected model, the installation length (130 or 180 mm), the type of connection (flanged or coupling), the presence of an automatic air vent. Also pay attention to the brand - in no case do not buy cheap models from little-known developers. The water pump is not the part to save on

The water pump is not the part to save on.

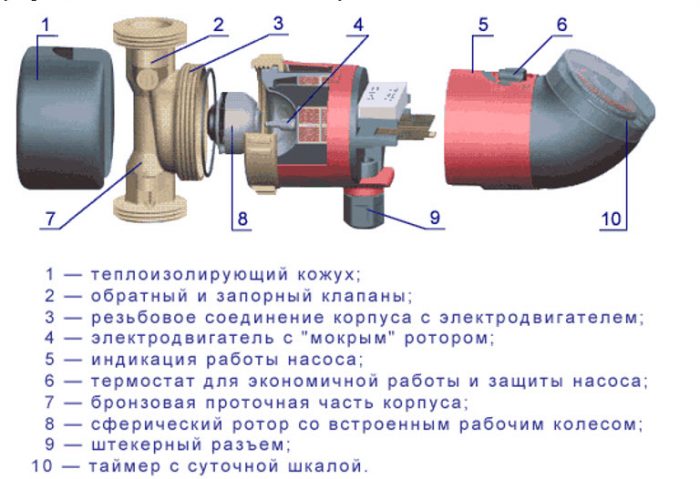

Pump device

Since the motor stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material.

The main elements that make up the circulation pump are:

- body made of stainless steel, bronze, cast iron or aluminium;

- rotor shaft and rotor;

- a wheel with blades or an impeller;

- engine.

As a rule, the impeller is a construction of two parallel disks, which are connected to each other by means of radially curved blades. One of the discs has a hole for fluid to flow through. The second disk fixes the impeller on the motor shaft. The coolant passing through the engine performs the functions of lubrication and coolant for the rotor shaft at the place where the impeller is fixed.

Since the motor stator is energized, it is separated from the rotor by a cup made of stainless steel or carbon material. The walls of the glass are 0.3 mm thick. The rotor is fixed on ceramic or graphite sliding bearings.

How to choose the best pump for a private house heating system

Depends on the type of system and the required functions, calculations carried out during the creation of the project.

Common parameters

It is recommended to pay attention to 4 characteristics:

- Permissible temperature. High-quality devices support operation in the range of 110-130 ° C. It should be borne in mind that even an inexpensive device must have at least 90 ° C in the description. This does not apply to low temperature systems. On the contrary, for solid fuel boilers, this indicator is very important.

- The material used in the manufacture of the case. Cast iron is considered the most favorable in terms of price-quality ratio. With a lack of budget, it is recommended to look for a pump made of heat-resistant plastic.

- The connection size is from G1 to G4. And the type is also important: threaded or flanged. Threaded is divided into external and internal, and for them it is necessary to install special adapters. Flanged - one-piece mount, for the selection of which it is enough to take into account the diameter of the mounting point.

- Two types of protection are required: against dry running and against overheating. Both types are used in circulating pumps to prolong operation. The first serves in "wet" devices for safe cooling of the motor. The second is designed to turn off the device when the critical temperature is reached. High-quality protection will ensure safety and avoid accidents.

Choice based on performance

The power of the device should be enough to transfer the hot coolant through all sections of the piping. To calculate, use a simple formula:

K = N, where N is the boiler power in kW.

The unit of K is liters per minute. So, for a 30 kW heater, a 30 l/min pump is used.

Pressure in one-story and two-story houses

Each device has an upper limit, the intersection of which threatens to cause malfunctions. In private two-story houses, it is taken as 3-4 atmospheres, in other cases - for 1.5-2.5.

Be sure to calculate the height of the water rise by the device. To do this, determine the length of the strapping and multiply it by 0.06 m. For example, for 80 m of a pipe, a pressure of 4.8 atm is required.

It is advisable to choose a pump with several speeds. This will allow you to control the flow or warm up the room faster, if necessary.

Important! It is recommended to select devices up to 1.6 m/s, otherwise noise will be generated

External conditions

The diameter of the pipes must correspond to the calculations for the piping. The number is found when creating a project. Using smaller materials will reduce system pressure. This rule also works in reverse.

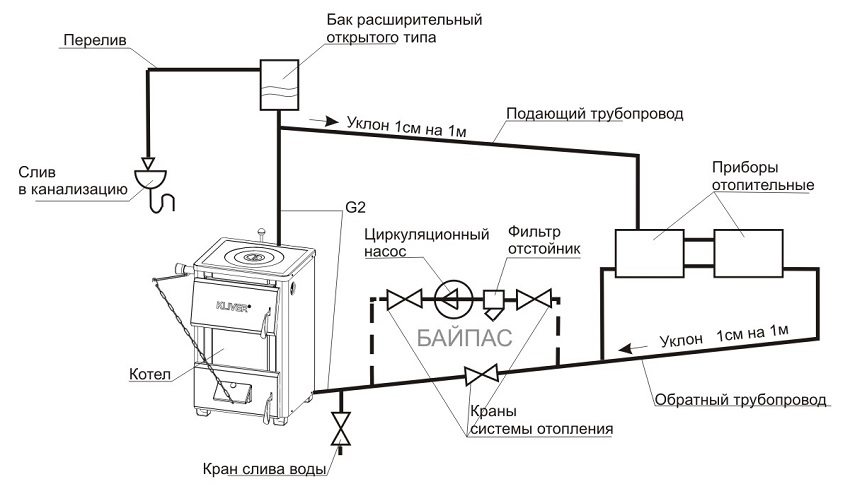

It is possible to use a bypass, which will create a natural circulation of the coolant. For installation, you will need to purchase pipes of a smaller diameter.They are placed around the pump, crashing the tap into any area.

How to choose a device based on consumption patterns

0.1 kW / m2 for small private houses; Depends on the size of the building and the region in which it is located. In warm climates:

- 0.07 kW/m2 for apartment buildings;

- 2 for industrial buildings.

In cold areas, the norms of SNiP 2.04.07-86 are used, according to which:

- For low-rise buildings, pumps with a capacity of 173-177 W / sq. m.

- For 3-storey and higher - 97-101 W / sq. m.

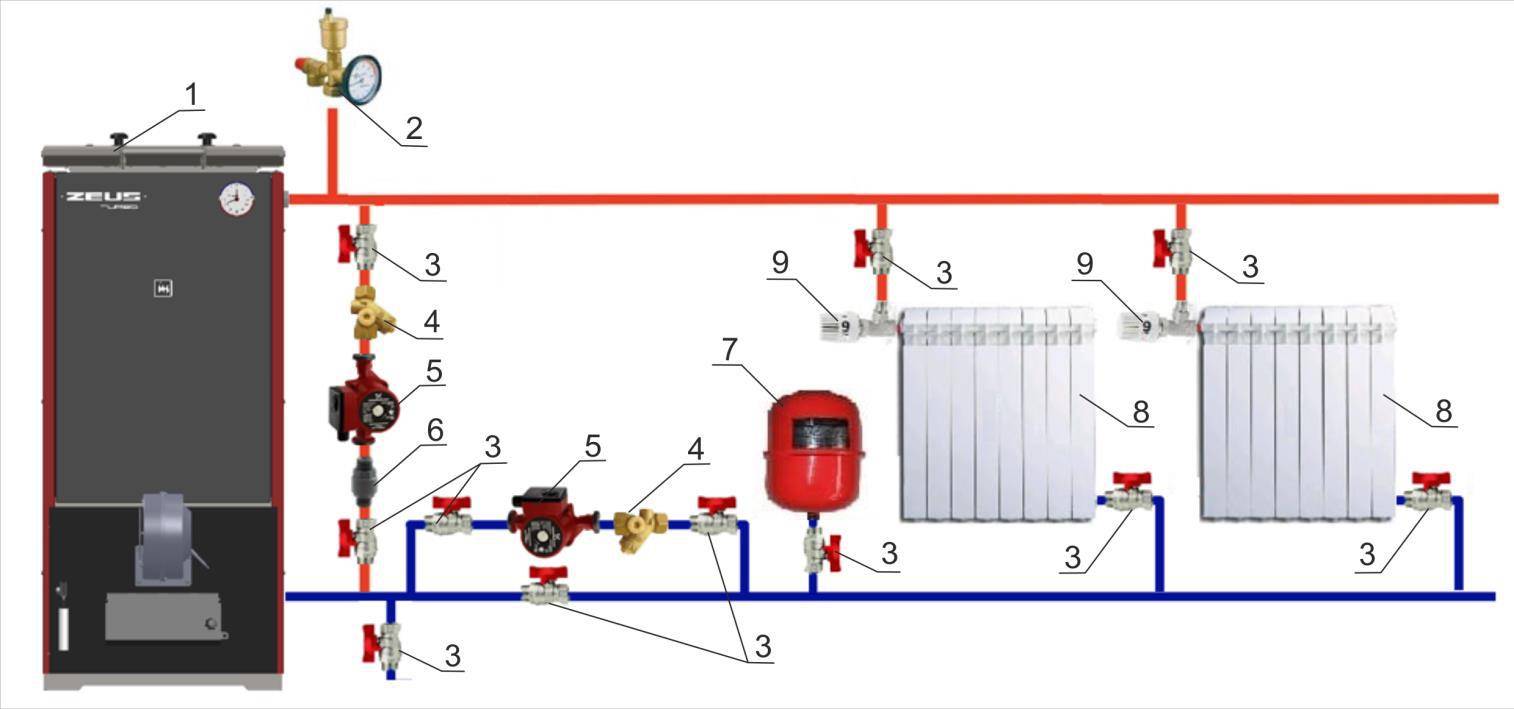

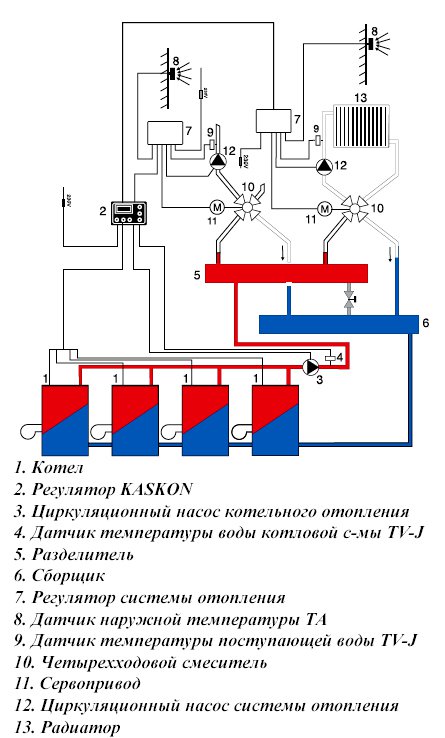

TECHNICAL DATA OF THE CIRCULATION PUMP

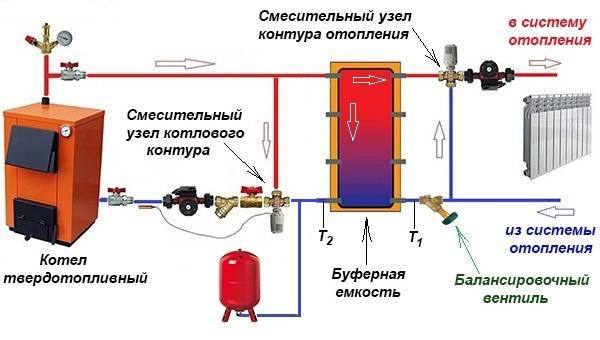

The choice of a suitable pump model for a heating boiler begins with a study of the basic parameters. The heating system is preliminarily calculated and components are selected based on the data obtained.

Not only the technical component is taken into account, but also the manufacturer. The duration of non-repair work depends on the quality of the assembly and compliance with the technology.

Main technical characteristics:

- performance;

- feed height;

- number of speeds;

- installation dimensions;

- power consumption;

- maximum allowable coolant temperature.

The defining characteristic is performance. It indicates the maximum volume of pumped liquid per unit of time. For household models, it varies from 25 to 60 l / min. Depends on the actual hydraulic resistance of the system elements.

The delivery height, or hydraulic resistance, determines the maximum height to which the pump can raise the water column. It can be from 3 to 7 m. Every 10 meters of height corresponds to one atmosphere of pressure.

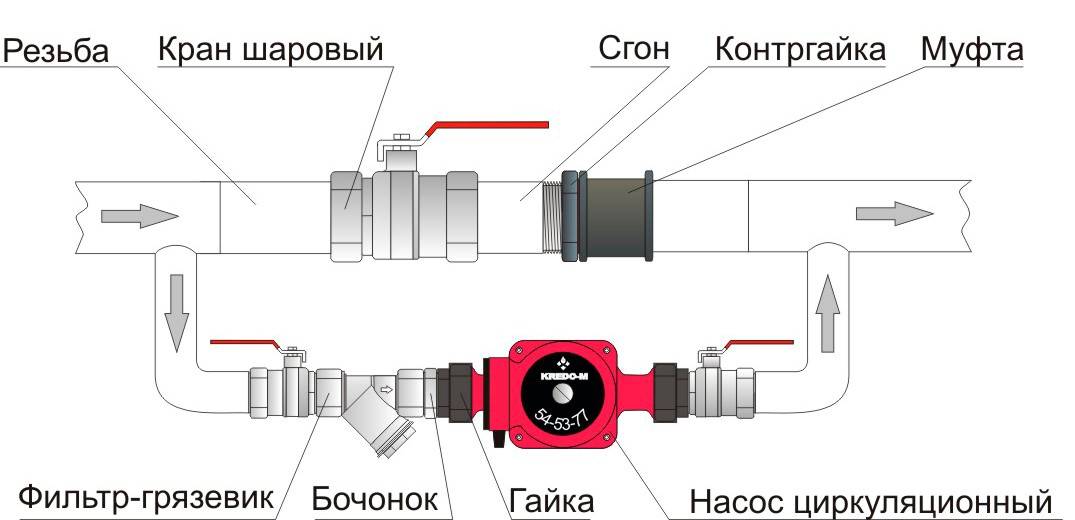

The settings are taken into account for the correct connection of the pump to the heating system

Important - the diameter of the pump nozzle must be less than the cross section of the main line. Otherwise, the pressure will create an area of low pressure.

Power consumption is negligible, does not exceed 0.8 kW. But it must be taken into account when calculating the heat supply loads. This is especially true for electric heating.

The number of speeds for household models does not exceed three. This is enough to adjust the pressure and optimize the operating parameters.

The maximum allowable exposure temperature depends on the operating mode of the heating. For low-temperature heat supply, up to +75/40С, this parameter is insignificant. But for a reserve, it is recommended to buy models designed for maximum thermal effects - up to + 110C.

Calculation of pump parameters.

To determine the values of the characteristics of the pump, you need to know the basic parameters of heating - the power of the boiler and the mode of operation of the heat supply. They also depend on the heat loss of the building. According to SNiP 2.04.07-86, with the proper value of heat transfer resistance of external walls and window structures, 177 W of thermal energy is required per 1 m² of living space.

With an increase in the number of storeys, the norm increases to 101 watts.

For a one-story building with an area of 120 m², in compliance with thermal insulation standards, the boiler power will be equal to:

The calculation of the performance, or flow, of the pump is carried out according to the following formula:

.

Where:

- Q – pump capacity, m³/h;

- N is the design power of heating equipment, kW;

- t1 and t2 - water temperature at the outlet of the boiler and in the return pipe, C.

For boiler with rated power 22 kW and at operating temperature 90/70 you can calculate the pump flow:

.

It is recommended to take a small margin of performance so that the equipment does not constantly operate at maximum power.

The height of the feed or pressure is calculated using complex formulas. For autonomous heat supply of a private house or apartment, you can take approximate values. Empirically, data on the hydraulic resistance of certain sections of the system were revealed, depending on their configuration and purpose.

Hydraulic resistance values, Pa/m, for heating components:

- straight sections of pipelines - up to 150;

- fittings - up to 45;

- three-way mixers - 30;

- temperature control equipment - 105.

The values for all system components must be summed. To calculate the head, the result is multiplied by 0.0001.

Important - height differences are not taken into account, as they are compensated by the vertical section of the return pipe. But besides them, you need to take into account the turning points

For them, the hydraulic resistance depends on the diameter of the line and the value of the angle of rotation.

Which pumps are suitable for residential installations

Installation of a circulation pump.

The optimal temperature of the heating system of a country house is achieved using built-in thermal valves. If the set temperature parameters of the heating system are exceeded, this may lead to the fact that the valve will be closed, and the hydraulic resistance and pressure will increase.

Using pumps with an electronic control system helps to prevent noise, as the devices will automatically follow all changes in water volumes. The pumps will provide smooth adjustment of pressure drops.

To automate the operation of the pump, a model of an automatic type unit is used. This helps protect it from misuse.

The pumps used may differ according to the type of application. For example, dry ones do not come into contact with the coolant during operation. Wet pumps pump water when they are submerged. Dry types of pumps are noisy, and the installation scheme of the pump in the heating system is more suitable for enterprises rather than residential premises.

For country houses and cottages, pumps designed to work in water, having special bronze or brass cases, are suitable. The parts used in the housings are stainless, so the system will not be damaged by water. Thus, these structures are protected from moisture, high and low temperatures. Installation of such a design is possible on the return and supply pipelines. The whole system will require a certain approach in its maintenance.

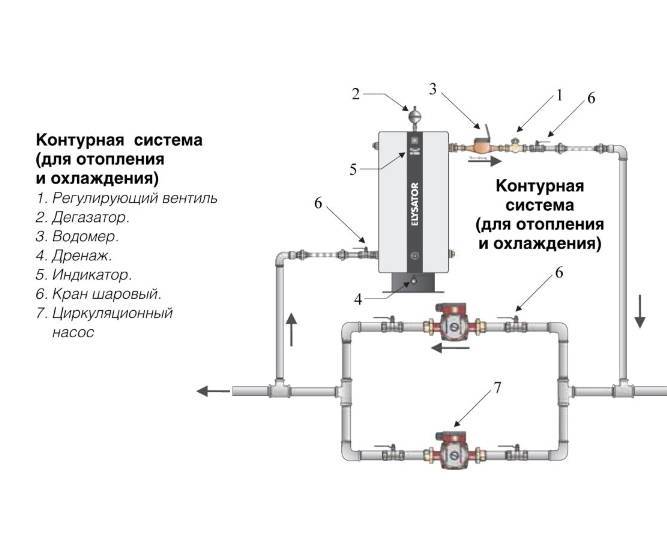

In order to increase the degree of pressure attributable to the suction section, you can install the pump so that the expansion tank is nearby. The heating piping must be descending at the point where the unit is to be connected. It will be necessary to make sure that the pump can withstand strong pressures of hot water.

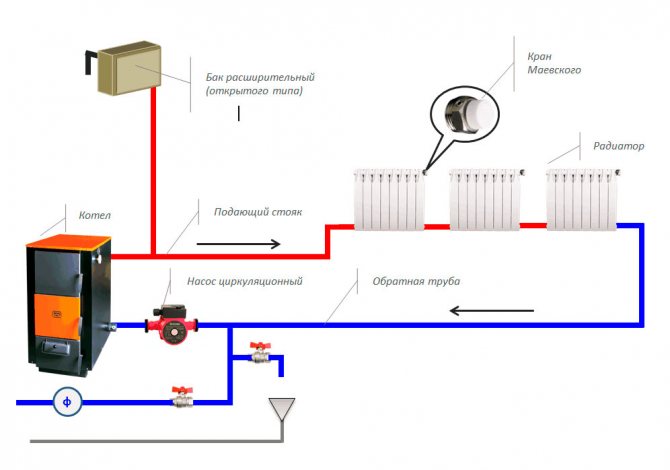

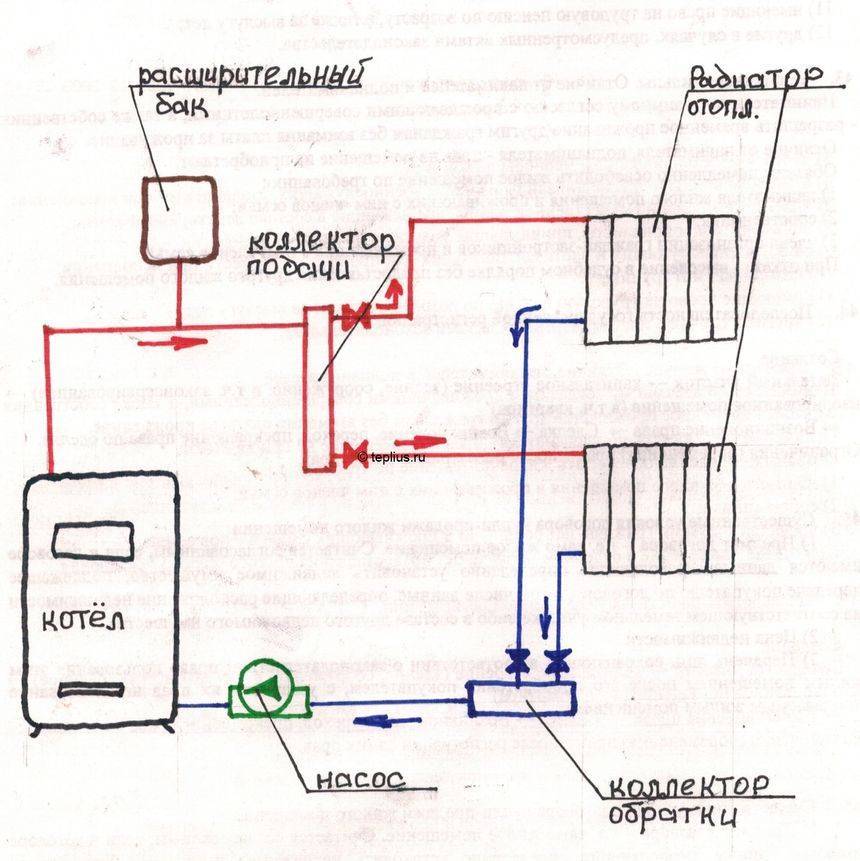

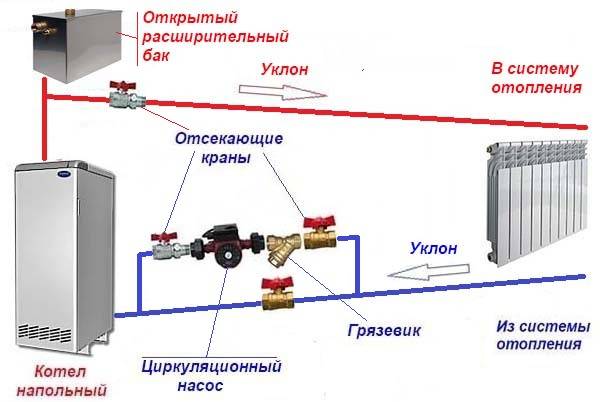

Where to put the circulation pump?

Most often, the circulation pump is installed on the return line, and not on the supply. It is believed that there is a lower risk of rapid wear and tear of the device, since the coolant has already cooled down. But for modern pumps this is not necessary, since bearings with so-called water lubrication are installed there. They are already designed specifically for such operating conditions.

This means that it is possible to install a circulation pump in the supply, especially since the hydrostatic pressure of the system is lower here. The installation location of the device conditionally divides the system into two parts: the discharge area and the suction area. The pump installed on the supply, immediately after the expansion tank, will pump water out of the storage tank and pump it into the system.

The circulation pump in the heating system divides the circuit into two parts: the injection area, into which the coolant enters, and the rarefaction area, from which it is pumped out

If the pump is installed on the return line in front of the expansion tank, then it will pump water into the tank, pumping it out of the system. Understanding this point will help to take into account the features of hydraulic pressure at various points in the system. When the pump is running, the dynamic pressure in the system with a constant amount of coolant remains constant.

It is important not only to choose the optimal place for the installation of pumping equipment, but also to install it correctly. We recommend that you familiarize yourself with the nuances of installing a circulation pump

The expansion tank creates a so-called static pressure. Relative to this indicator, an increased hydraulic pressure is created in the injection area of the heating system, and a reduced one in the rarefaction area.

The rarefaction can be so strong that it reaches the level of atmospheric pressure or even lower, and this creates the conditions for air to enter the system from the surrounding space.

In the area of pressure increase, air can, on the contrary, be pushed out of the system, sometimes boiling of the coolant is observed. All this can lead to incorrect operation of heating equipment.To avoid such problems, overpressure must be ensured in the suction area.

To do this, you can use one of the following solutions:

- raise the expansion tank to a height of at least 80 cm from the level of the heating pipes;

- place the drive at the highest point of the system;

- disconnect the accumulator branch pipe from the supply and transfer it to the return line after the pump;

- install the pump not on the return, but on the supply.

Raising the expansion tank to a sufficient height is not always possible. It is usually placed in the attic if there is the necessary space.

At the same time, it is important to follow the rules for installing the drive in order to ensure its trouble-free operation.

We provided detailed recommendations for installing and connecting an expansion tank in our other article.

If the attic is not heated, the drive will have to be insulated. It is quite difficult to rearrange the tank to the highest point of the system with forced circulation, if it was previously created as natural.

Part of the pipeline will have to be redone so that the slope of the pipes is directed towards the boiler. In natural systems, the slope is usually made towards the boiler.

An expansion tank installed indoors does not need additional protection, but if it is installed in an unheated attic, care should be taken to insulate this device

Changing the position of the tank nozzle from supply to return is usually not difficult to perform. And it is just as easy to implement the last option: to insert a circulation pump into the system on the supply line behind the expansion tank.

In such a situation, it is recommended to choose the most reliable pump model, which can endure contact with the hot coolant for a long time.

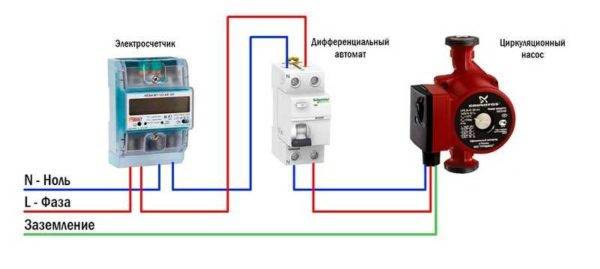

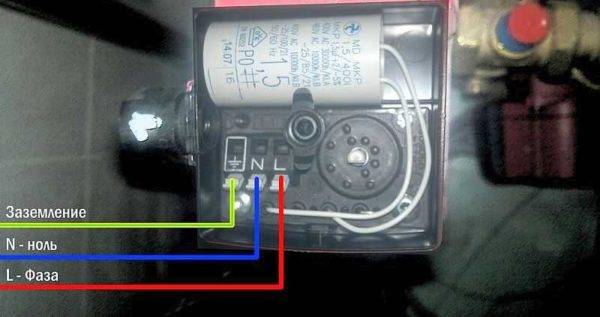

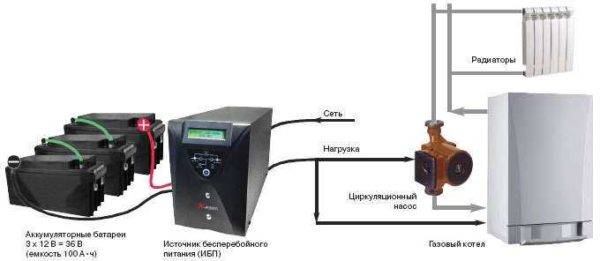

Power connection

Circulation pumps operate from a 220 V network. The connection is standard, a separate power line with a circuit breaker is desirable. Three wires are required for connection - phase, zero and ground.

Electrical connection diagram of the circulation pump

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power cable. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing a few bolts, we find three connectors. They are usually signed (pictograms are applied N - neutral wire, L - phase, and "earth" has an international designation), it is difficult to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - put a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 watts. But when organizing, you need to calculate everything and select the capacity of the batteries. The disadvantage of such a system is the need to ensure that the batteries are not discharged.

How to connect a circulator to electricity through a stabilizer

Hello.My situation is that a 25 x 60 pump stands right after the 6 kW electric boiler, then the line from the 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, the branch goes up, then 4 m, down, rings the house of 50 sq. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bath branch 40 mm up, leaves the bath, enters the 2nd floor of the house 40 sq. m. (there are two cast-iron radiators) and returns to the bath in the return line; the heat did not go to the second floor; the idea to install a second pump in the bath for supply after a branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

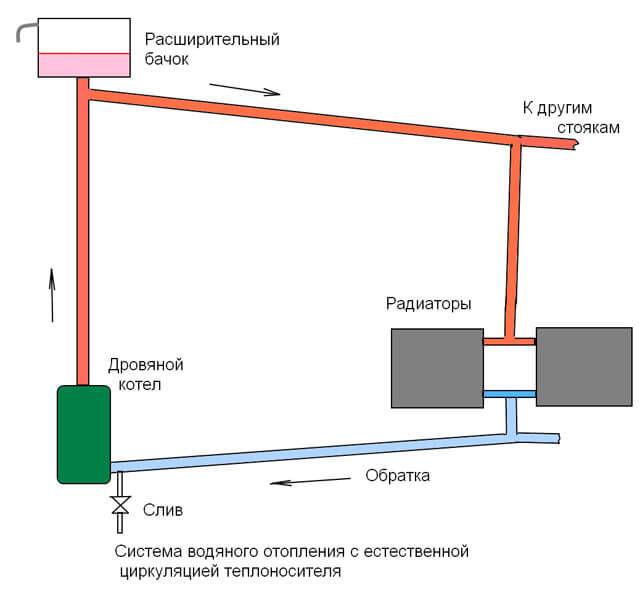

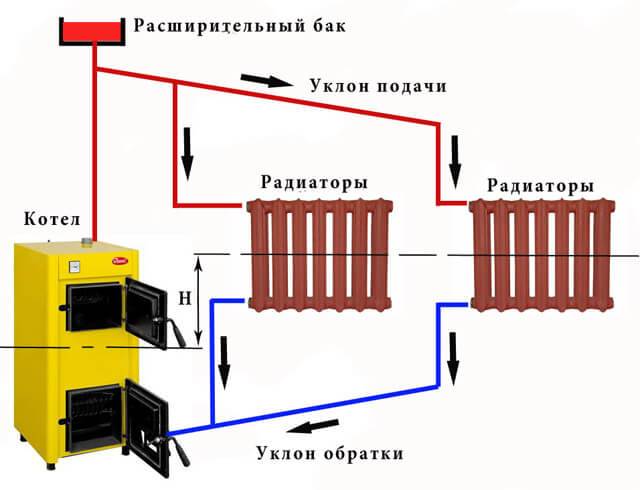

Heating with water as heat carrier

The functional features of water heating systems with a natural type of coolant circulation are determined by a number of characteristics.

Based on which expansion tank is used to equip a heating system with natural circulation of the coolant, there are:

- open type systems. In this case, the expansion tank is installed as high as possible in order to create excess pressure in the expansion tank. In addition, thanks to this, you can get rid of air pockets in the heating circuit. From time to time, through an open expansion tank, water is added to the pipes, partially evaporated during the operation of the heating.

- Closed systems. In such heating with natural circulation, the expansion tank is replaced by a special membrane hydrostorage cylinder. It provides additional pressure in the circuit within 1.5 atmospheres.For safety reasons, systems of this design are usually equipped with a pressure gauge unit, the task of which is to adjust the pressure inside the pipeline.

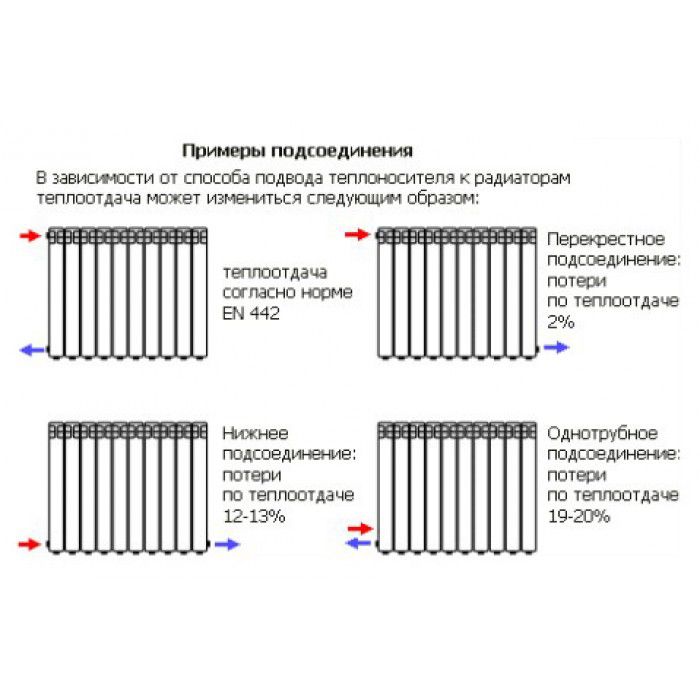

Another fundamental point that distinguishes the design of heating systems with a natural type of water circulation is the connection diagram of the heating elements.

According to the method of connecting heating appliances to a gas boiler without a pump, the following options can be distinguished:

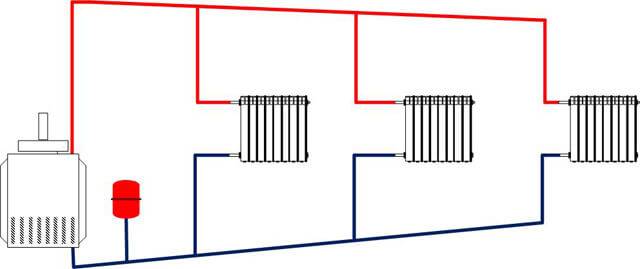

- Single pipe heating system. With this type of heating, all radiators are connected in series to the same pipe. That is, water passes through each subsequent heater and only after that it moves on. Among the advantages of single-pipe wiring equipment are the ease of installation, as well as low material consumption.

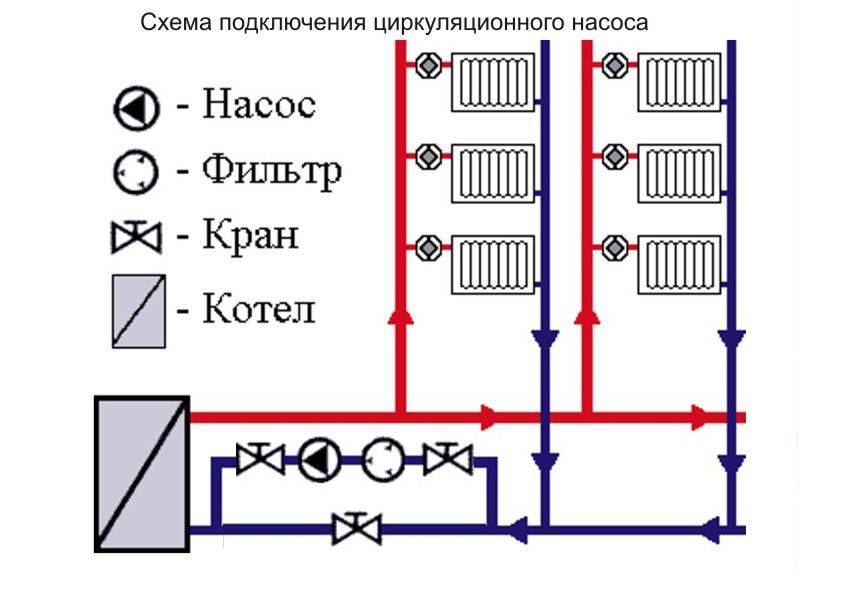

- Two-pipe wiring in a heating system with natural circulation. In this case, all radiators that are part of the heating system are connected to the pipeline in parallel. At the same time, the temperature of the coolant that enters each radiator is the same. After the water passes through the entire radiator and cools down, it returns to the boiler heat exchanger through the return pipe.

It is believed that a two-pipe wiring diagram is the most appropriate in terms of the efficiency of housing heating. True, in order to equip such a system, it will take a lot of pipes and additional elements for mounting the heating circuit.