- What is quick freezing?

- The principle of operation of a compression refrigerator

- The electrical system in the compression refrigerator and the principle of its operation

- Absorption refrigerators, how they are arranged, the principle of operation

- Refrigerators depending on the number of chambers

- Single chamber refrigerators

- Two-chamber refrigerators

- Multi-chamber refrigerators

- Refrigerators Side-by-Side

- Linear Compressor Options

- Common faults in refrigerators

- How the refrigerator works

- Single chamber and double chamber

- Linear devices

- centrifugal motor

- Piston type of work

- Rotary operating principle

- How car refrigerators work

- Features of the device and operation of refrigerators with the NO Frost system

- The principle of operation of the inverter compressor

- Advantages and disadvantages of refrigerators with an inverter compressor

- Results

- Video: The principle of operation of the refrigerator (No. 2)

What is quick freezing?

In modern freezers of two-compartment refrigerators there is a quick freezing function. What is it? Everything is very simple. For a long time, the compressor runs without turning off. This achieves the effect of rapid freezing. But there are downsides to this as well. You should always be aware that the compressor will not turn itself off. This means that the life of the compressor is shortened.After forcibly turning off this function, the compressor will turn off.

Despite the fact that there are a very large number of types, as well as firms that produce refrigerators, the principle of operation of the cooling system of household refrigerators is approximately identical. Knowing this, you will be more calm in the event of a breakdown of your refrigerator. And, calling a refrigerator repairman to your home, you can competently explain to the specialist the reason for his call.

Video about how the refrigerator works:

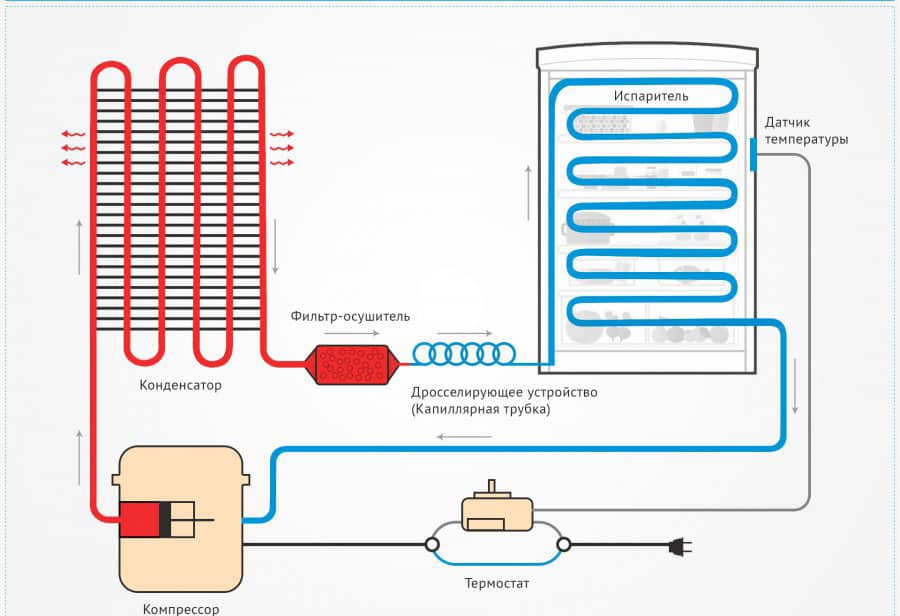

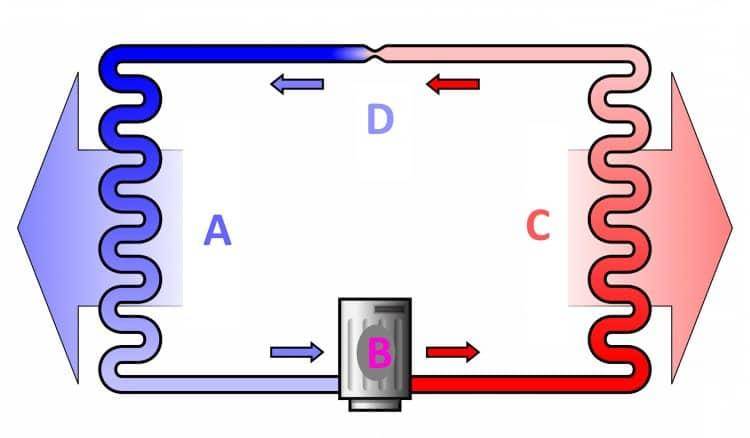

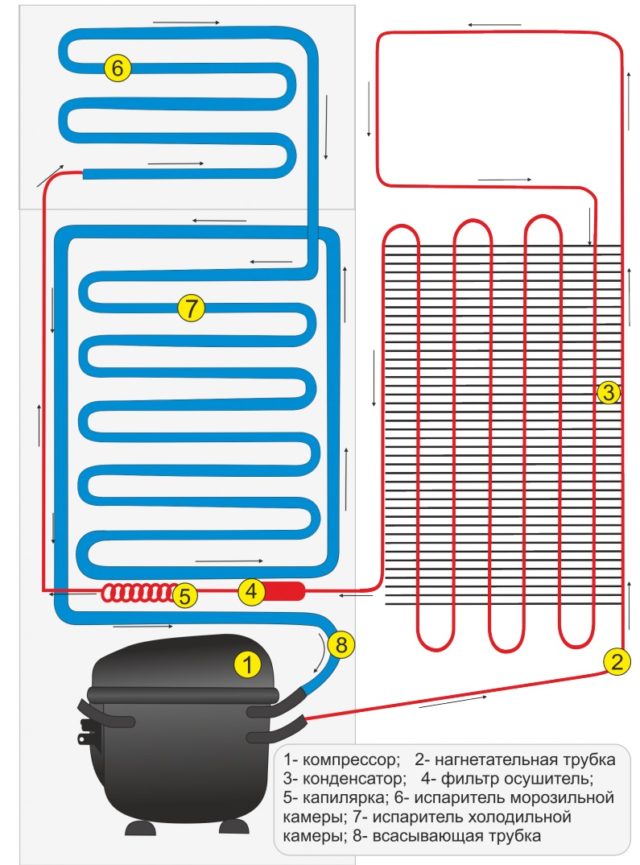

The principle of operation of a compression refrigerator

Freon, used as a refrigerant, is fed to a drying filter, which will clean the gas from various solid particles and collect all excess moisture from it. The dehydrated and purified freon will then flow out through the capillary tube, which is a kind of border separating high and low pressure zones. Coming from the tube to the evaporator, where the pressure decreases from approximately 9 atmospheres to 0.1 atmospheres, freon boils due to the heat of those products that were left in the cooling chamber. Any liquid, boiling, evaporates, and freon is no exception: its vapor is sucked in by the compressor, and the whole cycle starts all over again.

Particular attention should be paid to the mechanisms of action of each element of the refrigerator, because it is on them that the entire operation of the refrigeration machine depends. The compressor includes the compression unit itself and a small electric motor, which are hidden in a sealed housing.

It is the compressor that can be called the key device that provides cooling - its constant work on the distillation of freon guarantees the operation of the entire cycle.

There are two types of capacitors installed on the refrigerator:

- shield or sheet-pipe, which looks like a sheet of metal with a coil planted on it;

- ribbed tube, which is a coil with fins.

For example, Indesit NBS 18 AA is a compression refrigerator.

A two-compression refrigerator is just one of the varieties of devices of this type, that is, a conventional refrigerator with a freezer. One of the compressors works to cool the "freezer", the second - to the refrigerating chamber. Thanks to this, the temperature in each chamber can be regulated separately. The disadvantage of such a refrigerator will be its increased consumption of electricity.

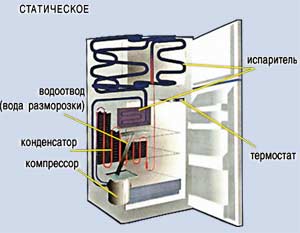

The electrical system in the compression refrigerator and the principle of its operation

After connecting the refrigerator to the mains, the current of electricity passes through a closed contact in the thermostat, the freeze / defrost button, the start relay coil and enters the compressor motor. Since the motor has not yet been started, the electric current flowing through its winding exceeds the maximum allowable several times, thereby closing the contacts and turning on the “starter”, opening the start relay contacts. After the evaporator cools down to the value set on the temperature controller, the contacts open and the engine stops. When the temperature in the refrigerator compartment rises to a fixed value, the cycle starts again.

Depending on the design of a particular refrigerator, the electrical system can be made in different ways: protection and start relays can be combined, a defrost button can be completely absent, certain elements are often added. However, this scheme is the basis for the operation of a compressor-type device without “no frost” technology.It is used, for example, in the LG GL-M 492 GQQL refrigerator.

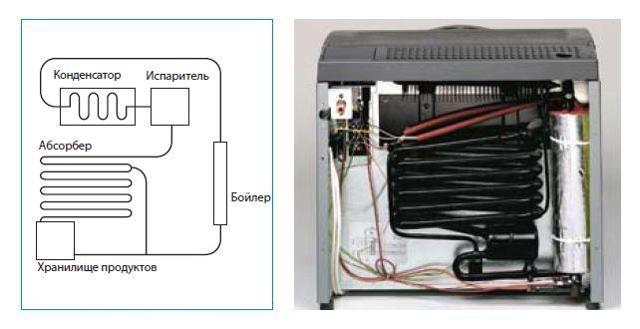

Absorption refrigerators, how they are arranged, the principle of operation

Just like in compressor-type refrigerators, the cooling of the internal chambers in devices of this type is associated not with the generation of cold, but with the evaporation of the working fluid, which is most often used as ammonia, however, in addition to it, it also contains hydrogen or some still an inert gas.

Such devices are equipped with an absorber, desorber and dephlegmator. When ammonia is dissolved in water, the whole mixture begins to move. The solution in the absorber, due to its physical properties, moves into the desorber, where it decomposes again into two preliminary components. In the condenser, the working mixture again comes into a liquid state, and then again goes to the evaporator. The movement of ammonia is provided by means of jet pumps.

Most often, an absorption type refrigerator is used where a conventional compressor unit cannot be used. In everyday life, such devices are rarely installed due to the presence of a poisonous substance in their composition, which is extremely toxic to humans.

Refrigerators depending on the number of chambers

Modern manufacturers offer a fairly extensive range of refrigerator models, differing both in the number of internal compartments and in their location. This, in turn, can affect the dimensions of the product.

Single chamber refrigerators

Such devices do not assume the presence of a separately located freezer. As a rule, it is combined with a compartment designed for cooling products, and in some models it may be completely absent.Today, both small-sized single-chamber refrigerators and full-size appliances are on sale. However, their specifications may differ significantly.

When choosing such a refrigerator, one should start not only from the number of intended users living in the house, but also from the free space available in the room. In most cases, single-chamber devices are great for both an apartment and a country house. Relatively low cost, as well as minimal power consumption makes them quite popular among consumers.

Two-chamber refrigerators

The design, consisting of two chambers, implies the presence of a stand-alone freezer, which can be located both above and below. At the same time, the chamber itself, designed for cooling products, can be divided into two compartments. Due to the zoning of the internal space, it is possible to store chilled products in different conditions:

- for meat, fish and poultry, a zone with a humidity level of up to 50% is intended;

- storage of vegetables, fruits and herbs is carried out in an area where humidity levels reach 90%.

These types of refrigerators are preferred to be used in families where, in addition to storing ready-made meals, there is a need for the preparation of one or another food product.

Multi-chamber refrigerators

Models consisting of three or four compartments allow you to separately place certain products that have different storage requirements. The most popular three-chamber refrigerators have such compartments as:

- independent freezing compartment;

- compartment for cooling with certain indicators of humidity;

- freshness zone (aka “zero chamber”).

With a compartment dedicated to fresh food, you can be sure that the useful elements found in vegetables or meat will be preserved. Typically, household appliances consist of three chambers and have 4 doors. Models with a large number of compartments are already classified as professional.

Refrigerators Side-by-Side

Premium class refrigerators, which came to the domestic market from America, are large and fairly roomy appliances made in the form of two-door cabinets. Both compartments - freezing and refrigeration in this case are located vertically, completely occupying the left and right parts of the structure.

The width of such a device is much larger compared to conventional multi-chamber models, which requires additional free space in the room. On the outer surface of the door of the freezer compartment, as a rule, there is a dispenser that supplies cold water or ice cubes.

Linear Compressor Options

For this device, the most important parameters are the cooling capacity, the developed power and the operating pressure. On average, the latter indicator for most models ranges from 2–4 atmospheres. This pressure level is optimal for the normal circulation of freon through the cooling system.

Many manufacturers supply their equipment with special pressure regulators in order to keep it at the right level and prevent rupture of the pipes of the cooling system.

If we talk about cooling capacity, then this indicator is inextricably linked with the power of the device and the brand of refrigerant it uses.Refrigeration capacity is measured in kilocalories per hour, and for many refrigerators using freon with the R12 index (for example, for some LG models), it ranges from 45 to 150 kcal / hour, depending on the electrical power of the device.

Reference. At one time, a linear compressor was considered quite energy-efficient, but today inverter-type devices clearly hold the palm in this tacit competition. Since they work without ever turning off (namely, at the moment of switching on the engine of the refrigeration unit has the most serious load), their resource is much higher, and energy costs are lower.

However, this positive moment is easily offset by the cost of a refrigerator model with an inverter compressor type.

In order to find out if the compressor is working properly, repairmen use a multimeter. By connecting it between the coil winding and the housing, they measure the resistance of the winding. An upward deviation from the norm indicates damage to the winding, and a deviation from the norm indicates a short circuit in the system. Since the winding may have a different source material and structure, the value of its normal resistance for each model may be different.

Common faults in refrigerators

Common problems with refrigerators include:

- The device does not cool or does it poorly even when the maximum power is selected. In this case, the compressor is almost always to blame. It has worn out or the relay has failed. It is also possible that almost all of the refrigerant in the system has come out due to the appearance of microcracks;

- Intensive formation of a layer of ice inside the freezer. Often the root cause is loss of tightness.In this case, the rubber seal is replaced or the door is adjusted;

- Water accumulates underneath. Almost always, the problem lies in the joints of the drainage tubes. As a result of moving the refrigerator, they sometimes move.

How the refrigerator works

The working unit of the device includes the following components:

- compressor;

- discharge and suction pipeline;

- capacitor;

- evaporator;

- capillary tube;

- filter dryer;

- evaporator;

- refrigerant (working substance).

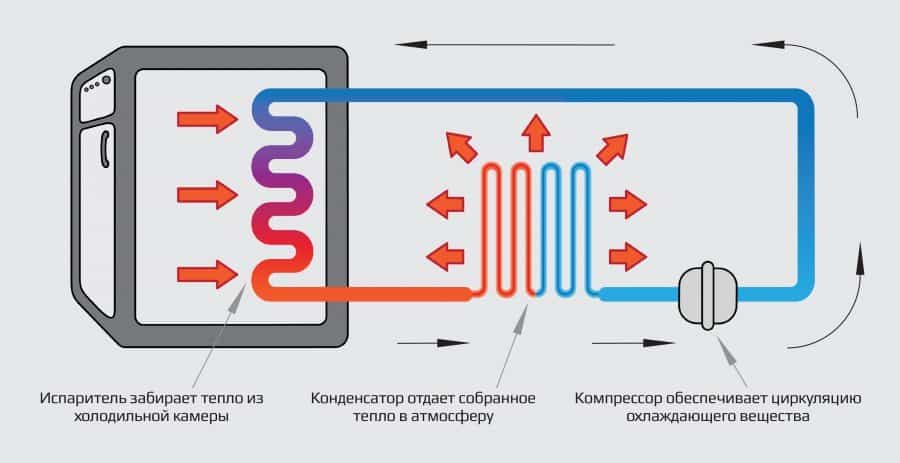

The basis of the entire system is the compressor, it ensures the circulation of the working substance in the device. The condenser is a system of tubes located on the outer wall. It is designed to release heat into the surrounding air. The second part of the tubing system is the evaporator. The condenser and evaporator are separated by a filter drier and a very thin capillary tube.

In order for the products inside the chamber not to become ice, a thermostat is installed inside. It allows you to set the required degree of cooling.

Freon is used as a refrigerant, most often isobutane (R600a).

Compression evaporative cooler device

Compression evaporative cooler device

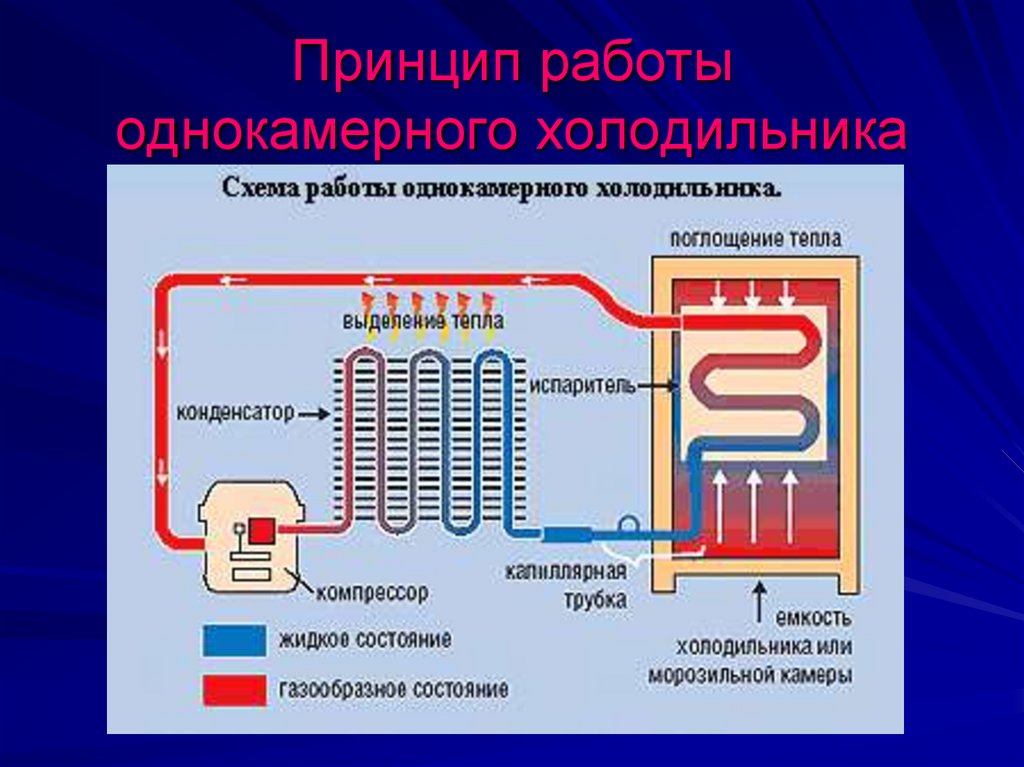

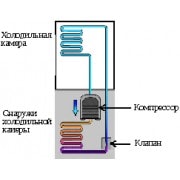

Single chamber and double chamber

After you understand the compressor device and the role of freon in the operation of the refrigerator, you can go directly to the operation of the refrigerator. For single-chamber and two-chamber products, the device and the principle of operation are somewhat different.

A single-chamber refrigerator cools the air due to freon vapor, which comes from above, from the freezer, down into the refrigerator compartment.First, the vapors enter the condenser due to the operation of the compressor, and then they turn into a liquid state and enter the evaporator tank through the filter and capillary tube. Freon boils there, and then cools the refrigerator.

The cooling process occurs in a cyclic manner, and moves until the temperature reaches the proper level. The compressor then turns off.

In most single-chamber units, the temperature in the refrigerator is regulated by simple manipulations with special windows. Under the freezer compartment there is a special panel with windows that allow cold air to pass through - the wider they are open, the colder it is in the chamber. A very simple yet reliable and efficient device.

A two-chamber refrigerator works in a slightly different way. The device of such a system provides for the presence of two evaporators, one for each chamber. First, freon in a liquid state is pumped through a capillary tube and a condenser into the freezer evaporator, and begins to pump cold air there.

Only after it becomes cold enough in the freezer, the freon enters the second evaporator and cools the air in the refrigerator compartment. Once the required temperature has been reached, the compressor switches off. As you can see, the device of the cooling system is quite simple, and that is why frequent breakdowns are excluded (with proper operation).

Linear devices

If you look at such a compressor visually, you can see a small barrel, consisting of two halves connected by welding. Tubes come out of its middle, and terminals are located on the body for supplying electrical energy to them.The principle of operation of linear devices is based on the operation of the pump. This type of compressors for refrigerators are divided into the following types:

- centrifugal;

- piston;

- rotative.

This classification divides devices not only according to the principle of operation, but also, more importantly, in terms of power, as well as the value of the coefficient of performance (COP). In refrigerators with this type of compressor, the engine always runs at maximum power. This approach of use creates a load on the power grid and the refrigeration system. Starting and stopping the engine is always accompanied by interference in the electrical network that occurs when the relay is switched.

centrifugal motor

Centrifugal or dynamic compressors are similar in operation to centrifugal pumps. They consist of one or more impellers placed in a spiral housing. When the wheel rotates, a centrifugal force is created that transfers kinetic energy to the refrigerant, which is in a gaseous state. This energy is then converted into pressure.

Thus, all the work of moving the gas occurs due to the fan. It can be: centrifugal and axial. In addition to the impeller, the centrifugal fan has suction and discharge pipes in its design. The axial one consists of a propeller with blades.

Piston type of work

The main part of the compressor design, in addition to the working cylinder, is the piston. The piston type of the motor works by analogy with a single-cylinder internal combustion engine. There are two valves in the cylinder head: discharge and suction.The crank mechanism and the crankshaft are responsible for the movement of the piston.

The direct drive of this mechanism starts the piston, and during reverse movements it compresses the gas, pushing it out. Most often, in two strokes of the piston, one revolution of the shaft occurs. When the piston moves to the right, a vacuum is created in the condenser, and the cooling gas is sucked into the cylinder. As the piston moves back, the pressure increases. The suction valve is closed and the pressurized gas is pushed into the condenser. As soon as the piston changes direction, the discharge valve closes, and the compressor begins to pump out gas vapors again.

The free volume formed when the piston is lowered discharges the chamber, and after it crosses the point corresponding to the greatest compression volume, it closes the release valve. The increase in gas pressure increases. To reduce the wear of the walls, oil is introduced into the cylinder. To get rid of its particles in the refrigerant, a separator is installed.

The average capacity of such compressors does not exceed one hundred liters per minute. The positive aspects include a simple production process, and the negative ones: low efficiency, high noise and vibration.

Rotary operating principle

When considering a rotary compressor in the section, you can see two screws, between which and the housing there is a refrigerant. Therefore, this type is often called screw. One rotor is the lead and the other is the driven. There is no physical contact between them. There are two holes in the body - inlet and outlet. When gas enters through the inlet, it is compressed between the screws, and its volume decreases, and then it is sent through capillary tubes to the refrigeration unit. The housing is liquid cooled to avoid heating.

How car refrigerators work

Cold energy in thermoelectric devices of automobile refrigerators is generated as follows: heat from food placed in the refrigerator is absorbed by plates in the container body made of aluminum.

A current flows through the thermoelectric plates, heating the outer side of the semiconductor plates and, accordingly, cooling the inner side adjacent to the body of the refrigerating chamber. Structurally, part of the plates is located directly in the chamber, and the second is outside.

Next, the modules move warm air into a special device - a stabilizer. A small fan is also installed there, which releases heat into the ambient air of the vehicle interior.

The device of an absorption-type auto-refrigerator uses a refrigerant, which is a solution of ammonia mixed with water. The solution is heated by constant electrical energy and circulates through the system. Since the boiling point of pure ammonia is less than that of water, the vapors of the ammonia-water solution are sent to the condenser and release the accumulated heat to the environment.

Through the pipe system, ammonia moves to the evaporator of the refrigerator chamber and cools its volume and the products contained in it. Due to the heat obtained during cooling, ammonia boils and turns into a gas phase. After that, the vapors are absorbed by water and, further, the liquid solution begins a new cycle.

The refrigerant solution circulates constantly: the absorber acts as a suction part, and the thermal pump acts as a supercharger.

Features of the device and operation of refrigerators with the NO Frost system

The main disadvantage of conventional household refrigerators is the regular freezing of moisture that enters the chamber and remains on the walls of the evaporator. As a result, the resulting frost prevents the cooling of the air inside the chamber. The normal cooling process is interrupted.

Freon continues to circulate in the system, but its ability to absorb thermal energy is reduced.

When a thick layer of snow coat appears in the freezer, the user faces two problems at once:

1. Food inside is less chilled.

2. The compressor motor is under increased load, as it is forced to work continuously, since the thermostat does not work in high temperature conditions. In this case, the parts of the mechanism wear out much faster.

That is why during the operation of refrigerators equipped with drip evaporators, it is necessary to periodically resort to their forced defrosting.

When using the No Frost system, moisture does not freeze. Accordingly, the scheme of operation of this type of refrigerator does not imply regular defrosting.

The No Frost system consists of:

- electric heater;

- timer built into the design;

- a fan that promotes heat absorption;

- special tubes through which melt water is drained.

The evaporator placed in the freezer is a compact enough radiator that can be installed almost anywhere. A fan is used to more efficiently absorb the heat generated inside the freezer.

No frost system fan.

Being directly behind the evaporator, it provides a constant movement of air in the required direction. Thus, food products are constantly exposed to air flow, due to which they are ideally cooled.

At the same time, condensate accumulates on the walls of the evaporator, as a result of which frost gradually forms. However, due to the timer that the No Frost system is equipped with, at a certain moment the heater starts and the defrosting process takes place.

When the heating element is turned on, the layer of the snow coat noticeably decreases, and the thawed water moves through the tubes, filling the tray located outside the refrigeration chamber. In the future, there is a natural evaporation of moisture, which enters the air of the room.

Predominantly, the device of a domestic refrigerator assumes the presence of a No Frost system exclusively for the freezer.

But there are also modern models in which it is installed, including in the refrigerator.

Such devices require much less systematic maintenance. The only inconvenience associated with their operation can be considered a fairly quick drying of the food in the chamber.

This is due both to the continuous circulation of air in the system, and to the almost continuous process of removing excess moisture.

The principle of operation of the inverter compressor

If the future owner shows interest in the topic, which refrigerator compressor better, it is recommended to consider a new generation of equipment with inverter compressors.

The principle of operation of units with an inverter system:

- When the device is turned on, the set temperature is injected into the chambers. The inverter is responsible for long-term support of the required level;

- Unlike its predecessor, these devices do not have the “shudder” effect when turned on or off, like a linear unit several times a day.

inverter compressor

Such functioning ensures a smooth and measured running of the engine, and the temperature regime operates without drops. In view of this, the service life of such equipment is much higher than that of linear models.

What's more, inverter-based machines are reliable and practical to use, as well as provide low power consumption. According to the results of the tests, the load on the network is reduced by 25%.

It is noteworthy that this type of device is used in the premium segment of the Bosch brand. Refrigerators of this brand are characterized by a long service life, have a high power reserve, so that at maximum load they continue to work without using the maximum power. In addition, representatives of the product line are characterized by low noise effect. Thus, it becomes clear which compressor in the refrigerator is better.

Refrigerator with inverter compressor

However, if the equipment fails, the restoration of working capacity should take place only under the guidance of a qualified master. Therefore, users should contact the authorized service centers of the manufacturer.

Note: Samsung provides a 10-year warranty for refrigeration equipment with a Digital Invertor system.

Advantages and disadvantages of refrigerators with an inverter compressor

Positive aspects:

-

Refrigeration units of this type are characterized by low energy consumption. In view of this, the units have been assigned a high energy saving class. In this case, the savings are 20% in contrast to other types of power plants. This feature is due to the use of maximum power only at the moment of switching on. The rest of the time, the system operates at reduced speed to ensure the required temperature in the chambers;

- When considering the design and operational aspects, it should be noted a single inclusion in quiet mode. At the same time, there is no sound from the sensor;

- The temperature regime set by the user is constantly at the set mark;

- Long service life is due to the absence of amplitude jumps, leading to increased depreciation of the system. As a rule, the manufacturer provides a 10-year warranty for devices, which additionally confirms the quality of the products;

- Virtually silent operation, since the compressor does not use maximum power;

- The positive aspects of using inverter installations can also be seen in the feedback from consumers who have bought more than two models. Studies have shown that owners note the absence of high loads.

When choosing a model of the device, future owners naturally show interest: the type of compressor in the refrigerator, which one is better. Experts note that the choice of installation depends on the budget of the user.

Despite the advantages of this type of installation, there are also disadvantages:

- The disadvantage of the assortment line is the high cost. Of course, in the future, the initial costs of purchasing the device will pay off due to savings in electricity consumption. However, this takes up to 3 years;

- Refrigeration units with this type of compressor are highly sensitive to fluctuations in the electricity network. Such situations can cause equipment failure. However, a number of manufacturers additionally equip the equipment with a protective system by installing built-in stabilizers or barriers.

If it is planned to install the unit in a country house or in a country cottage, then the user can independently protect the equipment from surges in the network by additionally purchasing a voltage stabilizer. The devices are triggered when there is a threat to stable operation, and the device goes into standby mode. After the network returns to normal, the system is restored.

Results

There is nothing complicated in the device of refrigeration equipment, regardless of which type is considered - compressor, absorption, vortex or thermoelectric. Each type has its own advantages and disadvantages and is used for specific purposes. But, the most common type of refrigerators - compressor. Units of this type are mainly used for domestic purposes. Their device is simple, they work due to the action of the simplest physical laws.

The refrigerant that is present in the sealed pipeline, under the action of the compressor, enters other elements, simultaneously giving and taking heat, as well as cooling the interior of the chambers. When the pipeline has lost its tightness, the refrigerator does not freeze, as well as in the event of a breakdown of any part. Knowing how the main components of the unit work allows you to extend the operating period of household appliances.

Video: The principle of operation of the refrigerator (No. 2)

The principle of operation of the refrigerator

Watch this video on YouTube

I recommend to read:

- The principle of operation of a start-up relay for a domestic refrigerator - The compressor drive of a domestic refrigerator is usually an asynchronous electric motor powered by a single-phase 220 V network. Its peculiarity is that when starting, a starting ...

- The principle of operation of compressor, absorption and thermoelectric refrigerators - Fundamentally, the device of the refrigerator is a closed thermally insulated chamber in which a constant low temperature is maintained. If it were perfect...

- By what principle does a compressor work in a domestic refrigerator - Refrigerator Compressor - what is a Compressor called a device that compresses a substance (in our case, it is a refrigerant in the form of freon), as well as its ...

- The principle of operation of a car refrigerator - Departure for a picnic or just out of town is almost always accompanied by a collection of food and drinks. But in summer, chilled food in a car heats up quickly, and in winter it cools ....

- The principle of operation of domestic household refrigerators "Donbass" - Refrigerators Donbass, Soviet production were produced in the city of Donetsk - now the plant is called NORDFROST and remains popular. Refrigerators of the old brand are not ...

- The principle of operation of gas refrigerators - The history of the development of refrigeration equipment is quite long and it is marked by the development of various subspecies of household units. Existing designs include…

- The electrical circuit of the refrigerator - The article will discuss electrical wiring diagrams for refrigerators from different manufacturers, answers to your questions: what does the connection diagram look like, what is it, ...