- The term for checking the gas meter VK-G4 of the company "Elster"

- List of works

- Professional problem solving

- What does a major overhaul include?

- Consider the diagnostic procedure in order.

- Obtaining a license to service a gas boiler house

- List of works

- Seasonal maintenance schedule

- Overhaul

- In the event of a breakdown

- Self cleaning gas boiler

The term for checking the gas meter VK-G4 of the company "Elster"

So for the household meter VK-G4 of the company "Elster" in the passport of the manufacturer, the verification period for the equipment is 10 years.

Decree of the Government of the Russian Federation No. 549 dated July 21, 2008, approved clause 25 of the Rules for the supply of gas to ensure household needs citizens that the determination of the amount of fuel used is calculated according to the data of the reader, verified on time according to the passport data. That is, the readings are not taken into account for presentation for payment if the verification actions are not completed on time.

The subscriber department of the gas supply organization enters data on the installation and suitability of the measuring equipment. And without fail, they inform the subscribers with a personal notice of the verification period, even if the device is working properly. Information is sent along with a receipt for payment, which indicates the contact details of the metrological and gas services.

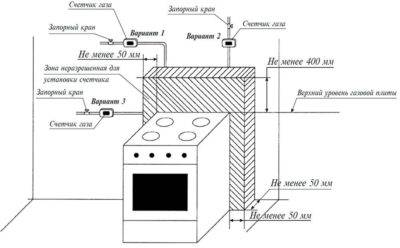

The suitability of a gas meter in an apartment or a private house also depends on the location of the equipment. Initially included in the package gas meter enclosed passport, which lists information about the instrument's design and installation and operating requirements. When the rules for installing devices that affect the life of the meter are not spelled out in the manufacturers' instructions, then we use the rules for placing gas appliances in an apartment or in a private house, prescribed in the gas equipment design standards (SP 42-101-2003 General provisions for design and construction gas distribution systems):

- height from the floor to the measuring device - 1.6 m.

- the distance along the radius from the gas meter to the heater and to the stove is also 0.8 m.

It is unacceptable to mount above the stove, sink and in areas with a large amount of excess heat and excess moisture.

The gas meter is a complex device and certain conditions prescribed in the rules for installing gas equipment must be observed during installation. It is forbidden to install a meter, and to mount gas pipes on your own. Installation actions are carried out by specialists certified for work for the replacement of measuring gas devices. If the customer wishes, a metering device is also installed from the side of the street on the wall of a residential building. In this case, the gas measuring device is protected from direct sunlight, strong temperature changes, and moisture. Such influences shorten the life of the device.

The calibration interval of the measuring instrument is determined by the manufacturer and is prescribed in the established document for the instrument.The interval between verifications is determined from the date of issue, but not from the installation of the meter.

List of works

Watch infomercials

For gas stove:

- Adjustment of the combustion process of the gas-air mixture in all modes of operation of household gas-using equipment (removal of burners, lifting of the stove table, adjustment of the air supply damper, fixing with a clamping bolt);

- Stove tap lubrication (lifting the plate table, removing the handles of the stove taps, removing the front panel of the stove, removing the flange with the stem, lubricating the stopper of the stove tap, lapping the tap, assembling the nodes and installing them in place. Each tap is lubricated separately and disassembled separately, gas communications devices and devices up to the burner nozzles are checked for leaks using a soap emulsion);

- Cleaning the gas supply burners from contamination (fixing the nozzle hole with a special awl, opening the stove valve, circular movements with the awl, removing the awl from the nozzle hole, closing the valve. In case of severe clogging, unscrewing the nozzle, cleaning with an awl, blowing the burner tube by opening the stove valve, place, check combustion if necessary, repeat);

- Checking the safety automation (checking the performance, adjusting and adjusting the devices provided by the manufacturer in the design of household gas-using equipment, which make it possible to automatically turn off the gas supply when the controlled parameters deviate beyond acceptable limits).

- Checking the gas stove oven with a leak detector and cleaning the oven burner mechanically.

- Visual inspection of the integrity and compliance with regulatory requirements (inspection) of in-house gas equipment.

- Visual check of the availability of free access (inspection) to the in-house gas equipment.

- Visual inspection of the state of painting and fastenings of the gas pipeline, the presence and integrity of the cases in the places of laying through the external and internal structures of apartment buildings and households (inspection).

- Checking the tightness of connections and disconnecting devices in equipment (pressure testing, instrumental method, soaping).

- Instructing gas consumers on the safe use of gas to meet household needs.

- Implementation of round-the-clock emergency dispatch support.

For instantaneous gas water heaters (HSV):

- Checking the tightness of the coil to the walls of the fire chamber, the absence of drops or water leaks in the heat exchanger, the horizontal installation of the fire surface of the main burner, as well as the absence of displacement of the main and pilot burners, the absence of gaps between the links of the connecting pipe, the sufficiency of the vertical section of the pipe and the absence of sharply curved turns.

- Checking the condition of the pilot burner (igniter), if any.

- Checking the smoothness of switching on at the start of water heating (at start-up there should be no popping and flame delay).

- Checking the operation of the main burner (the flame must be blue, burning over the entire area of the burner), if it does not comply, the burner is cleaned (removal of the VPG casing, removal of the main burner, the burner is cleaned by flushing, assembled in the reverse order).

- Lubrication of the crane (block crane) VPG (if necessary).

- Checking the safety automation (checking the performance, adjusting and adjusting the devices provided by the manufacturer in the design of household gas-using equipment, which make it possible to automatically turn off the gas supply when the controlled parameters deviate beyond acceptable limits).

- Checking the gas block and nozzle bar with a leak detector.

- Visual inspection of the integrity and compliance with regulatory requirements (inspection) of the in-house gas equipment, the availability of free access to the in-house gas equipment, the painting and fastening of the gas pipeline, the presence and integrity of the cases in places where they are laid through the external and internal structures of apartment buildings.

- Checking the tightness of connections and disconnecting devices in equipment (pressure testing, instrumental method, soaping).

- Instructing gas consumers on the safe use of gas to meet household needs.

- Implementation of round-the-clock emergency dispatch support.

When a contract for maintenance of VKGO is concluded with Project-Service Group LLC, our gas service specialists will come to you at any signal, regardless of the number of applications.

Professional problem solving

At first glance, there is nothing complicated in carrying out preventive measures for the maintenance of boiler units. But you should not engage in self-configuration and cleaning of the gas boiler. And it's not just about experience.

Such a critical procedure should be performed only by a qualified specialist who has the exact technique necessary for diagnosing malfunctions.

The quality of maintenance of boiler equipment directly depends on the professionalism of the master. Therefore, such work should be entrusted only to professionals who have a special permit.

In the event of an unforeseen situation, the master will be able to respond correctly and quickly, thereby preventing unnecessarily serious, sometimes catastrophic consequences.

According to clause 6.2 of the current SNiP, service maintenance of boiler equipment should be carried out by licensed organizations that have their own emergency dispatch service at their disposal.

Leading manufacturers of gas boilers, in order not to open branded service centers in every region of the country, issue licenses to organizations specializing in the field of maintenance.

You may be interested in information on how to choose a good and reliable gas boiler, discussed in our other article.

In addition to a certificate for performing a given range of work, such organizations receive full access to technical documentation for equipment manufactured by the manufacturer, as well as the opportunity to receive new boiler components for warranty replacement. The list of certified firms is usually listed on the manufacturer's website.

When choosing a service organization and drawing up a contract, you should focus on two parameters:

- Certification of the boiler manufacturer, which is confirmed by the presence of a license to carry out work.

- The location of the service center in the same city or region, which will reduce the response time of the field master.

In most cases, a service contract is signed even before the boiler is fully put into operation. It clearly prescribes a list of future work and the timing of their implementation.

As an addition to the contract, a boiler passport is attached, which contains all the design features of the system, a complete list of its components and elements, as well as the timing of maintenance

The work offered by service organizations is divided into three types:

- Routine maintenance - regular preventive work carried out to assess the technical condition of the unit, identify and eliminate imminent breakdowns, to prepare the unit for the heating season and after its completion before summer inactivity.

- Service at the request of the subscriber - includes measures to identify violations and damage to the system, diagnostics of the performance of the gas apparatus or its individual parts, elimination of breakdowns and malfunctions.

- Overhaul is a set of measures in case of a unit breakdown, carried out in the event of emergency situations provoked by the influence of external factors or as a result of equipment breakdown.

The regularity of preventive maintenance of the equipment depends on the purpose of the installed unit and its design.

A list of mandatory "procedures" for routine maintenance and overhaul, as well as the frequency of their execution, is provided by the manufacturer for each specific model

On average, current inspections are recommended to be performed 2 times a year. They are also carried out for devices included in the heating circuit, and for units of hot water systems.

Failure to meet the deadlines for such an important event can lead to serious consequences. Thus, pipeline clogging can cause a failure of the heating system, and depressurization of the gas pipeline can cause an explosion and fire.

Image gallery

Photo from

Stage 1: General diagnostics of the technical condition of the equipment

Stage 2: Adjustment of the column ignition and gas combustion process

Step 3: Checking the tightness of the heat exchanger

Stage 4: Monitoring the condition and performance of the turbine

This is interesting: Pellet heating boilers - how to choose a boiler pellet powered?

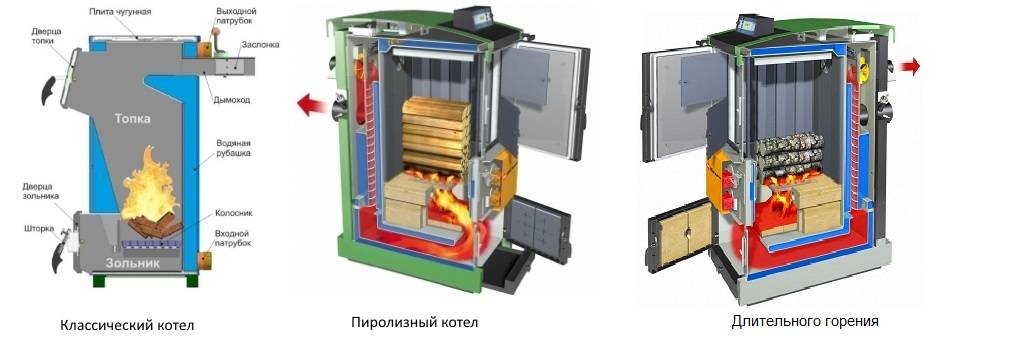

What does a major overhaul include?

After the expiration of the operational period specified in the passport for the product, the gas boiler is subject to technical diagnostics. The main task of engineering and technical measures is to determine the possibility of further safe operation of the equipment.

Overhaul is carried out in order to restore the technical characteristics of gas heating equipment. As necessary, worn parts and functional units are replaced.

In addition to diagnosing as part of the capital service, they perform:

- Washing the heat exchanger.

- Comprehensive examination and cleaning of all closed boiler units.

A well-conducted set of measures is a guarantee of the correct operation of gas equipment during the subsequent service life.

Scale build-up in the heat exchanger coil due to improper maintenance leads to a gradual deterioration in the efficiency of the equipment

Cleaning of the heat exchanger from scale is carried out after the first five years from the date of commissioning of the boiler unit. Although most service organizations recommend preventive flushing every two years. A simple procedure for flushing the boiler heat exchanger eliminates the problem at the stage of scale formation.

To carry out a major cleaning, remove the casing of the device and disassemble all removable parts of the unit.Separately dismantle the heat exchanger and using a pumping station washed thoroughly with chemicals. Such washing allows you to remove all the scale that has formed in the pipelines and fins of the heat exchanger over several years. After that, the boiler is assembled and the system is filled with coolant.

Apart from maintenance of the gas boiler itself and the gas pipeline leading to it, it is important to regularly check the condition of the chimneys

Cleaning of smoke channels, designed to divert combustion products from gas appliances and create traction, is not included in the list of measures necessary for the master to perform. This work can be done for an additional fee. If desired, cleaning the chimney can be done on your own. It is advisable to flush it at least once a year.

Consider the diagnostic procedure in order.

Firstly, before starting the gas boiler, it is necessary to analyze its appearance. Carefully inspect the outer casing, water, gas, see if there are any traces of splashes, stains, soot, burning around. The turned off boiler must be thoroughly cleaned from dirt, dust, cobwebs, scale, both inside and outside.

You should not turn a blind eye to minor flaws, in the future this can lead to major problems, up to completely changing gas equipment.

The next step is to pay attention to the smell of gas. If there is a suspicion of a gas leak, in no case do we independently ignite

We turn off the gas valve and call the specialists of the GorGaz service. They are quick to respond to emergency calls.Clearly explain to the visiting specialists the essence of the problem.

The gas equipment is visually in order, the smell of gas is completely absent. It remains to check the presence of traction in the exhaust system.

If possible, the exhaust system is checked visually. The next way is with a burning match, or a lighter

But, before that, it is important to make sure that there is no smell of gas, other extraneous odors. The air in the boiler room must be fresh

In modern two-loop boilers, there is a variant of their own wall hood. In this case, it is necessary to inspect the end of the exhaust pipe from the outside. There should be no ice, debris.

If you have a simple heating boiler with a manual ignition system, then before ignition, by cutting off the gas supply, using a torch, you can simply detect the presence of traction.

If the boiler is equipped with an auto-ignition system, then attention should be paid to the operation of the electronics system. If the boiler goes out after several ignition attempts, this is a lack of draft

There may be no draft if the upper casing of the boiler is not worn after repair. If the chimney is clogged, if it is mounted at an incorrect, negative slope, if the hood motor or sensor is out of order.

In modern gas boilers error ignition is necessarily confirmed by a digital error code.

If the error cannot be eliminated by elementary actions, then the boiler cannot be ignited.

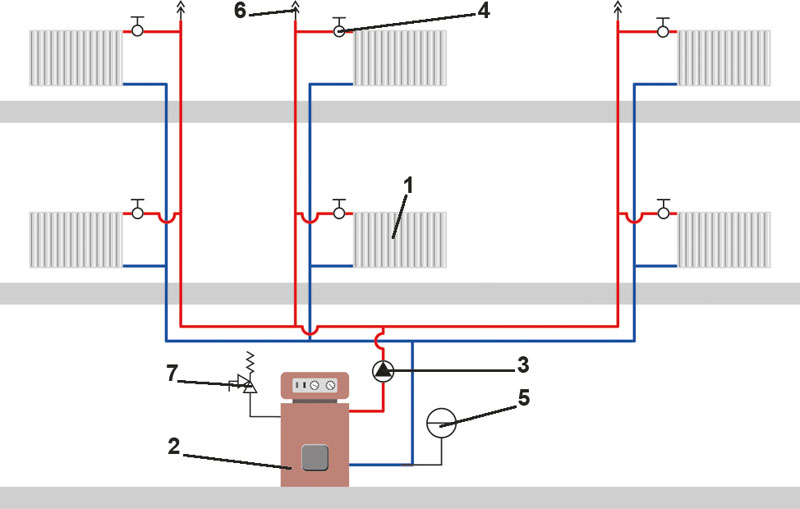

It is also important to make sure that there is a coolant in the system. This can be checked with a manometer.

The minimum pressure should be about 0.5 atmospheres. If the system is electronic, then at a lower pressure the system turns off. If simple manual mechanical system, then the boiler may fail - the heat exchanger will burn out.And this is one of the most important and expensive components of a gas heater. Replacement is carried out only by a specialist, and with an admission to this particular type of gas boilers.

Most modern heating systems have a circulation pump. This pump makes the coolant circulate throughout the system, up to far points. It can be built-in or external. But his work is essential. You need to make sure it works. This can be tested by placing your hand on the pump housing and on the pipe that exits the pump. When the circulation pump fails, the system is able to work, but the heat supply parameters are reduced significantly.

In the first weeks of the heating season and in the most severe frosts, it is necessary to monitor the pressure of the coolant in the system, the readings on the boiler control panel. It is worth remembering that it is contraindicated for many gas boilers to add coolant to a hot system in order to increase pressure. This is fraught with a rupture of the heat exchanger housing, and even failure of all boiler mechanisms.

It is also worth remembering that the maximum temperature of the coolant in the system should not be more than 90 degrees Celsius. This can lead to the destruction of radiators and heating pipes, which, according to current regulations, are not designed for long-term operating temperatures of 90 degrees.

Competent regular maintenance, especially thorough at the first autumn start-up, is the key to the long-term operation of a gas boiler.

Obtaining a license to service a gas boiler house

Russian legislation provides that the activities of commercial enterprises aimed at the operation of high-risk production facilities must be licensed by the state.

So, how to get a license, if necessary, to operate a boiler room? In general, the presence of a license indicates that the enterprise has a complete material and technical base for the operation and gas boiler service.

The license is a stamped paper with seals and signatures of the relevant persons with an individual number entered in the state register.

This is approved by the Law of the Russian Federation No. 99 “On Licensing Certain Types of Activities” of 2011, as well as the aforementioned Decree of the Government of the Russian Federation No. 492 “On Licensing of Objects of Hazard Classes I, II and III” and Federal Law No. 116 “On Industrial Safety”

Obtaining a license is provided for by all private enterprises and legal entities operating boiler equipment of the corresponding hazard category.

A license is required if:

- boiler units are used that operate at a pressure of 1.6 MPa and heating the coolant above 115 ° C;

- pressure in gas consumption networks from 0.005 MPa;

- supply of heat to social facilities of high importance;

- over 20 thousand tons of liquid fuel are stored on the territory of the boiler house.

To obtain a service license, you must meet the following requirements:

- the licensed entity must have the required material and technical base for the performance of the work provided for by the license, and the buildings must be in its possession or lease;

- must present documentation confirming the successful installation of the gas boiler and putting it into operation;

- the enterprise must comply with safety rules at industrial facilities;

- have contractual relations with the rescue and emergency recovery services;

- funds in the bank account, guaranteeing the localization and elimination of accidents.

You will also need:

- Write an application with the provision of documents confirming the ownership of the building (lease agreement);

- Documents on putting the equipment into operation.

- Certificates of conformity, including TR TS certificate.

- Copies of certificates of employees who have passed safety certification.

- Declaration of industrial safety.

- Action plan in case of an accident.

- List of equipment for emergency protection and signaling.

- Copies of contracts with rescue services and emergency recovery work.

- Copies of civil liability insurance.

- Information from the bank confirming the availability of funds.

- Receipt of payment of state duty.

List of works

To understand what exactly should be cleaned, checked and adjusted in the boiler, with what frequency, it is enough to look at the instructions and technical documentation, which must be attached to the boiler upon purchase. These documents provide a complete list of components and elements involved in the equipment, maintenance requirements and the frequency with which to check the status, perform service and update settings if necessary.

It is absolutely impossible to focus on this information for self-cleaning of a gas boiler. This information gives a clear idea of what to expect from a service company with which to conclude a contract for the maintenance of gas equipment.

Works are conditionally divided into three groups:

- Regular work carried out before the start of the heating season and after it, preparing the boiler for summer inactivity.

- Capital service. Works carried out every few years and aimed at servicing elements with an initially long service life (flushing the heat exchanger, replacing seals and valves, maintenance of fans, etc.).

- Repair in case of breakage. The procedure for actions and mandatory work in the event of an emergency, breakdown or consequences of external factors.

Seasonal maintenance schedule

Before the start of the heating season, the boiler should be brought into proper working condition, the operation of the sensors responsible for safety should be checked. Only after that the boiler is switched on for operation.

If the manufacturer is allowed to carry out routine maintenance only once a year before starting, then in addition to commissioning, the main elements of the boiler are cleaned, with the exception of flushing the heat exchanger and a complete overhaul of the control units. If maintenance (maintenance) is carried out after the season, then cleaning is assigned to this stage.

Required list of works:

- General inspection, removal of dirt from internal and external surfaces.

- Cleaning filters (air, gas, coarse cleaning for water).

- Cleaning and checking the burner.

- Cleaning the fire section of the combustion chamber.

- Checking the tightness of the internal gas channels.

- Checking the ignition electrodes (piezoelectric element and burner).

- Test and diagnostics of the electronic control unit.

- Test and diagnostics of sensors and automation responsible for safety.

- Boiler parameters adjustment, combustion adjustment. The process is accompanied by the analysis of off-gases.According to the composition and concentration, the master judges the accuracy of setting the boiler.

- Checking the condition of the shut-off valve.

- Checking the gas supply pipeline in the section from the main to gas equipment.

- Checking and adjusting the pressure in the expansion tank.

Overhaul

In addition to routine maintenance carried out every season, during the overhaul of a gas boiler, elements with a limited warranty period are replaced, the internal surface of the heat exchanger is cleaned, seals and valves are flagged. The main task is to replace elements that are not subject to maintenance during routine maintenance, but still have a service life.

In the event of a breakdown

In an emergency situation, when a breakdown occurs during operation, it is very important to react to the problem as soon as possible and return the boiler to working condition. Breakdowns, if they appear, are just during the heating season, for example, if the boiler operates for a long time at maximum power in the coldest period of the year. At this time, it is extremely difficult to find a specialist for a quick repair, but with a service contract, all you need is to leave a request so that the repair team arrives in a short time to fix the problem

Since the service center keeps records of boilers, a specialist already arrives at the customer with a set of necessary tools and spare parts for a specific model of gas boiler

At this time, it is extremely difficult to find a specialist for a quick repair, but with a service contract, all you need is to leave a request so that the repair team arrives in a short time to fix the problem.Since the service center keeps records of boilers, a specialist already arrives at the customer with a set of necessary tools and spare parts for a specific model of a gas boiler.

Self cleaning gas boiler

If you still decide to save money on maintenance, then you need to decide which work can be done on your own, and which ones can be entrusted to professionals.

Do-it-yourself flushing of a gas boiler heat exchanger is a fairly simple process that does not require specialized tools and special knowledge. There are two ways to perform these works: with or without disassembly of the system. For to remove scale without disassembly, you need to purchase a descaling agent at the nearest household chemical store, dilute it in the correct proportion and pour it into the system. After that, you need to turn on the boiler and let it work at maximum power.

The second option is more difficult.

- Disconnect the boiler from the network.

- Perform measures to drain the coolant from the system and expansion tank.

- Remove the cover of the device with the controls located on it.

- Remove the heat exchanger. In some models, this will require disassembly of the combustion chamber.

- Rinse the heat exchanger with a solution of citric acid or a specialized descaling agent.

- Follow the reverse procedures for installation, assembly of the boiler, as well as filling the system with coolant.

It should be noted that for high-quality flushing of the heat exchanger in service centers, pumping stations are used, which will perform this procedure faster and better. It is enough for you to remove soot from the surface of the heat exchanger every year.

There are a lot of "experienced" tips on the Internet about self-cleaning the gas valve. Before following the instructions, understand its purpose and design.

Purpose of the gas valve gas supply to the burner depending on the given power. In addition, the gas valve is responsible for stopping the gas supply when any of the safety sensors are triggered. Cleaning this valve consists in cleaning the gas filter, which is installed inside the gas supply fitting. Despite the fact that this procedure is not particularly difficult, it is still better to entrust it to professionals.