- What is it and why is it needed

- Varieties of cranes

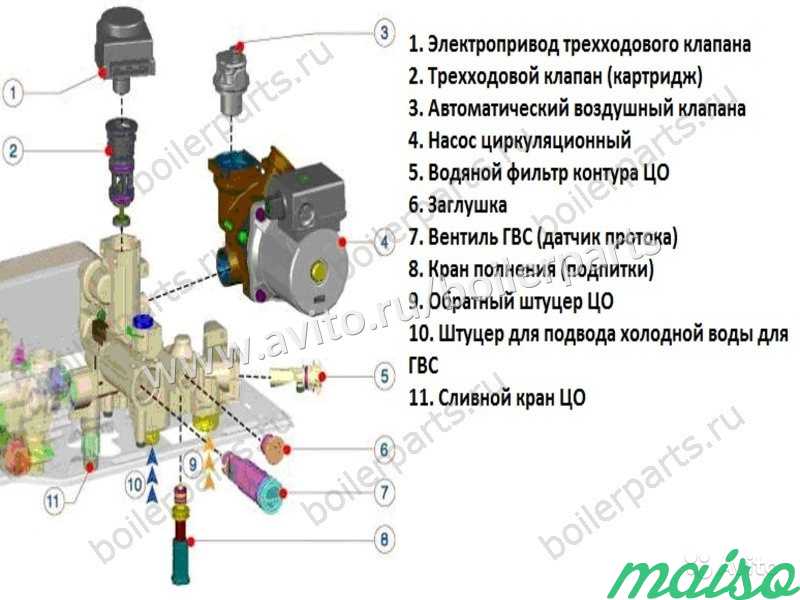

- Self-repair of boilers

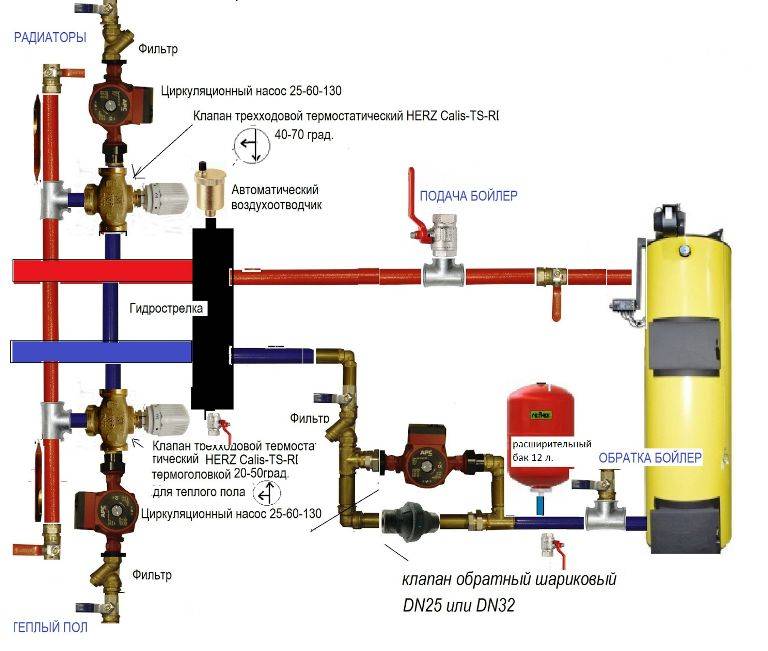

- Wiring diagram

- Important operating instructions

- Causes of failure

- Preventive measures

- Types of valves for underfloor heating

- mixing

- Mechanical

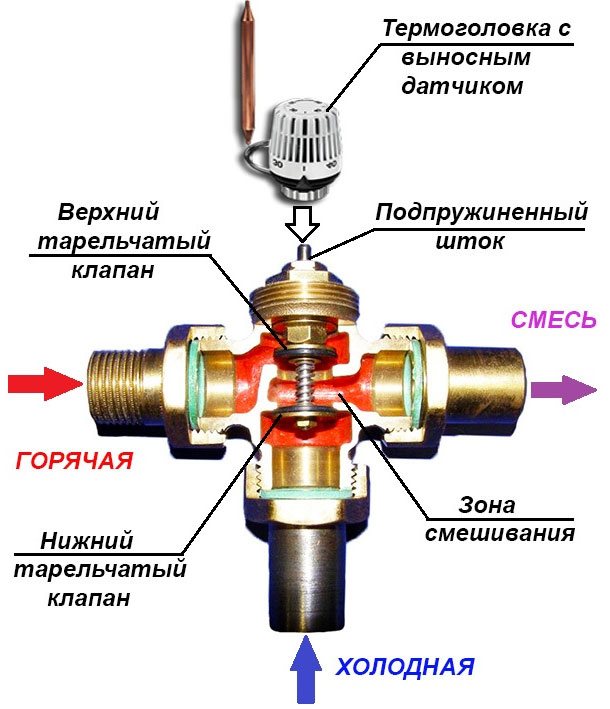

- with thermal head

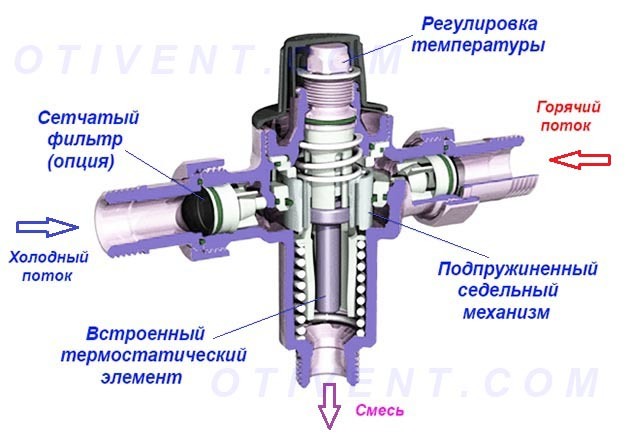

- Thermostatic

- Main malfunctions and methods of repair

- Checking electrical components

- Checking the electromagnet coil and its repair

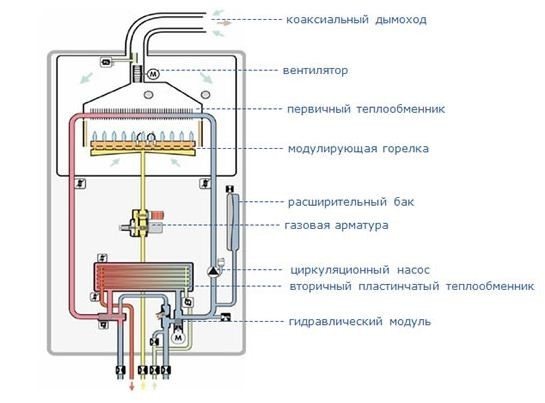

- The design and functionality of the device

- Solenoid valve

- Recommendations for selection and installation

- Where are three-way valves used?

- Gas boiler does not heat hot water

- How does a three-way valve work in a heating system

- Types of three-way valves according to the principle of operation

- Conclusions and useful video on the topic

What is it and why is it needed

It looks like a classic three-way valve for a heating system. As the name implies, this valve has 3 strokes. You can even call it a tap, as it refers to shut-off and control valves. It looks like an ordinary tee, but inside its device is much more complicated. Roughly speaking, it serves to change the temperature of the water. There are two ways: in the first, the return is mixed with the supply to lower the temperature; the second method, on the contrary, separates the flows, discharging hot water into the return line. This is useful in different cases:

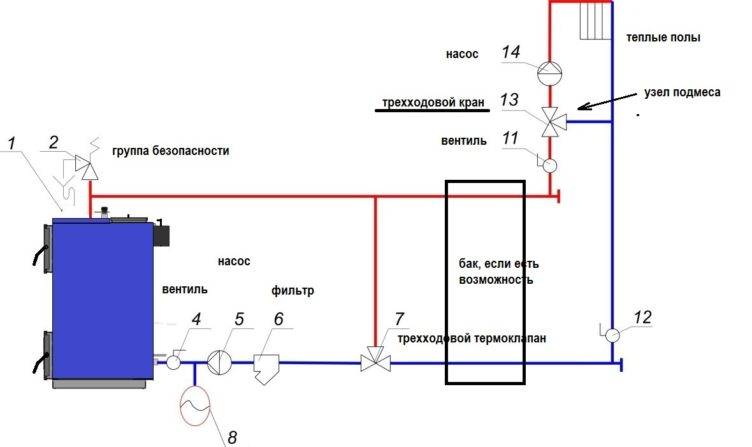

- Warm floor. The return flow and heating supply are connected to the valve. Since the return is colder, water at a lower temperature is supplied to the floors. At the same time, the temperature of the rest of the heating remains the same.

- Temperature maintenance. For normal operation of almost any heating equipment, it is necessary that the return flow is not colder than the supply by 60 degrees. Otherwise, the boiler will not last long. Therefore, the valve takes water from the supply and sends it back.

- Condensation protection. For the same reason. If water warmer than the dew point enters the heat exchanger, condensation begins to accumulate on it.

- Overheat protection. Modern boilers are equipped with various sensors. If it is, for example, a simple solid fuel boiler, it will continue to work even when overheated. The three-way valve solves this problem.

- For piping an indirect heating boiler. In order to have hot water in the house, you can connect a boiler to the boiler. And then the water will be heated by heating. The three-way tap serves for uninterrupted supply of hot water. It opens when the temperature of the water in the boiler drops.

- When organizing a bypass. In some cases, it is required to direct the water along an alternative path - a bypass. For example, for more efficient heating. The easiest way to do this is through a three-way valve. It will open and close at the right time.

But why install a valve when you can just lower the temperature? The question seems logical, but in fact, in conventional boilers at low temperatures, the heat exchanger quickly fails. For this mode of operation, a condensing boiler is better suited, but their price is much higher. Therefore, it is better and easier to install a three-way valve.

Varieties of cranes

Classification of the product according to various criteria:

Depending on the valve, there are:

Regulatory. It is equipped with an electromechanical device that opens the desired valves

It also includes a stem with manual or automatic adjustment. Important! The rod cannot be knocked out even by the strongest water pressure, since it is located inside the device. shut-off

In its complexion there is a ball device that switches the flow of water

Shut-off. In its complexion there is a ball device that switches the flow of water

The peculiarity of this device is that it is installed on systems with low pressure. It is very simple in design, requires constant care and wears out quickly.

By product material:

Brass is the most demanded material, due to the long period of operation, small dimensions and low weight.

Carbon steel is a great alternative to brass.

Cast iron - used for pipes of large diameter (from 40 mm and more). It is not practical for private houses.

Bronze is a material with a long service life.

Depending on the installation method: coupling;

flanged;

tsapkovy;

for welding;

fitting-end.

For the heating system use such types as:

With a constant hydraulic mode - regulated in accordance with quality indicators. It is suitable for consumers with high-quality heat carriers of a certain volume.

With variable hydraulics - adjustable according to the required amount of water. It is more suitable for those for whom quantity matters.

From the variant of the flow part of the device: test-bleed;

full bore.

From the type of built-in shutter: cone;

cylindrical;

ball.

The following types are distinguished according to the shape of the plug valve: T-shaped;

L-shaped;

S-shaped.

From bolt mechanics:

Stuffing box - controls the adjustment of the water jet from above the fittings due to the stuffing box;

Tension - controls the adjustment of the water jet from the bottom of the reinforcement due to the nut.

Depending on body heating:with heating;

without heating.

Depending on the technical indicators, the following valves are distinguished:

T-shaped - the adjusting knob can be in 4 positions;

L-shaped - the adjustment knob has two modes, including a 180 degree rotation angle.

From device control mechanism:

Manual - connects water flows in approximate proportions, cheap, looks like a standard ball valve;

Electric drive - additional equipment is used for operation - an engine or a magnetic method, it is possible to get a shock from the current;

Pneumatic actuator is the best option for use. Important! With an electric drive, you can easily balance the heat so that the temperature level in the rooms farthest from the boiler is the same as in the nearest ones.

Self-repair of boilers

A gas boiler is a very complex and dangerous heating system. In case of incorrect installation, there is a risk of explosion of the unit. Failure to correct problems promptly or improper maintenance will result in the release of carbon monoxide and combustion products into the room, which is very dangerous for the health and life of humans and pets.

Built-in automatic devices are responsible for the operation of the boiler. They are not easy to understand. And if the automation turned out to be faulty, then you should not repair it yourself. It's better to call a specialist Troubleshooting in an automatic system.With your own hands, it is only possible to remove all contaminants in the chimney, pipe and other parts of the boiler, as well as fix visible damage to the unit.

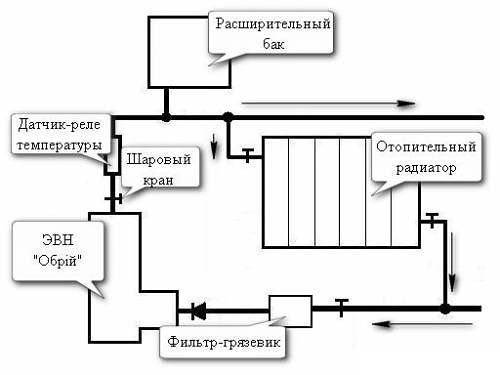

Wiring diagram

Let's return now to the general scheme of the valve. We analyzed the mixing of two coolant flows that have different temperatures. Here, the main drawback of the “three-way” comes to the surface, which cannot dose the amount of coolant. The cold stream is mixed with the hot stream, and a rather unpredictable temperature is obtained at the outlet.

The thermoblock tries to maintain a given level, but it is extremely difficult to do this. An unstable equilibrium is constantly present in this case. Such a scheme resembles the phenomenon, as if you open two taps with cold and hot water, it will be almost impossible to determine the exact temperature of the water. Thus, if it is not possible, using a valve, to influence the mixture, then it is necessary to install an additional unit that can influence the cooled coolant.

Most often mounted:

- balancing valve.

- Tuned Radiator Valve

These two elements are mounted on the bypass so we will get the desired temperature. If there is no coordination between the pump of the boiler and the underfloor heating, then in this case the transfer of the coolant (the boiler is more powerful) immediately into the return of the boiler circuit. Thus, nothing will reach the warm floor. This phenomenon can be avoided by installing a check valve, it can also be installed at the outlet. Thus the problem will be solved. Average cost:

- Three-way valve 3300 rub.

- Thermal head 2700 rub.

- Check valve per inch 500 rub

- Valve, radiator valve up to 700 rubles

- The total amount is about 7200 rubles.

This does not take into account pipes fixing materials.

It is worth considering the temperature range. For underfloor heating, the temperature does not exceed 40°C. There are also pressure tolerances: expensive designs “hold” pressure up to 16 bar, for household appliances 2.5 times less (5-5 bar) is enough. These indicators are regulated by GOST 26349-84.

Three-way valves have different nozzle diameters. The most popular of them: these are 1 and ¾ inches, while the thread can be both internal and external.

Three-way valves in underfloor heating seem nondescript, but they are necessary in operation and are used in various fields, performing important functions. It is recommended to use valves from well-known manufacturers, then this compact device will work without failure for many years. When buying, you should get acquainted so that there are no damages or cracks on the case. The regulator should turn freely in any direction. The thermal head is tested with a slight heat. This can be done using o

Read also:

Important operating instructions

In terms of operation, gas boilers with a closed combustion chamber are considered safer. Their firebox does not communicate with the air of the room. However, the power of such boilers is significantly inferior to the power of boilers with an open combustion chamber. Therefore, in private households, the second type of boilers is often installed.

The choice of the future coolant depends on the goals and operating conditions of the system. If frequent shutdown of the boiler is expected, then it makes sense to think about using antifreeze

The operation of such boilers requires compliance with safety regulations. So, for arranging a powerful floor boiler, it is customary to use a separate room with certain dimensions. The boiler is mounted at some distance from the walls. Nearby walls must be protected with fireproof material to prevent ignition.

The boiler room needs a ventilation system. There should also be a source of natural light. The width of the front door must be at least 80 centimeters. The chimney is laid in accordance with the instructions for the boiler and from heat-resistant material. The chimney must rise above the roof ridge by at least half a meter.

One of the security measures is the installation of carbon monoxide detectors. The gas detector will detect the leakage of volatile toxin in a timely manner and warn users about it. It can also be set to automatically turn on the ventilation and turn off the gas supply. Modern automation allows the introduction of a variety of smart systems.

If the temperature, pressure or gas content sensor is out of order, then you must immediately turn off the boiler and call the master from the service department. Using the boiler without these devices is fraught with serious negative consequences.

The requirements of SNiP state that it is necessary to connect a gas boiler to the main line using a copper pipe or a bellows hose. In this case, a crane must be installed

If signs of gas leakage are found, immediately turn off the gas valve and open windows to ventilate the room. Do not turn on the light and try to illuminate the room by lighting matches or a lighter.

The gas boiler must be serviced at the intervals specified by the manufacturer. Data on the necessary procedures are indicated in the instructions for the device. For example, you need to clean the chimney, remove scale from the heat exchanger or clean the cinders from the burner. Then the boiler will last a long time, and the risk of serious malfunctions will be significantly reduced.

When using a gas appliance, do not turn it on at maximum power for a long time. This can lead to the release of steam, which is unacceptable.

Sometimes the boiler starts to make unusual noises and vibrations. This may be due to the operation of the fan. We warn you that all actions for which you have to disassemble the boiler casing automatically deprive the owner of the right to warranty repair or replacement.

However, the owner of the unit needs to control the operation of the mechanisms and systems that protect the boiler from fire. It is necessary to maintain the temperature in the circuits at around 50 degrees, which significantly reduces the likelihood of mineral deposits on the inner surfaces of pipes and appliances.

Causes of failure

In the conditions of constant operation of a double-circuit boiler, breakdowns or inaccurate information supply by the smoke sensor are possible.

The following negative aspects can lead to such consequences.

- Contact oxidation. When the fan is turned on, a switch beep is heard, however, due to oxidation processes on its current-carrying elements, the circuit cannot close.

- Membrane wear. The operation of the pressure switch can deteriorate significantly if the technical properties of its moving element (membrane) deteriorate.

- Cork from debris, damage to the condensate collector tube.If the tube is cracked, torn, or clogged, flooded with water, the smoke sensor may start to give an error in the readings.

Preventive measures

To prevent breakage of any parts of the boiler, special preventive measures are taken. Before the start of the heating season and after it, the unit must be serviced in a special way. If possible, it is disassembled and all components of the spare part are carefully inspected for damage. All malfunctions must be eliminated, broken parts replaced with new ones or repaired.

Due to the danger of gas boilers, you should not deal with problems on your own if there is no experience in repairing units. It is better to entrust the repair of the device to a master who, without errors, will identify broken parts and repair or replace them with new ones. During operation and maintenance, the manufacturer's instructions must be followed.

Types of valves for underfloor heating

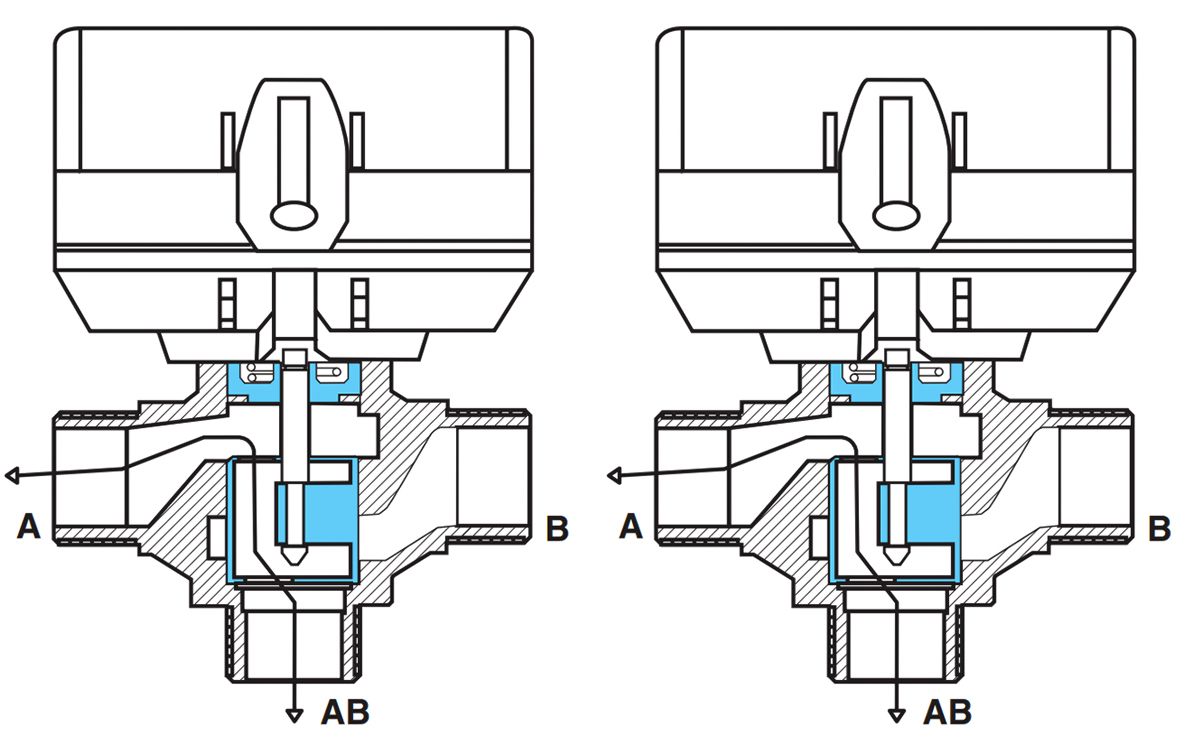

mixing

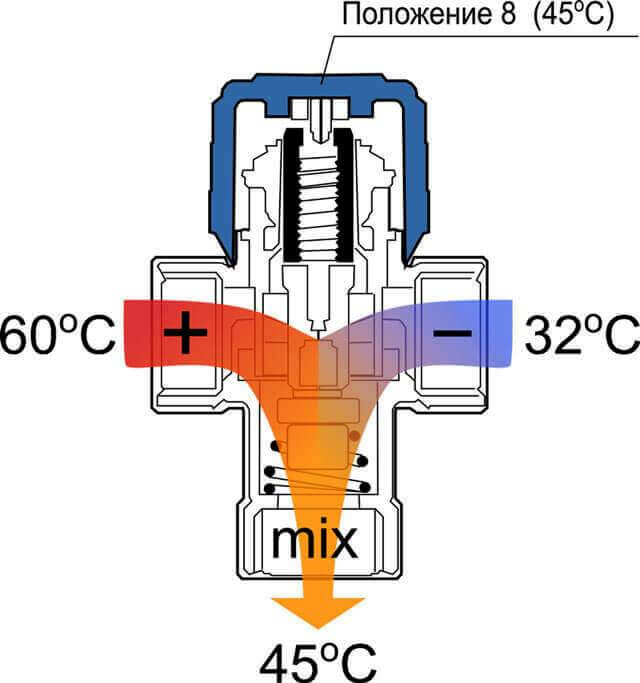

When the valve is raised, two passages are open. In this case, actively cold and hot water are mixed, thus the acquired temperature is set, which is controlled by the sensor of the thermal head.

If the temperature of the coolant is too high, then the valve is lowered. Thus, only the zone of cold coolant admixture remains free. In this case, internal water is stored in the underfloor heating unit.

Mechanical

In the second version of the three-way valve, we observe that the zones are all in other places. The warm floor zone moved to the lower part, the "plus" moved from right to left. All these details don't mean much.

The stem is attached to the valve, there are markers under them, focusing on them, you can adjust the temperature.The method is simple and very reliable. Such an element is inexpensive, but all modes have to be adjusted manually. The heating circuit can then heat up unevenly.

with thermal head

Most importantly, when the stem is raised, no mixing occurs. Hot water without the slightest delay is sent to the underfloor heating circuit

Such a phenomenon is not productive and does not carry a positive charge. If the plug is closed, then internal circulation continues (as in the first version).

Thermostatic

A thermostatic three-way valve for underfloor heating is a device where there is a special thermostat. The adjustment in this case is done once, after which the movement of the valve is automatically adjusted. This process is controlled by a thermosensitive substance (sometimes a gaseous substance). As the temperature increases, these consistencies expand in volume and affect the valve. Such a device is more expensive, but it works quite reliably.

The location in the third last version of the three-way valve for underfloor heating is exactly the same as in the first. The fundamental difference is that when the valve is raised, the coolant penetrates into the inside of the warm floor. We observed a similar phenomenon in the second variant. If the valve closes, then active circulation takes place, as in the first and second cases. The situation is thus with a closed valve as it combines all three valves.

You can call the valve like this:

- No. 1 - Mixing

- No. 2 - Dividing

- No. 3 - Dividing

The last two are auxiliary, they do not work without admixture and only change the direction of movement of the coolant.

Having considered the whole picture, it is easy to guess that the first valve is ideal for a warm floor. The reason is simple: the system includes a coolant that has undergone the necessary training. It should be borne in mind that the valves operate at different temperature conditions, have different throughput, there are differences in the materials from which they are made.

Here are the consequences of using a warm floor without mixing:

Main malfunctions and methods of repair

The loss of HA functionality leads to a shutdown of all boiler equipment of heating equipment, or partial shutdown, when it is impossible to adjust the desired level of heating in the room, due to the partial opening of the membrane.

Sometimes there are situations that, on the contrary, lead to a continuous supply of fuel to the burner device, when the gas-air valve is constantly open.

All of the above failures must be immediately eliminated, as they can create an emergency in the house. If the user does not know what to do with a faulty valve, immediately turn off the inlet gas valve, thoroughly ventilate the room and call the representatives of the gorgaz.

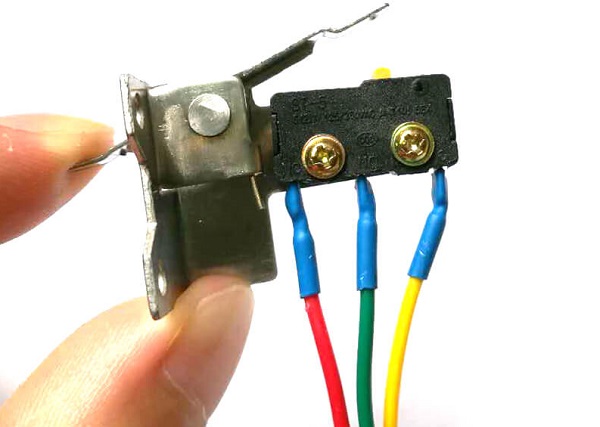

Checking electrical components

It is possible to test the functionality of the electromagnetic main cutter without dismantling. To perform the test directly on the boiler, you need to turn off the gas supply by turning the valve on the gas pipeline.

In addition, the boiler can remain connected to the mains. On the fuel supply regulator to the burner, there is an electronic unit - a microswitch, which, when the heater is turned on, supplies power to the main technological components.

micro switch

Voltage supply zones by microswitch:

- ignition system device;

- fan heater;

- electromagnetic coil.

In the event that forcibly, for example, with a screwdriver, act on the hydraulic pusher plate of the microswitch, power will be supplied to the boiler automation system.

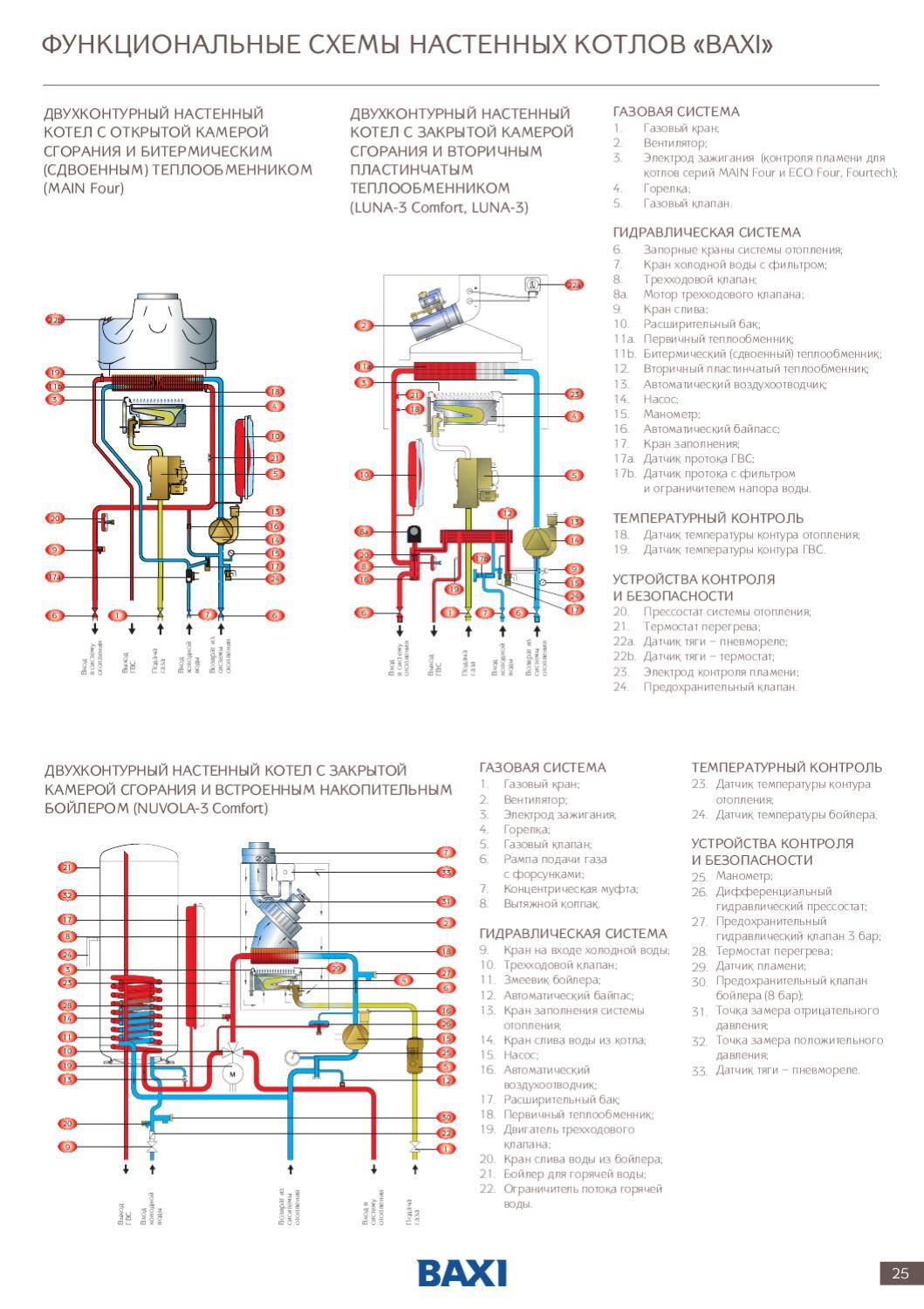

As a result, the activity of the following elements is activated, for example, at the gas valve for the Baxi boiler:

- fan

- piezo ignition;

- solenoid shut-off valve.

The examiner will hear the sound of the fan running, the clicking sound of the piezo ignition, and the distinctive click of the valve stem. A similar position of the device shows the performance of the elements, in any case, in the electrical part.

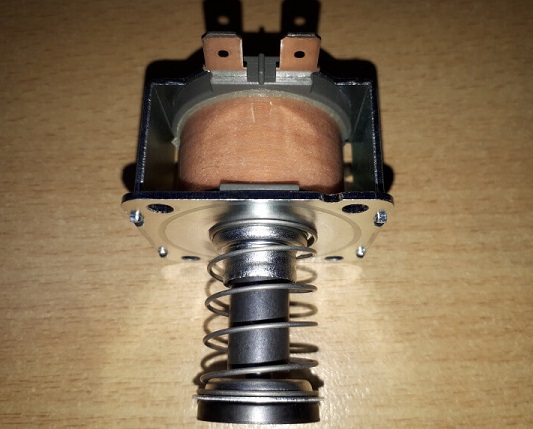

Checking the electromagnet coil and its repair

The practice of operating gas equipment of boiler units indicates that a malfunction of the electromagnet coil does not always occur due to a break in the winding conductor.

There are frequent episodes of interturn short circuit, which similarly leads to the loss of functionality of the protection unit. In connection with this, it will be necessary to diagnose the condition of the solenoid valve of the heating boiler.

The performance test of the inductor is performed using a tester for rupture or interturn short circuit. The measurement of the inductor is usually carried out in the order of measuring the resistance - by attaching probes to its contacts. When the node does not respond to the connection in any way, it seems that there is an open circuit.

valve coil

In the event that the diagnosed resistance parameter differs from that specified in the documentation, most likely, an interturn short circuit occurs. In both cases, the coil must be changed.

The gas valve is a very critical piece of equipment, when repairing or maintaining it, you must adhere to the following recommendations.

It is necessary to avoid impacts, drops, shocks on the device and keep the technical label affixed to the valve. The data indicated on it is very important for future repairs.

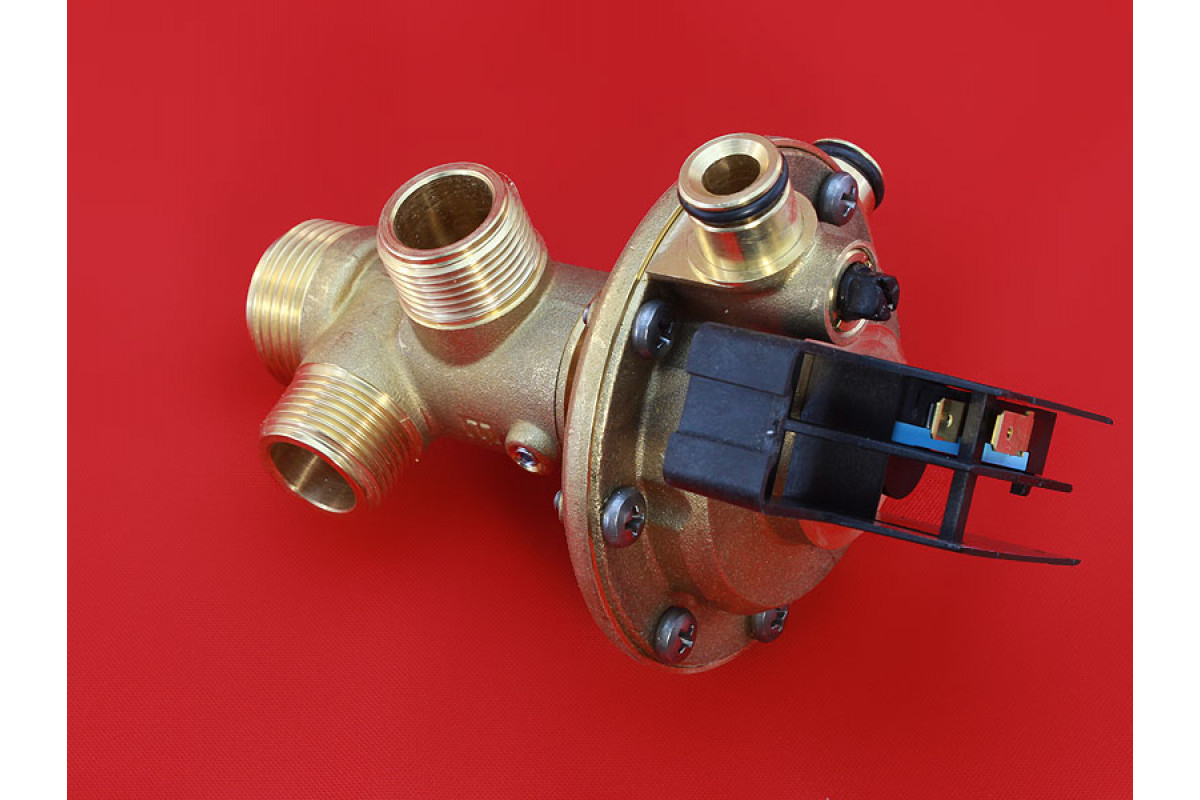

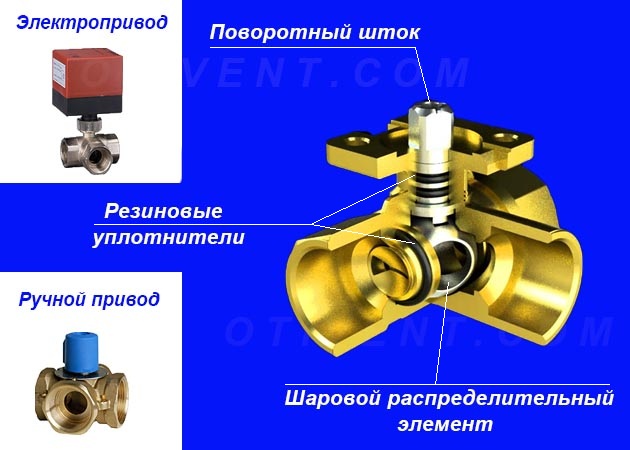

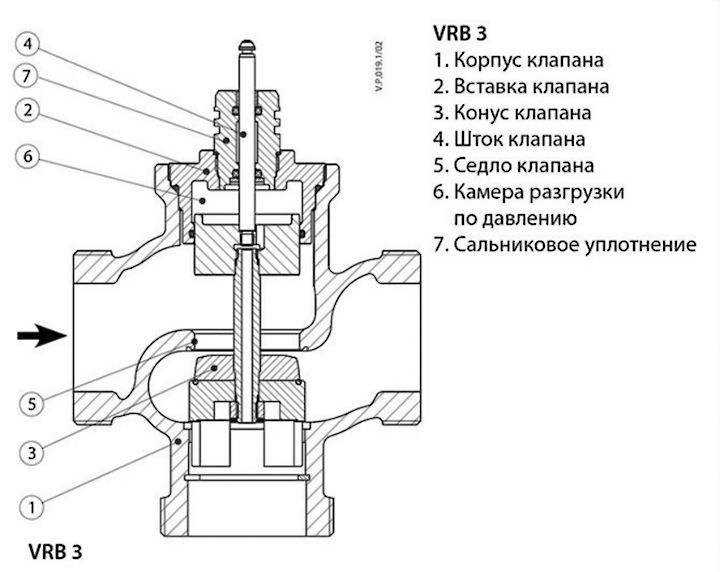

The design and functionality of the device

Three-way valves (TK) differ in size and materials: stainless steel and bronze. The body can be made of both metal and polymer material. Although the latter is not very popular.

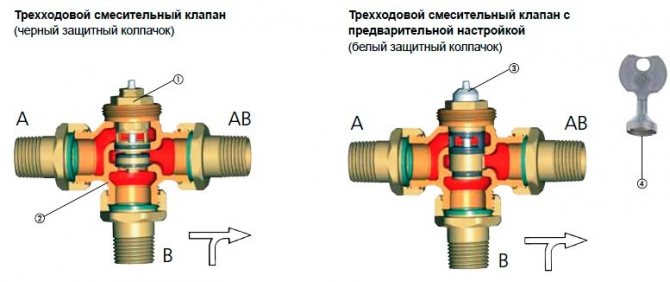

Valve types

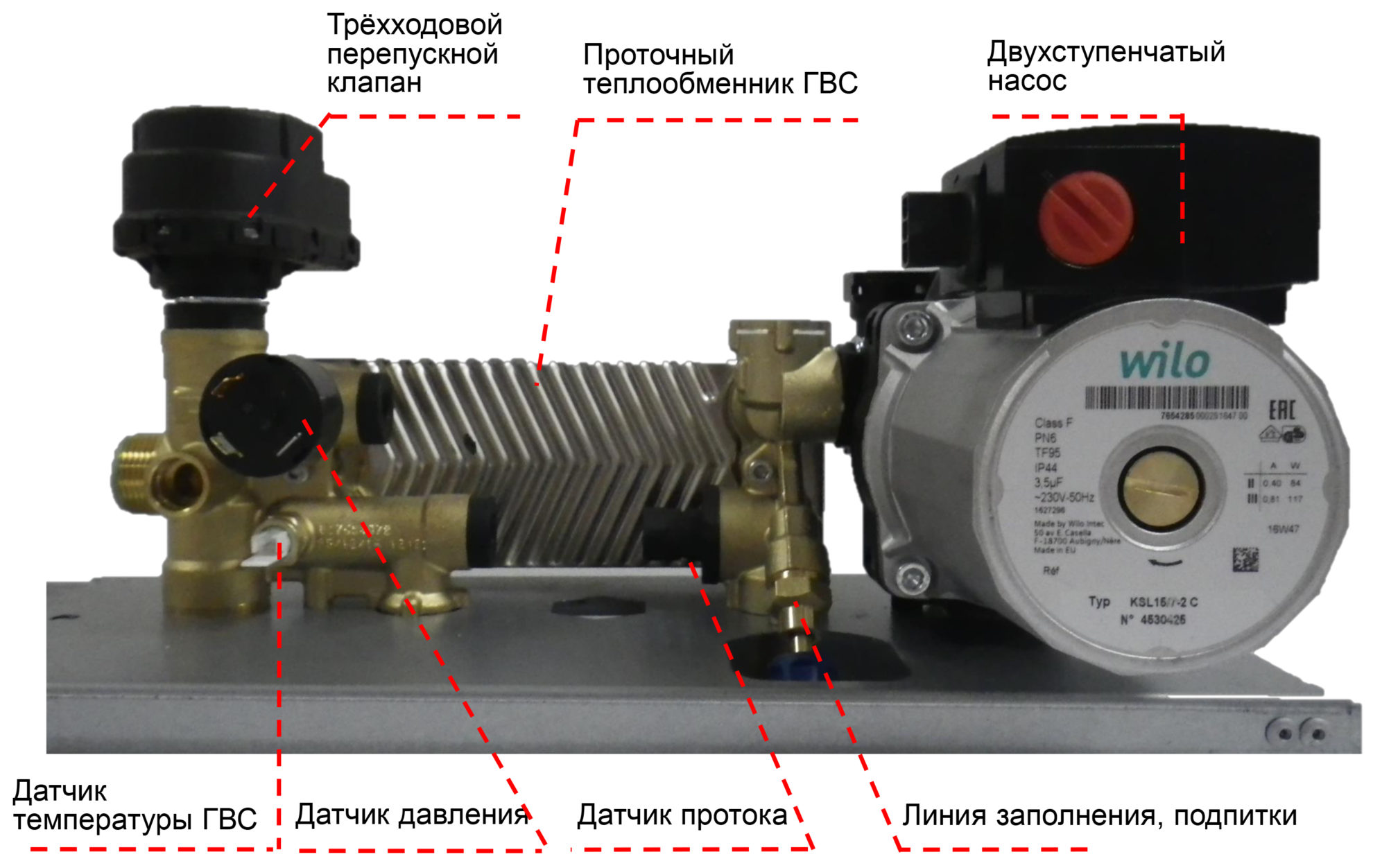

The design has 3 openings: an inlet and two outlets, inside there is a drive that controls the flows to obtain the desired temperature.

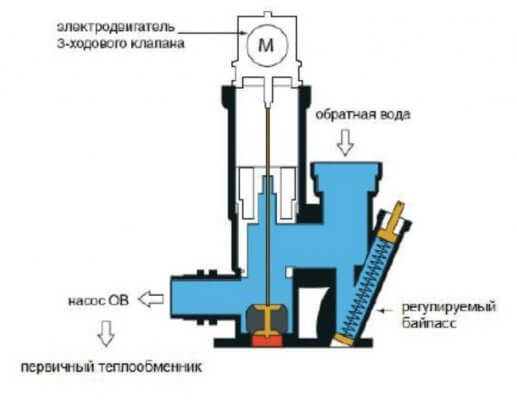

Structurally, the product performs the relationship of the action of a pair of two-way valves. The main difference is that TC does not stop the flow of the medium, but regulates its intensity. 3-way devices are divided into groups according to the adjustment system: “stem-seat” and “ball-socket”, and can be paired with a Hertz thermal head.

The control of the movement of the rod is usually performed by an electromechanical type drive, and are used for installation in automatic control systems for thermal processes of the Proterm boiler and other modern solid fuels.

Valve design

The principle of operation of the TC is based on mixing 2 temperature flows of the coolant on the supply and return lines, into a common flow, with a temperature indicator set by the user.

The medium in the internal cavity of the device moves from one nozzle to another until its temperature indicator changes to the desired size.

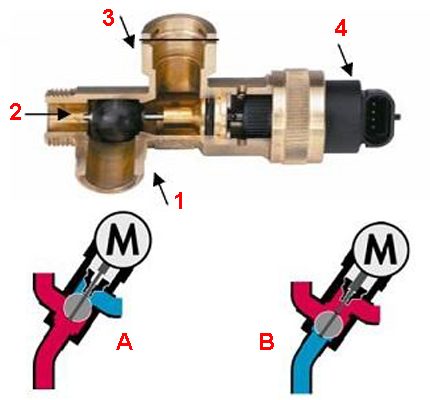

Solenoid valve

The solenoid valve is a shut-off valve that directly affects the safety of the unit. It is mainly installed so that in the event of a malfunction, it closes the fuel supply. Emergency situations in the operation of gas heating can occur due to various factors:

- fuel pressure drop;

- lack of fluid in the system (you can check the joints, three-way valve and pipes);

- traction deterioration;

- gas leak.

Each of the above problems is dangerous for human life, and therefore the further operation of the system is unacceptable. That is why the solenoid valve works. Its original position is open. To close it, an electrical impulse is applied to it, coming from a thermocouple installed above the flame in the combustion chamber or on the chimney.

It must be said right away that this element rarely comes out of standing position, since it has great potential for use. Despite this, moments still happen.

There are two ways to check the operation of this valve:

- Fire. The used thermocouple is replaced with a new one. The automatic button is turned on. Next, the igniter is ignited and fire is brought to the end of the thermocouple. In this case, the automation should work.

- Instrumental. The sensor is removed from the housing and a repair contact is inserted. It is supplied with voltage from 3 to 6V. If the solenoid valve is in order, the automation will work. Otherwise, you need to replace this element.

Recommendations for selection and installation

Since far from all manufacturers of heating equipment complete their products with a safety group, you often have to make the choice of a safety valve for a heating system yourself.To do this, it is necessary to study the technical characteristics of the boiler plant, namely, to know its thermal power and the maximum pressure of the coolant.

For reference. Most well-known brands of solid fuel heat generators have a maximum pressure of 3 bar. The exception is STROPUVA long-burning boilers, whose limit is 2 bar.

The best option is to purchase a pressure-controlled valve covering a certain range. The control limits must include the value for your boiler. Then you need to choose a product according to the power of the thermal installation, but it is difficult to make a mistake here. The instructions from the manufacturer always indicate the limits of the thermal power of the units, with which a valve of one or another diameter can work.

On the section of the pipeline from the boiler to the place where the overpressure relief valve is installed, it is strictly forbidden to install shutoff valves. In addition, you can not put the device after the circulation pump, do not forget that the latter is not able to pump the steam-water mixture.

To prevent splashing of water in the furnace room, it is recommended to connect a pipe to the outlet of the valve, which discharges the discharge into the sewer. If you want to visually control the process, then a special drain funnel with a visible jet break can be placed on the vertical section of the tube.

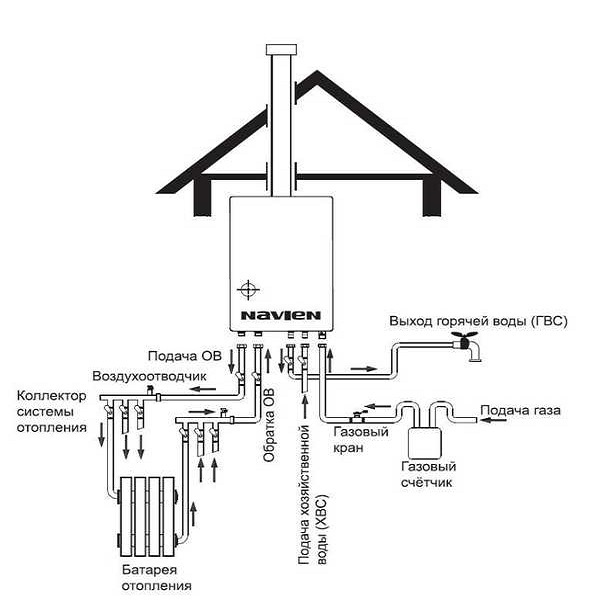

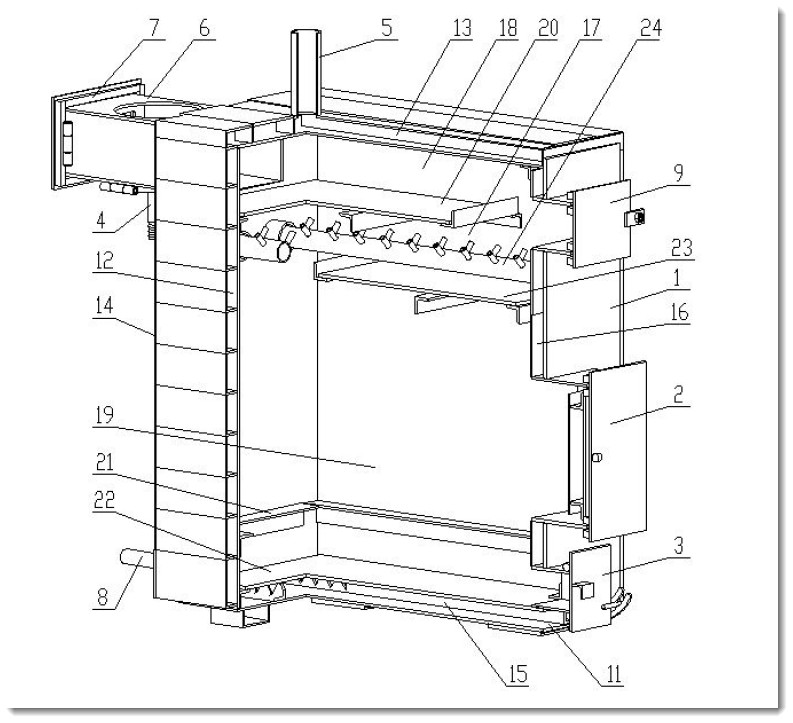

Where are three-way valves used?

There are valves of this type in different schemes. They are included in the wiring diagram of underfloor heating to ensure uniform heating of all its sections and to prevent overheating of individual branches.

In the case of a solid fuel boiler, condensate is often observed in its chamber. The installation of a three-way valve will help to deal with it.

The three-way device works effectively in the heating system when there is a need to connect the DHW circuit and separate the heat flows.

The use of a valve in the piping of radiators allows you to do without a bypass. Installing it on the return line creates the conditions for a short circuit device.

Gas boiler does not heat hot water

Flow sensor (flow) of water of a gas boiler Protherm Gepard (Panther) The flow sensor (flow) of DHW water is a rotating impeller with blades, the rotation speed of which depends on the intensity of the water flow. From the experience of operating Protherm Gepard (Panther) gas boilers, it is known that a frequent reason for the failure of the DHW heating function in these boilers is the shutdown of the turbine due to the ingress of foreign particles into it. Although the impeller is protected from clogging by a strainer, it does not always cope with its task.

If, when the hot water tap is opened, the boiler burner does not ignite, and cold water flows from the tap, then check the serviceability of the DHW flow sensor. It is necessary to call line d.36 of the service menu, which displays the readings of the flow sensor. If, with the hot water tap open, the flow readings in line d.36 are equal to or close to zero, then we conclude that the flow sensor is not working.

The location of the water flow sensor is indicated by the green arrow in the figure below.

The water flow sensor is removed by pulling the fixing steel bracket to the left.Having removed the bracket, it is necessary to pull the sensor towards you and pull it out of the socket. Before removing the sensor, it is necessary to drain the water from the DHW path of the boiler, as described above.

To avoid failures in the operation of the flow sensor, it is recommended to supply water to the boiler through an additional tap water filter installed in front of the boiler.

How does a three-way valve work in a heating system

The principle of operation of the valve is to mix water flows with different temperatures. Why should this be done? If you do not go into technical details, you can answer this way: to extend the life of the heating boiler and its more economical operation.

The three-way valve mixes the heated water with the cooled water after passing through the heating devices and sends it back to the boiler for heating. To the question of which water to heat faster and easier - cold or hot - everyone is able to answer.

Simultaneously with mixing, the valve also separates the flows. There is a natural desire to automate the management process itself. To do this, the valve is equipped with a temperature sensor with a thermostat. In this case, the electric drive works best here. The quality of the functioning of the entire heating system depends on the drive device.

- Such a valve is installed in those places of the pipeline where it is necessary to divide the circulation flow into two circuits:

- With constant hydraulic mode.

- With variables.

Typically, a constant hydraulic flow is used by consumers for whom a high-quality coolant of a certain volume is supplied. It is regulated depending on the quality indicators.

A variable flow is consumed by those objects for which quality indicators are not the main ones.They care about the quantitative factor. That is, for them, the supply is adjusted according to the required amount of coolant.

There are in the category of valves and two-way analogues. What is the difference between these two types? A three-way valve works in a completely different way. In its design, the stem cannot block the flow with a constant hydraulic regime.

It is always open and set to a certain volume of coolant. This means that consumers will receive the required volume both in quantitative and qualitative terms.

Essentially, the valve cannot shut off the supply to a circuit with constant hydraulic flow. But it is capable of blocking a variable direction, thereby allowing you to adjust the pressure and flow.

If you combine two two-way valves, you get a three-way design. In this case, both valves must work reversibly, that is, when the first is closed, the second must open.

Types of three-way valves according to the principle of operation

- According to the principle of action, this type is divided into two subspecies:

- Mixing.

- Dividing.

Already by the name you can understand how each type works. The mixer has one outlet and two inlets. That is, it performs the function of mixing two streams, which is necessary to lower the temperature of the coolant. By the way, to create the desired temperature in underfloor heating systems, this is an ideal device.

Adjusting the temperature of the outgoing ceiling is quite simple. To do this, it is necessary to know the temperature of the two incoming streams and accurately calculate the proportions of each in order to obtain the required temperature regime at the outlet. By the way, this type of device, if properly installed and adjusted, can also work on the principle of flow separation.

A three-way dividing valve splits the main flow into two. Therefore, it has two outputs and one input. This device is commonly used for hot water separation in hot water systems. Often, experts install it in the piping of air heaters.

In appearance, both devices are no different from each other. But if we consider their drawing in section, then there is one difference that immediately catches the eye. The mixing device has a stem with one ball valve.

It is located in the center and covers the saddle of the main passage. There are two such valves in the separation valve on one stem, and they are installed in the outlet pipes. The principle of their operation is as follows - the first closes one passage, clinging to the saddle, and the second at this time opens another passage.

- A modern three-way valve is divided into two types according to the control method:

- Manual.

- Electric.

More often you have to deal with a manual version, which is similar to a regular ball valve, only with three nozzles - outlets. Electric automatic systems are most often used for heat distribution in private housing construction.

Like any device, a three-way valve is determined by the diameter of the supply pipe and the pressure of the coolant. Hence the GOST, which allows for certification. Failure to comply with GOST is a gross violation, especially when it comes to pressure inside the pipeline.

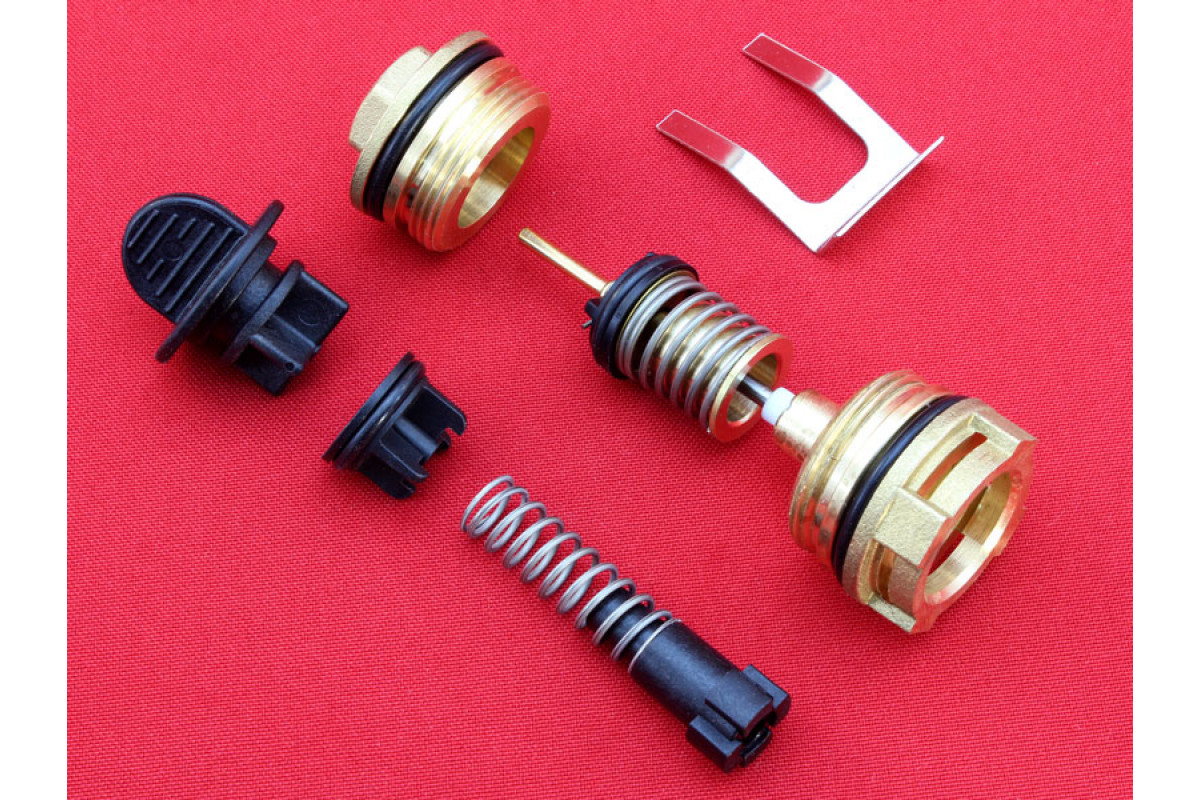

Conclusions and useful video on the topic

Below is a useful video for review, which demonstrates the disassembly of a device that regulates heat flows in a gas boiler. Moreover, the practice of disassembling with your own hands is given.

The spreader shown in the video is equipped with a hydraulic stem drive. Familiarization with this repair practice will help you understand how to check instruments of a similar type and repair if defects are found.

Thus, a three-way valve for a domestic gas boiler can be tested in almost any design, regardless of the individual design. The main point is to correctly determine which drive the gas boiler switchgear is used with. Information on this issue can be obtained from the documentation for the equipment or based on the drive demonstration examples in this article.

Do you have useful information on the topic discussed above and want to share it with other users? Write your remarks and comments in the block below, add a photo, leave your recommendations - the feedback form is located below.