- How to spot pressure sensor malfunctions?

- How to check the air conditioner compressor of a split system: diagnostic nuances + tips in case of breakdown

- How to test the performance of the air conditioning compressor?

- Compressor symptoms

- Troubleshooting

- Diagnostics of malfunctions of the autoconditioner

- Compressor fault diagnosis

- Importance of verification

- Reasons for reducing the power of the air conditioner

- Why is the air conditioner getting colder?

- A few tips for using your air conditioner

- How to check if the air conditioner is charged

- Video: Checking air conditioning refueling

- Common air conditioner problems

- How to Check the A/C Compressor Clutch

- Freon evacuation features

- Why does the air conditioner fail

- Do-it-yourself air conditioning hose repair

- Modern appliances

How to spot pressure sensor malfunctions?

Now let's get acquainted with the malfunctions of the air conditioner pressure sensor, how to check it and replace it if necessary. Basically, elementary pollution or mechanical damage can cause failure or incorrect operation of this element. So after the first signs, be sure to check the condition of the connectors and wires. Any cracks, traces of moisture and corrosion are unacceptable.Do not forget about computer diagnostics.

Computer diagnostics of the air conditioning system

To understand that you need to visit a car service or climb under the hood on your own, you can use the following signs. Firstly, the operation of the compressor is disrupted, it can turn on at excessive pressure or function even without freon. Sometimes the compressor does not turn on at all. Secondly, there are interruptions in the operation of the fan. And the entire air conditioning system is unstable.

How to check the air conditioner compressor of a split system: diagnostic nuances + tips in case of breakdown

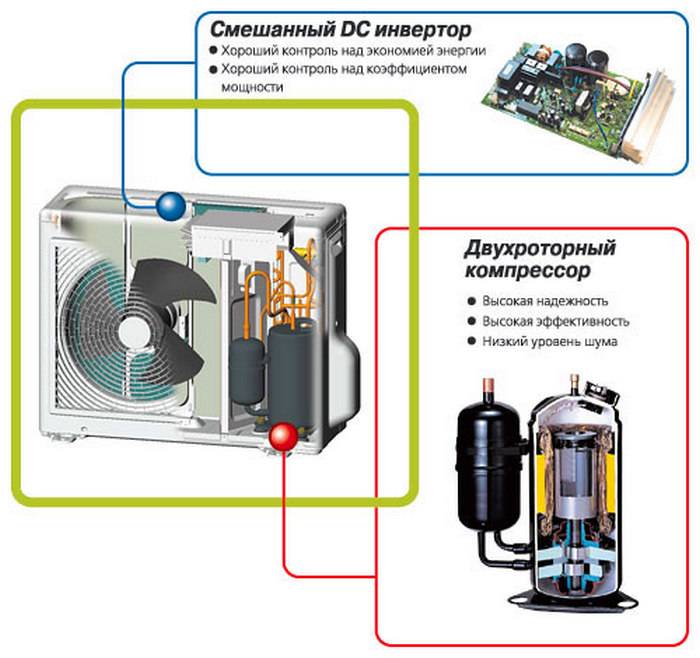

A significant component of the split system, of course, is the refrigeration compressor. It is thanks to this component of the technological scheme of a household or other machine that a cooling effect is obtained, as well as an air humidification effect.

If it happens that the compressor unit does not work for some reason, the split system, in fact, turns into an ordinary windmill. The desired effect from such a "mill" can no longer be obtained, and it is time for the owner of the system to think about repair.

However, in order to repair, you need to know how to check the split system air conditioner compressor for a malfunction. It is this question that we will deal with in our article. We will also consider the device of the module, common types of malfunctions and provide recommendations for repair.

How to test the performance of the air conditioning compressor?

If the indoor unit, the fan, drives the air in the room, but does not cool, and the outdoor unit does not start, then there may be two breakdowns.

- Capacitor needs to be changed

2. The compressor is “tired” completely ...

In this article, we will describe compressor troubleshooting.

Very often, when repairing an air conditioner, they sin on the compressor, but in the end it may not be the case at all. So how do you properly diagnose a compressor?

Single-phase compressors with starting winding.

To gain access to the compressor contacts, it is necessary to disassemble the air conditioner so that there is access to the compressor. Usually the contacts are protected by a cover that is screwed on, you can find it by the wires that fit the compressor. After removing the cover, you will see three contact terminals on which you will put on terminals with wires.

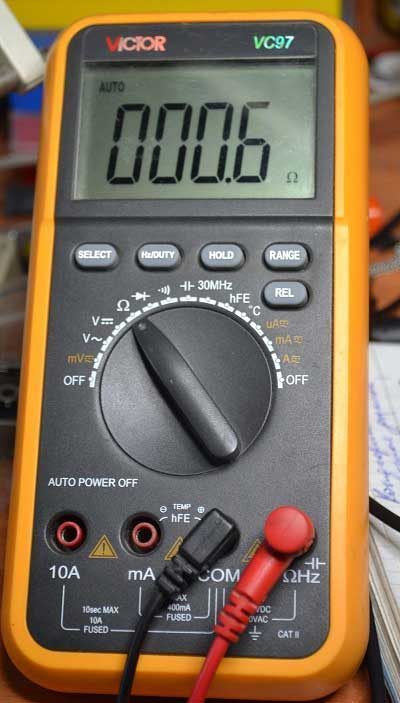

It is necessary to remove the wires and measure the resistance between the terminals with a multimeter. We put the device switch on the resistance measurement function (indicated by the letter Ω). If the multimeter shows an infinite resistance between terminal C and the rest, then this means an open circuit, in the case of built-in protection, you need to make sure that the compressor is not overheated and the protection has not worked, otherwise, and if the external protection is faulty. If the resistance tends to zero, this means a short circuit and the compressor is also faulty.

The exact value of the resistance depends on the power of the compressor, the accuracy of your device and can vary between about 1-50 ohms. The resistance of the windings is the same, so it can be seen from the diagram that the resistance between terminals M and C should be the same as between S and C, and between S and M twice as much.

Each compressor has thermal protection, but it can be built-in as in the diagram or located under the cover, next to the compressor outlets.If it is not built-in, the so-called "tablet", then it can be called separately and replaced in case of a malfunction (it must be closed in the normal state, it opens when a certain temperature of 90-120 ° C is reached).

I’ll make a reservation right away that in this way we will not be able to determine short-circuited turns, for this there are other devices (but they are not stable enough to determine short-circuited turns).

Measurement of insulation resistance with a megohmmeter.

It will not work with a conventional tester to check insulation breakdown - it measures resistance using a low voltage of 3-9 V. A megohmmeter allows you to measure resistance with a higher voltage of 200-1000 V. closing the winding to the housing.

On the device, you can select the voltage by which the resistance will be measured and the time during which the windings will be tested.

It is necessary to measure the resistance between one of the three terminals on the compressor and, for example, a copper tube coming out of the compressor with a voltage of 250-500 V. The resistance should be in the range of 7-10 MΩ. If not, then the compressor is also under replacement.

Before measuring, carefully read the instructions for your device, high voltage is used, therefore, if used incorrectly, you can get an electric shock or damage the device.

Three-phase compressors and inverter air conditioner compressors.

For three-phase compressors and for inverters, the resistance between the windings must be the same, since they do not have a starting winding, and otherwise the troubleshooting procedure is the same as for a single-phase compressor.

Compressor symptoms

It should be clear that when the split system is unable to provide the desired temperature, this factor may indicate that the compressor is not working.

In addition, the functioning of the compressor unit of the air conditioner is clearly determined by the characteristic noise effect that the refrigeration unit creates. The noise of the equipment is not to say that it is strong, but during the operation of the unit it is heard confidently.

If a decision is made to repair internal defects of the refrigeration compressor, it is necessary to dismantle the device from the system, having previously freed the circuit from the refrigerant

If a decision is made to repair internal defects of the refrigeration compressor, it is necessary to dismantle the device from the system, having previously freed the circuit from the refrigerant

By the way, again, based on the noise level, some types of defects in the compressor machine are determined. So, if during operation there is an increased clicking sound or a rattle sound, most likely, wear or damage to the valves can be ascertained.

With such a malfunction, the compressor performance drops sharply, the device body is very hot. Ultimately, the internal thermal relay is activated, the operation of the machine is blocked.

Often there is a situation when, almost immediately after starting the compressor, there is a cessation of its operation. However, the device itself is actually intact and efficient.

The cause of the defect in this situation is usually a lack or overflow of the refrigerant circuit. An emergency stop is provided by a thermal relay, which, by the way, can also fail.

One of the designs of a thermal relay, one of those that are used to protect the compressor of a split system from heating above the permissible temperature. Meanwhile, this device may also be defective

Finally, the owner of the split system may encounter a working moment - when the compressor unit simply does not start. At the same time, the air conditioner is quite efficient in terms of all other functions.

The compressor does not give grounds for ascertaining defects - outwardly it looks safe and sound. The traditional reason for this option, as a rule, is the inoperability of the starting capacitor with a capacity of 10 microfarads or more.

This is what the capacitors responsible for starting the split system compressor look like. Depending on the power of the compressor unit, the working capacity of such parts varies.

The most severe and practically unrecoverable defect of a split system compressor is an interturn short circuit in the stator windings of the drive motor. True, we should pay tribute - in modern designs of hermetic compressors, such a malfunction is extremely rare.

Troubleshooting

Modern refrigeration technology can automatically alert you to individual fixture failures. This is done by flashing the indication on the display or various inscriptions. Having studied the attached instructions, you can easily figure out the decoding of failures in the system. More detailed information about encodings is available to service centers with authorization, but basic information is also open to ordinary users.

Modern refrigeration technology can automatically alert you to individual fixture failures. This is done by flashing the indication on the display or various inscriptions. Having studied the attached instructions, you can easily figure out the decoding of failures in the system. More detailed information about encodings is available to service centers with authorization, but basic information is also open to ordinary users.

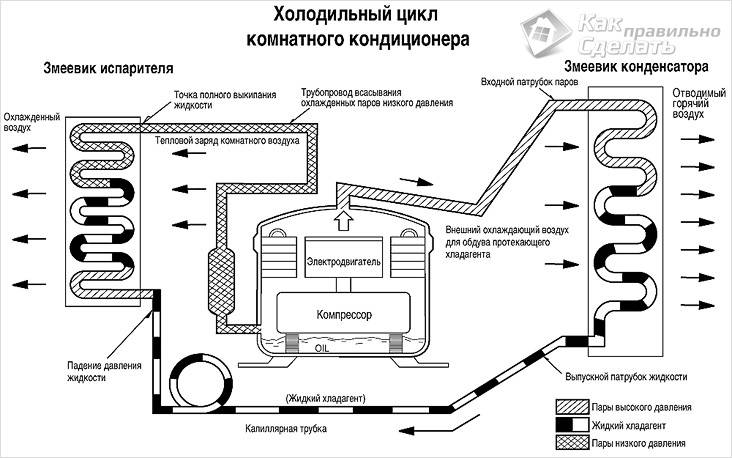

The design of air conditioners consists of common components:

- The compressor is a working element responsible for compressing the refrigerant and moving it around the entire cooler circuit;

- Air heat exchanger installed in the outdoor unit - designed for condensing, cooling the refrigerant;

- The internal heat exchanger is necessary for evaporation during the operation of the device in cooling mode. The refrigerant takes a gaseous form from a liquid state;

- The capillary tube is provided in the form of a throttle device, which affects the increase in refrigerant pressure in the high performance area and reduces it in the area of the air heat exchanger of the indoor unit;

- Fan - used to create an air flow for blowing the evaporator and condenser.

The refrigerant in the gaseous state under low pressure passes into the compressor, after which it is compressed and heated to +70 degrees and above. Having done this move, it enters the condenser. In the area of the outdoor air heat exchanger, the cooling element condenses and becomes a liquid from a gaseous form, thus generating heat. Moving along the capillary tube, the refrigerant is throttled, while the opposite effect is carried out with the release of cold from the heat-absorbing room.

How an air conditioner works

How an air conditioner works

If failures begin in the system, then in the light device the indicator flashes the corresponding number of times, depending on the detected error. Decoding codes for standard breakdowns, taking into account a certain number of flashes:

- 1 - the operation of the thermistor located on the indoor unit is suspended;

- 2 - disconnection of the outdoor thermistor;

- 3 - simultaneous operation of the device for heating and cooling;

- 4 - disable overload protection;

- 5 - a malfunction in the cable or information block exchange schemes;

- 6 - excess of standards in power consumption;

- 7 - voltage increase in the internal module;

- 8 - the fan motor is out of order;

- 9 - malfunction of the running valve;

- 10 - disable the thermistor responsible for controlling the temperature of the compressor casing.

Healthy! In the case when all the LEDs flash at the same time, this means a failure in the control board with program settings, it is necessary to reprogram the system. Such a malfunction may occur during a power surge.

To carry out repairs and preventive maintenance, it is necessary to make a detailed diagnosis of the climate system, to determine the cause of the breakdown. Breakdown diagnostics should be carried out in accordance with the required sequence. This requires checking:

- Detection of mechanical damage;

- Mounting modules;

- Clamps fixing the contact connections of the unit;

- Air filters;

- Cooling and heating functionality;

- Options indication;

- Operation of mechanical blinds;

- The temperature regime of the air at the outlet of the evaporator;

- Suction and discharge pressure indicators;

- Tightness of the entire drainage system and connections.

If self-elimination of the error is not possible or professional skills are required, then you should contact the service center.

Important! Manufacturers can create decryption codes in different ways in software settings that are known only to service centers, however, the instructions indicate a list of errors displayed for self-elimination

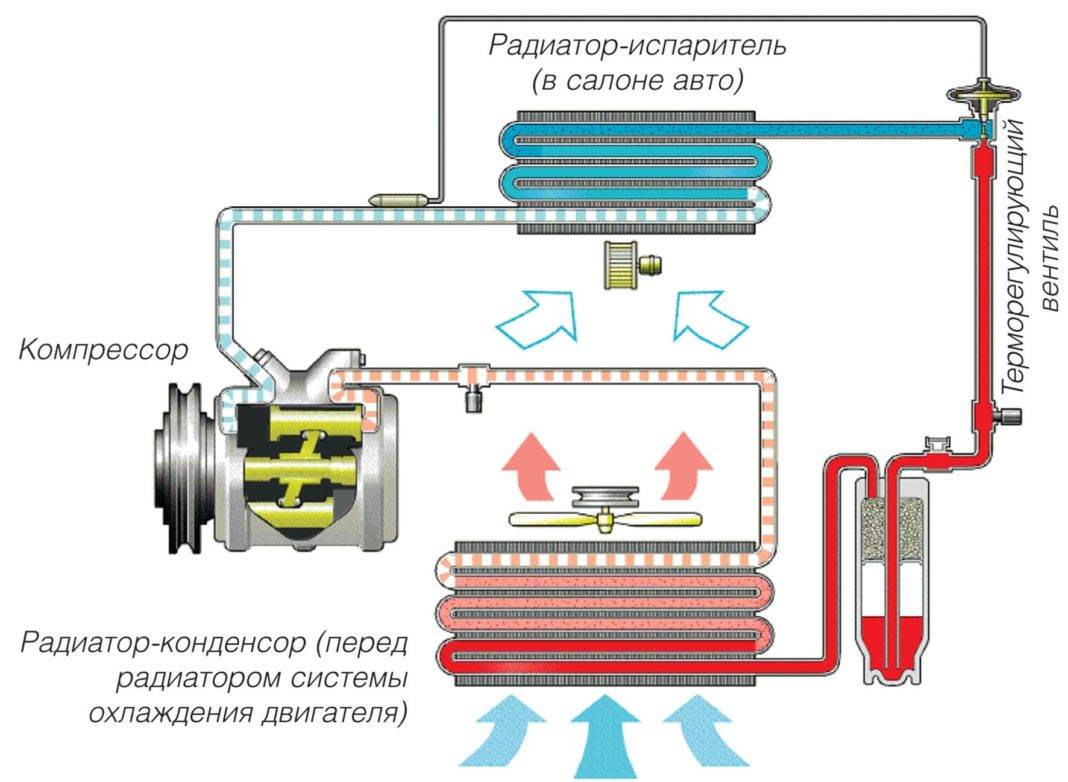

Diagnostics of malfunctions of the autoconditioner

There is a fairly simple and reliable way to check how well the air conditioning system is working. To do this, with the engine idling, you need to turn on the air conditioner and touch the return pipe with your palm (it is the thickest). As the system operates, it must be cooled down. After 1.5 - 2 minutes, the tube should become so cold that you can only hold your hand with willpower. If you turn off the air conditioner for a few minutes, and then turn it on again, you should clearly feel a new wave of cold.

Touch the thin pressure pipe (with extreme caution) - it should be very hot, especially if it is also hot outside

If both conditions coincide, that is, cold and heat on the highways in the indicated places are clearly manifested - the air conditioner is working. The same check can be carried out directly in the cabin by inserting an electronic thermometer into a straight deflector. With the air conditioning system turned on at full power, the temperature in the deflector should be near the 10 degree mark.

Compressor fault diagnosis

The easiest way to diagnose a breakdown of the electromagnetic clutch, since it is located outside the housing. It is enough to turn on the air conditioner and see if the plate is pressed against the rotating pulley. In this case, the compressor shaft should also begin to rotate. If the discs are burnt, this can also be easily seen.

Problems with the windings are diagnosed using an ohmmeter - zero or infinitely large resistance indicates a short circuit or an open circuit, respectively.

To identify a malfunction in the mechanical part, measure the pressure on the "hot" line (at the outlet of the compressor unit).If the pressure is not high enough, the cause may be worn pistons or valves. To be more precise, you need to remove the compressor and completely disassemble it.

IMPORTANT! Before proceeding with the repair, it is necessary to determine the true cause of the malfunction. For example, an electromagnetic clutch could burn out due to a piston jamming.

But the real cause of the breakdown is poor-quality oil, worn bearings, or dirt in the evaporator tubes. If the root cause is not eliminated, then the repair will not work - in a month or two the problem will recur. That is why diagnostics and repairs should be carried out by a car service specialist who gives a guarantee for his work.

Importance of verification

Checking such an important device should never be neglected, as negligence can lead to costly repairs. Yes, refueling equipment with freon is not so expensive - about 1000 rubles. Although for some, this amount will seem considerable.

Although for some, this amount will seem considerable.

But the replacement of a faulty unit can cost about 1000 conventional units - already a significant amount! Inexperienced owners risk getting into such repairs in the following situations:

- Continuation of operation with a floundering unit. As a result, the failure of important parts, including the expansion valve.

- Purchasing a used car whose air conditioning system is not working properly, which promises unreasonably high costs in the future.

Some sellers simply turn off a faulty cooler in order to deceive potential buyers. To do this, the drive belt is removed, freon is released from the circuit, or other methods are used.

For this reason, this important component must be checked in any case, and not only as the owner of the vehicle, but also before buying it.

Reasons for reducing the power of the air conditioner

There are various reasons, the main ones being:

Freon leak. Freon is the main element of the air conditioning system, without which its operation is impossible. Leakage can occur for technological reasons, and also occurs accidentally. You need to check the tightness of the air conditioner. In addition, he needs refueling if necessary.

Causes of freon leakage in the air conditioner.

Failure of the main components of the heat pump parts. This means that the operation of the evaporator, compressor, fan, valves, sensors, or any of the controls is disrupted. In this case, it is necessary to replace faulty components with new parts.

The occurrence of various deviations in the electrical network. these include surges, dips and voltage drops. These problems are taken into account when connecting climate equipment to home electrical networks. If possible, you should try to eliminate these problems, because otherwise, equipment malfunctions will become normal.

Checking and cleaning the air filters of the air conditioner.

Clogged filters. This is the most banal reason why the performance of climate equipment is declining. Therefore, it is necessary to monitor the filters, periodically and timely clean the filter elements, which include the impeller and fan, and clean the air duct cavity.Cleaning of all components is carried out according to the recommendations of the manufacturer, specified in the instructions issued for the air conditioner.

Why is the air conditioner getting colder?

One of the reasons for the poor performance of the air conditioner is the lack of freon or a decrease in its amount. Freon gas itself sooner or later disappears, and this is quite normal. Therefore, it will have to be refilled once every 2-3 years. But also freon can erode due to breakdown of the radiator. And although this most often happens in car air conditioners, such a breakdown also occurs in ordinary household ones.

The air conditioner may start to work poorly for various reasons. Therefore, the most important thing is to call the service department and invite an air conditioner repairman to your home. If the equipment is under warranty, you can contact the store for help, where the breakdown will be fixed for free.

A few tips for using your air conditioner

Finally, here are some tips that will help you extend the life of the air conditioner, as well as detect a malfunction in time:

- try to keep the air conditioning system clean. Dirt in the engine compartment leads to increased moisture and surface corrosion;

- if your car has a large air intake, install additional radiator protection behind it in the form of a nylon or metal mesh;

- in winter, turn on the air conditioner only after the car and interior have completely warmed up;

- to determine the malfunction of the air conditioner, start the "cold" car and grasp the return line of the air conditioning system (thick tube) with your hand. Within a few seconds after starting, you should feel cold. After 30-40 seconds, the tube should become literally ice.If the tube cools for a long time, then the air conditioner does not work, so do not expect cold in the car either. Accordingly, you need to immediately find the cause of the malfunction, without waiting until the system completely fails.

As you can see, many air conditioner malfunctions can be not only detected in time, but also eliminated on their own.

How to check if the air conditioner is charged

An important component in the operation of an air conditioner is its filling with freon. The lack of this substance leads to improper functioning of the system and insufficient cooling. Therefore, it is important to know how to determine the level of refrigerant in order to top it up if necessary.

The check is performed as follows:

Therefore, it is important to know how to determine the level of refrigerant in order to top it up if necessary. The check is performed as follows:

- Open the hood and wipe a special eye, then turn on the air conditioner to the maximum.

-

At first, we observe the appearance of a liquid with air bubbles, then they decrease and practically disappear. This indicates a normal level of freon.

- If the liquid appeared with bubbles, the number of which decreased, but remained constant, then this indicates an insufficient level of refrigerant.

-

If there is a milky white liquid, then this clearly indicates a low level of freon in the system.

Video: Checking air conditioning refueling

Knowing how the air conditioning system is diagnosed, you can independently deal with the nuances that have arisen and determine what caused this or that malfunction. Do-it-yourself testing does not require any special tools and devices.It is enough to familiarize yourself with the step-by-step actions and follow them in the course of work.

Common air conditioner problems

Of course, the question arises as to whether it is possible to start repairing such complex equipment as an air conditioner on your own, without resorting to the help of specialists? And this is interesting to everyone who has purchased and installed climate equipment in their home.

However, before you find the answer to this question, you need to familiarize yourself with what problems may arise during the operation of the climate system. There are many reasons why air conditioners break down.

The most common problems that arise during the operation of climate equipment, and leading to the need for air conditioning repair, are the following:

- The air conditioner reduces the production of heat or cold.

- Condensation begins to flow due to clogged drainage.

- It is impossible to turn on equipment that refuses to respond to commands sent by the control panel.

- There is an unpleasant smell when the air conditioner is running.

If the air conditioner reduces the production of heat or cold, then it is wasting electricity and not performing its main function. Therefore, you need to know what caused the performance degradation of the equipment and how to fix the problem.

How to Check the A/C Compressor Clutch

The most reliable way to check the air conditioning system is diagnostics at a specialized car service, but the buyer does not always have the opportunity to check the car's serviceability at a service station. Often the seller, when asked if the air conditioner is working, begins to answer evasively:

- the system works, but freon is not charged;

- one of the tubes burst, it needs to be replaced, otherwise the air conditioner is in order;

- removed the belt for the winter, as it broke.

All answers of this kind should be alarming, since the main reason for the malfunction of the air conditioning system is the failure of the compressor, this particular part is the most expensive in the air conditioning system. In the compressor, the clutch is the first to fail, so you should check its performance.

How to check the air conditioning compressor clutch? We do the following:

- turn on the air conditioner operation button, the power indicator should light up;

- during switching on, a click should be heard in the engine compartment, so the clutch is connected to the compressor itself.

It is desirable to carry out the check together - one of the participants presses the button, the second person looks under the hood, how the coupling is connected to the air conditioner. When the compressor is off, only the pulley rotates on it, and the pressure plate remains in place. When the air conditioner is turned on, the plate is magnetized to the pulley - the drive hub begins to rotate with it, and therefore a distinct click is heard.

It should be noted that such a check is not valid for all cars, on some modern models the plate rotates with the pulley, and the connection to the hub takes place inside. There are cars of complex design with many additional units, and it is difficult to consider the compressor clutch in the engine compartment. But in any case, you should be guided by a click; during the magnetization of the coupling, it should be heard. If you don't hear a click, the clutch is most likely not engaged, and this indicates a compressor malfunction.

There is another way to check the performance of the clutch, for this you do not need to start the engine. We check as follows:

- turn off the engine, disconnect the power from the compressor by disconnecting the plug;

- we connect the positive terminal of the battery with the connector on the compressor with a wire, at the moment the wire is connected, the clutch should work - it is noticeable how it moves, and at this moment a click is heard;

In this way, you can check the clutch even without freon in the system, all the same, the working clutch should move with a characteristic sound.

Freon evacuation features

One of the important components of the cooler is the freon circulating in the chiller. Most commonly used

colorless gas with the smell of chloroform. This type is non-explosive, and also has excellent thermophysical properties.

characteristics. R22 is considered to be a common refrigerant, but it is not environmentally friendly. Last

time

began to use alternative options, including R-410A. It is characterized by the absence of chlorine and

the lowest possible ozone depletion potential.

Pumping out freon from the chiller is carried out only in exceptional cases, for example, before dismantling the equipment

or in the event of a refrigerant leak. It is impossible to deal with the problem on your own, as it is required

special

evacuation devices and related skills. In addition, there is a high risk of freon release into

atmosphere,

which is harmful to the environment.

Freon evacuation from the chiller

Description: The process of freon evacuation from the chiller

Why does the air conditioner fail

The main malfunctions awaiting the air conditioner:

- compressor failure. It is possible to determine that the compressor has failed by the appearance of extraneous noise during the operation of the device and oil smudges that appear on its surface. These factors indicate the following reasons for the failure of the unit: cracks may appear on the compressor housing, gaskets may wear out or the line may fail. These phenomena lead to refrigerant leakage and system depressurization. Also, the drive belt in the compressor may weaken or even fail, the oil seal located on the shaft may wear out. Dirt may enter the system, a short circuit may occur in the compressor's electrical network, or vice versa, loss of contact;

- failure of the condenser. Its task is to reduce the temperature of the refrigerant that cools the air entering the car. If a lot of dirt appears in it, then it will not fulfill its role, which will force the climate control system to turn off randomly. It will be necessary to urgently clean the air conditioner radiator, as the pressure in the system rises due to overheating;

- if an unpleasant smell occurs in the cabin and the appearance of water that comes from nowhere, it is necessary to check the operation of the air conditioner evaporator. Most likely it's out of order. The cause of the malfunction here is a blockage of the tube through which water is drained due to corrosion or contamination;

- failure of the receiver-dryer, which is used to purify the refrigerant and remove water from the system, may occur when the air conditioner is not charged properly or contaminated, which may be caused by repair of the air conditioner cooling system.It is possible to determine that this device is out of order by freezing of hoses and unauthorized shutdown of the device.

Do-it-yourself air conditioning hose repair

Due to a violation of the seal in the hoses and main pipes, the air conditioner does not work properly. This is the most common failure in the car cooling system.

The pipes in question are located at the bottom of the car. Due to their location, they are affected by external mechanical impact, which leads to various damages and the car's air conditioning stops working correctly. The most reasonable solution to this problem is to replace the hose of the device.

There is a version that the decrease in the life of the hose and tubes is associated with their contact with dirt and high humidity. In addition, debris on the road and vibration in the area of the wheel arches provoke cracks, so you should think about replacing the lines with metal ones, as they are more resistant. Although, even such a resistant material as metal has its drawback - tubes made of it are subject to corrosion and are not resistant to temperature changes.

Hose repair

Replacing a hose is far from cheap, so it's worth knowing how to do it yourself.

If the rubber hose is not significantly damaged, this problem can be solved with a patch. The patch is done using specialized tools and substances, its damage is significant, then the hose must be replaced with a new one.

If you decide to replace the hose yourself, follow the description below:

- First, you need to choose a hose that is the right size.

- After that, crimp cylinders are hung on it.

- In conclusion, it is put on the teeth and crimped with cylinders.

To avoid such problems, it is important to regularly repair and prevent the climate system of the car, if you do not repair the breakdown on time, the malfunction can become a bigger problem. Video detailing the repair of air conditioning hoses:

Video detailing the repair of air conditioning hoses:

Modern appliances

A refrigerant leak does not always lead to breakdowns and complete failure of the air conditioner. In fact, parts of the device will experience an unusual impact and pressure only if there is absolutely no refrigerant in the system. The compressor will begin to experience overheating, and this is the “root of evil”. In order to independently detect a leak, it is not necessary to have serious knowledge and tools in service.

First of all, it is necessary to find out whether there is freon in the air conditioner, or whether it has all flowed out. Depending on this, you will need to choose a specific verification method. Above are two simple methods that allow you to independently check the tightness of the air conditioner.

Fortunately, technology does not stand still, and not so long ago, devices were developed that can “feel” freon in the air. This technique reacts both to freon and other types of gas. There is a special scale that shows the level of freon. If its amount in the air reaches a certain threshold or even steps over it, a signal sounds. In other words, there is no need to check the air conditioner for leaks if a special device is located next to it. You can buy such equipment along with the air conditioning system, since they are often sold in one place.

To determine the immediate location of the leak, it is necessary to drive this device throughout the pipeline system. As you get closer to the leak, the signal will get stronger. If there is a draft in the room, then the device can be misleading with its signal, since it will react to any gases coming from outside. Especially brightly and quickly reacts to exhaust gases.