- What other tool might be needed?

- Bulgarian

- electric jigsaw

- We work with ceramic tiles with improvised tools

- Special drill bits

- Diamond crowns

- How to drill a hole in metal

- How to drill metal with a drill

- Features of deep hole drilling

- Elementary technology: drilling tiles in the bathroom

- Advantages and disadvantages of tools

- Choosing consumables and accessories

- How to drill through tile so it doesn't crack

- Drilling large diameter holes

- Core drilling

- Drilling a ballerina

- Tool types

- Drilling tiles with a drill bit

- Drilling holes in tiles for dowels

- What points should be considered when drilling porcelain tiles? Tiler life hacks.

- One of the secrets for drilling a hole in porcelain tiles:

- Making holes of small diameter

- Video description

- Making big holes

- Video description

- Video description

- Helpful Hints

- Briefly about the main

What other tool might be needed?

Repairs often require a lot of powerful appliances and electrical tools.

At the same time, it is important to choose which drill to drill the tile in the bathroom so that there are no cracks.

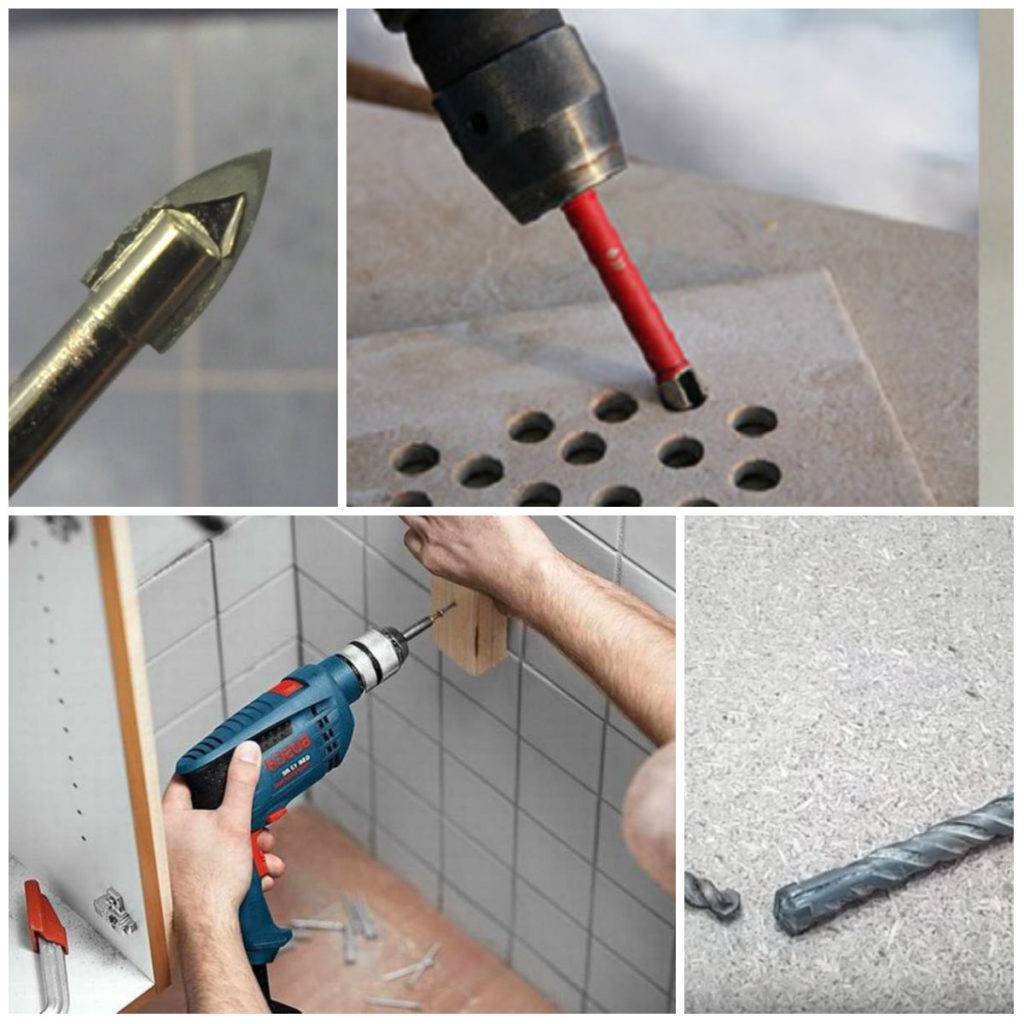

Spear drills can be used to drill dowel holes. They are strong and durable.In addition, crowns with tungsten carbide coating. In work, you can use not only electric drills, but also screwdrivers.

Crown with tungsten carbide coating.

Crown with tungsten carbide coating.

Bulgarian

For work, you do not always need to buy some special equipment. In everyday life, you can easily use the grinder, which does an excellent job with any task. The universal tool perfectly processes wood and a tile.

You can also cut out certain pieces of unnecessary tiles with a grinder. With the help of a grinder, you can make straight and curly cuts. At the same time, all this is done quite quickly and simply. Here, different cutting methods are applicable.

A grinder can cut tiles into certain pieces.

A grinder can cut tiles into certain pieces.

electric jigsaw

As for the jigsaw, it can be used to cut wall tiles. Floor tiles are considered more durable, so they will be more difficult to cut.

When processing with a jigsaw, the tile often splits, so it is necessary to work with the tool very carefully, without overheating it. It is easy to allow deformation of the material here, therefore, before cutting, the tile should be moistened with water.

After an hour, you can start processing the finishing material.

Before processing the material, the cutting surface must first be cleaned of all unnecessary. Nothing should be superfluous at work. Everything is just the essentials. It is advisable to use the tool at medium speeds. The cut must be strictly along the marked lines. For manual sawing, there is a special jigsaw with which you can carefully process durable material.

The main thing is quality and accuracy

The jigsaw is suitable for cutting wall tiles.The floor is stronger and it will be much more difficult to work with a jigsaw with it.

The jigsaw is suitable for cutting wall tiles.The floor is stronger and it will be much more difficult to work with a jigsaw with it.

We work with ceramic tiles with improvised tools

As for improvised means, here you can use a glass cutter by making a suitable furrow. The material is easy to cut, thanks to such a tool. The remaining irregularities can be removed with pliers. This toolkit is in great demand. To align the edges of the cut, they can be processed with special grinding.

You can cut tiles without much difficulty with a simple glass cutter.

You can cut tiles without much difficulty with a simple glass cutter.

Improvised tools will help to cut tiles of different sizes. Excess cut can be easily sharpened with a special device. Finishing material is quickly processed with a small number of tools.

If you use pre-prepared products and materials and do everything right, then the quality of the work performed will be at the proper level. Edges and protrusions can be easily sanded

At home, it is enough to simply do everything, it is only important to choose the time for repair work. After processing, the tile is smooth and even.

Grinding a cut of a tile at an angle of 45 degrees.

Grinding a cut of a tile at an angle of 45 degrees.

Special drill bits

In work, you can not do without special nozzles. Often a special stop is required, with which you can drill deeply. The thrust device is equipped with a special handle, and there is a metric scale on its handle. In addition, consoles are often needed on which it is convenient to put tools.

This is what the dust extractor looks like.

This is what the dust extractor looks like.

Diamond crowns

A coated crown is worn on top of a perforator or drill. It treats the selected surface well. The dusting of the crumb perfectly grinds the edges of the tile.The hard coating can be easily sanded thoroughly. This is an effective option in obtaining the proper result. The strength and reliability of the nozzles used is time-tested.

A diamond-coated crown is worn on top of a perforator or drill.

A diamond-coated crown is worn on top of a perforator or drill.

The cutters located on the crowns are very durable, so the material can be processed quickly and with high quality. As you know, crowns come in diameters of 10 mm or more. You can buy both a separate nozzle and a set of them. A set of tools should always be at hand. At first, you can use nozzles in a single copy.

Such a set of crowns with diamond coating is always useful in the household.

Such a set of crowns with diamond coating is always useful in the household.

How to drill a hole in metal

Metal products, in comparison with parts made of other materials, have increased hardness and strength, therefore, for successful work with them, it is necessary to follow the technological process and use high-quality cutting tools.

Metal drilling tools:

- Electric or hand drill;

- twist drill;

- Kerner;

- A hammer;

- Protective glasses.

Drills for metal are selected based on the diameters of the holes and the properties of the material being processed. As a rule, they are made of high-speed steels, such as R6M5K5, R6M5, R4M2. Carbide drills are used to work with cast iron, carbon and alloy hardened steels, stainless steel, and other difficult-to-cut materials.

The power of the electric drill must be designed to drill a hole of the required diameter. Power tool manufacturers indicate the relevant technical data on the product.For example, for drills with a power of 500 ... 700 W, the maximum drilling diameter for metal is 10 ... 13 mm.

There are blind, incomplete, and through holes. They can be used to connect parts to each other by means of bolts, studs, pins and rivets.

If the hole is drilled for the purpose of threading, it is worth paying special attention to the choice of drill diameter. Due to its beating in the cartridge, a breakdown of the hole occurs, which must be taken into account. Indicative data are presented in the table

Indicative data are presented in the table.

| Drill diameter | 5 | 10 | 15 | 20 |

|---|---|---|---|---|

| Hole breakdown | 0,08 | 0,12 | 0,20 | 0,28 |

| Result | 5,08 | 10,12 | 15,20 | 20,28 |

To reduce breakdown, drilling is performed in two stages: first with a smaller diameter drill, and then with the main one. The same method of sequential reaming is used when it is necessary to make a hole of a large diameter.

How to drill metal with a drill

After marking the workpiece, the center of the future hole should be punched. This will prevent the drill from moving away from the set point. For the convenience of work, the workpiece should be clamped in a bench vise or placed on a stand so that it takes a stable position. The drill is set strictly perpendicular to the surface to be drilled.

This is important to avoid breakage.

When drilling metal, the drill does not need to exert much pressure. On the contrary, it should decrease as you go. This will prevent breakage of the drill and also reduce burr formation on the trailing edge of the through hole. Chip removal should be monitored. If the cutting tool jams, it is released by reverse rotation.

Cutting mode selection

When using a tool made of high speed steel, you can refer to the speed according to the data in the table. When working with carbide drills, the allowable values are 1.5 ... 2 times higher.

| Drill diameter, mm | up to 5 | 6…10 | 11…15 | 16…20 |

|---|---|---|---|---|

| Rotation frequency, rpm | 1300…2000 | 700…1300 | 400…700 | 300…400 |

Drilling of metal products must be carried out with cooling. If it is not used, there is a high probability that the tool will lose its cutting properties due to overheating. The cleanliness of the surface of the hole in this case will be quite low. An emulsion is usually used as a coolant for hard steels. At home, machine oil is suitable. Cast iron and non-ferrous metals can be drilled without coolant.

Features of deep hole drilling

Holes are considered deep if their size is greater than five drill diameters. The peculiarity of the work here lies in the difficulties associated with cooling and chip removal. The length of the cutting part of the tool must be greater than the depth of the hole. Otherwise, the body of the part will block the helical grooves, through which chips are removed, and liquid is also supplied for cooling and lubrication.

First, the hole is drilled with a rigid short drill to a shallow depth. This operation is necessary to set the direction and centering of the main tool. After that, a hole of the required length is made. As you progress, you need to remove metal shavings from time to time. For this purpose, use coolant, hooks, magnets, or turn the part over.

Elementary technology: drilling tiles in the bathroom

In order to hang a shelf, hooks, install electrical equipment and for any other purpose, it may be necessary to make a hole in a solid tile and it can be successfully drilled if all the advice is followed strictly and according to the technological process. In fact, the algorithm of operation is simple, you need to drill a hole penetrating the wall, insert a dowel into it, and then screw in a screw or self-tapping screw. But first you need to figure out how to drill tiles in the bathroom, as the success of the entire enterprise may depend on this.

Advantages and disadvantages of tools

Before proceeding directly to work, it does not hurt to think about how to drill ceramic tiles in the bathroom, that is, to finally decide on the equipment. Today on the market there is a wide variety of drills, rotary hammers, hand rotators and who knows what else. Among this variety, it is worth choosing only the most suitable one.

The most suitable tool for drilling tiles is an electric drill, in which the speed is switched. It will be much more convenient and faster to work with it, and low speeds will eliminate or at least minimize the risk of cracking the glazed ceramic surface. A high-quality drill is not cheap, but it is an indispensable assistant for a home master, so you should not spare money for equipment from well-known manufacturers.

A cordless screwdriver is another useful and handy tool for drilling through bathroom tiles without much hassle. It also has one more advantageous property - it can be used even where equipment cannot be connected to the network.

Hammer drills from well-known companies also have an enviable multifunctionality, so you can use such a tool when drilling holes in tiles. True, the price of such equipment is even higher than that of a drill, when it comes to professional models.

The most dreary and time-consuming process is drilling ceramics with a hand drill. However, if you only need to make a few small holes, you can try to do just that.

Choosing consumables and accessories

Mostly for drilling holes in ceramic tiles, low-angle drills, screwdrivers or rotary hammers are used.

There are three most suitable consumable options that will best suit your needs:

Drills with diamond coating show themselves best in drilling dense and slippery ceramics, which is why their tips look like sparklers. These are quite expensive components, because natural diamond chips are used in their production, and it is not advisable to purchase such drills for making one or two holes. If you have a major overhaul, construction or decoration in front of you, this is your professional occupation, then you just need to have it in your “arsenal”.

The second place is rightfully occupied by spear-shaped drills for drills with victorious tips. They are designed in such a way as not to split the tile, and a special sharpening does not allow them to slip off at the beginning of work. The grip of swept drills with the surface is improved due to this shape, and the risk of getting cracks and chips is reduced

It does not hurt if such equipment is new, perfectly sharpened, and besides, it also has a winning coating or tip.

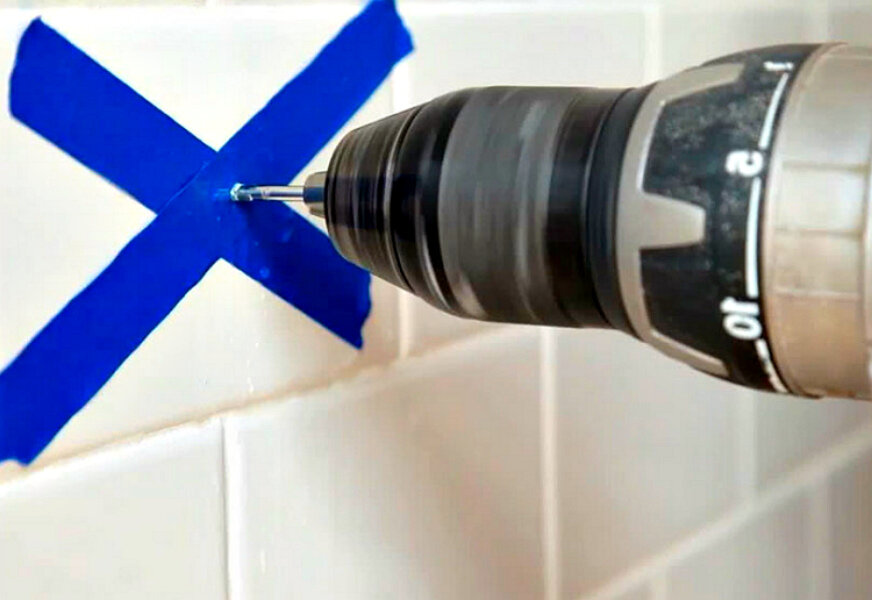

How to drill through tile so it doesn't crack

To get you started, here are a few general tips and tricks:

If you have the opportunity (there are unnecessary fragments of tiles available), then you should try to practice on them

When everything starts to work out for you, you can move on to fulfilling your goal.

It is very important that you make a good, and most importantly, accurate markup in advance. Naturally, for this you should put a point for future drilling with a marker or pencil on the surface of the tile

But pay attention to the fact that, firstly, not every pencil can leave a trace on a tile (in particular, on a glazed one).

Secondly, such a mark will be quite easy to erase even because of one awkward movement.

The best way in such a situation is to seal the hole area with a standard masking tape, and after that it will be possible to make markings and in this case everything will be perfectly visible.

The benefits of masking tape don't stop there. As practice has shown, it is much easier to drill a tile, since the sharply sharpened edge of the drill will not slip off the marked point. This is much better than trying to drill the center. When working with a core (although it can be a hardened nail or a sharp file), there will always be a chance of damaging the surface of the tile or even creating a chip (crack). As you can see, even a small piece of tape can solve several problems at once.

You should never put an electric tool at high speeds while drilling tiles.The speed range should be from 100 and reach a maximum of 400 rpm. The exact value is difficult to specify, since everything will depend on the type of drill used, diameter, thickness and components that make up the tile. But as practice has shown, the required frequency will be very easy to find empirically.

If you plan to drill a tile that has not yet been laid on the surface of the floor or wall, then you should prepare a convenient place for work. The surface must be smooth, not vibrate. From below there must be a material that will not be an obstacle to the drill - wood, plywood or even an old piece of drywall.

In order to drill tiles, you should prepare in advance a stable, stable table that had a plasterboard or wooden lining. Be sure to check that there are no hard fragments left on the table that will prevent the tile from fitting snugly to the surface.

The cutting tool can start to get very hot during the work, and overheating of the place where the drilling is carried out often leads to the fact that cracks form on the tile. For this reason, try not to apply excessive force, but rather allow a little more time to get the hole. You can cool the drill itself, for example, if you lower it into engine oil. In some cases, when working on a horizontal surface, one can resort to “local” cooling, namely, to mold holes from plasticine around the intended center, and fill the resulting container with water.

If a hole is drilled on a wall with tiles already laid out, then you should be careful with cooling the oil drill, as drops can fall into the grout, and it will take a long time to suffer to get rid of such stains. In some cases, it will be necessary to resort to the forced supply of liquid for cooling. Most professionals have a blower vessel in which pressure is created using a hand pump, and there is also a special jig that will center the drill and provide cooling fluid to the drilling area.

The drill should be located perpendicular to the surface of the tile, and if there are no special holding devices, then you will need to constantly monitor this yourself.

Drilling ceramic surfaces (especially when making holes of large diameter) can be accompanied by the scattering of very small, but extremely sharp fragments of tiles. Keep this in mind and therefore use personal protective equipment, especially for eyes and hands.

Now that the basic concepts have been explained to you, you can safely move on to typical drilling of ceramic tiles - small holes for dowels, as well as large holes for laying communications and installing plumbing, switches or sockets.

Drilling large diameter holes

When drilling holes for water pipes, a socket or a switch, where the diameter is more than 20 mm, use a ballerina or crowns.

Examples of unsuccessful drilling of tiles for electrical outlets

A crown is a tubular type instrument with a special (diamond) coating. The rather high price of the cutter is offset by the savings in time and the quality of drilling.With the help of diamond crowns, it is just right to make holes with a diameter of up to 160 mm.

Drilling with cooling

Ballerina - a drill with a sharp tip, similar to a spear, on the lower part of which a holder is attached. On it is fixed another of the same drill. By moving the bracket, you can set the diameter of the intended hole.

Core drilling

Fixation of the crown

The drilling technique is similar to dowel drilling. The cutter is placed exactly parallel to the tile so that, deepening, the drill begins to evenly cut the ceramic around the circumference. Movement to the side is not allowed.

Drilling porcelain stoneware

Drilling with a diamond crown involves the process of operating a drill at high speeds. Overheating in this case cannot be avoided, in order to avoid heating and burning of the crown, it is necessary to moisten the device with water. Of course, you can drill ceramics "dry", but only at a low speed.

If the cutter does not have diamond protection, do not use the “dry” method. Moreover, the use of water when drilling speeds up the process.

Drilling a ballerina

The work of a ballerina begins with setting the desired diametrical size. It is necessary to hold the tile and start drilling strictly at low speed. When working, it is recommended to use protective goggles so that the spent particles do not get into the eyes.

Drilling with a circular drill "ballerina"

The drill must be held precisely, without changing position or tilting. Do not forget to install a container with water next to it, when drilling ceramics with a ballerina, it is also needed

The main thing is not to rush, act with caution so as not to damage the tile

A hole in the tile is cut by a ballerina

Tool types

The following tools are suitable for making holes in tiles:

manual drill.Its strengths are full control of the rotation speed and the absence of vibrations. These advantages make the hand drill the most suitable tool for drilling ceramic tiles;

electric drill. It is used in most cases, since hand drills are extremely rare on sale. A model with continuously adjustable chuck rotation speed is preferable: it is desirable that this parameter does not exceed 1000 rpm when drilling ceramics;

screwdriver The power of this device is quite enough, because significant efforts are not required to drill tiles.

In comparison with a drill, a screwdriver has an important advantage: there are models with batteries that allow you to work on objects without power supply;

jigsaw. It is used to make large holes, if there is no more suitable tool.

Drilling tiles with a drill bit

- Determine the location of the future hole and seal the surface with masking tape.

- If you are not too confident in your abilities, you can make a plywood stencil and press it firmly against the wall in the right place.

- Install the hole saw of the required diameter and start drilling at the lowest possible speed.

- Try to keep the tool perpendicular to the wall. So the crown can evenly “bite” into the tile along the entire circumference of the cut.

- If you are using a diamond-tipped bit, the RPM can be slightly increased. And to avoid excessive heating of the surface, pour water over it while drilling.

Drilling holes in tiles for dowels

The surface of ceramic tiles is hard and smooth, so when drilling, the tool slides over it.To securely fix it in the desired position, masking tape must be glued to the place of the future hole, and already drilled through it.

Another important point mentioned above: holes in the tile cannot be made with an ordinary drill, which is used for concrete or brick. When using it, the tile will almost certainly crack, so the result directly depends on the correct choice of tool. In this case, you need to use a tile drill, which can be:

- with diamond coating;

- with a winning tip;

- special for tiles.

A diamond-coated drill is expensive, although this is the most suitable option. The diamond is much stronger than the top layer of the tile, so it drills through quickly and effortlessly. But it makes no sense to buy such a drill for the sake of two or three holes, therefore, if possible, it is better to rent it from professional builders.

Diamond Drill

Diamond Drill

Pobeditovy drill, for drilling walls

Pobeditovy drill, for drilling walls

When the drill is selected, it's time to go directly to work. Drilling holes in ceramic tiles consists of the following steps:

- masking tape is glued to the place chosen for the hole;

- the exact drilling location is marked with a dot or a cross;

- a tile drill is installed in the tool;

- a hole is drilled in the tile;

- "tile" drill is replaced by "concrete";

- a hole of smaller diameter and the required depth is drilled in the wall. To determine the depth, a mark is pre-applied on the drill, upon reaching which drilling stops;

- the drill is removed;

- the resulting hole is blown and cleaned of dust;

- a dowel is inserted into the hole, deepening into the tile by a couple of millimeters.

This algorithm is designed to obtain holes with a diameter not exceeding 15 mm. But often this is not enough, for example, for installing sockets or for laying pipes.

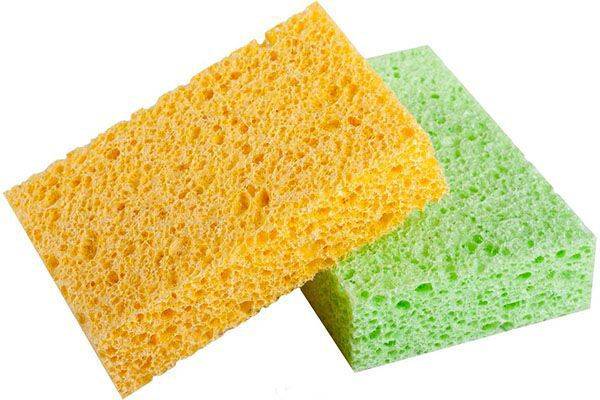

What points should be considered when drilling porcelain tiles? Tiler life hacks.

Don't forget to cool the drill.

One of the secrets for drilling a hole in porcelain tiles:

use a small, damp sponge to cool the bit and prevent overheating.

If you are working by yourself and cannot hold the tool in one hand and cool the drill at the same time, then you can stop from time to time and spray a little water on it.

Do not allow water to enter the motorized area of the tool.

Another trick you can use to keep cold is to keep a damp sponge under the drill bit.

So, you not only prevent the tool from overheating, but also trap dust and splinters from the cut tile.

Not to mention that you prevent water from running down the wall and all over the floor.

Note: for another way to drill porcelain stoneware yourself and cool it with water without assistance, see below on the page.

If you want to increase the life of your tools, you need to drill the tile slowly, don't press too hard, and cool it with cold water.

So, one more turn of the drill and…. relaxation.

_____________________________________________________________________

You have just learned how to drill holes and holes for sockets, pipes, faucets and other accessories in porcelain tiles.

Take a step back and admire the result.

You can even pat yourself on the back in approval.

You did well.

No, feel the hole made in the tile! You were surprised: the perfect edge without chips!

Now you're ready to take your next project with more confidence from start to finish.

____________________________________________________________________

To consolidate the information, take a look at how and with what the experienced Master Tiler tilers drill holes in porcelain stoneware.

Making holes of small diameter

For hanging shelves, mirrors and other pieces of furniture, you need holes for plastic dowels or anchors. As a rule, such nests are made 6 or 8 mm in diameter. For this, a spear-shaped drill is used on ceramic tiles of the appropriate size. If the tile is already glued, the work is carried out in two stages:

- the tile itself is drilled until the tip enters the plane of the wall;

- to obtain the desired depth, a perforator with a drill of the appropriate diameter is used.

Before drilling the tiles, it is recommended to stick a strip of masking tape on the wall (sometimes two strips are used crosswise). This will reduce the risk of the drill tip slipping off the marking and protect the hole edges from chipping or cracking.

Video description

The full process of drilling tiles and installing shelves can be viewed in the video:

Making big holes

For drilling holes of large diameter, crowns or ballerinas are used. The first option allows you to get the exact size, but is only possible when using a stationary machine. For already installed tiles, this method is not suitable. Working with a ballerina is easier, you can make holes both in an already installed tile, and in advance, before laying on a wall or floor.

Video description

This video shows how to drill porcelain stoneware with a diamond bit:

Video description

How to work with a tubular drill, in the following video:

It should be borne in mind that the authors of the videos show their understanding of the technology of working with tiles, which is not the ultimate truth. Often there are alternative drilling methods, additional processing of the edges of the holes and other actions are used. However, all methods require care and attention so as not to spoil the tool or the surface of the coating.

Helpful Hints

When drilling tiles, the same type of situations often arise that require the use of standard working methods. Consider a few useful tips that can save the master from surprises or marriage in work:

- Before drilling a tile, it is recommended to moisten it by immersing it in a container of water for a while. This will reduce the heating of the tool, reduce the thermal load on the material.

- In order to speed up and facilitate the cleaning process after drilling tiles on the wall, it is recommended to make a bag of newspaper and attach it with tape to the wall under the future hole. During the work, the dust will fall into the bag, which is removed and thrown away at the end of the work.

Drill dust bag

The rotation of the drill at high speed is unacceptable. The only case where you can work at a sufficiently high speed is when working with soft wall tiles.

Some sources recommend that you first punch the hole so that the drill does not lead away from the center. However, this step is only necessary for "ballerinas" or carbide tools with a shallow cutting edge angle.

For spear drills, punching is optional.

If the hole is located close to the edge, care must be taken.The drill often slips into the tile joint, so it is more correct to first make a small hole, and then expand it with a tool of the desired diameter.

If a hole is made for the dowel, it is recommended to first drill the tile with a spear-shaped drill, the diameter of which is 1 mm larger than the size of the perforator drill

This will keep the tile from damage and chipping, possible due to the beating of the drill.

Using a puncher

These simple but very useful tips will help you avoid breakage of tiles and tools when drilling holes of different diameters.

Briefly about the main

To make holes in wall or floor coverings, a special drill for ceramic or porcelain tiles is used. There are several varieties with different capabilities and degrees of strength.

In order not to make a mistake in choosing a tool, it is necessary to take into account the thickness and material of the tile. More dense varieties require the use of a diamond-coated tool; for soft wall tiles, a spear-shaped drill is chosen.

There are different methods of work, due to the placement of the coating and the size of the hole. When performing work, you should be guided by the advice of specialists so that the result is of high quality and without damage.