- Safety Rules for Cylinder Cleaning

- Do-it-yourself rocket stove from an oxygen cylinder

- Foam gun: how to clean in advanced cases

- Rules for storing empty containers

- Checking gas cylinders

- External signs of faulty equipment

- What if you don't wash?

- What is the correct way to clean the burners

- Chemical cleaning of cylinders - air retainers

- Folk remedies in the fight against pollution time-tested

- Rules for the care of the oven

- Safety Rules for Cylinder Cleaning

- Features of flux cored wire

- Removal of contaminants from combustion products

- Lists of the best

- Torch 2 - best spray range

- Aerosol gun PA-2 - best price

- Jet gel fighter - for closed space

- When to Clean Your Gas Boiler

- How to flush the column from scale

- Conclusions and useful video on the topic

Safety Rules for Cylinder Cleaning

Even if the old gas cylinder has not been used for its intended purpose for a long time, the presence of propane inside the tank cannot be ruled out. If you immediately start cutting the receiver without first washing it, the case may end in a large explosion, which will be provoked by even the slightest spark.

If after the first washing the smell of the odorant does not disappear, then it is better to re-clean the receiver or let it air out.

Due to the tightness of the propane receiver, gas residue will still remain inside the tank until the valve is safely removed.

Therefore, when preparing a cylinder for sawing, it is important to adhere to the following rules:

try to unscrew the valve on your own, especially if it is fully functional, without resorting to sawing the structure;

even after successful unwinding of the valve, it is important not to roll or drop the gas cylinder;

it is not recommended to wash the container near the source of fire, since even in combination with water, the gas can ignite;

it is advisable to rinse the cylinder away from living quarters, because the pungent smell of the odorant can “settle” in your home for a long time;

cutting the valve with a grinder is contraindicated due to the likelihood of a fire or explosion.

If the gas cylinder has been standing with the valve open for a sufficiently long time, this does not mean that it does not need to be cleaned.

There are still gas residues on the inner walls of the container, which must be washed out with at least plain water.

When unwinding the valve, the master cannot cope without an assistant, since one of them must hold the cylinder, and the other must unscrew the valve with a key

In the process of unscrewing the valve, it is recommended to use a professional gas wrench, but in the absence of one, you can build the tool yourself.

If the valve cannot be unscrewed with a simple key, you can resort to cutting the valve with a hacksaw.

Do-it-yourself rocket stove from an oxygen cylinder

- Step one: cutting the balloon

- Step two: loading chamber

- Step three: loading hole

- Step four: ash pan

- Step Five: Vortex Flow

- Step Six: Welding

- Step seven: insulation

- Step eight: afterburning system

- Step nine: cover

- Step ten: support

There are several options for building such a furnace. The master combined two such variants of photo 1, and 2., and made his own photo 3.

For the manufacture of the master DIYer used the following

Tools and materials:

- Oxygen balloon;

- Cardboard;

- Marker;

- Insulating tape;

- angle grinder;

- Magnetic square;

- Welding machine;

- profile pipe;

- Band saw for metal;

- Channel;

- Roulette;

- Metal brush;

- A hammer;

- Clamp;

- Metal container;

- Pliers;

- Bolt;

- Two bushings;

- Perlite;

Foam gun: how to clean in advanced cases

You won’t surprise anyone with a tool left for a couple of days, and truly absent-minded people easily forget the mounting gun, closing the summer season and leaving until spring. In this case, with the first sunny days in full growth, the task is not for wimps - cleaning the gun from dried mounting foam, which has managed to gain reinforced concrete strength. The force designed to hold the double-glazed windows tightly fastened the parts of the gun together.

Let's face it, the likelihood that you will not be able to return the tool to working condition is very high. But since the prospect of sending the gun to the landfill still looms, then there is nothing to protect it, and it is worth trying to clean it using the most radical methods. Aggressive chemical environments are completely powerless in front of hardened polyurethane foam, and direct physical impact will have to be removed.

photo from the site http://zaporizhia.all.biz

Arm yourself with a hard metal wire, with a diameter slightly smaller than the barrel hole.Acetone will also come in handy for you, so you should wear gloves on your hands, and protect your airways with a respirator - the process will be long.

Completely disassemble the gun, unscrewing everything that can be dismantled. The design of different models may vary, but all of them do not have fragile parts, so proceed boldly, being careful not to strip the threads.

Remove large fragments of mounting foam with a construction knife where possible.

Wielding a wire, and gradually digging up the solvent, successively scrape off the adhering foam. First of all, cleaning the foam gun is carried out for the valve and the trigger lever.

Proceed to restore the patency of the trunk. After dripping acetone, wait 10 minutes, and, helping yourself with an impromptu wire ramrod, pick off pieces of foam or try to push the cork further.

When the main part of the barrel is cleaned, fill the solvent to the maximum level, and leave it in this state for 15-20 minutes to remove dirt on the inner walls, which will negatively affect the foam pressure during subsequent operation.

Once the bore is clear, reassemble the tool and rinse it thoroughly with a can of cleaner.

Get ready for the fact that you will have to allocate at least an hour to resuscitate the instrument. Do not rush, so as not to damage the parts of the mechanism. In most cases, the efforts made will be crowned with success and the performance of the pistol will be restored.

Don't repeat your mistakes

It will still not be possible to completely remove the frozen foam residues in the round cavity of the barrel, and for the first time this will not be critical for the pressure created.But with each repetition of such a situation, the narrowing will become more pronounced, and forgetting about your instrument 2-3 times, you will no longer be able to bring it back to normal.

Rules for storing empty containers

The attitude to an empty container should be exactly the same as to a freshly filled one. Store empty containers tightly closed in a separate room. Therefore, an apartment for storing gas cylinders, even if already used, is not suitable.

The old tank must not:

- open, cut, cut;

- heat;

- use for the manufacture of explosive devices, including for peaceful domestic or construction purposes;

- independently dispose of the remaining gas;

- to be scrapped without proper treatment.

Used equipment should be handed over to a collection point of a specialized service for inspection or replacement.

Checking gas cylinders

Each container is equipped with a stamp or a metal "passport", which indicates the expiration date, storage and crimping. Pressurization is a validation test. During such a check, specialists unscrew the valve and inspect the inner surface.

On the stamp of a standard propane cylinder, you can find information about the working and test pressure, volume, initial mass of empty containers and weight filled to capacity. The serial number, dates of manufacture and the next certification are also indicated there.

If the walls are in order, there are no visible damages on them, the tank is filled with water and subjected to pressure testing: a pressure is applied that is one and a half times higher than the working values.

The container that remains intact after such an event is “awarded” with an updated brand and is allowed for further operation.

External signs of faulty equipment

Any user can independently determine the unsuitability of the container by external signs:

- the presence of rust - products are not subject to further operation, more than a third of the surface of which is occupied by corrosion;

- the presence of traces from the effects of fire - a damaged layer of paint;

- swelling - barrel-shaped specimens with a distorted shape;

- the presence of dents.

All these signs are the reason for the speedy disposal. Another good reason is the expiration of the storage period, information about which is displayed on the stamp.

What if you don't wash?

Be sure to wash! Then everyone will benefit - both the consumer and the seller.

And it's not just about the hardware. The main thing is health and safety. Indeed, in the structure of the beer stone, harmful microorganisms are formed, pathogenic microflora, which enters the beer, and then into the consumer's body.

Sediment in a mug or bottle will cause dissatisfaction among the buyer. It is unlikely that he will once again want to buy beer in your store. And even more so recommend it to friends. Moreover, the organoleptic of the drink changes - taste, smell, color. It becomes sour, becomes cloudy, and fails before the expiration date.

And again, back to the consumer. If a favorite variety loses its usual taste, will they buy it again? Or imagine, in a beer restaurant, a guest was brought a mug of their favorite craft, but the taste is not the same. And all because the institution did not take care of the cleanliness of the bottling system in a timely manner. The image is falling, the guests do not want to return.

Hygiene, first of all, is respect for customers.

And yet, the beer stone harms the equipment, leads to breakdowns and additional costs for replacement and repair.

What is the correct way to clean the burners

First of all, you need to take care of safety. Close the gas supply and ventilate the room. It is possible to clean the burners using improvised methods, or with special preparations. Choose the method at your own discretion. Water or vinegar. If there is little dirt, then you can simply wipe the stove and burners with a simple soft cloth, which will be soaked in a solution of simple soda. Make sure the stove is no longer hot. Remove each burner and remove each element. If necessary, wipe the divider.

Boil water in an ordinary kettle and pour it into a saucepan. In a simple case, it is possible to use hot water from a conventional faucet. Then add vinegar or soda. Put everything into the finished solution for a while, then put on gloves and start cleaning the items. Use for an ordinary sponge that will not harm the surface of the burners. Properly wash all the elements in water and leave to dry. After all this, simply assemble the burner back. When cleaning, use only ecological methods.

Chemical cleaning of cylinders - air retainers

2.1.

Choice of technological process of cleaning

produced subject to availability

and the degree of corrosion of the inner surface

balloon.

2.2.

If, when viewed on the inner surface

cylinder will be found to be corroded, then

to remove it, you must

activation with a solution of orthophosphoric

acids (100–120 g of phosphoric acid

per 1 liter of fresh water) with a temperature of plus

18–20оС.

For better cleaning of the inner surface

the balloon is filled with a solution in an amount

15–20% of the volume of the cylinder being cleaned and

roll it over for 15-20 minutes with

angular velocity 0.32–0.48 rad/s.

After

of this acid solution from a cylinder

drained and visually inspected

internal surfaces of the cylinder

no signs of corrosion. If traces

corrosion is not completely removed, then

the activation operation must be repeated.

Making sure

that traces of corrosion have been removed, the cylinder

washed with cold fresh water (with

temperature plus 5–20оС)

within 10-15 minutes.

Further

produce degreasing of the internal

the surface of the cylinder with a solution of caustic

soda (20 g of caustic soda per 1 liter of fresh

water) and soda ash (50–60 g

soda ash per 1 liter of fresh

water) with a temperature of plus 60–70 ° C,

which is poured in an amount of 40 to

50% of the volume of the cylinder to be cleaned. Time

rolling degreasing process

balloon with an angular velocity of 0.32–0.48 rad/s

– from 30 to 40 min. Adding to alkaline

surfactant solution

"Sintonol DS-10" or "Progress"

(3-5 g of substance per 1 liter of solution) reduces

degreasing time up to

20–30 min.

After

draining the alkaline solution cylinder should be

rinse with hot fresh water

temperature plus 60–70оС

for 15-30 minutes, and then cold

fresh water with a temperature of plus 5–20 ° C

within 10-15 minutes.

2.3.

If, when viewed on the inner surface

no traces of the balloon will be found

corrosion or will be detected

slight traces of corrosion

activation and degreasing operations

are combined.

AT

the balloon is filled with hot solution (with

temperature plus 60–70оС)

orthophosphoric acid (50–70 g of orthophosphoric

acids per 1 liter of fresh water) and

surfactant

"Sintonol DS-10" or "Progress"

(3–5 g of substance per 1 liter of water) in the amount

15–20% of the volume of the cylinder being cleaned and

roll it over for 15-20 minutes with

angular velocity 0.32–0.48 rad/s.

After

draining the solution, the cylinder should be washed

hot fresh water at a temperature

plus 60–70оС

for 15–20 minutes, and then cold

fresh water with temperature plus

5–20оС

within 10-15 minutes.

2.4.

After rinsing the bottle with cold water

cleaning operations will be completed and

the cylinder should be purged with air (dry)

until complete removal of moisture from the internal

surface for approximately

40–60 min.

For

drying the inner surface of the cylinder

should be used dry and

free from oil and mechanical particles

air (passed through the drying unit and

cleaning), compressed to a pressure of 0.15–0.20 MPa

(1.5–2.0 kgf/cm2)

and heated to a temperature of plus 50–60°C.

2.5.

Allowed with the same solution

clean no more than four or five cylinders,

after which it is necessary to prepare

fresh solution.

2.6.

After drying the interior

cylinders are visually checked

purity. On the inner surface

cylinders products are not allowed

corrosion, grease, residues

cleaning solutions, dark and black spots

from crumbling slag.

Quality

cleaning of the inner surface should be

control white cotton

wad. After wiping the inside

surface cotton wad

light tones should not have visible

pollution.

2.7.

Cleaned and drained cylinders must

be protected from dirt

technological plugs until the moment

their installation at a regular place and connection

pipelines.

For

protection for a specified period

internal surfaces of cylinders from

slight rust build-up

preserve by filling

cylinders with clean dry air up to

pressure 0.5–1.0 MPa (5–10 kgf/cm2)

or other preservation method

(for example, by passivation).

Folk remedies in the fight against pollution time-tested

The modern chemical industry offers a lot of products that will easily and quickly clean your stove from any contaminants. But recently, housewives have been skeptical about such substances. There are several reasons for this: such products can be expensive, they are unsafe, therefore they require special storage (which becomes more relevant if there are children in the house), and it is recommended to use them with rubber gloves.

The stove can be perfectly cleaned with the help of folk remedies

For women, it is important that such products, even with protection, negatively affect the skin of the hands, which means that creams should be used. This adds expense to the already high cost of cleaning gels and powders. In addition, we all faced such a situation: it is urgent to clean the stove, and the industrial tool is over

And running to the store is not an option. This is where the well-known and used tools will come to our aid, which are probably always at hand:

In addition, we all faced such a situation: it is urgent to clean the stove, and the industrial tool is over. And running to the store is not an option.This is where the well-known and used tools will come to our aid, which are probably always at hand:

- laundry soap solution;

- lemon acid;

- vinegar;

- ammonia alcohol;

- baking soda;

- ammonia-anise drops.

Almost all of these tools will easily help you cope not only with pollution on the gas stove, but also clean almost all household appliances to a shine - a refrigerator, a boiler, an electric kettle, a washing machine, a juicer.

They can handle any dirt, and most importantly, their advantage is the possibility of safe use even with children.

Rules for the care of the oven

How to clean the oven on a gas stove? Strong chemicals will not work, replace them with others:

It is possible to return the nurse to the original brilliance and purity, the main thing is to know the methods and suitable means. And do not leave stains for a long time, it is better to carry out the cleaning procedure more often.

The stove is the most difficult appliance to maintain in the kitchen, especially if it is gas. Indeed, unlike the electric one, it has a heavy cast iron grate, burners that periodically clog, and handles that get dirty very quickly with grease. Stationary gas stoves also have an oven and a drying cabinet, a back shield or a cover. In this article, you will learn how to clean your gas stove at home from grates to knobs, as well as how to make cheap and super-efficient DIY cleaning solutions.

Safety Rules for Cylinder Cleaning

Even if the old gas cylinder has not been used for its intended purpose for a long time, the presence of propane inside the tank cannot be ruled out.If you immediately start cutting the receiver without first washing it, the case may end in a large explosion, which will be provoked by even the slightest spark.

Due to the tightness of the propane receiver, gas residue will still remain inside the tank until the valve is safely removed.

Therefore, when preparing a cylinder for sawing, it is important to adhere to the following rules:

try to unscrew the valve on your own, especially if it is fully functional, without resorting to sawing the structure;

even after successful unwinding of the valve, it is important not to roll or drop the gas cylinder;

it is not recommended to wash the container near the source of fire, since even in combination with water, the gas can ignite;

it is advisable to rinse the cylinder away from living quarters, because the pungent smell of the odorant can “settle” in your home for a long time;

cutting the valve with a grinder is contraindicated due to the likelihood of a fire or explosion.

If the gas cylinder has been standing with the valve open for a sufficiently long time, this does not mean that it does not need to be cleaned.

There are still gas residues on the inner walls of the container, which must be washed out with at least plain water.

In the process of unscrewing the valve, it is recommended to use a professional gas wrench, but in the absence of one, you can build the tool yourself.

If the valve cannot be unscrewed with a simple key, you can resort to cutting the valve with a hacksaw.

Features of flux cored wire

Flux cored wire has different diameters, the smallest diameter starts from 0.8 mm. The thickest wire for semi-automatic welding without gas has a diameter of 2.4 mm.In turn, such a large selection of diameters provides the widest possibilities for semi-automatic welding: starting from welding thin metals, only 1.2 mm thick, and ending with metals, one centimeter thick.

Cored wire and semi-automatic without gas, you can cook both carbon steel and galvanized iron with stainless steel

At the same time, the filler inside the wire may differ in its composition, and this is very important to consider when choosing a flux-cored wire for welding.

Removal of contaminants from combustion products

Soot, soot and other solid products of combustion, although formed in such devices in small quantities, can still cause serious damage.

If you need to clean this part of the device, you need to remember the manufacturer's instructions again, especially if the warranty period has not yet expired. Some manufacturers require that such work be carried out only by professional gasmen.

You can remove soot and soot from the surface of the heat exchanger using an ordinary hard brush, but you will need a metal wire to clean the nozzles

The easiest way to clean the column radiator from combustion products. To do this, turn off the gas and remove the protective cover from the device. After that, the surface of the element is treated with a conventional household vacuum cleaner.

If the gas in the column does not ignite, or burns unevenly and weakly, the nozzles may be clogged. To clean them from the accumulated layers of soot, use a thin wire or brush with metal bristles.

Of course, in this case, turn off the gas and remove the casing.Cleaning must be done carefully so as not to damage the elements of the device.

When the soot accumulates too quickly, it makes sense to think about the presence of other faults that provoke this situation. A common cause of this phenomenon is a leak at the junctions of the gas pipes inside the column.

The gas column burner consists of narrow nozzles. If they are clogged with soot, the gas will flow unevenly, the water will heat up more slowly.

The gap may be so small that it is not possible to detect a leak by smell. If you suspect a malfunction of this type, you need to apply a soapy solution to the joints, and then apply gas to the device.

If the solution begins to bubble, stop work, turn off the gas and immediately call an experienced gasman. Self-activity at this stage can be fatal.

The water pressure is normal, the soot is removed, but the column still does not turn on? It's time to check the traction. In modern models, there are usually special sensors that detect the absence of traction and do not allow the device to be turned on, blocking the gas supply to the ignition device.

To check, it is better to use strips of thin paper. The flame of a candle or lighter can be dangerous if the problem is due to a gas leak.

If soot particles and other products of combustion accumulate in the column too quickly, you need to find the fault that leads to this result.

Having found a weak traction, it is necessary to identify the cause of the situation that has arisen. It is usually enough to clean the chimney to restore normal operation of the appliance.If this does not help, it is worth consulting with a gas equipment engineer, perhaps there are flaws made during the installation of the chimney structure.

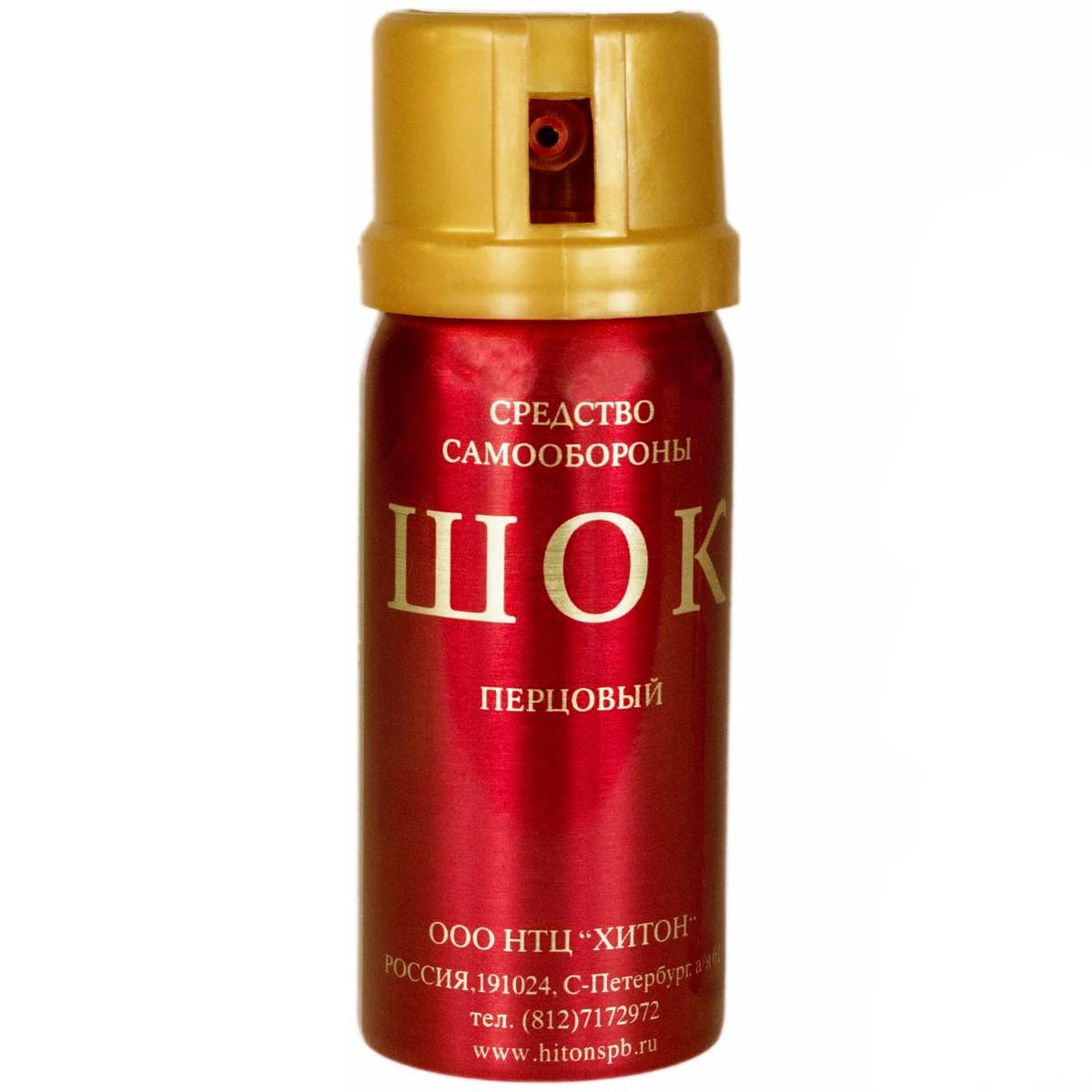

Lists of the best

In addition to the models presented above, we want to offer you a list of the best spray cans according to the following criteria:

- The best spray distance.

- Best price.

- For closed space.

Torch 2 - best spray range

Gas cartridge based on the consistency of tear gas (5%) and hot pepper (95%). Ignoring the aerosol type of spraying, the range of destruction is an impressive three meters - according to this indicator, it is on a par with gel and jet methods of self-defense. The result was achieved due to an increase in throughput and a slight processing of the supply drug, relative to the earlier GB Fakel.

Cost: from 435 to 685 rubles.

Torch 2 gas spray for self defense

Aerosol gun PA-2 - best price

The type resembles a pistol of unusual shape - the handle and barrel are reduced in order to lighten the weight and carry it in a pocket or a special holster. The model is distinguished by a rather massive spray: in 1 second it shoots out more than 10 g of irritant, which seeps through the skin pores, functions on nerve endings and causes a powerful pain shock in the attacker. It does not cause any harm to well-being, but for 20-30 minutes it makes it impossible to continue an aggressive attack.

Cost: from 885 to 1050 rubles.

self-defense Aerosol gun PA-2

Jet gel fighter - for closed space

For obvious reasons, it is impossible to use aerosols in a car, subway or in any other room, however, an aggressive attack can occur in any of these places, it will not be superfluous to protect your health with a Russian-made gel spray from a new series - "Fighter". Due to the thick and viscous mixture, the contents are not sprayed, but cover the senses. Apart from the direct irritating effect of pepper capsaicin, an unusual remedy can frighten an attacker, in fact, allows you to win a few decisive minutes.

Cost: from 320 to 480 rubles.

self defense canister

When to Clean Your Gas Boiler

Information on the frequency of cleaning geysers is rather contradictory. Some sources on the Internet recommend maintenance annually, others - once every 6 months, and so on. The homeowner will correctly navigate by the quality of tap water and some signs indicating that the device is contaminated:

- the heating efficiency and pressure in the DHW line have decreased - the heat exchanger is clogged;

- the igniter burns with a yellow or red flame (should be blue);

- the color of the fire on the main burner has also changed;

- the column does not ignite and turns off on its own at normal network pressure.

The average interval between preventive cleanings of an instantaneous water heater is 1 year. But you should take into account the quality and hardness of local water. If it is saturated with salts, scale will be deposited much sooner. In such cases, it is appropriate to use softener filters, otherwise all water heating equipment will quickly become unusable.

How to flush the column from scale

What kind of means are not used by the owners of private houses and apartments when cleaning gas water heaters with their own hands - various acids, household chemicals and even electrolyte from batteries. We warn you: most of these compounds are unsuitable for servicing water heaters, their use will not work, and it can easily do harm.

We will recommend 2 tools whose effectiveness has been proven by practice and confirmed by numerous user reviews:

- An inexpensive powder sold in grocery stores is food grade citric acid. In 1 liter of washing water, 50-70 grams of the product is diluted.

- Special fluids designed for descaling the coils of gas water heaters and plate heat exchangers of double-circuit boilers.

Scale is a combination of salts of various metals, which is a solid deposit of a light shade. Hydrochloric, sulfuric or acetic acid slightly dissolves this substance, but with pleasure "eats" copper. But the cheap "lemon" works flawlessly, as you can see by watching the comparison video:

Conclusions and useful video on the topic

The article presented step-by-step instructions for disassembling a gas cylinder, including the secrets of properly venting the gas and rinsing the cylinder with clean water. A few simple rules for working with an angle grinder will help you correctly cut the cylinder capacity, reducing the likelihood of a fire or explosion to a minimum.

A prerequisite is the preservation of the sequence of actions presented in the instructions, since the successful completion of the dismantling of the gas receiver depends on this.

You can learn how to avoid an explosion of a gas cylinder during its disassembly from the video:

You can unscrew the valve of the propane receiver, without the need to cut it, in the following way: