- Procedure for installing the air conditioner

- Types of air conditioners: monoblock, split systems and multi-split systems

- Separate laying of highways

- Pressure and seal test

- Wall laying

- Connecting freon pipes

- Principle of operation and features

- System start

- freon inlet

- Vacuum pump

- Conclusion

- SEQUENCE OF WORK

- Installation of the air conditioner route - what you need to know

- Principles of laying with a slab base

- Selecting the location of the indoor unit

- Repair options

- Requirements

- Requirements for installing split systems

- Options for laying highways for air conditioning

Procedure for installing the air conditioner

Installation work is carried out according to the developed algorithm. All requirements and rules are taken into account. How to install the air conditioner:

- Electrical wiring is being laid to connect the system to the network.

- Installation of the unit outside the room.

- selection of the optimal place for installation, which will be located above 2 m from ground level;

- fixing the brackets to the selected anchor bolts;

- installation of the block on the prepared place (brackets);

- creation of main holes in the wall, the diameter of which is from 50 to 60 mm for all communications;

- installation of a waterproofing cylinder in the holes and connecting communications.

- Installation of the unit indoors:

- selection of the optimal location, according to the requirements described above;

- installation of brackets for air conditioning;

- installation of the indoor unit in its place.

- Wiring connection:

- installation of an internal or external box;

- joining copper pipes through which freon will circulate, connecting electrical wires;

- evacuation - air and all moisture is removed from the system. Special equipment will allow you to perform the operation in about 45 minutes, no less.

- Test operation of the installed air conditioner. For this purpose, special hardware and software equipment is used.

The air conditioner is installed and ready to go.

Types of air conditioners: monoblock, split systems and multi-split systems

According to the design, all air conditioners are divided into two types: "monoblock", consisting of one unit and "split systems" (from the English word "split" - "separate"), consisting of several units. If a split system consists of three or more units, then it is called a "multi-split system":

- Monoblock air conditioners consisting of one unit (window, mobile and roof air conditioners). In such air conditioners, all elements are placed in a single housing, which makes it possible to simplify the design of the air conditioner and reduce its cost.

-

Split systems - consisting of two blocks (wall, channel, cassette and other types of air conditioners). The split-system air conditioner is divided into two blocks - outdoor and indoor, which are interconnected by an electric cable and copper pipes through which freon circulates. Thanks to this design, the most noisy and bulky part of the air conditioner, containing the compressor, is moved outside.The internal block can be placed practically in any convenient place of the apartment or office.

All modern split systems are equipped with a remote control with a liquid crystal display. With it, you can set the desired temperature with an accuracy of 1 degree, set a timer to automatically turn the air conditioner on and off at a given time, adjust the direction of the air flow, and much more.

Another advantage of split systems is a large selection of different types of indoor units. Among them, the following modifications are distinguished: wall, duct, ceiling, column and cassette air conditioners. At the same time, household split systems are only wall-mounted, all other air conditioners are semi-industrial. Note that in relation to split systems, the names “air conditioner” and “split system” are synonymous, that is, we can say “duct air conditioner”, or “channel split system”, or “duct type air conditioner”.

-

Multi split systems are a type of split system. Their difference is that not one, but several indoor units are connected to one outdoor unit, usually from 2 to 4-5 pieces (each indoor unit is controlled by an individual

control panel). At the same time, indoor units can be not only of different power (usually from 2 to 5 kW), but also of different types. Such a constructive solution saves space on the outer wall of the building and does not spoil the appearance of the outdoor units so much.At the same time, contrary to popular belief, replacing several split systems with one multi split system does not lead to a gain in price, since the cost of equipment is about the same, and the labor intensity and cost of installation are 1.5-2 times higher due to longer communications. In addition, in the event of failure of the external multi split system unit all indoor units stop working. Therefore, multi-split systems are usually used only when it is impossible to place several external units on the outer wall of the building.Multi split systems are usually divided into "fixed" and "composite". "Fixed" multi-split systems are sold as ready-made kits, which, in addition to one outdoor unit, include a certain number of indoor units. You cannot change the number or types of indoor units. Such systems belong to household equipment and usually have 2 or 3 indoor units. In "set-up" multi-split systems, several indoor units are selected for one external unit from a wide range, usually up to 4-5 pieces. At the same time, only the maximum number of blocks and their total power are limited. Indoor blocks can be of different types. Such multi-split systems belong to semi-industrial equipment. If the number of indoor units exceeds 5-6 pieces, then this is already an industrial multi-zone system.

Separate laying of highways

The separate laying method is used when it is more profitable and easier to bring the condensate pipe into the sewer system. Also, this approach is used for architectural features, instructions from the Housing Office, and so on. In this embodiment, the main gate can be made in any direction.The second strobe should be made with the same slope (3 degrees).

However, there are cases when laying the condensate pipe is not possible at a certain angle. Then a special pump is used, which will drain water directly into the sewer.

There is also another nuance - the likely ingress of an unpleasant odor from the sewer. In order to avoid such a problem, it is necessary to install special equipment (siphon) in the tube.

Pressure and seal test

Before the process of pumping freon, be sure to check the drainage. To do this, after removing the filter, pour clean water onto the evaporator of the indoor unit, as if simulating the formation of condensate.

If the drainage is done correctly, then the water will freely exit through the tube and not overflow over the edge of the inner pan.

Also, before opening the ports of the freon line, it is advisable to check the pressure in the system. The manufacturer, as a rule, fills the refrigerant for 5 meters of the route, and reports this on the nameplate of the outdoor unit.

However, there are also half-empty copies (they save freon).

Next, the tightness of all connections is checked. Super-professionals do it for the right price with nitrogen, at a pressure of 38 bar. But are you willing to pay money for such quality?

In the standard version, after disconnecting the vacuum pump, a certain amount of refrigerant (5-7 bar) is simply released into the route and the pressure value is memorized.

Wait 20 minutes and check if the readings have changed.With a positive result, using the hexagons, the service valves of the air conditioner are fully opened and all the freon is launched into the line.

Next, apply voltage to the air conditioner and test it in all modes. During cooling, measure the surface temperature of the evaporator with a pyrometer, and best of all with a contact thermometer.

After entering the operating mode, it should be at least + 6C. If the temperature is higher, additional freon charging may be required.

In this case, a complete reload of the system is used more, and not just its refueling, due to the complexity of the process.

If all the installation steps are completed without comment, you can enjoy the coolness and assume that your air conditioner is installed correctly.

Wall laying

Next, the facade fasteners are used. If you purchase factory fittings, the distance is already regulated: at least 6 cm from the cable to the wall.

Then the cable route is marked and holes for fasteners are prepared. The distance between attachment points is usually at least 70 cm. At bends, the frequency of attachment increases to prevent free sagging.

Then, with the help of regular bolts, all facade fasteners are fixed. To prevent corrosion and destruction of fasteners, metal caps are closed with special plugs.

If house communications are located on the laying route, it is necessary to ensure a safe distance. To water pipes at least 10 cm, to gas pipes at least 40 cm.

Under wind load, the cable can fray the insulation, and the wires will short circuit.

It is not allowed to use fasteners that are intended for other purposes.For example, pipe clamps or cable clips for indoor installation.

Connecting freon pipes

We pass to the stage of connection of communications.

Connect the flared pipes to the indoor unit of the air conditioner using adjustable wrenches.

If you are rich with a torque wrench, then it is better to use it.

Here are the recommended tightening torques for freon tubes of various diameters:

Next, take the interconnect cable and twist it all together with the freon line using reinforced tape or vinyl tape.

Do not forget to stretch the insulation of the required diameter on the copper pipes.

To prevent dirt from accidentally getting inside the tube, wrap its ends with electrical tape.

Mistake #8

In no case should the thermal insulation of the pipes be left unprotected.

Otherwise, from the side of the street under the influence of UV rays, within a few seasons it all turns into dust.

If your thermoflex is light-resistant and not afraid of the sun, then think about birds. Ravens are very good at pecking and pulling such material into their nests.

Mistake #9

Also, do not leave any area indoors without insulation. Especially the connection points.

Condensation will gradually form here and eventually a neat trickle of water will appear on your wallpaper.

Condensation will gradually form here and eventually a neat trickle of water will appear on your wallpaper.

The line itself, wrapped with tape inside the room, is hidden in a plastic box.

However, if you have a short section and old wallpaper remains, then instead of using a box, you can paste over the highway with them. You get an almost imperceptible picture.

Next, pass the line through the through hole to the outside.

Principle of operation and features

Like conventional split systems, a cassette air conditioner includes an outdoor unit and an indoor unit.The outer one is located on the outside of the room, and the inner one is installed in the inter-ceiling space and is masked behind the false ceiling. At the same time, the front panel matches the size of the suspended ceiling slab, so it fits seamlessly into the room. Such installations can be used for offices, conference rooms, cinemas, restaurants and other spacious premises for any purpose.

Like conventional split systems, a cassette air conditioner includes an outdoor unit and an indoor unit.The outer one is located on the outside of the room, and the inner one is installed in the inter-ceiling space and is masked behind the false ceiling. At the same time, the front panel matches the size of the suspended ceiling slab, so it fits seamlessly into the room. Such installations can be used for offices, conference rooms, cinemas, restaurants and other spacious premises for any purpose.

If you have a large room with warm or cool areas, a cassette air conditioner can easily fix this. Some models offer the ability to cover one or two vents, which is convenient if airflow is not needed in any of the directions. For example, this is very convenient for a corridor where you can only direct the air flow in two directions. Well, if you install it near a wall, and you only want to direct air in three directions, which is logical, you can block one vent so that it does not blow directly onto that wall.

Cassette-type air conditioners have the following advantages:

- Ceiling mounted for even space cooling. However, its installation must be planned in advance, as it requires a large distance between the base and false ceilings.

- Large cooling area combined with low noise level during operation. This allows the use of this type of climate technology for industrial and commercial premises.

- High performance. Unlike classic household split systems, cassette models are suitable for large areas. They are installed in halls where there are always a lot of visitors.

System start

Having finished all the work on switching, proceed to the launch. The system must be prepared by removing all air, nitrogen and moisture from it. They get into the pipes during their installation. If the system is not cleaned of foreign gases, then the load on the compressor will increase, and its useful life will decrease.

Moisture also has a negative effect on the performance of the system. The composition of freon pumped into the air conditioner contains oils. It is designed to lubricate the internal elements of the system. Since the oil has a hygroscopic structure, it will lose its effectiveness when mixed with water. In turn, this will lead to premature wear of the system elements.

It becomes clear that this operation is necessary. The system will start, of course, but for a short time. Removal of air and other foreign matter is carried out in two ways:

- the inlet of freon into the system;

- vacuum pump.

The first method can be carried out due to a small additional supply of freon pumped into the indoor unit. It is only suitable for trails no longer than 6 meters. That is why a vacuum pump is required for longer communications. If you blow a long system out of the indoor unit, then there will be no freon left for its operation.

Control valve at the bottom of the block

freon inlet

Before starting the operation on the outdoor unit, the plugs and covers on the valves are unscrewed. Next, the valve of the indoor unit on the larger diameter pipe opens for 1 second. This is done based on the design of the valve. Typically a hex wrench is used.

Having supplied freon to the system and creating excess pressure, it is necessary to relieve it.This is done with the help of a spool on the same pipe, by pinching with a finger. At the same time, you need to leave a small amount of freon in the system so that fresh air does not enter there. This procedure is repeated a couple of times.

After its completion, a plug is screwed onto the spool, and the valves on both pipelines are fully opened. To check the quality of the joints, you can smear them with soap suds.

Vacuum pump

This procedure requires not only a vacuum pump, but also a high pressure hose. You will also need two pressure gauges - for low pressure and high pressure.

The hose is connected to the spool of the thick pipeline. In this case, both valves must be closed. After switching the vacuum pump to the system, it is turned on and left to work for 15-30 minutes. This time is quite enough to pump out air and other impurities from the pipelines.

Vacuum pump with pressure gauge

After turning off the pump, it must be left connected to the pipeline with the valve closed. In this position, the system should stand for about 30 minutes. During this period of time, pressure indicators are monitored. If all connections are tight, the instrument arrows should remain in place.

If the readings begin to change - somewhere poor-quality sealing. As a rule, these are the places where pipes are connected to the blocks. Their additional broach eliminates the problem. If it does not help, then the leak is detected with soap suds.

System pressure control

If the complete tightness of the system is confirmed, then leaving the pump connected, the valve on the thick pipeline opens. After the characteristic sounds fading, indicating that the pipes are filled with freon, the pump hose is unscrewed.It is better to do this with gloves so as not to get frostbite from freon residues. Now you can open the valve on the thin pipeline. Everything is ready - the system can be turned on.

In the video, see how the evacuation of the nose is carried out:

Conclusion

In conclusion, I would like to note that the installation and launch of both air conditioners and split systems is a rather complicated undertaking. It is necessary to have the skills of construction and installation works, to understand the technical documentation and materials. That is why, in most cases, specialists are involved in such work.

Moreover, some large split systems are installed only by representatives of the manufacturer's plant. Otherwise, the service warranty will be void.

We also note that the launch of air conditioning systems using vacuum pumps is carried out in Russia and neighboring countries. In world practice they are not used. For example, the same Israel where air conditioners are not turned off all year round. Why this is done is a question for foreign experts.

Source

SEQUENCE OF WORK

The laying of engineering networks and communications is carried out by the company in several stages, which allows you to organize an efficient workflow and, if necessary, make current adjustments without the risk of delays.

The initial stage is the preparation of engineering surveys and project documentation, it involves the collection of all necessary documents, conducting surveys, on the basis of which the terms of reference and conditions for future work are determined. After the detailed design begins, approvals are carried out.The project for the production of works is drawn up in accordance with all technical norms and standards, regardless of whether it is planned to lay the power supply networks or install the pipeline of an industrial enterprise inside or outside the building.

The next stage is obtaining permits for the performance of work in various instances, a construction permit and an order for the right to carry out work.

When the WEP is prepared, approved and agreed, permits are issued, the stage of construction and installation works begins, which includes the supply of necessary materials, equipment, construction of engineering networks and communications, landscaping, as well as commissioning. After acceptance tests, duly executed as-built documentation with a register is transferred to the customer, and the facility is put into operation.

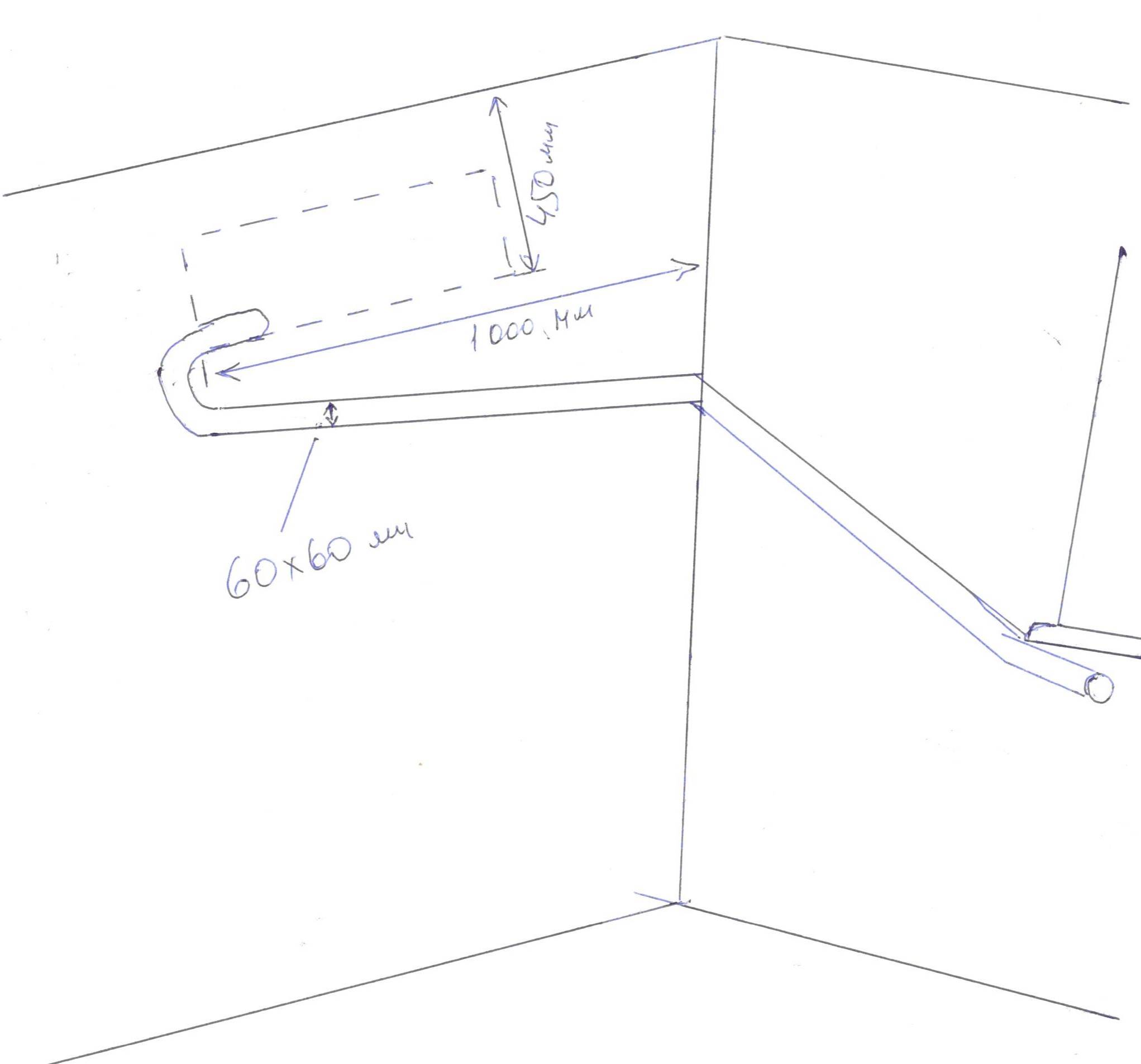

Installation of the air conditioner route - what you need to know

Greetings to all guests of the Conditioner site! Nowadays, in almost every apartment of a new house, the installation of an air conditioner

For those who have a poor idea of what a “track” is for a “conder”, I will briefly give the information:

- For domestic use, wall-mounted split systems are widely used. This type of air conditioner consists of two blocks - indoor and outdoor.

- Between themselves, the blocks are connected by wires and tubes (through which freon moves). In addition to them, a condensate (water) drain hose is output from the indoor unit. This whole bunch of communications is usually called a "route".

- In order to “hide” such a line into the wall, the air conditioner is installed in 2 stages.

Principles of laying with a slab base

When designing a slab foundation at the time of determining the scheme of engineering systems, designers use the following principles as a basis:

- Communication networks are laid up to the moment of concreting the screed.

- It is not recommended to lay pipes under the slab without a protective sleeve. The sleeves should be slightly larger than the diameter of the pipes and at the same time made of high-strength material in order to prevent mechanical damage when pouring concrete.

- To prevent the risk of freezing sewer pipes, they are laid below the freezing level of the soil. At the same time, it is necessary to take into account the fact that the drains go in the direction from the house, therefore, they initially have a higher temperature than in the water supply lines. This allows builders to reduce the thickness of the shell for insulation.

- If water lines are laid above the freezing point, which is typical for most sites in all Russian regions, then the developer needs to consider measures for their insulation.

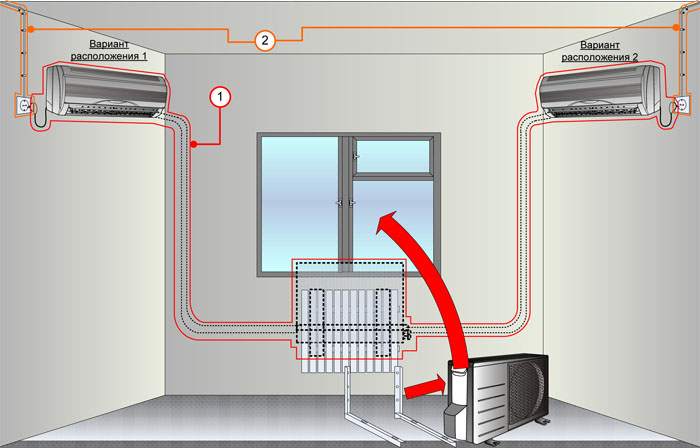

Selecting the location of the indoor unit

The air outlet from the air conditioner has a temperature of about 10°C, so it is necessary to carefully choose the installation location of the indoor unit so that the direct flow of cold air does not fall on people. In cooling mode, the louvers of the air conditioner direct the airflow horizontally along the ceiling. Thus, the most comfortable conditions will be on the side of the indoor unit or directly below it (note that with the help of vertical blinds, you can adjust the direction of the horizontal flow to some extent, shifting it to the right or left of the air conditioner). How about installing an air conditioner? against workplace or head of the bed is not recommended. It is better to install it as shown in the figure - in this case, the air flow will pass over the bed and will not fall on people.

Repair options

If damaged floor heating pipes can be replaced by opening the floor covering and the top layer of concrete, then repairing communications under the insulation layer is accompanied by significant labor, time and material costs. At the same time, violation of the compacted layer of the sand cushion will certainly lead to a deterioration in the stability of the base, which cannot be compensated for after the elimination of the emergency.

The maintainability of communication systems under the slab foundation, as already mentioned earlier, is ensured by laying sleeves under the line:

- water supply,

- power supply,

- sewerage.

As a rule, all cases are brought to a pit, to which the owner of the structure has access. Damaged lines can be pulled through the sleeves, as well as new and restored networks can be pulled. You can also get to the pipes by digging from the side of the house.

In the latter case, the bearing capacity of the soil is violated, so most practicing engineers recommend laying maintainable communication networks in a slab foundation. At the same time, the choice of the optimal angles of inclination of trenches for sleeves and the layout of communication lines should be entrusted to professionals.

Requirements

The rules for the installation of life support systems (power supply, water supply, sewerage) in cottages built on a slab foundation are regulated by the established standards for SP No. 31-110-2003, No. 31.13330 and No. 32.13330

At the same time, practicing engineers recommend paying special attention to the maintainability of communication lines.

According to the current rules in construction, they do not punch holes in the hardened monolith for engineering networks, but organize places for laying sleeves at the stage of formwork construction.

The following factors must be taken into account in the process:

- For laying the "warm floor" system and water supply lines, pipes with a diameter of 16 to 20 mm are used. For sewerage, PVC pipes with a standard diameter of 110 mm are used. If, according to the project, there are a lot of plumbing fixtures in the house, a large length of the sewer line or no pit is provided, then pipes with a diameter of 160 mm are used.

- The minimum allowable sleeve size is 5 cm.

- With seasonal temperature differences in the soil, linear expansions occur, therefore, when laying engineering systems, special compensators are used.

- Water supply lines are laid below the freezing level, otherwise heating cables are run in parallel or polystyrene shells are used.

- The electrician is laid in sleeves with a bending radius of 0.3 to 0.7 m. This position makes this communication unit repairable in case of damage. Power supply lines are displayed in the shield, which, as a rule, is located next to the house.

- It is forbidden to introduce a gas pipe into the house through the thickness of the foundation; for this purpose, a hole is made in the outer wall and a sleeve is inserted into it for protection. All places where pipes are connected must be located in such a way that at any time the point of contact can be examined and repaired if necessary.

Requirements for installing split systems

wall-mounted indoor unit installation requirements

wall-mounted indoor unit installation requirements

Specifically for split systems, there are also certain installation rules:

- the installation of the outdoor unit is done on a solid basis;

- brackets must be attached to the wall with reliable mechanisms;

- the distance from the wall to the heat exchanger of the outdoor unit is at least 10 cm;

- distance from the right side of the module - at least 10 cm;

- distance from the left side of the module - at least 40 cm;

- there should be no obstacles within 70 cm in front of the block;

- there should be free access to service ports;

- the indoor unit is placed away from sources of heat and moisture;

- you can not install the unit opposite the doorway of the front door or a permanently open window;

- no interior items should interfere with the air outlet;

- air should not go directly to people and places of their frequent stay;

- provide high-quality removal of moisture through a drainage hose;

- from the ceiling to the block must be at least 15 cm;

- the mounting plate is fixed to the wall with screws strictly according to the level.

Column split system additionally fixed to the wall for structural strength. For floor-to-ceiling and cassette systems, filters can be easily removed.

To better understand what the article is about, you can watch the installation video of air conditioners below.

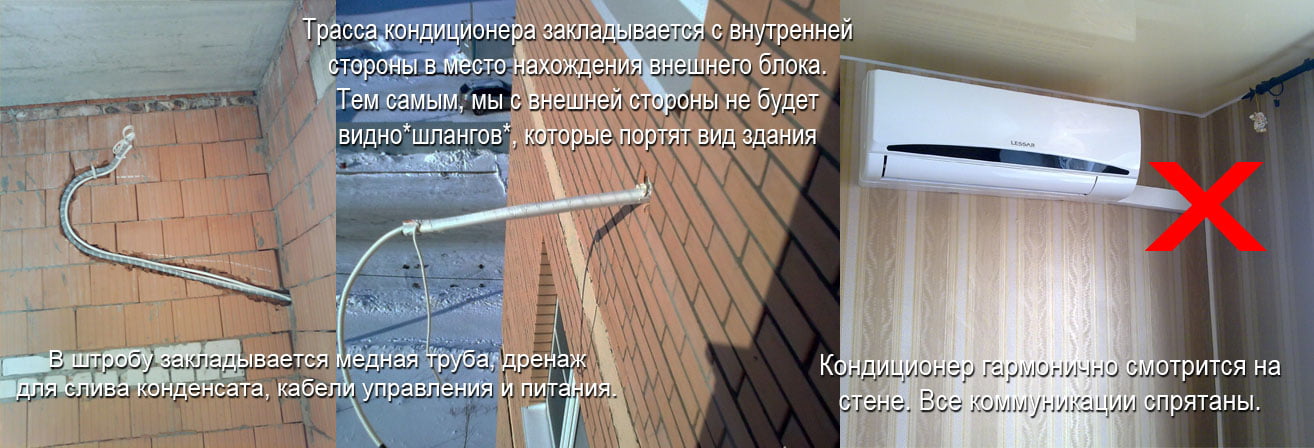

Options for laying highways for air conditioning

The line for the air conditioner is mounted in two ways. For example, in a room (apartment) with a ready repair, you can lay a highway using special shafts made of plastic, which are usually mounted on the walls themselves.If the installation of the system will be carried out in an apartment (room) where cosmetic repairs are planned, then the most correct solution is to lay the route in special (technological) slots in the wall. They must be completed in advance. Later, these holes will be hidden by finishing material.

The second method is more acceptable, because the track and the entire system will have an aesthetic and attractive appearance. Communications are simply not visible, since they were laid covertly. However, only professionals with extensive experience in this field can implement this option, because there are a number of nuances that cannot be ignored.

There are also two ways to lay a drainage tube: with a freon line or separately. Both methods will be discussed in more detail.