- Adjusting the power of a gas boiler

- Varieties of automation

- Volatile automation devices

- Non-volatile devices

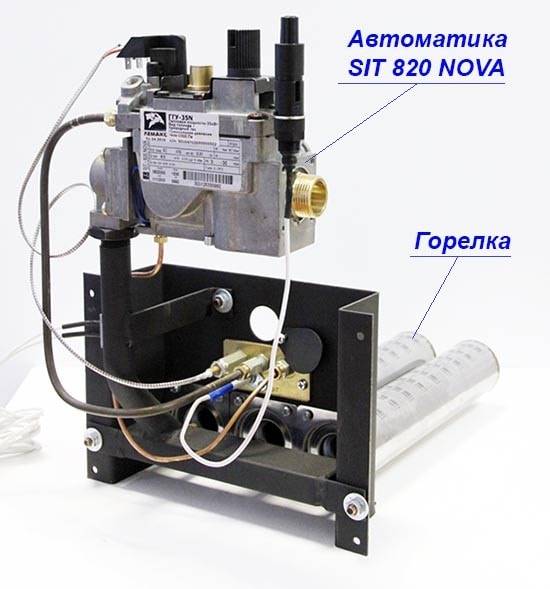

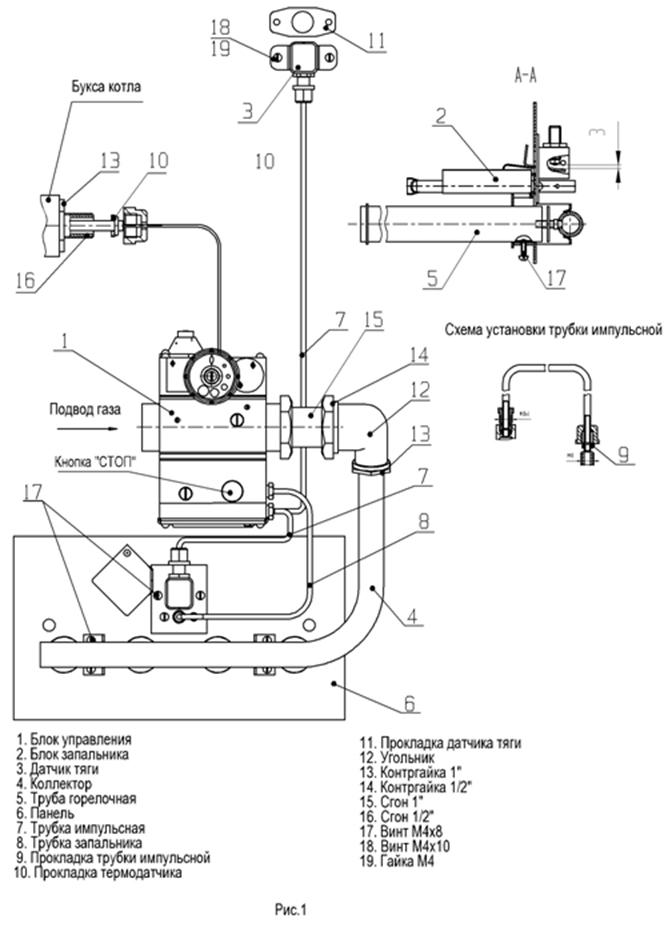

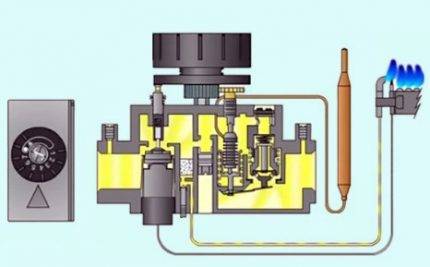

- The principle of operation of non-volatile automation

- Overview of gas boilers

- Automated thermal stations

- Functions and varieties of gas valves

- Requirements for boiler rooms for the installation of solid and liquid fuel boilers

- Setting up the boiler with your own hands

- Accompanying work when starting a gas boiler

- Automation responsible for safety

Adjusting the power of a gas boiler

In this case, the task is to reduce or increase the indicator. The indirect method of adjustment involves a decrease in the flow through the taps: which is after the connection to the boiler and the one on the lower. The control range will decrease, so it is better to prefer direct methods.

To increase power, select an option:

- Set the burner to the desired value - relevant for modulating units.

- Buy a more efficient burner.

- Replace nozzles with larger ones. Remember, with an increase in heat transfer from the boiler, gas consumption will increase, the risk of failure ahead of time, and efficiency will decrease.

Ideally, it is better to entrust the setting for increasing power to a boiler specialist. The increase in capacity for these options reaches 15%.If this is not enough, use additional room heating devices. Don't forget to clean the boiler to maintain the power level.

Tubes with microtorches for an atmospheric burner - such a device operates almost silently, but has a low power, dries the air in the room and depends on a large number of external factors

Tubes with microtorches for an atmospheric burner - such a device operates almost silently, but has a low power, dries the air in the room and depends on a large number of external factors

Sometimes you have to turn down the power. First, it is regulated through the menu: the parameters of the heat exchanger temperature and the anti-cycling time. Then set up the circulation pump. If necessary, change the burner to modulating.

Reasons for changing the boiler output:

- Increase: it is necessary to re-equip the device at the same time as increasing the power, connect an indirect heating boiler, the area for heating has increased.

- Reduction: failure of one of the functions (heating or hot water supply), part of the functionality (heating of individual rooms, underfloor heating), decrease in boiler performance.

In case of excessive fuel consumption, it is worth inspecting the secondary heat exchanger and removing salt residues manually or with a chemical composition. Pollution will be indicated by a characteristic gurgle during operation of the boiler.

Consumption increases due to the low specific heat of combustion (calorific value) of the gas. The norm is at least 7,600 kcal m³. For poorly drained fuel, the calorific value drops by almost a factor of two.

Adjust also the gas valve. They are regulated, depending on the structure:

- single-stage ones have only “on” and “off” positions;

- two-stage valves are equipped with 1 inlet and 2 outlets, and they open in an intermediate position;

- three-stage boilers have two power levels;

- with the help of modeling valves, power can be regulated more smoothly, they have many flame modes, in addition to the “on” and “off” positions.

Look at the color of the flame. If it has a noticeable yellow part, tighten the valve on the lower to reduce the fuel supply.

845 SIGMA Power Modulated Multifunctional Gas Valve with Outlet Pressure Regulator and Fuel Control Unit - Multiple Threads and Flanges

845 SIGMA Power Modulated Multifunctional Gas Valve with Outlet Pressure Regulator and Fuel Control Unit - Multiple Threads and Flanges

Once again, set the operating temperature of the heating on the thermostat. The principle of its operation is that the rod is included in the work. As the temperature drops, the element shrinks and opens the fuel supply. An increase in temperature leads to an increase in the rod, which causes the gas to flow in a smaller volume.

If there is a lack of air, inspect the damper, boost and temperature controller. Popping when igniting the main burner appears due to clogged air paths. Remove dust from them and inlets.

Varieties of automation

Depending on the principle of operation and design features, automation for gas heating boilers can be one of the types:

- Volatile.

- Non-volatile.

Volatile automation devices

These devices are small electronic devices that respond to gas supply by opening / closing a tap. The device differs in constructive complexity.

Tasks that electronic boiler automation allows you to solve:

- Close/open the gas supply valve.

- Start the system in automatic mode.

- Regulate the power of the burner, thanks to the presence of a temperature sensor.

- Turn off the boiler in emergency cases or within the specified operating mode.

- A visual demonstration of how the unit works (what temperature is maintained in the room, to what mark the water is heated, and so on).

Due to the constant growth of consumer requests for ease of use, manufacturers of modern devices offer a number of additional features:

- Management and control of equipment operation.

- Protection of the heating system against a malfunction of the three-way valve.

- Freeze protection of the system. In this case, the device starts the boiler when the room temperature drops sharply.

- Self-diagnostics in order to identify faulty spare parts, failures in the operation of structural elements. This option allows you to avoid breakdowns that can disable the boiler, and, consequently, high material costs associated with major repairs or replacement of equipment.

So the electronic automatic safety of gas boilers ensures smooth operation of the equipment when:

- no jumps;

- the specified temperature regime is precisely observed;

- there are no other problems during long-term operation.

Today, a wide range of volatile-type automation is presented on the market. It can be both with the possibility of programming, and without it. In the first case, you can set the system to work in day-night mode or set different temperature conditions for 1-7 days, taking into account the weather forecast.

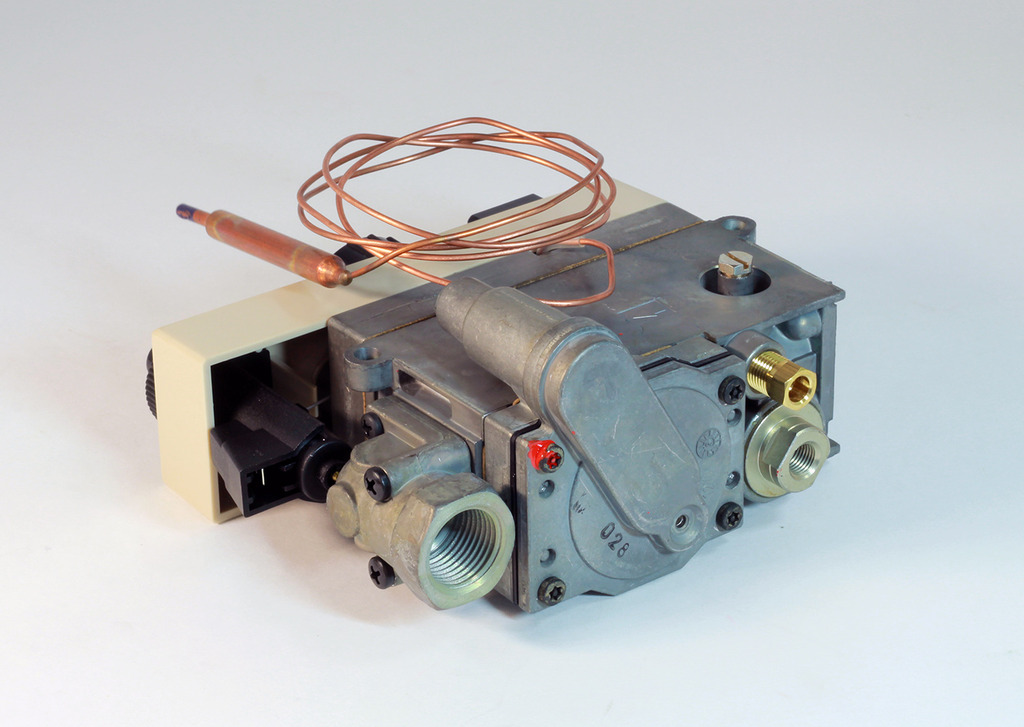

Non-volatile devices

This type of automatic equipment for control of the operation of gas heating boilers is mechanical. And many consumers prefer it to him.

Main reasons:

- Low price.

- Manual setting, which is simple, which makes it easy to control the device for people far from technology.

- The autonomy of the device, which does not require electricity to operate.

Manual setting is as follows:

- Each device is equipped with a temperature scale from the minimum value to the maximum value. By selecting the desired mark on the scale, you set the operating temperature of the boiler.

- After the unit is started, the thermostat takes over the operation, which controls the set temperature by opening / closing the gas supply valve.

The principle of operation is based on the fact that the gas boiler thermocouple, which is built into the heat exchanger, is equipped with a special rod. The part is made of a special material (an alloy of iron and nickel - Invar), which quickly reacts to temperature changes. Depending on the increase or decrease in temperature, the rod changes its dimensions. The part is firmly connected to the valve, which regulates the gas supply to the burner.

But besides this, today's automation for a gas boiler of a non-volatile type is additionally equipped with draft and flame sensors. They will immediately stop the fuel supply if there is a sharp drop in draft in the chimney or as a result of a decrease in pressure in the pipe.

A special thin plate is responsible for the operation of the flame sensor, which is in a bent state during normal operation of the system. So she holds the valve in the "Open" position. As the flame decreases, the plate straightens out, causing the valve to close. The same principle of operation of the thrust sensor.

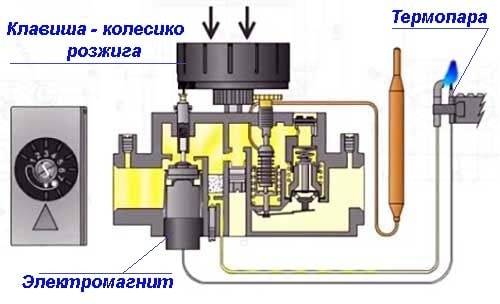

The principle of operation of non-volatile automation

At the same time, individual parts of the boilers that perform the control function do not need to use electricity.Their adjustment is made manually, as well as under the influence of geometric changes that occur in the mechanisms under the influence of heating.

Despite the large range of models with electronic equipment, mechanically controlled options are also very popular, which is due to several reasons at once:

- democratic value. Prices for such devices are much lower than for fully automatic counterparts.

- Ease of use. The simplicity of the device of non-volatile automation used in mechanical models allows you to quickly understand the settings even for a person who is not related to technology.

- Reliability. Mechanical devices do not depend on power surges or complete power outages, so they can function without a stabilizer, which is desirable when working with volatile equipment.

The disadvantages of such models include the lower accuracy of adjustments, as well as the need to monitor the operation of the boiler.

How manual tuning is done

Each mechanical device is equipped with a temperature scale, the numbers of which indicate the limit values (from min to max). The operating temperature is set by selecting the required mark on the gradation ruler.

After starting the unit, the thermostat is responsible for its operation. The active element of this device is a rod, which, shrinking when cooled, opens the gas supply valve, and then increases in size due to an increase in temperature and blocks the flow of blue fuel. It is also possible to decrease or increase the heating level by means of a similar process.

Overview of gas boilers

"Prometheus" is a well-known domestic brand of energy-independent floor-standing boilers with a steel heat exchanger. Prometheus models are used to heat rooms with a large area up to 750 sq. meters. The efficiency is 92%. Microflare burner with automatic ignition, steel plate heat exchanger ensures efficient and safe operation of the heating system. This company produces not only high-quality models that can successfully heat areas from the size of one apartment to large buildings of various functions, but also affordable. Gas boiler "Prometheus" - the best combination of quality and price.

Neva gas boilers is a St. Petersburg brand of Gazapparat OJSC, which specializes in the production of gas boilers and water heaters. The company carefully checks and tests all equipment for performance, electrical safety and tightness. The range of gas boilers is represented by 3 classes suitable for any wallet: “economy class” (Neva brand), “comfort class” and “premium class” (Neva Lux brand ). Since 2005, the company has been assembling wall-mounted gas boilers from ready-made purchased European kits. Since 2007, she has been manufacturing Neva Lux equipment, which has parts manufactured by the company itself. All boilers are made in a modern design, the consumer can purchase equipment at an affordable cost.

The Korean company Daesung is a leading manufacturer of heating boilers. The company's boilers are economical, of excellent quality and safe in operation. The first heat exchanger is made of copper, therefore it has a high efficiency and, accordingly, a long service life.The second heat exchanger is made of steel plates, so there will always be hot water in any quantity and instantly. The boiler is usually used to supply hot water.

Mimax LLC is a domestic company whose main focus is the manufacture of automatic gas equipment. Mimax gas heating boilers have a 3 mm thick steel heat exchanger, thanks to which they have excellent heat dissipation. When assembling the equipment, heat-resistant materials are used, which can significantly reduce the temperature of the outer case to 40 -50 °C. The efficiency of the company's boilers is 87%. The service life of heating equipment is more than 15 years. The Mimax company has developed a series of universal boilers that operate on both gas and solid fuels. Wood, coal, peat are used as fuel. The average time of transition from one fuel to another does not exceed 1 hour.

Gastroy LLC is engaged in the production of gas boilers of the Ochag trademark, which successfully sells 40 types of heating boilers. Among them gas boilers heating hearth, designed to provide heat to small rooms with an area of about 1000 m². All Ochag devices are easy to use, have an excellent level of quality combined with reasonable prices.

Protherm's Medved gas boiler has a heat exchanger constructed from several links. This design allows the combustion of fuel to give off heat to the heating water as much as possible.Advantages of heating equipment of the Medved series: compact dimensions of the boiler, easy installation, simple control, efficiency is 92%, maximum heat transfer with minimal losses, two-stage regulation.

Both in the domestic and in the European market of heating equipment, worthy models are presented, from which you can choose a boiler that suits you in terms of functionality and price.

Any heating equipment has its own lifespan.

Therefore, when choosing equipment, we pay attention to the quality of materials, strength and place of production. Every customer wants their heater to last as long as possible.

To do this, it is important to understand what the standard service life of gas boilers depends on.

On average, he works 7-12 years

To do this, it is important to understand what the standard service life of gas boilers depends on. On average, he works 7-12 years. What factors negatively affect performance and contribute to wear? How to prevent breakage? This article will help you understand how to choose and operate a gas boiler correctly to avoid rapid wear and tear.

What factors negatively affect performance and contribute to wear? How to prevent breakage? This article will help you understand how to properly select and operate a gas boiler to avoid rapid wear and tear.

Automated thermal stations

In 1992, the organization that manages the Moscow municipal energy sector - MOSTEPLOENERGO - decided to introduce a modern process control system in one of its new buildings. The district heating station RTS "PENYAGINO" was chosen. The first stage of the station was built as part of four boilers of the KVGM-100 type.

At that time, the development of Remikonts led to the emergence of the PTK KVINT software and hardware complex. In addition to the Remikonts themselves, the complex included an operator station based on a personal computer with full software, a software package for a computer-aided design CAD system.

Functions of the process control system for a district heating plant:

- fully automatic start-up of the boiler from a cold state until reaching the operating mode by clicking on the “START” button on the monitor screen;

- maintaining the outlet water temperature in accordance with the temperature schedule;

- management of feed water consumption taking into account make-up;

- technological protection with shutdown of fuel supply;

- control of all thermal parameters and their presentation to the operator on the screen of a personal computer;

- control of the state of units and mechanisms - "ON" or "OFF";

- remote control of actuators from the monitor screen and selection of control mode - manual, remote or automatic;

- informing the operator about violations in the operation of controllers;

- communication with the district dispatcher via a digital information channel.

The technical part of the system was arranged in four cabinets - one for each boiler. Each cabinet has four frame-modular controllers.

Tasks between controllers are distributed as follows:

Controller No. 1 performed all the operations to start the boiler. In accordance with the start-up algorithm proposed by Teploenergoremont:

- the controller turns on the smoke exhauster and ventilates the furnace and chimneys;

- includes an air supply fan;

- includes water supply pumps;

- connects gas to the ignition of each burner;

- flame control opens the main gas to the burners.

Controller No. 2 is made in a duplicated version. If during the start-up of the boiler, a failure of the equipment is not terrible, since you can stop the program and start all over again, then the second controller leads the main mode for a long time.

A special responsibility on him in the cold season. When automatically diagnosing an emergency situation in the boiler room, an automatic shockless switching from the main controller to the backup takes place. Technological protections are organized on the same controller. Controller No. 3 is designed to perform less critical functions. If it fails, you can call a repairman and wait a while. The boiler model is programmed on the same controller.

With its help, a pre-launch check of the operability of the entire control program is carried out. It is also used in the training of operational personnel.

Work on the creation of the head process control systems for the Moscow RTS PENYAGINO, KOSINO-ZHULEBINO, BUTOVO, ZELENOGRAD was carried out by a team consisting of MOSPROMPROEKT (design work), TEPLOENERGOREMONT (control algorithms), NIITeplopribor (microprocessor central part of the system).

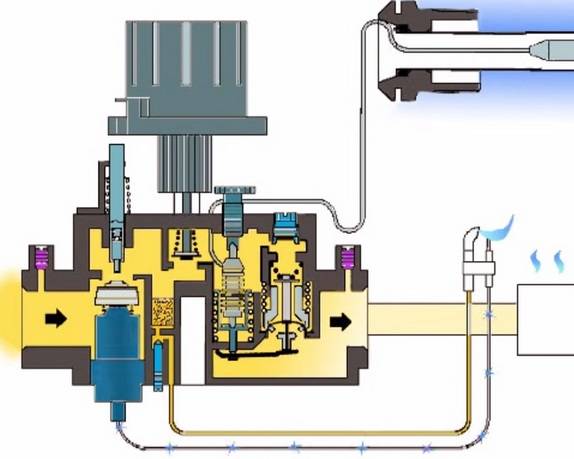

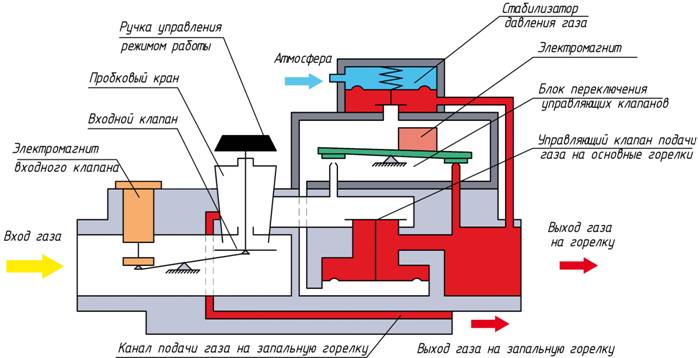

Functions and varieties of gas valves

The gas valve is one of the stages of pipeline fittings. It regulates, distributes and shuts off the gas flow.

The opening in the valve through which the gas moves is called the seat. It is covered by a disc or piston.

Gas valves, depending on the number of operating positions and the number of inputs, can be different:

Gas valves, depending on the number of operating positions and the number of inputs, can be different:

- one-stage;

- two-stage;

- three-stage;

- modulating.

Single-stage (or one-way) have only two inputs and two working positions: on / off.

A two-stage device has one input and two outputs.Opening occurs through an intermediate position and the start is smoother.

A three-stage valve is placed on boilers with two degrees of power.

Modulating valves - for boilers with a smooth change in power.

Requirements for boiler rooms for the installation of solid and liquid fuel boilers

The requirements for volume, dimensions and materials for the boiler room are the same. However, there are several specific ones that are associated with the need to organize a chimney and a place to store fuel. Here are the basic requirements (mostly they are written in the boiler passport):

- The cross section of the chimney must not be less than the diameter of the boiler outlet pipe. It is not allowed to reduce the diameter along the entire length of the chimney.

- It is necessary to design a chimney with the least number of elbows. Ideally, it should be straight.

- At the bottom of the wall there should be an inlet (window) for air to enter. Its area is calculated from the power of the boiler: 8 sq. see per kilowatt.

- The outlet of the chimney is possible through the roof or into the wall.

- Below the chimney inlet there should be a cleaning hole - for revision and maintenance.

- The chimney material and its connections must be gas-tight.

- The boiler is installed on a non-combustible base. If the floors in the boiler room are wooden, a sheet of asbestos or mineral wool cardboard is laid, on top - a sheet of metal. The second option is a brick podium, plastered or tiled.

- When using a coal-fired boiler, the wiring is only hidden; laying in metal pipes is possible. Sockets must be powered by a reduced voltage of 42 V, and switches must be sealed. All these requirements are a consequence of the explosiveness of coal dust.

Please note that the passage of the chimney through the roof or wall must be made through a special non-combustible passage

Oil fired boilers are usually noisy

It is worth saying a few words about liquid fuel boilers. Their work is usually accompanied by a fairly high level of noise, as well as a characteristic smell. So the idea of putting such a unit in the kitchen is not the best idea. When allocating a separate room, you should make sure that the walls give good sound insulation, and the smell does not penetrate through the doors. Since the internal doors will still be metal, take care of the presence of a high-quality seal around the perimeter. Perhaps the noise and smells will not interfere. The same recommendations apply to attached boiler houses, although they are less critical.

Setting up the boiler with your own hands

Proper adjustment of the gas boiler is needed for:

- saving resources;

- comfortable stay in the room;

- increase the service life of equipment.

First of all, it is necessary to correctly determine the power of the heating equipment

It is important to take into account the features of the room: the number and area of windows, doors, the quality of insulation, the material from which the walls are made. The minimum calculation is based on heat loss per unit of time

As you know, the heating power is directly dependent on the modulation of the gas burner. If you have an electronically controlled unit, then a thermostat is activated, which is connected to a room thermometer.

Adjustment is carried out in automatic mode: the thermometer measures the temperature in the room.As soon as its indicators become below comfortable, it gives a signal to start the burner or increase the strength of the flame.

In normal mode, the thermometer controls the temperature in only one room. But if you install valves in front of each radiator, there will be control in every room.

You can adjust the burner manually by acting on the gas valve. This is true for atmospheric boilers with an open combustion chamber. For example, in the Protherm Cheetah, Proterm Bear models, the valve is controlled by an electric motor. To change the settings, you must go to the service menu. Usually this work is performed by a specialist, and the user himself is already acting according to the instructions.

However, it is still necessary to know how to call up the hidden menu for adjustment. Let's look at a few examples.

Before going to the menu and setting up, you need to perform a sequence of actions:

- open taps on batteries;

- on the room thermostat, you need to set the maximum values;

- in the user settings, set the maximum temperature mode, which you usually set at the lowest possible temperature outside. The burner always turns off when the reading is 5°C higher than the set value. For example, at 75°C, shutdown will occur when 80°C is reached;

- the coolant should be cooled to 30°C.

For Protherm Gepard:

-

- You need to hold down the Mode key on the panel. As soon as you see zero on the display, set the value to 35 by pressing "+" and "-".

- Then press Mode to confirm;

when d.0 lights up on the screen, you must enter the line number in the menu. These manipulations are also performed by pressing "+" and "-" d. (number).In order to set the maximum burner power, select d.53, for the minimum - d.52.

- In order to proceed to the parameter selection, Mode is also used, it changes “+” and “-“.

- The installation receives an automatic confirmation.

- Return to the original menu and hold Mode.

While making adjustments via the panel, monitor the flame change and temperature intensity.

Gas boiler display Proterm Panther

For Proterm Panther, the procedure is different:

- Hold Mode for about seven seconds.

- Next, code 35 is entered.

- Input is confirmed.

- When d.00 appears on the left side of the screen, you must enter the number using two buttons.

- Then change the parameter on the right side of the screen using the 3 keys.

- After confirmation, click mode to exit the menu.

Accompanying work when starting a gas boiler

The first start involves pressure testing and flushing of the system. This stage is bypassed by many specialists, but it is still recommended not to refuse it. In order to carry out all further operations, it will be necessary to use a pressure pump. Pressure testing of the system is carried out to determine the strength and density of all components and connections of the system. During pressure testing, the system is checked for leaks. Pressurization can be done with a water column or compressed air. To do this, pump water at a pressure that is equal to one and a half times the working pressure, after which the system must remain at rest for 15 minutes. Then the operating pressure should be restored. If the pressure gauge showed a decrease in pressure during the pressure test, this means that a leak has formed somewhere.Defects should be eliminated by carrying out a repeated crimping process after that.

Next, you should do the flushing of the system, this is considered an indispensable process that should accompany the first start-up of the unit. Initially, a rough flush should be performed, which will remove light suspensions. The flushing process must be carried out at a pressure of 4 bar. The final flush will be the second step, for which pressure pumps should be used. There is a possibility that there will be clogging of the filters, which are installed directly in front of the boiler. If this happens, you should close the shut-off valve and clean the filter, having previously disassembled it.

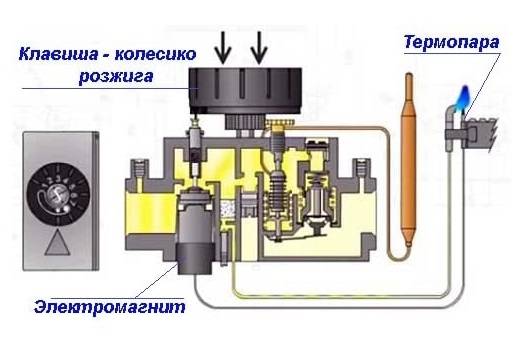

Automation responsible for safety

According to the rules set forth in the regulatory documentation (SNiP 2.04.08-87, SNiP 42-01-2002, SP 41-104-2000), a security system must be provided in gas boilers. The task of this block is an emergency shutdown of the fuel supply in the event of any breakdown.

The principle of safe operation of the gas boiler automation system is based on control over instrument readings. The control unit monitors the following factors:

- Gas pressure. When it falls to a critical level, the supply of combustible substance immediately stops. The process takes place automatically with the help of a valve mechanism, pre-configured to a certain value.

- Responsibility for this property in volatile devices lies with the maximum or minimum relay. The mechanism of operation consists in bending the membrane with the rod with an increase in the number of atmospheres, which leads to the opening of the contacts of the heater.

- No flame in the burner.When the fire is extinguished, the thermocouple cools down, which stops the generation of current, and the gas supply stops due to the electromagnetic damper closing the gas valve.

- The presence of traction. With a decrease in this factor, the bimetallic plate heats up, which causes a change in its shape. The modified element presses on the valve, which closes, stopping the supply of combustible gas.

- Heat carrier temperature. With the help of a thermostat, it is possible to maintain this factor at a given value, which makes it possible to prevent overheating of the boiler.

The above possible malfunctions can cause the main burner to go out, resulting in the possibility of gas entering the room, leading to fatal consequences.

To avoid this, all boiler models must be equipped with automatic devices. This is especially true for outdated samples, where such devices have not yet been provided by manufacturers.