- Model selection

- Pros and Cons of Installing a Wind Turbine

- Wind generator power calculation

- alternative energy

- Calculation of propellers of wind turbines

- Wind generator power calculation

- Formulas for calculation

- What to Consider

- Ready-made vertically oriented wind generator

- Payback of wind farms

- Which wind turbines are the most efficient

- Wind speed

- What is wind load

- Selection of generators for windmills

- How to cut blades

- Device and principle of operation

- New justifications for old concepts

- Procedure value

- Wind power utilization factor

- Summing up the above: Is a wind turbine profitable?

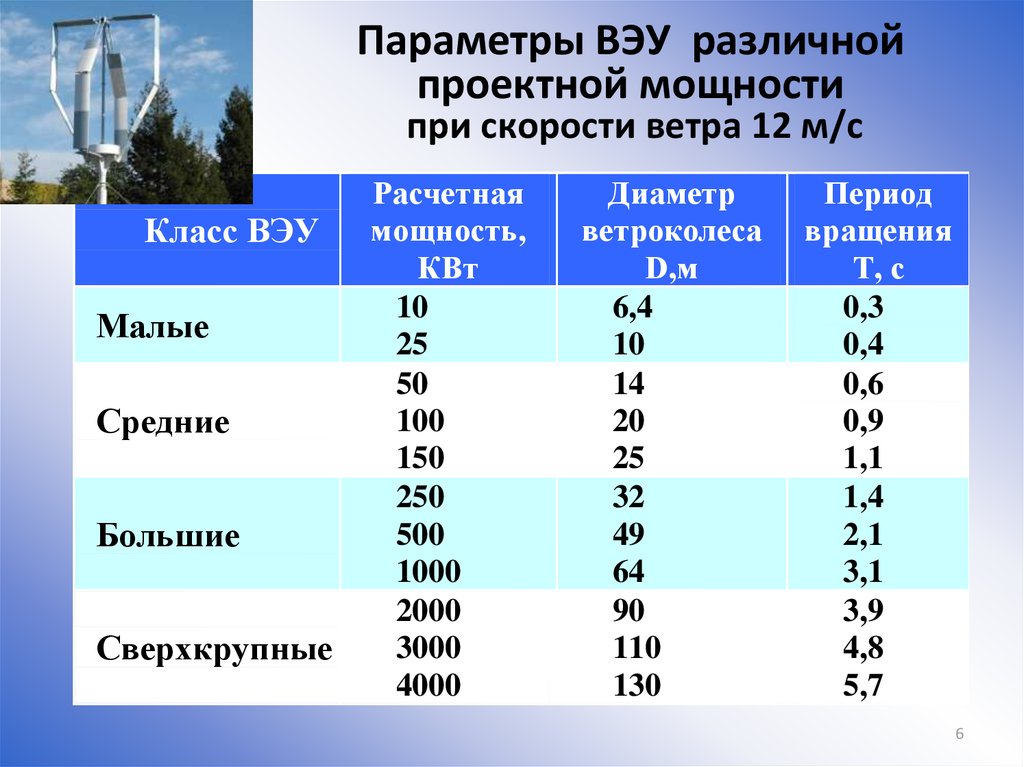

Model selection

The cost of a set of a wind generator, an inverter, a mast, a SHAVRA - an automatic transfer switch cabinet, directly depends on the power and efficiency.

| Maximum power kW | Rotor diameter m | mast height m | Rated speed m/s | Voltage Tue |

| 0,55 | 2,5 | 6 | 8 | 24 |

| 2,6 | 3,2 | 9 | 9 | 120 |

| 6,5 | 6,4 | 12 | 10 | 240 |

| 11,2 | 8 | 12 | 10 | 240 |

| 22 | 10 | 18 | 12 | 360 |

As you can see, in order to fully or partially provide the estate with electricity, high-power generators are needed, which are quite problematic to install on your own. In any case, high capital investments and the need for mast installation with the help of special equipment significantly reduce the popularity of wind energy systems for private use.

There are portable low power wind turbines that you can take with you on a trip. These models are compact, quickly mounted on the ground, do not require special care, and provide enough energy for a comfortable pastime in nature.

And although the maximum power of such a model is only 450 W, this is enough to illuminate the entire campsite and makes it possible to use household electrical appliances away from civilization.

For medium and small enterprises, the installation of several generating wind farms could provide significant savings in energy costs. Many European companies are engaged in the production of products of this type.

For medium and small enterprises, the installation of several generating wind farms could provide significant savings in energy costs. Many European companies are engaged in the production of products of this type.

These are complex engineering systems that require preventive maintenance and maintenance, but their rated power is such that it can cover the needs of the entire production. For example, in Texas, at the largest wind farm in the United States, only 420 such generators generate 735 megawatts per year.

Pros and Cons of Installing a Wind Turbine

This equipment, like solar panels, belongs to the category of alternative energy sources. But, unlike photovoltaic cells, which need sunlight, a wind turbine can operate efficiently 24 hours a day, 365 days a year.

| Advantages | Flaws |

| Free energy anywhere | Equipment price |

| Ecological energy | Installation cost |

| Energy independence from the state and its tariffs | Service cost. |

| Independence from sunlight | Dependence on wind speed |

To balance all these pros and cons, they often make a bunch: a wind generator with a solar panel. These installations complement each other, thereby reducing the dependence of electricity generation on the sun and wind.

Wind generator power calculation

In most cases, the process of feasibility of mounting wind farms will depend on the average wind speeds in a particular area. Installation of wind turbines is justified with a minimum wind force of four meters per second. With a wind speed of nine to twelve meters per second, the wind turbine will operate at maximum speed.

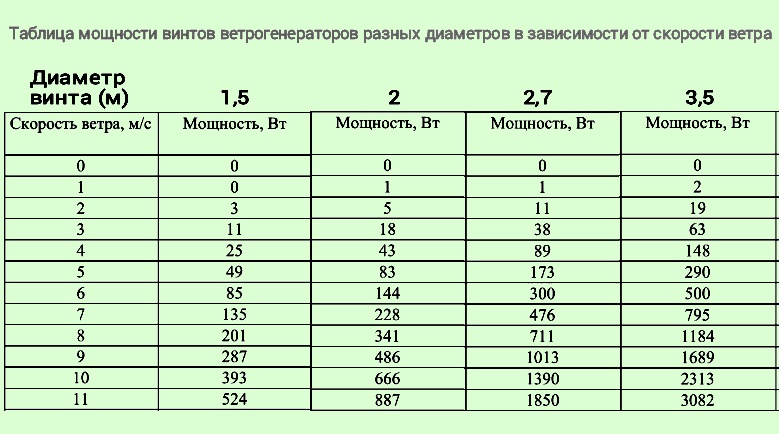

Horizontal wind generator

In addition, the power of such devices also depends on the surfaces of the blades used and on the diametrical size of the rotor device. With known average wind speeds for a given region, it is possible to select the required generator using a certain propeller size.

The calculation is made according to the formula: P \u003d 2D * 3V / 7000 kW, in which P is the power, D is the diametrical size of the screw device, and a parameter such as V indicates the wind strength in meters per second. But this formula is only suitable for horizontal wind turbines.

alternative energy

The wind load can also be beneficial, for example, by converting the force of the wind in wind turbines. So, at a wind speed V = 10 m/s, with a circle diameter of 1 meter, the windmill has blades d = 1.13 m and produces about 200–250 W of useful power. An electric plow, consuming such an amount of energy, will be able to plow about fifty (50 m²) of land in a personal plot in one hour.

If you use a large size wind generator - up to 3 meters, and an average air flow speed of 5 m / s, you can get 1-1.5 kW of power, which will completely provide a small country house with free electricity.With the introduction of the so-called "green" tariff, the payback period for equipment will be reduced to 3-7 years and, in the future, can bring net profit.

Calculation of propellers of wind turbines

When designing a windmill, two types of screws are usually used:

- Rotation in the horizontal plane (vane).

- Rotation in the vertical plane (Savonius rotor, Darrieus rotor).

Screw designs with rotation in any of the planes can be calculated using the formula:

Z=L*W/60/V

For this formula: Z is the degree of speed (low speed) of the propeller; L is the size of the length of the circle described by the blades; W is the speed (frequency) of rotation of the propeller; V is the air flow rate.

This is the design of the screw called "Rotor Darier". This version of the propeller is considered effective in the manufacture of wind turbines of small power and size. The calculation of the screw has some features

Based on this formula, you can easily calculate the number of revolutions W - the speed of rotation. And the working ratio of revolutions and wind speed can be found in the tables that are available on the network. For example, for a propeller with two blades and Z=5, the following relation is true:

| Number of blades | Degree of speed | Wind speed m/s |

| 2 | 5 | 330 |

Also, one of the important indicators of the windmill propeller is the pitch. This parameter can be determined using the formula:

H=2πR*tgα

Here: 2π is a constant (2*3.14); R is the radius described by the blade; tg α is the section angle.

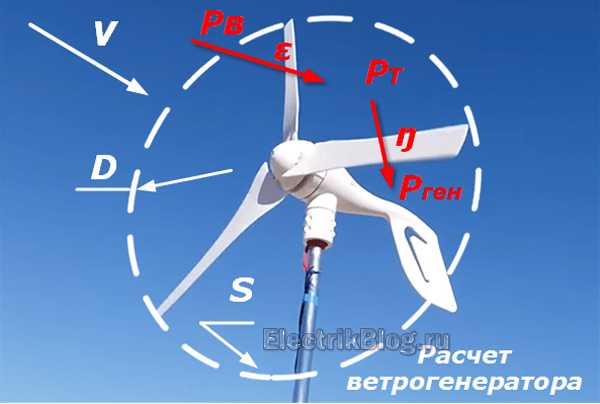

Wind generator power calculation

Self-manufacturing of a windmill also needs a preliminary calculation. No one wants to spend time and materials on the manufacture of who knows what, they want to have an idea about the capabilities and expected power of the installation in advance.Practice shows that expectations and reality correlate poorly with each other, installations created on the basis of approximate estimates or assumptions that are not supported by accurate calculations give weak results.

Therefore, simplified calculation methods are usually used, which give results close enough to the truth and do not require the use of a large amount of data.

Formulas for calculation

For calculation of the wind generator must be made the following actions:

- Determine your home's electricity needs. To do this, it is necessary to calculate the total power of all devices, equipment, lighting and other consumers. The resulting amount will show the amount of energy needed to power the house.

- the resulting value must be increased by 15-20% in order to have some power reserve just in case. There is no doubt that this reserve is needed. On the contrary, it may turn out to be insufficient, although, most often, the energy will not be fully used.

- knowing the required power, one can estimate which generator can be used or manufactured to solve the tasks. The end result of using a windmill depends on the capabilities of the generator, if they do not meet the needs of the house, then you will either have to change the device or build an additional kit

- wind turbine calculation. Actually, this moment is the most difficult and controversial in the whole procedure. The formulas for determining the flow power are used

For example, consider the calculation of a simple option. The formula looks like this:

P=k R V³ S/2

Where P is the flow power.

K is the coefficient of wind energy use (a value that is inherently close to efficiency) is taken within 0.2-0.5.

R is the air density. It has different values, for simplicity we will take equal to 1.2 kg/m3.

V is the wind speed.

S is the coverage area of the wind wheel (covered by rotating blades).

We consider: with a radius of a wind wheel of 1 m and a wind speed of 4 m/s

P = 0.3 x 1.2 x 64 x 1.57 = 36.2 W

The result shows that the power flow is 36 watts. This is very small, but the meter impeller is too small. In practice, wind wheels with a blade span of 3-4 meters are used, otherwise the performance will be too low.

What to Consider

When calculating the windmill, the design features of the rotor should be taken into account. There are impellers with vertical and horizontal type of rotation, having different efficiency and performance. Horizontal structures are considered the most effective, but they have needs for high installation points.

It will be equally important to ensure sufficient impeller power to rotate the generator rotor. Devices with stiff rotors, allowing to obtain a good energy output, require considerable power on the shaft, which can only be provided by an impeller with a large area and diameter of the blades.

An equally important point is the parameters of the source of rotation - the wind. Before making calculations, you should learn as much as possible about the strength and prevailing wind directions in a given area. Take into account the possibility of hurricanes or squally gusts, find out how often they can occur. An unexpected increase in the flow rate is dangerous for the destruction of the windmill and the failure of the converting electronics.

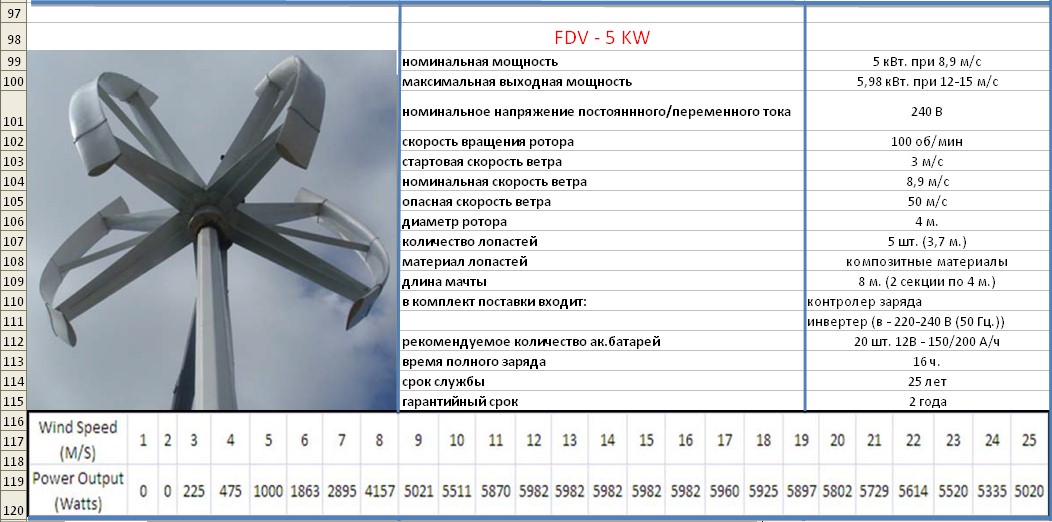

Ready-made vertically oriented wind generator

There has been renewed interest in wind turbines, especially in recent years. There are new models that are more convenient and practical.

Until recently, horizontal wind turbines with three blades were mainly used. And vertical views did not spread due to the heavy load on the bearings of the wind wheel, as a result of which increased friction arose, absorbing energy.

But thanks to the use of the principles of magnetic levitation, the wind generator on neodymium magnets began to be used precisely vertically oriented, with a pronounced free inertial rotation. At present, it has proven to be more effective than horizontal.

Easy start is achieved thanks to the principle of magnetic levitation. And thanks to the multi-pole, which gives the rated voltage at low speeds, it is possible to completely abandon the gearboxes.

Some devices are able to start working when the wind speed is only one and a half centimeters per second, and when it reaches only three or four meters per second, it can already be equal to the generated power of the device.

Payback of wind farms

For wind power plants created for the purpose of selling electricity, i.e. as industrial production, the payback issue looks somewhat more successful. The sale of products - electric current - allows you to reimburse the costs of purchasing, operating and repairing windmills. At the same time, practical results do not always look brilliant. Thus, the largest wind power plants existing in the world, with large volumes of energy production, have extremely low profitability, and some of them are recognized as unsustainable.

The reason for this situation lies in the unfortunate ratio of the cost of equipment, service life and performance of the complex. Simply put, during the service life of the turbine does not have time to produce enough energy to justify the cost of its purchase and maintenance.

This situation is typical for most wind farms. The instability of the energy source, the low efficiency of the design, in total, form a low-profit production, if we talk purely economically. Among the opportunities to increase profitability, the most effective are:

- productivity increase

- lower operating costs

Taking into account the peculiarities of Russian meteorology, a promising way is to increase the number of wind turbines in the station, but reduce their power. It turns out a system that has a lot of advantages:

- individual windmills are able to generate power in light winds when large models cannot start

- equipment purchase and maintenance costs are reduced

- the failure of an individual unit does not create serious problems for the plant as a whole

- reduced commissioning and transportation costs

The last point is especially relevant for our country, where the installation of wind power plants takes place in remote or mountainous regions, and the issues of delivery and assembly of the structure are extremely acute.

Another way to increase profitability is to use vertical structures. This option is considered in world practice as low-productive, suitable for providing energy to individual consumers - a private house, lighting, pumps, etc.

Which wind turbines are the most efficient

| Horizontal | vertical |

| This type of equipment has gained the greatest popularity, in which the axis of rotation of the turbine is parallel to the ground. Such wind generators are often called windmills, in which the blades turn against the wind flow. The design of the equipment includes a system for automatic scrolling of the head. It is required to find the wind flow. A device is also needed to turn the blades in order to use even a small force to generate electricity. The use of such equipment is more appropriate in industrial enterprises than in everyday life. In practice, they are more often used to create wind farm systems. | Devices of this type are less effective in practice. The rotation of the turbine blades is carried out parallel to the earth's surface, regardless of the strength of the wind and its vector. The direction of the flow also does not play a role, with any impact, the rotational elements scroll against it. As a result, the wind generator loses part of its power, which leads to a decrease in the energy efficiency of the equipment as a whole. But in terms of installation and maintenance, units in which the blades are arranged vertically are more suitable for home use. This is due to the fact that the gearbox assembly and the generator are mounted on the ground. The disadvantages of such equipment include expensive installation and serious operating costs. Enough space is required to mount the generator. Therefore, the use of vertical devices is more appropriate in small private farms. |

| Two-bladed | Three-bladed | multi-bladed |

| This type of units is characterized by the presence of two elements of rotation.This option is practically inefficient today, but is quite common due to its reliability. | This type of equipment is the most common. Three-bladed units are used not only in agriculture and industry, but also in private households. This type of equipment has gained popularity due to its reliability and efficiency. | The latter can have 50 or more elements of rotation. To ensure the generation of the required amount of electricity, it is not necessary to scroll the blades themselves, but to bring them to the required number of revolutions. The presence of each additional element of rotation provides an increase in the parameter of the total resistance of the wind wheel. As a result, the output of the equipment at the required number of revolutions will be problematic. Carousel devices equipped with a plurality of blades begin to rotate with a small wind force. But their use is more relevant if the very fact of scrolling plays a role, for example, when pumping water is required. In order to effectively ensure the generation of a large amount of energy, multi-bladed units are not used. For their operation, the installation of a gear device is required. This not only complicates the entire design of the equipment as a whole, but also makes it less reliable compared to two- and three-bladed ones. |

| With hard blades | Sailing units |

| The cost of such units is higher due to the high cost of production of rotation parts. But compared to sailing equipment, generators with rigid blades are more reliable and have a long service life. Since the air contains dust and sand, the rotating elements are subjected to a high load.When the equipment is operating in stable conditions, it requires an annual replacement of the anti-corrosion film that is applied to the ends of the blades. Without this, the rotation element begins to lose its working properties over time. | This type of blades is simpler in terms of production and less expensive than metal or fiberglass. But savings in manufacturing can lead to serious costs in the future. With a wind wheel diameter of three meters, the speed of the tip of the blade can be up to 500 km / h, when the equipment revolutions are about 600 per minute. This is a serious load even for rigid parts. Practice shows that the elements of rotation on sailing equipment have to be changed often, especially if the wind force is high. |

In accordance with the type of rotary mechanism, all units can be divided into several types:

- orthogonal Darier devices;

- units with a Savonius rotary assembly;

- devices with a vertical-axial design of the unit;

- equipment with a helicoid type of rotary mechanism.

Wind speed

Regardless of whether you plan to buy a ready-made generator or build it yourself, wind speed will be one of the most important parameters in determining the power of the installation.

Firstly, each type of wind turbine has its own initial speed. For most installations, this is 2-3 m/s. If the wind speed is below this threshold, the generator will not work at all, and, accordingly, electricity will also be generated.

In addition to the initial speed, there is also a nominal one, at which the wind generator reaches its rated power. For each model, the manufacturer indicates this figure separately.

However, if the speed is higher than the initial one, but lower than the nominal one, then the electricity generation will be significantly reduced. And in order not to be left without electricity, you should always first of all focus on the average wind speed in your region and directly on your site. You can find out the first indicator by looking at the wind map, or by looking at the weather forecast in your city, which usually indicates the wind speed.

The second figure, ideally, should be measured with special instruments directly in the place where the wind turbine will stand. After all, your house can be both on a hill, where the wind speed will be higher, and in a lowland, in which there will be practically no wind.

In this situation, those who constantly suffer from hurricane gusts are in a better position, and can count on greater wind turbine performance.

What is wind load

The flow of air masses along the surface of the earth occurs at different speeds. Bumping into any obstacle, the kinetic energy of the wind is converted into pressure, creating a wind load. This effort can be felt by anyone moving against the flow. The generated load depends on several factors:

- wind speed,

- the density of the air jet, - at high humidity, the specific gravity of the air becomes larger, respectively, the amount of transferred energy increases,

- shape of a stationary object.

In the latter case, forces directed in different directions act on individual parts of the building structure, for example:

Selection of generators for windmills

Having the calculated value of the number of revolutions of the propeller (W), obtained by the method described above, it is already possible to select (manufacture) the appropriate generator. For example, with the degree of speed Z = 5, the number of blades is 2 and the speed is 330 rpm. with a wind speed of 8 m/s, the generator power should be approximately 300 watts.

The generator of the wind power plant "in the context". An exemplary copy of one of the possible designs of a generator for a home wind power system, assembled by myself

This is how an electric bicycle motor looks like, on the basis of which it is proposed to make a generator for a home windmill. The design of the bicycle motor is ideal for implementation with little or no calculations and modifications. However, their power is low.

The characteristics of an electric bicycle motor are approximately as follows:

| Parameter | Values |

| Voltage, V | 24 |

| Power, W | 250-300 |

| Rotation frequency, rpm | 200-250 |

| Torque, Nm | 25 |

A positive feature of bicycle motors is that they practically do not need to be redone. They are structurally designed as low-speed electric motors and can be successfully used for wind turbines.

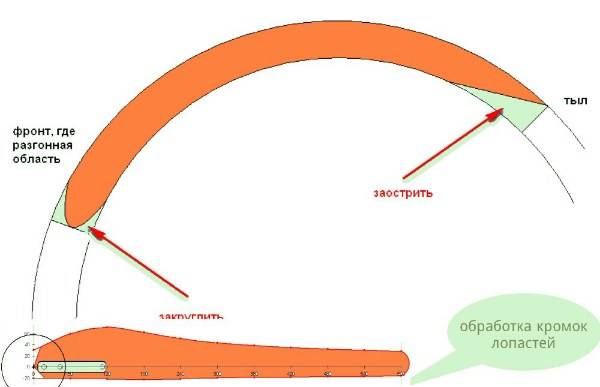

How to cut blades

Further along the line starting from blade root note the dimensions of the blade radius - in the "Blade radius" column in the green columns. According to these dimensions, put dots on the line to the left and to the right of the root of the blade. To the left, if you look from the root of the blade to the tip, there will be the coordinates of the Rear mm pattern, and to the right of the line, the coordinates of the Front mm pattern. After you connect the dots and you have a blade, which is usually cut out with a blade from a hacksaw, or with an electric jigsaw.

Holes for attaching the blade to the hub are made strictly along the center line of the blade, which was drawn on the pipe at the very beginning, if you move the holes, the blade will stand at a different angle to the wind and lose all its qualities. blade edges it is necessary to process, round off the front part of the blade, sharpen the back part ’and round off the tips of the blades so that nothing whistles and makes noise. The Excel spreadsheet already takes into account the edge processing in the calculation in the way as in the picture below.

>

>

I hope it became clearer to you how to use the plate and how to select a screw for the generator. For example, of course, I chose a generator with unsuitable parameters, since charging of a 12v battery starts too early, for 24v and 48 volts the results would be different and the power would be even higher, but you can’t describe all the examples.

The most important thing is to understand the principles, for example, choosing a propeller if it has good power at one speed, this does not mean that it will have it in practice, if the generator loads the propeller too early, it will not reach its speed and will not develop the power that should be at lower speeds, although the wind will be calculated or even higher. Blades customized to a certain speed and will take maximum power from the wind at their speed.

Device and principle of operation

The wind generator works with the help of wind power. The design of this device must include the following elements:

- turbine blades or propeller;

- turbine;

- electric generator;

- the axis of the electric generator;

- an inverter, the function of which is to convert alternating current to direct current;

- a mechanism that rotates the blades;

- a mechanism that rotates the turbine;

- battery;

- mast;

- rotary motion controller;

- damper;

- wind sensor;

- wind sensor shank;

- gondola and other elements.

Industrial units have a power cabinet, lightning protection, a rotary mechanism, a reliable foundation, a fire extinguishing device, and telecommunications.

A wind generator is a device that converts wind energy into electricity. The forerunners of modern aggregates are mills that produce flour from grain. However, the connection diagram and the principle of operation of the generator have not changed much.

- Due to the force of the wind, the blades begin to rotate, the torque of which is transmitted to the generator shaft.

- The rotation of the rotor creates a three-phase alternating current.

- Through the controller, alternating current is sent to the battery. The battery is necessary in order to create a stable operation of the wind generator. If wind is present, the unit charges the battery.

- To protect against a hurricane, the wind power generation system has elements to steer the wind wheel away from the wind. This happens by folding the tail or braking the wheel with an electric brake.

- To recharge the battery, you will need to install the controller. The function of the latter includes monitoring the charging of the battery to prevent its breakdown. If necessary, this device can dump excess energy into the ballast.

- Batteries have a constant low voltage, but it must reach the consumer with a power of 220 volts. For this reason, inverters are installed in wind turbines. The latter are able to convert alternating current into direct current, increasing its strength to 220 volts.If the inverter is not installed, then only those devices that are designed for low voltage will need to be used.

- The converted current is sent to the consumer to power heating batteries, room lighting, and household appliances.

New justifications for old concepts

Unfounded assumptions that modern developments should dramatically increase the efficiency of wind turbines have no basis at all. Modern horizontal models achieve 75% efficiency of their theoretical Bentz limit (approximately 45% efficiency). After all, the section of physics that regulates the efficiency of wind turbines is hydrodynamics, and its laws are immutable from the moment they were discovered.

Some designers are trying to increase efficiency by increasing the number of blades, making them thinner. You can increase their length, and this gives a greater effect due to the growth of the swept area.

But still, it is necessary to maintain a balance between the slowing down of the wind and its residual speed.

There is another direction - to increase the wind speed by passing it through a diffuser. But hydrodynamics is replete with already discovered effects of flow around obstacles along the path of least resistance.

There are more or less successful DAWT models with large cone angles, but these attempts to “cheat the wind” do not increase efficiency as much as advertised.

The most successful modern wind turbines are vertical models with Darrieus blades, mounted on magnetic levitating thrust bearings (MAGLEV). Working almost silently, they begin to rotate at a wind speed of less than 1 m / s, and withstand heavy gusts up to 200 km / h.It is on the basis of such sources of alternative energy that it is most profitable to form a private independent energy system.

Thank you for reading to the end! Don't forget if you liked the article!

Share with friends, leave your COMMENTS (Your Comments help the development of the project a lot)

Join our VK group:

ALTER220 Alternative energy portal

and suggest topics for discussion, together it will be more interesting!!!

Procedure value

If you neglect the calculations of the load of air movement, you can, as they say, ruin the whole thing in the bud and endanger people's lives.

If there are usually no difficulties with the pressure of snow on the walls of buildings - this load can be seen, it can be weighed and even touched - then everything is much more complicated with the wind. It is not visible, it is very difficult to predict it intuitively. Yes, of course, the wind has some effect on the supporting structures, and in some cases it can even be destructive: it twists advertising banners, overwhelms fences and wall frames, and rips off roofs. But how is it possible to predict and take into account this force? Is it actually calculable?

Gives in! However, this is a dreary business, and non-professionals do not like to calculate the wind load. There is a clear explanation for this: the significance of calculations is a very responsible and difficult matter, much more complicated than snow load calculations. If only two and a half pages are devoted to the snow load in the joint venture specially dedicated to this, then the calculation of the wind load is three times more! Plus, a mandatory application is attributed to it, they are placed on 19 pages indicating the aerodynamic coefficients.

If the citizens of Russia are still lucky with this, then for the inhabitants of Belarus it is even more difficult - the document TKP_EN_1991-1-4-2O09 "Wind effects", which regulates standards and calculations, has a volume of 120 pages!

With the Eurocode (EN_1991-1-4-2O09) on the scale of building a private structure for wind effects, few people want to deal with a cup of tea at home. Those who are professionally interested are advised to download and study it thoroughly, having a specialist consultant surrounded by it. Otherwise, due to the wrong approach and understanding, the consequences of calculations can be disastrous.

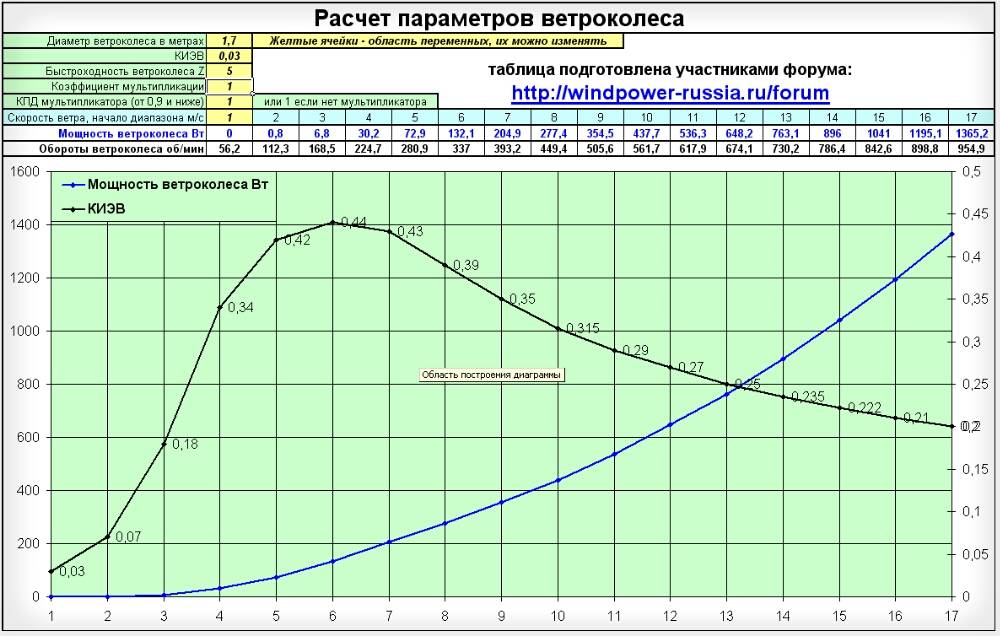

Wind power utilization factor

It should be noted that for wind turbines there is a specific efficiency indicator - KIEV (Wind Energy Utilization Coefficient). It indicates what percentage of the air flow passing through the working section directly affects the blades of the windmill. Or, to put it more scientifically, it shows the ratio of the power received on the shaft of the device to the power of the flow acting on the wind surface of the impeller. Thus, KIEV is a specific, applicable only to wind turbines, analogue of efficiency.

To date, the values of KIEV from the original 10-15% (indicators of old windmills) have increased to 356-40%. This is due to the improvement in the design of windmills and the emergence of new, more efficient materials and technical details, assemblies that help reduce friction losses or other subtle effects.

Theoretical studies have determined the maximum utilization factor for wind energy to be 0.593.

Summing up the above: Is a wind turbine profitable?

The above results clearly prove the return on investment for the purchase and launch of a wind turbine. Especially since:

- The cost of a kilowatt is constantly growing due to inflation.

- When using a windmill, the object becomes non-volatile.

- The "surplus" of generated electricity can be accumulated and stored in case of calm weather thanks to an uninterruptible power supply system.

- Many objects remote from the centralized power supply network are forced to exist in the absence of electricity, since their connection is unprofitable.

So, the wind generator is profitable. Its purchase for energy-intensive consumers without power supply is economically feasible. A hotel outside the city, an agricultural farm or a livestock enterprise, a cottage settlement - in any case, the costs of connecting an alternative source of electricity will be justified. It remains only to choose a suitable model of a windmill and install it, guided by the recommendations of the manufacturer. The power of the device should correspond to the average wind speed in your area. You can specify it using a special wind map or according to the local weather station.

Please note: for wind turbines from Chinese manufacturers, the rated power of the device is calculated taking into account wind speeds at 50-70% of ground level. Installing a windmill at such a height is problematic

Too high a mast is expensive, and strict requirements are imposed on its strength. In addition, at the indicated height, gusts of wind form strong eddy currents. They not only slow down the operation of the wind generator, but can also cause blade breakage.The solution is to install the device at a height of 30-35m, which will provide access to strong winds, but will prevent the windmill from breaking.