- What is strapping and what is it made of

- What should be in the harness

- What pipes to make

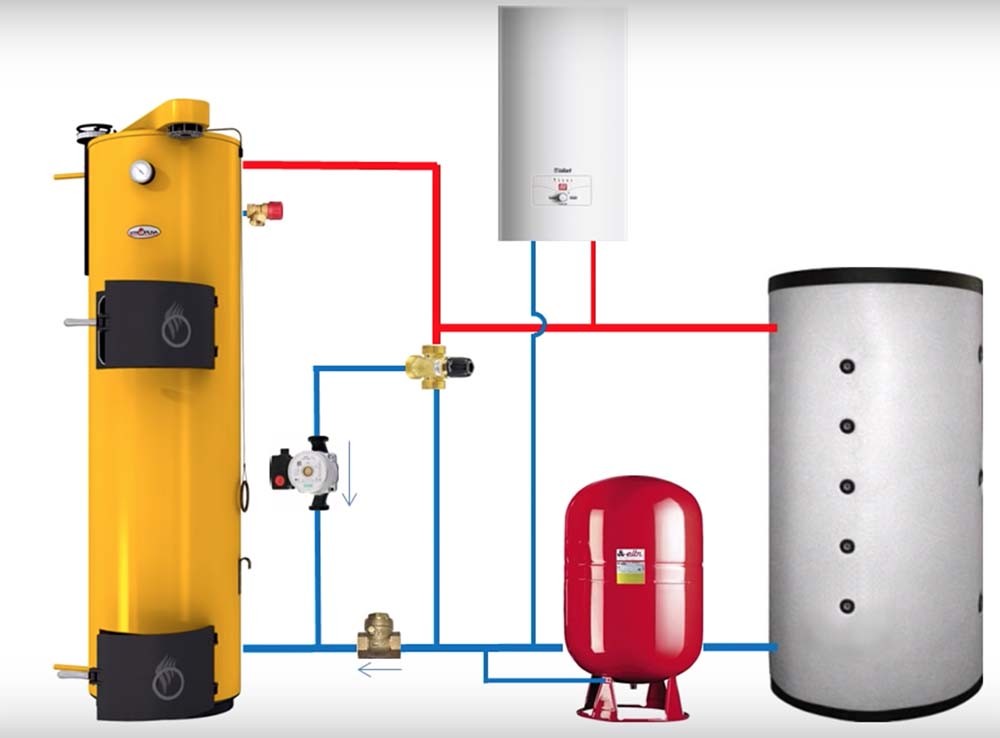

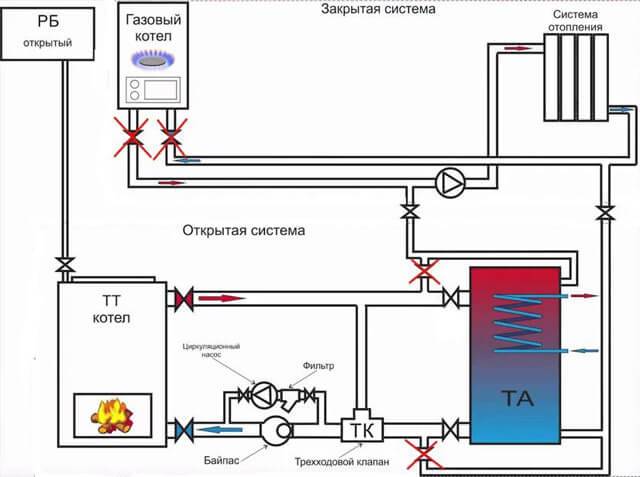

- Arrangement of a heating system with a heat accumulator

- Mounting diagrams

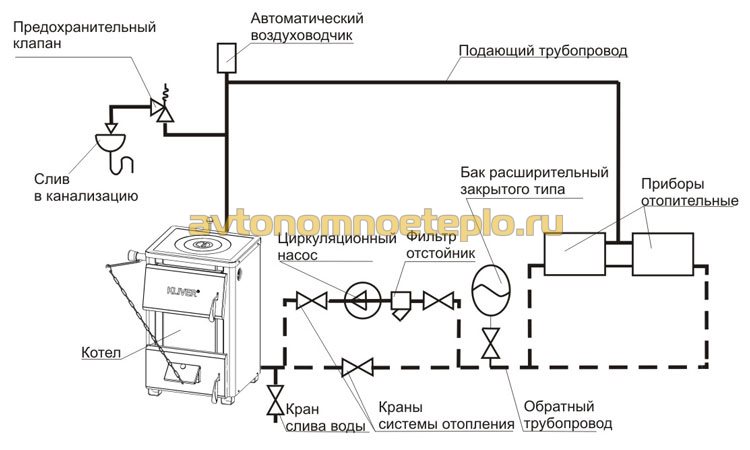

- open system

- Closed heating circuit

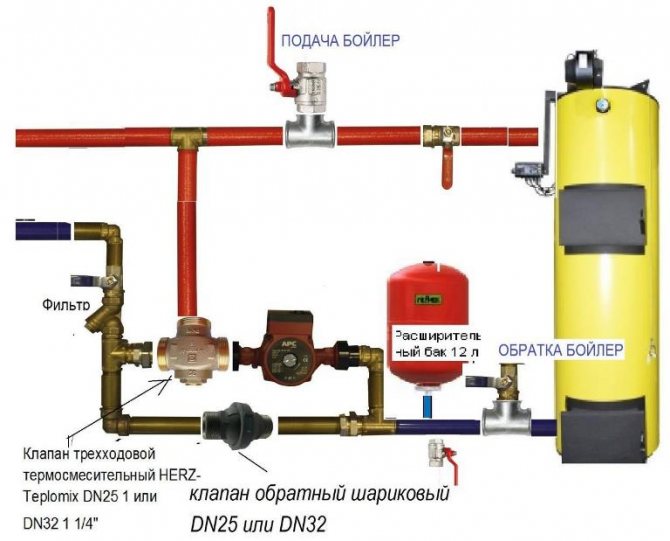

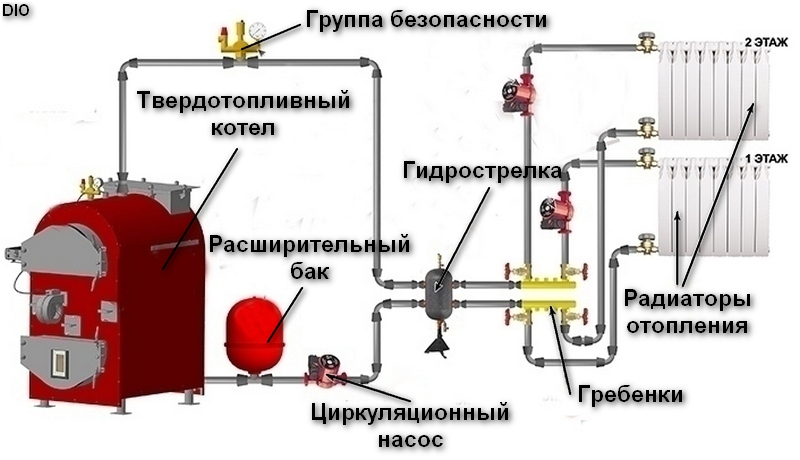

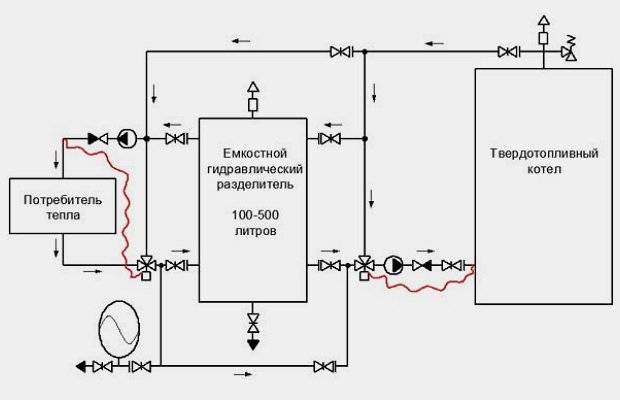

- Connection via manifolds

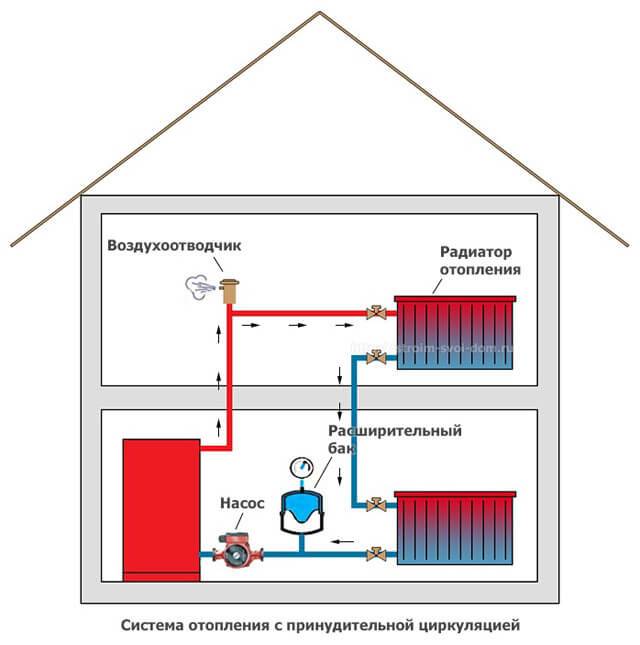

- Types of water heating systems

- Recommendations for the safe and efficient use of a solid fuel boiler

- What is the difficulty of connecting two boilers

- Scheme and procedure for installing the boiler

- Step 1: Choosing a Location

- Step 2: Preparing the Components

- Step 3: Hardware Installation

- Step 4: Mounting pipes and electronics

- Step 5: Mounting the chimney

- Step 6: Filling Out the Outline

- Step 7: Connection

- Equipment in a closed system with forced circulation

- What to look for when choosing a heating boiler

- Mini-boiler rooms

What is strapping and what is it made of

There are two main parts in the heating system - the boiler and radiators or underfloor heating. What binds them and provides security - this is the harness. Depending on the type of installed boiler, different elements are used, therefore, the piping of solid fuel units without automation and automated (more often gas) boilers is usually considered separately.They have different operation algorithms, the main ones are the possibility of heating the TT boiler in the active combustion phase to high temperatures and the presence / absence of automation. This imposes a number of restrictions and additional requirements that must be met when piping a solid fuel boiler.

An example of a boiler piping - first comes copper, then polymer pipes

What should be in the harness

To ensure the safe operation of heating, the boiler piping must contain a number of devices. Must be:

- Pressure gauge. To control the pressure in the system.

- Automatic air vent. To bleed air that has entered the system - so that plugs do not form and the movement of the coolant does not stop.

- Emergency valve. To relieve excessive pressure (connects to the sewerage system, as a certain amount of coolant is vented).

- Expansion tank. Needed to compensate for thermal expansion. In open systems, the tank is placed at the top of the system and is a regular container. In closed heating systems (mandatory with a circulation pump), a membrane tank is installed. The installation location is in the return pipeline, in front of the boiler inlet. It can be inside a wall-mounted gas boiler or installed separately. When using the boiler to prepare domestic hot water, an expansion tank is also required in this circuit.

-

Circulation pump. Mandatory for installation in systems with forced circulation. To increase the efficiency of heating, it can also stand in systems with natural circulation (gravitational). It is placed on the supply or return line in front of the boiler to the first branch.

Some of these devices are already installed under the casing of the gas wall-mounted boiler.The binding of such a unit is very simple. In order not to complicate the system with a large number of taps, the pressure gauge, air vent and emergency valve are assembled into one group. There is a special case with three taps. Appropriate devices are screwed onto it.

This is what a security group looks like

Install security group on supply pipeline immediately at the outlet of the boiler. Set so that it is easy to control the pressure and you can manually release the pressure if necessary.

What pipes to make

Today, metal pipes are rarely used in the heating system. They are increasingly being replaced by polypropylene or metal-plastic. Tying a gas boiler or any other automated (pellet, liquid fuel, electric) is possible immediately with these types of pipes.

The wall-mounted gas boiler can be connected with polypropylene pipes immediately from the boiler inlet

When connecting a solid fuel boiler, at least a meter of the pipe at the supply is impassable to make a metal pipe and, best of all, copper. Then you can put the transition to metal-plastic or polypropylene. But this is not a guarantee that polypropylene will not collapse. It is best to make additional protection against overheating (boiling) of the TT boiler.

In the presence of overheat protection boiler piping can be made with polypropylene pipes

Metal-plastic has a higher operating temperature - up to 95 ° C, which is enough for most systems. They can also be used to tie a solid fuel boiler, but only if one of the systems for protecting against overheating of the coolant is available (described below).But metal-plastic pipes have two significant drawbacks: narrowing at the junction (fitting design) and the need for regular checks of connections, as they leak over time. So the piping of the boiler with metal-plastic is done subject to the use of water as a coolant. Anti-freeze liquids are more fluid, therefore it is better not to use compression fittings in such systems - they will still flow. Even if you replace the gaskets with chemically resistant ones.

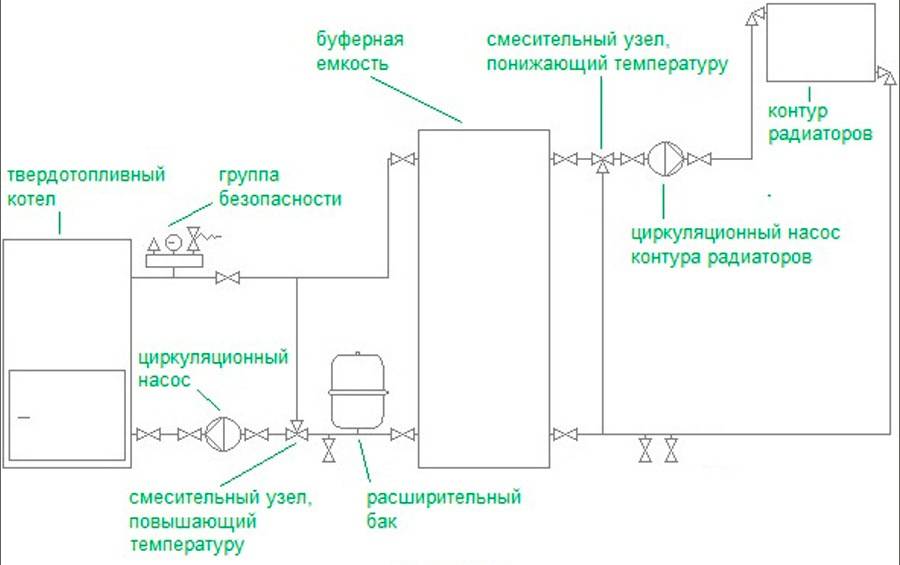

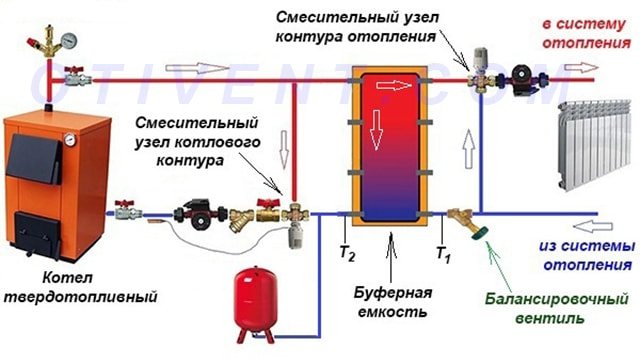

Arrangement of a heating system with a heat accumulator

The use of such an element in a scheme with two boilers in one heating system has several features, depending on the installed units:

- The heat accumulator, gas boiler and heating devices form a single closed system.

- Solid fuel boilers, working on wood, pellets or coal, heat water, thermal energy is transferred to a heat accumulator. It, in turn, heats the coolant circulating in a closed heating circuit.

To independently create a heating scheme with two boilers, you must purchase the following:

- Boiler.

- Heat accumulator.

- Expansion tank of the appropriate volume.

- Hose for additional removal of the heat carrier.

- Shut-off valves in the amount of 13 pieces.

- Pump for forced circulation of the coolant in the amount of 2 pieces.

- Three-way valve.

- Water filter.

- Steel or polypropylene pipes.

Such a scheme is characterized by operation in several modes:

- Transfer of thermal energy from a solid fuel boiler by means of a heat accumulator.

- Heating water with a solid fuel boiler without using this device.

- Receiving heat from a gas boiler connected to a gas cylinder.

- Connecting two boilers at the same time.

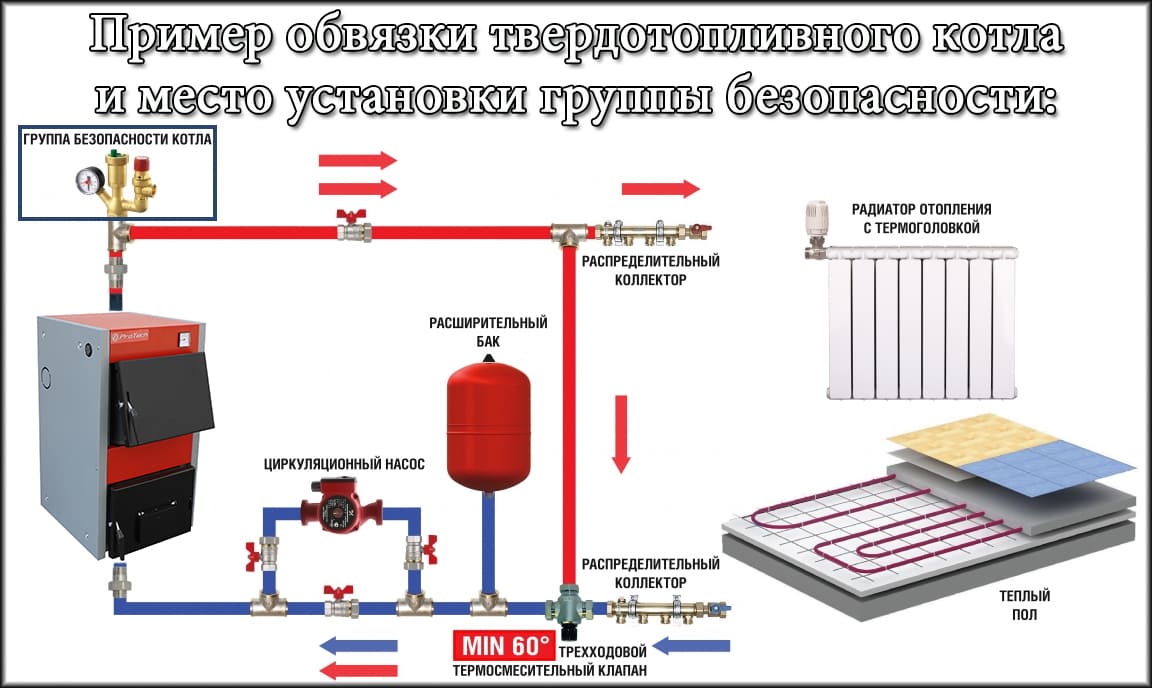

Mounting diagrams

There are a lot of binding options. To connect a solid fuel heating boiler with your own hands, it is better to use the simplest of them. Even if simple schemes are not suitable, then knowledge of the principles of the system will allow you to create your own project.

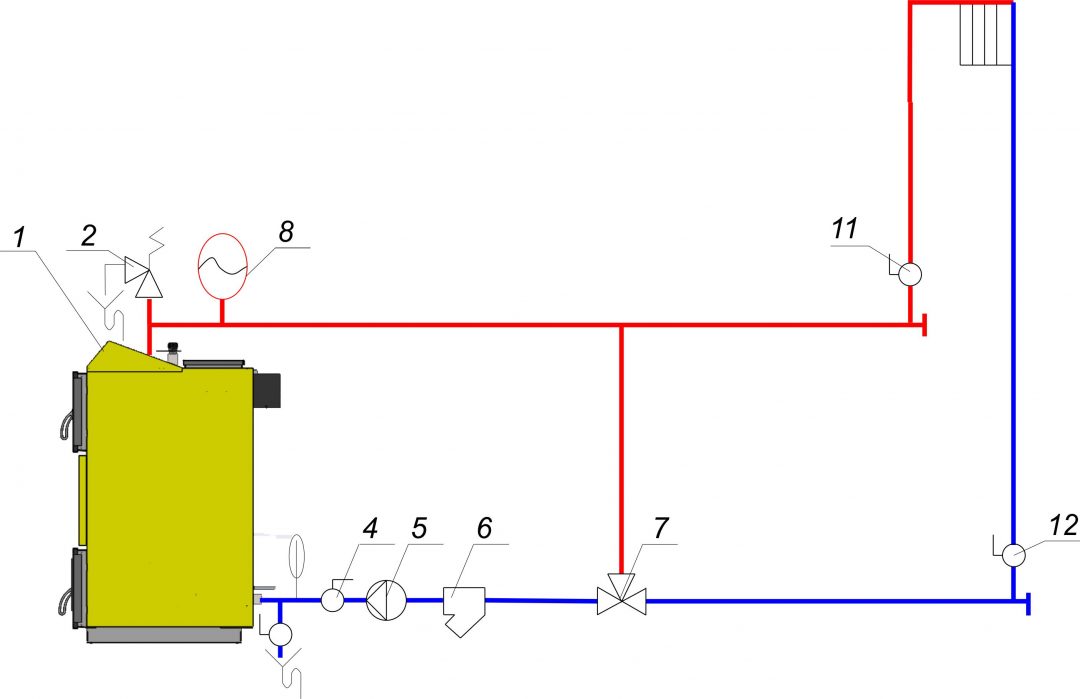

open system

Such solutions are best suited for solid fuel heaters. This is explained by the maximum security of the system. If a sharp increase in temperature occurs inside it, then the circuits will still remain sealed and operational. In addition, heating with natural circulation does not need electricity.

The disadvantages of this scheme include the following points:

- Oxygen enters freely inside the system, accelerating the formation of corrosion on the pipes.

- It is necessary to constantly replenish the liquid level in the circuits, as it evaporates.

- The heat carrier in the pipes has an uneven temperature.

But these shortcomings are invisible against the background of simplicity, minimal cost and very high reliability of the system. When installing the boiler according to this scheme, it should be taken into account that the inlet of the heat agent into the boiler must be at least half a meter below the radiators. The pipes must also have a slope.

It will be necessary to calculate the hydrodynamic resistance of all elements of the system, and during installation, minimize the number of fittings of various types. The expansion tank should be mounted at the highest point.

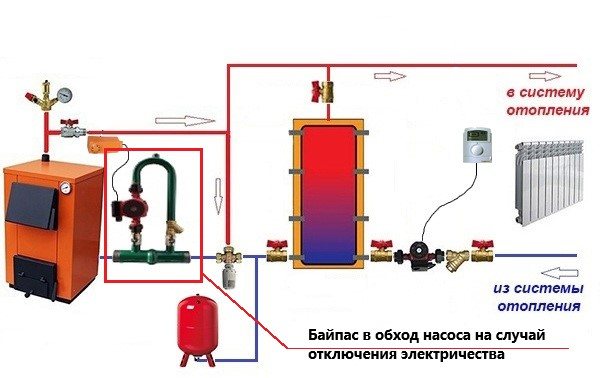

Closed heating circuit

Connecting a solid fuel boiler to closed heating system will only be safe if a diaphragm expansion tank is installed on the return pipe. The latter will perform 2 functions: to prevent the access of oxygen to the system and prevent the evaporation of the coolant.

When using this scheme, you need to remember the following points:

- The capacity of the tank with the membrane must be at least 10% of the capacity of the water in the system.

- The supply pipe will have to be equipped with a safety valve.

- At the top point, you need to install an air vent.

Additional elements of the system will have to be purchased. Manufacturers of TT boilers rarely complete their products with them. For example, Kordi boilers have places for attaching additional equipment, but there are no elements in the kit.

A closed system is relatively reliable, but does not have a uniform liquid temperature in different areas. The problem is solved by including a circulation pump in the circuit. It will provide forced movement of the coolant. In this case, the requirements for pipe slopes in the circuits and the installation level of the heat generator become minimal. The advantage of such a scheme is that in the event of a power outage, the bypass is activated, which ensures the gravitational movement of the liquid, that is, the system will continue to function.

The pump should be installed on the return before the boiler inlet fitting. Due to the lower temperature of the coolant flowing along the return line, the pump will work with less load. In addition, it should increase the level of security.

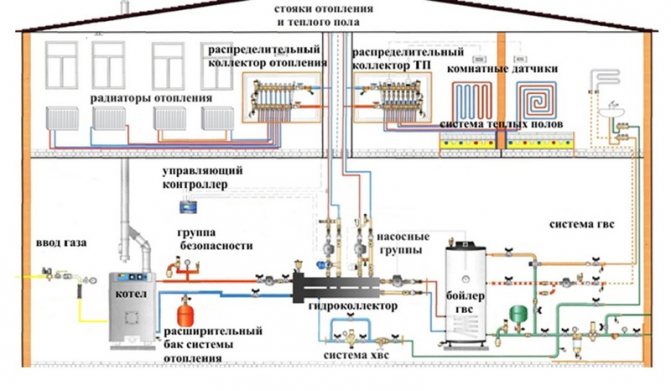

Connection via manifolds

Such a scheme is resorted to in cases where it is necessary to connect several pipe branches to one heater at once.For example, the main circuit with radiators on the walls and an additional one for underfloor heating. Here you can not do without the use of collectors. They are needed to balance the system. If it is not done, then the liquid will go where there is less resistance. As a result, some areas of heating will be hot, while others will be cold.

When using collectors, several pumps can be connected at once to ensure uniform delivery of water to consumers. In addition, you can adjust its supply. The main and only disadvantage of such a scheme is the complexity of the design, which entails an increase in financial costs.

Separately, mention should be made of the strapping using collectors and hydraulic arrows. It differs from the usual scheme in that an additional device plays the role of an intermediary. The arrow has the form of a pipe, simultaneously connected to the inlet and outlet pipes of the heating boiler.

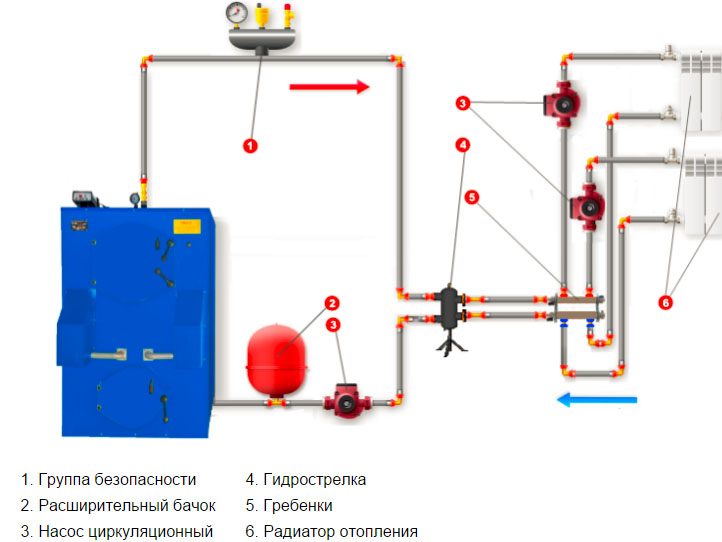

Types of water heating systems

According to the method of circulation of the coolant, water heating systems are divided into 2 types:

- Scheme with natural (gravitational) circulation, open system;

- Scheme with forced circulation, closed type system.

AT natural circulation system the movement of water is carried out due to the difference in the densities of the coolant. The heated water expands somewhat, acquires a lower density and weight, and rises up through the system. Its place is taken by a cold coolant, which, in turn, also heats up and continues to move.

Systems of this type communicate with the atmosphere through an open-type expansion tank. The tank serves as a natural air vent, takes in excess water when heated. The expander is often equipped with an overflow pipe to release water during rapid expansion.

The gravity system is applicable only to floor-standing boilers, since wall-mounted ones have a relatively small connection diameter and a small heat exchanger. These factors will not allow to implement the principle of natural circulation.

The boiler is installed at the lowest point of the system, a vertical riser at least 2.5 meters high rises from it. An expansion tank is installed at the top point, the pipe goes into a horizontal direction with a slope of at least 3 - 5 mm per linear meter, diverges to the heating devices.

In addition to the expansion tank, no equipment is required to be mounted in this scheme. The system is made of steel pipes with a diameter of 40 - 50 mm. The use of polymer (plastic) pipelines is not recommended due to the high temperature in the boiler area and the low thermal conductivity of the walls. Steel pipes themselves act as a heating surface.

Most often, cast-iron radiators with a large flow area are used as heating devices. Aluminum and bimetallic radiators have a small flow area - this prevents the movement of the coolant.

The closed type system is the most popular heating implementation scheme. The coolant in such a system moves forcibly, is pumped by a circulation pump. The working pressure in a closed circuit is 1.5 - 2.0 kgf / cm2, the limiting pressure (pressure of the safety valve) is 3.0 kgf / cm2.

Various types of materials are used for the installation of systems. Pipes in in this case have a smaller diameter compared to natural circulation, concealed laying is available.The range of pipeline sizes ranges from 15 to 25 mm (internal nominal diameter).

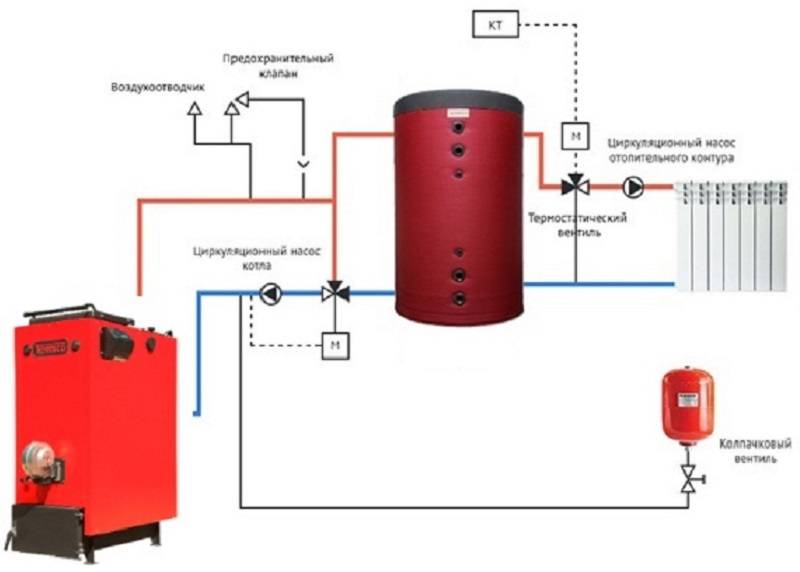

The closed circuit is universal for any types of boilers - wall and floor. The boiler piping in this case has a set of mandatory elements:

- Membrane-type expansion tank (expansomat);

- Circulation pump;

- Boiler safety group.

To ensure better work, additional equipment is installed - a hydraulic separator (hydraulic arrow), a heat accumulator.

The expansion tank is designed for pressure compensation in the system. When expanding, the plastic membrane is stretched, and the excess coolant fills the water chamber of the vessel. When cooling, the membrane displaces water back under the pressure of the air chamber of the expander (1.0 - 2.0 kgf / cm2).

The security group includes the following devices:

- Frame;

- Thermomanometer;

- Safety relief valve;

- Manual or automatic air vent.

Wall models usually have a full set of built-in equipment - a pump, an expander and a security group. Floor models are often produced without additional equipment, it must be purchased and installed separately.

Systems with natural (gravity) circulation are upgraded by installing a low power pump. This significantly improves performance, equalizes the temperature of the network, does not require the installation of other equipment.

Recommendations for the safe and efficient use of a solid fuel boiler

Unlike from gas boilers, during the operation of their solid fuel counterpart, part of the combustion products remain in the furnace.They must be periodically removed, as well as other measures to improve the efficiency of the combustion process:

- It is advisable to periodically remove deposits from the walls of the boiler. Experts have calculated that a layer of soot 1 mm thick reduces the power of the boiler by 3%. Cleaning is carried out on a cold boiler about once a week;

- When filling the grate with ash, the boiler output also decreases. In such cases, it is recommended to move the coals a little. In modern models of boilers, a special lever is provided for this. With it, you can also make an emergency discharge of coal;

- To improve the flow of water through the heating circuit, a circulation pump can be used. Installing a pump in the return before entering the boiler will increase work efficiency - the coolant will pass through the line faster, returning to the boiler hotter, therefore, less energy will be spent on heating it;

- It is necessary to monitor the draft in the chimney. To do this, it is desirable to regularly, at intervals of once a year, clean it. Sections of the chimney passing through unheated rooms must be insulated to prevent the formation of condensate, which, when frozen, prevents the free exit of combustion products;

Chimney output options for a solid fuel boiler

For more efficient fuel consumption, it is better to set the thermostat to a lower capacity with good heating of the room and an increase in the air temperature outside.

What is the difficulty of connecting two boilers

The main difficulty in using two boilers in one heating system is the need to equip different types of piping. Two gas boilers in one house can be installed only with a closed heating system. That is, connecting a gas boiler to the heating system will not cause problems. And for solid fuel units, an open system is needed. The fact is that the second version of the boiler is capable of heating water to a very high temperature, which leads to an increase in pressure in the system. Even with weak combustion of coals, the coolant continues to heat up.

In such a situation, pressure relief in the heating network is required, for which an open-type expansion tank is cut into the circuit. If the volume of this element of the system is insufficient, a separate pipe can be brought into the sewer to drain excess coolant. However, the installation of such a tank can cause air to enter the coolant, which can damage the internal elements of the gas boiler, pipes and heating devices.

To avoid all these difficulties of connecting two boilers to one heating system at the same time, you can use two options:

- Use a heat accumulator - a device that allows you to combine a closed and open heating system.

- Organize a closed heating circuit for a solid fuel and pellet boiler using a special security group. In this case, the units can work autonomously and in parallel.

Scheme and procedure for installing the boiler

Note that the installation of a solid fuel boiler is a very responsible matter, and any oversight will entail at least a malfunction of the system. But if you are not afraid to take a risk, let's turn to our step-by-step instructions.

Step 1: Choosing a Location

Such equipment should be placed in a separate room. As a boiler room, basements or basements are most often used.Hot coals can fall out of the firebox onto the floor, so the base under the boiler must be perfectly flat and non-combustible. A concrete slab is perfect. Be sure to keep the body in a strictly vertical position. His distortions are unacceptable.

You still need to maintain the following distances. There should be more than half a meter between the rear surface of the heating unit and the wall. And from the front side of the boiler to other objects and surfaces, at least 125 cm is maintained. The ceiling height cannot be less than 250 cm, and the volume of the room in which the heating equipment is located must be more than 15 cubic meters. Treat the floor and walls of the boiler room with special fire-fighting agents and take care of a good exhaust system.

In the photo - a room with solid fuel heating equipment

Step 2: Preparing the Components

The circuit consists of a radiator, a pipe, a circulation pump, an expansion tank and the heat unit itself. The kit also includes a heat accumulator, air and safety valves, a pressure gauge and a thermostat. Be sure to check the serviceability of all elements when buying and give preference only to reliable manufacturers.

Step 3: Hardware Installation

We expose the unit in the boiler room, adhering to all the above requirements

Pay special attention to the position of the body, it must be located strictly horizontally. Therefore, once again check the prepared area with a level, whether it is level enough. Then we connect all electric heaters, if any are included in the package.

In principle, there is nothing complicated in this, since a special place is provided in the boiler itself, where the heating element will be located, and next to this element there is a thermostat

Then we connect all electric heaters, if any are included in the package. In principle, there is nothing complicated about this, since a special place is provided in the boiler itself, where the heating element will be located, and next to this element there is a thermostat.

Step 4: Mounting pipes and electronics

Connection diagrams for solid fuel boilers require the presence of pipes. It is best to connect them through stopcocks. The joints are additionally sealed with flax fibers or a special plumbing tape. If we are talking about volatile units, then they, respectively, should be connected to the network. Don't forget about grounding. Next, we install all the devices responsible for the safe operation of the equipment. This is a thermostat, valves, pressure gauge, draft sensor.

Photo of the connection diagram for solid fuel boilers

Step 5: Mounting the chimney

Today it is not at all necessary to lay out a brick chimney, you can assemble it from special plastic elements. In this case, the diameter of the components is selected depending on the power of the equipment. Therefore, be sure to follow the recommendations given in the operating instructions for the selected boiler. Moreover, this stage is especially important, because the guarantee of high-quality operation of the thermal unit is good traction.

Step 6: Filling Out the Outline

First, we fill the heating circuit with water so that the pressure is slightly higher than the working one, and we carefully examine the entire system, especially the joints. This way you will identify any leaks, if any.Then we carefully check whether the internal elements of the furnace are located correctly. These include a kindling damper, grates, fireclay stones and plugs.

Step 7: Connection

If the whole circuit is in order, no leaks were found, then you need to relieve the pressure to the working one, adjust the position of the dampers and proceed directly to the operation of the heating device. To do this, lay and kindle the fuel, and after 10 minutes close the damper. As soon as the temperature reaches 80 degrees, set the thermostat to the desired level. It remains to throw firewood on time and enjoy a comfortable microclimate.

Equipment in a closed system with forced circulation

When the heating system is not in communication with the surrounding air and operates under pressure, such circuits are only closed.

In this case, the following equipment is required to tie the boiler:

- pump 100-200 watts, which should be installed on the supply;

- membrane-type expansion tank to provide the coolant with additional volume during expansion;

- safety valve for coolant discharge, in case of exceeding the permissible pressure;

- an automatic air vent that will help the air lock that has appeared to leave the system on its own so that the coolant circulates freely along the circuit;

- pressure gauge - to control pressure.

These are required items. The following options may also be included in the scheme:

- filter for gas unit;

- filter at the inlet to the heat exchanger to protect against debris;

- a heat accumulator, which is advantageous to be paired with solid fuel or electric boilers to save energy.

What to look for when choosing a heating boiler

The purchase of heating equipment is associated with a number of tasks that need to be solved in advance. Therefore, before making a purchase, you need to understand the following points:

- Power is the primary parameter by which units are selected. The calculation of the power of a solid fuel heating boiler is carried out according to a simple formula: the area of \u200b\u200bthe house is divided by 10. Why is it so? Because 1 kW of power is required for high-quality heating of ten square meters of housing.

- Heat exchanger type.

- Dependence on external factors - solid fuel electric heating boilers with a forced air fan do not function without electrical energy. If the circulation is natural, this problem is absent.

- Duration of work from one loading.

Polish solid fuel boilers "PEREKO" are equipped with a pressurization fan, which increases the time of continuous fuel combustion

Heating a wooden house with a solid fuel boiler is the right decision if the home is cut off from the benefits of civilization. But you need to understand that the correct operation of the system is possible when the design and installation of all components and components is carried out by masters. Competent specialists know the intricacies of their work and guarantee the smooth functioning of the equipment for many years.

Mini-boiler rooms

Now models of boilers are produced, equipped with an expansion tank, a pump, a valve and a pressure gauge. These can be heating elements, electric, diesel, gas units with forced draft. These units can be called mini-boiler rooms. So, safety valves in the electric heating circuit of a private house with a pump are mounted immediately on the heat exchanger together with the heating element.This design allows you to quickly dump excess coolant if it boils when the pump stops.

The scheme for connecting the boiler to the heating system in this case is not complicated. It is necessary to mount only two ball valves, which can be used to cut off the boiler if necessary. Repair of the unit or any maintenance work will not cause difficulties.