- Do-it-yourself sand well in the country

- Work order

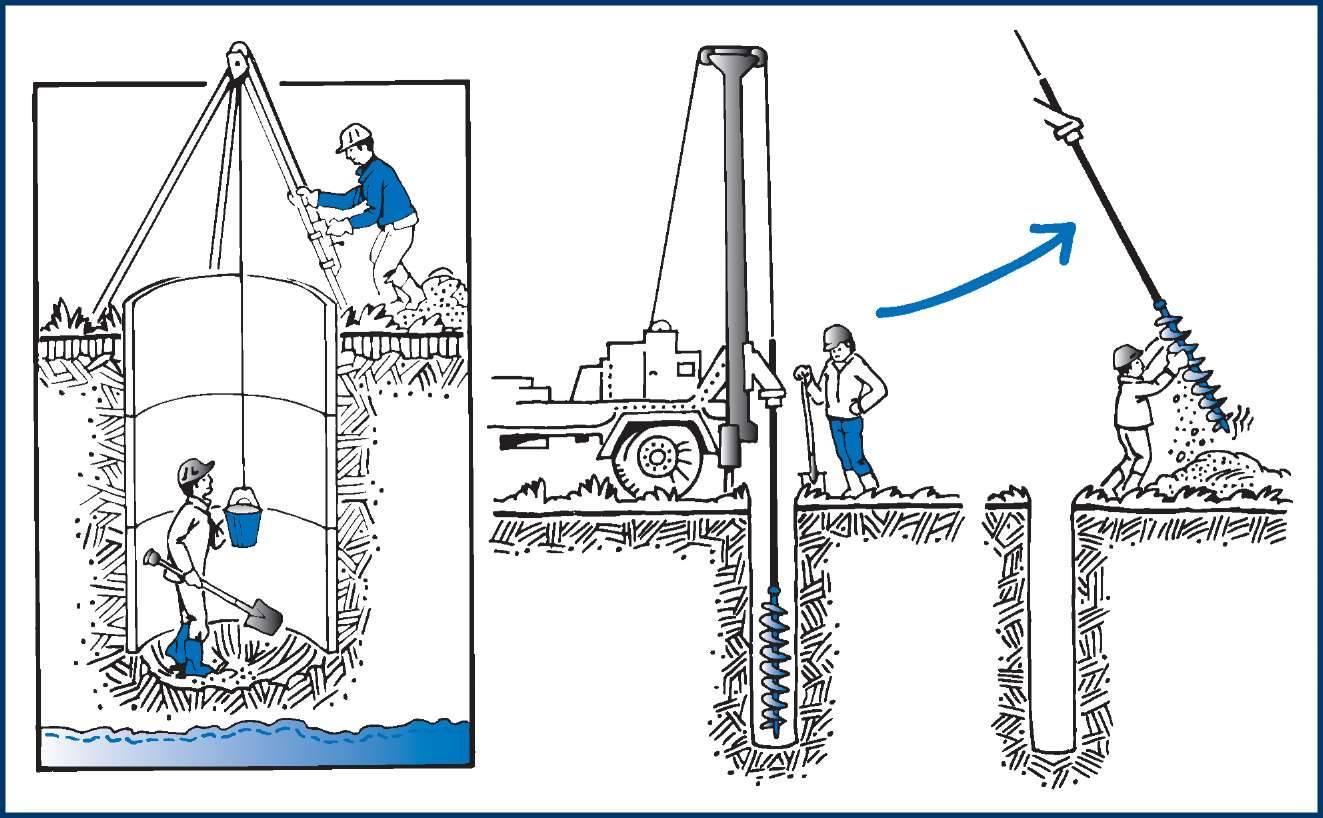

- Do-it-yourself drilling of a shallow well

- How is a typical well arranged?

- Casing Functions

- Inner tube with filter

- Borehole device

- Caisson, adapter, packer

- Homemade devices for drilling wells

- Abyssinian well

- Driving the "Abyssinian well"

- Design pros and cons

- Construction manufacturing

- Mounting

- Horizons and types of wells: accessible and not very

- Horizons have boundaries

- The whole range of wells

- Abyssinian well

- Well on the sand

- Artesian well

- What are aquifers

- Types and methods of drilling wells

- Conclusions and useful video on the topic

Do-it-yourself sand well in the country

Taking directly to the execution of work, you need to start with drawing up plans and schemes. First of all, think about where the well will be located in your yard. Consider all the buildings on the site to understand how convenient the location you have chosen. Do not forget about what you planned to build at your dacha in the future. Remember that a well is built once, and it will not be easy to move it to another place.

Work order

Having settled all the issues of location, creating work plans, it is necessary to proceed with their implementation:

- Carefully mark up for future work. Make sure that the accuracy is maximum.

- Prepare a hole for the entry of the drilling tool.

- Install the drilling equipment at the required position.

- Start drilling.

- Assemble the filter column from the pipe, sump, and filter, and lower it into the pit.

- Take a closer look and find the space between the soil and the walls of the casing from the outside. It must be covered with gravel or sand, your choice. If you choose crushed stone, be extremely careful not to damage the casing from the outside.

- Rinse the filter by pumping water into the pipe with a pump. This way you can seal the top of it.

- Using a screw pump, as well as a bailer, pump water out of the well.

- Make sure the well water is clean.

- Gently and slowly lower the submersible pump into the well. This procedure is performed using a safety type cable.

- Connect the water pipe or hose to the pump.

- In order for the water supply to be regulated, install a special valve on the pipe.

- A casing pipe that protrudes above the surface must not allow water to pass through in undesirable places. For this purpose, perform waterproofing.

- Equip the wellhead with a caisson, then carefully fix it on the head with a welding machine.

- If you were planning to bring pipes to the house, at this stage it's time to lay them in trenches.

- Sprinkle the caisson with soil, and also make a concrete blind area.

And so, in less than 20 steps, a well can be made in the country. Of course, everything is not so simple, but doing the work as accurately as possible, you will succeed.

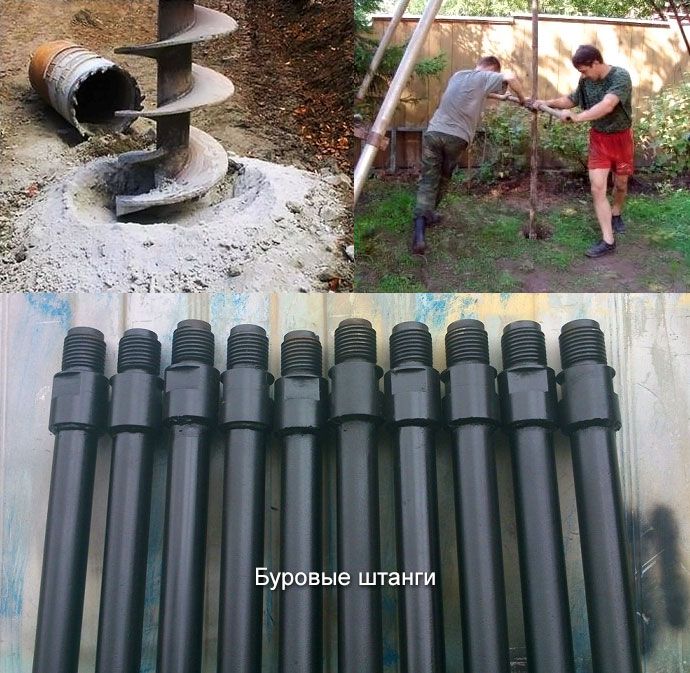

Do-it-yourself drilling of a shallow well

You can also drill a well manually, but this, of course, requires special equipment. We list it below:

- Boer;

- drilling rig;

- winch;

- casing;

- rods.

By the way, it is not necessary to take a drilling rig, but only if the well is not deep. For shallow holes, you can pull out the drill string by hand.

As for the drill rods, they are made from ordinary pipes, and are connected using threads or dowels. The lower of the rods should not be forgotten, because it is she who must be equipped with a special drill.

For the manufacture of cutting nozzles, you will need sheet steel with a width of 3 millimeters. And another very important point concerns the sharpening of the edges of the nozzles. They need to be sharpened in such a way that as a result they enter the soil underground in a clockwise direction.

Now you should set up a tower in the area where drilling will be carried out. Make sure that the height of the derrick exceeds the dimensions of the drilling rod so that lifting and retrieving the rod is completely unimpeded.

To create a well, you will probably need an assistant. You can start the rotation yourself, but after a while, when the drill goes underground, the efforts of one person will not be enough to continue drilling.

If, together with an assistant, you stumble upon problems or simply get stuck, try pouring water into the soil, as it will soften it somewhat.

When the drill reaches ground level, an additional bed is attached to it. Continue drilling until the very moment when you notice on the ground that you have finally reached the aquifer.After that, you need to clear the well from the ground and plunge the drill even deeper, trying to reach a layer called water-resistant. Having reached this layer, an abundant influx of water will begin in the well.

Pump out the dirty water with the help of a pump and soon you will find clean water. If suddenly you notice that the water is not getting clearer, you need to deepen the drill a few more meters.

How is a typical well arranged?

If you do not focus on the nuances, the essence of arranging a water well for a country house is the same: it is a long narrow vertical shaft that reaches the depth of water. The walls of the excavation are reinforced with casing pipes

Wells differ from each other in width, depth and additional devices that increase their productivity and reliability.

In addition to the casing pipe, the wells are equipped with equipment for the forced lifting of fluid and its distribution. To choose the right pumping equipment and storage capacity, you need to know the characteristics of the well, the most important of which is its depth and flow rate.

The flow rate of a well is an indicator of its productivity: the maximum volume of fluid obtained per unit of time. It is calculated in cubic meters or liters per hour or day.

Casing Functions

Casing pipes are the main element of the well. Casing is carried out using separate segments, soldered, welded or screwed together

Particular attention should be paid to their equal diameter: the whole structure should create a straight, even column

If the casing pipes have an external thread, the links are connected by couplings, due to which the penetration diameter increases.

Casing pipes are needed to:

- while drilling the well, there was no shedding of the mine;

- the barrel is not clogged during its operation;

- the upper aquifers did not penetrate the structure.

Casing pipes made of steel alloys and polymers (PVC, PVC-U, HDPE) are widely used. Cast iron and obsolete asbestos-cement products are used less frequently. The space between the pipe and the ground around the mouth is poured with concrete if the working was drilled in loose soils or the aquifer lies at a considerable depth.

Only after this work is completed, all other equipment is installed. Sometimes during the operation of the well, a slight "squeezing" of the pipe to the surface may occur. This is a natural process that does not require any additional measures.

Threaded metal and plastic casing pipes are considered the most popular. The photo shows the installation of a blue plastic casing

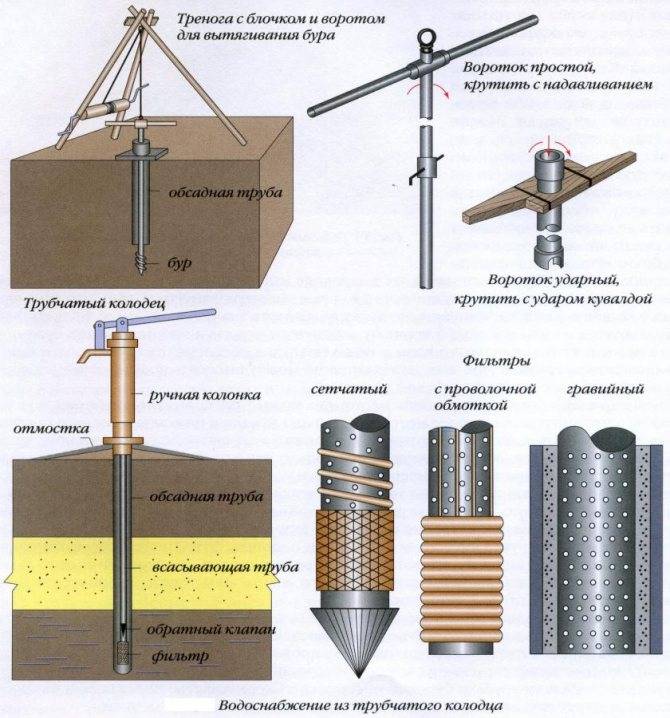

Inner tube with filter

A pipe with a filter is lowered into the wellbore, made according to the double casing scheme. Through its perforated first link, the filtered water will flow into the backing, and then be pumped to the surface.

After the pipe is installed at the desired depth, it is desirable to fix its mouth. For this purpose, a clamp is used to prevent spontaneous subsidence of the pipe.

Borehole device

The upper part of the casing pipe is equipped with a head. The basic design of this device is the same for heads of any kind. It consists of a flange, a cover and a rubber ring.

Different types of heads differ from each other in the type of material from which they are made, and additional options.

Heads are made of cast iron and plastic. This is a sealed device. It is used to fasten the pump cable and the outlet of the water pipe.

Due to the low pressure created by the head in the pipes, the inflow of water and, as a result, the flow rate of the well increases.

Caisson, adapter, packer

So that high humidity does not affect the operation of devices associated with the well, a special reservoir is provided for them - a caisson. It is made either from metal or plastic.

Metal caissons, unlike plastic ones, can be repaired, they are better adapted to the climate with significant temperature differences. In addition, a metal product can be independently assembled from parts that are sold separately. But plastic models are cheaper and they don't rust.

Those who wish to arrange a caisson for a well with their own hands will find detailed instructions for its construction on our website.

To hermetically connect the ground water supply and the well, you will need a downhole adapter. This device is usually placed in the place where all the equipment that needs to be protected from water is assembled. Most often this is a technical room. One part of the adapter is attached to the casing, and the hose from the pump is screwed to the other part.

A metal caisson is an expensive thing: its price reaches 40 thousand rubles, so you can buy it in parts and assemble it yourself, which will make the purchase cheaper

Sometimes there is a need to allocate a local section of a deep artesian well, where, for example, repair work will be carried out. For this purpose, packers are used - compactors for wells.

The listed elements are part of the well device, exerting a great influence on its functionality.

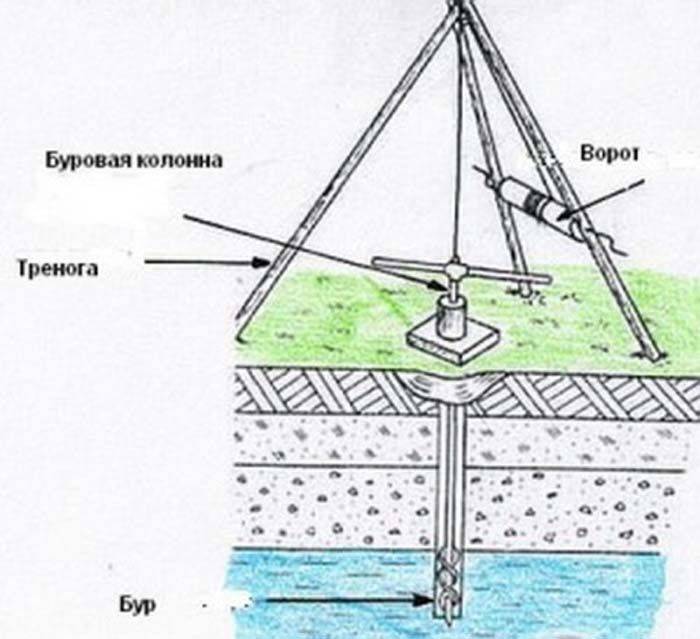

Homemade devices for drilling wells

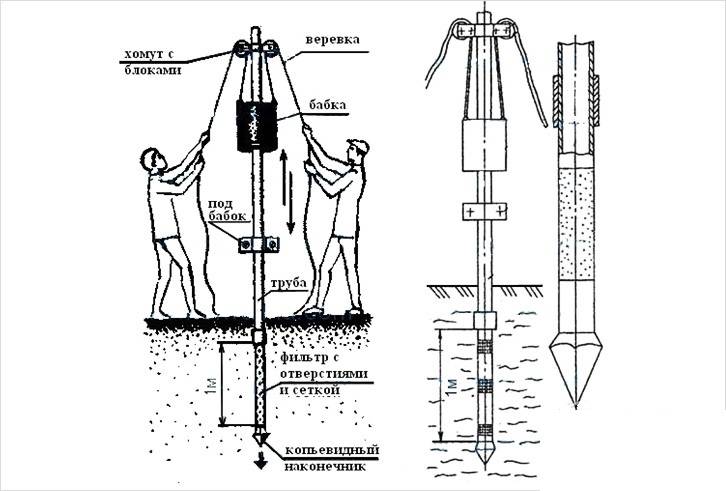

The simplest water intake device is the well of the Abyssinian well. To arrange it, you do not need sophisticated equipment or fixtures at all. It is enough to get a "woman", and this is a load of 20 - 25 kilograms and make a bollard - in fact, a clamp that securely covers the pipe being clogged.

An elementary device for punching Abyssinian wells is shown in Fig. 1, where:

1. Clamp for fastening blocks.

2. Block.

3. Rope.

4. Baba.

5. podbabok.

6. Driving pipe.

7. Water intake pipe with a filtering device. At the front end, it is equipped with a spear-shaped tip, the diameter of which is larger than all other components. Raising and sharply lowering the woman, two people reach the water carrier at a depth of up to 10 meters in one light day.

Drawing fig.1 does not include a tripod

Without denying the effectiveness of this method, we draw your attention to the fact that it is easier to control the direction of immersion with a tripod, because the pit must be strictly vertical. A tripod is easy to make with your own hands from improvised materials

Drilling of classic wells for water can be carried out by shock-rope method, the equipment for the implementation of this technology is so simple that it “asks” to be made by hand.

The simplest small-sized installations of this type allow drilling wells for water to a depth of 100 meters. A characteristic disadvantage of this method is the low productivity during penetration, since the process is associated with constant lifting of the tool to unload the soil from the wells after every 5–8 strokes.At the same time, the shock-rope method enables the most high-quality opening of aquifers. The simplest device shown in Fig. 1 can be easily upgraded by installing a drive on a winch with a reset clutch, as well as installing an additional manual lifting mechanism for assembling casing pipes, which can be done by hand at home.

Self-made installations for drilling water wells using auger tools are popular. This is a whole range of solutions from a simple garden drill, on which it is possible to increase the length of the drill rod, to quite complex mechanisms that fit the MGBU classification. They already use electric or internal combustion engines.

If you wish, you can make a simple auger drill with your own hands, because it is useful not only for drilling water wells, but also when building site fences and when creating a pile grillage foundation, significantly reducing the amount of earthwork. To do this, you can use the drawing from Fig. 3, if necessary, changing the dimensions in accordance with the preferences of the manufacturer.

More complex devices for drilling holes in this way include a drilling derrick, which is a traditional tripod.

One worker can do the job, but there is a danger of the drill string deviating from the vertical. Therefore, they usually work together, evenly loading both sides of the lever.

Given the complexity of the work, it is advisable to mechanize the drilling process as much as possible. There are all conditions for this, a field of short searches in the construction markets, you can purchase any parts or assemblies and make a drill yourself.

As can be seen from Fig. 6, many industrial designs cannot be compared with such a home-made product in terms of the elegance of execution and layout of such an installation. Judging by the type of conductors, the electrical circuit was designed and executed for a voltage of 220 volts. The size of the drilling tool shows that the rig is capable of drilling medium and high production wells.

Abyssinian well

Abyssinian well on site

Despite their name, "Abyssinians" are actually wells, which are often referred to as "needles". Due to the shallow depth, the daily productivity of such structures is low - no more than 25 cubic meters. The well is characterized by simplicity of design and consists of the following elements:

- cone-shaped filter;

- surface device for water supply (pumping station or manual "rocking chair");

- pipes ø25 cm.

Driving the "Abyssinian well"

First you need to understand a number of nuances associated with the installation.

- Do not drill near toilets, VOCs, garbage heaps, etc.

- Installation of the "Abyssinian" is possible only if the aquifer is located no deeper than 8 m from the surface.

- The surface pump used for such wells is not capable of handling hard rock.

- A hand pump will be a great addition to an electric one. Moreover, it will make the water supply of the site autonomous from electricity.

Design pros and cons

The advantages of the "Abyssinian" include:

- ease of installation (the entire arrangement procedure takes no more than ten hours);

- low installation cost;

- conditional mobility - if necessary, the well can be disassembled and installed in another place;

- no need to obtain a special permit for drilling;

- low hardness of the resulting water, the minimum concentration of inorganic iron;

- possibility of installation inside the building.

But there are also disadvantages:

- seepage of contaminants due to shallow depth;

- the well is not suitable for all types of soil.

Well drilling with portable rigs

Construction manufacturing

First you need to prepare all the elements of the well.

Step one. A ø25 cm pipe with a length of 1-1.1 m is used as a filter. Slots of 2.5 cm in increments of 2 cm are made in the walls of the pipe (not for the entire length, but only for 80 cm).

Filter manufacturing

Step two. Then the future filter is wrapped with steel wire and closed with a stainless steel mesh measuring 16x100 cm. Clamps are used to fasten the mesh - they must be installed in 10 cm increments.

Step three. Another element of the filter is a steel tip 10 cm long. It can be pre-ordered from the turner.

Cone hammer

Cone hammer

Step four. The mesh with the tip is fixed with tin solder.

Step five. The remaining pipes are cut into segments of 1-1.5 m. At the ends of the segments, a small thread must be cut.

Mounting

Below is the simplest installation option that does not require the use of special equipment.

Step one. First, a hole 1x1x0.5 m in size is dug in the required place.

Step two. This is followed by pre-drilling with a simple garden drill. After about half a meter, the drill is extended with a pipe ø12 cm (bolts and couplings from a pipe of a slightly smaller diameter are used for connection).

Step three. After the appearance of wet sand, drilling stops and the actual driving begins.The previously prepared structure is installed in the well and clogged with a headstock and an ordinary sledgehammer. To do this, the upper section of the pipe is wrapped with flax, a headstock is put on it. The blows are applied to the headstock until the pipe is completely hidden - after that the next segment is attached and the procedure is repeated.

Abyssinian well drilling scheme

Periodically, water is poured into the pipe and listening is performed. Every half a meter, the pipe turns clockwise, while you need to monitor the sound:

- in coarse sand, a rattle will be emitted;

- in fine fraction - rustling;

- there will be no sound in clay soil.

When noise occurs, the well is filled with water. If the water disappears slowly, then you need to go another half a meter, and if fast enough, then only 30 cm.

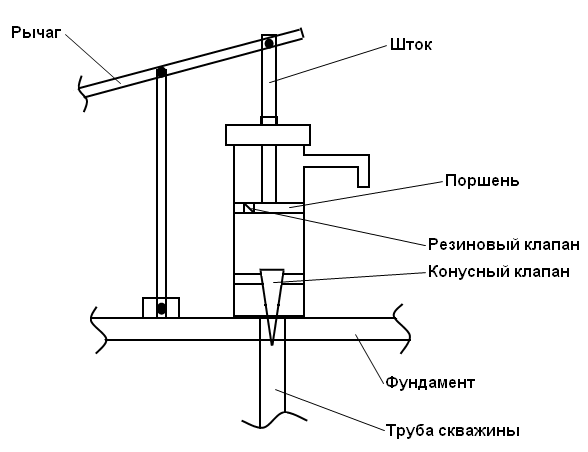

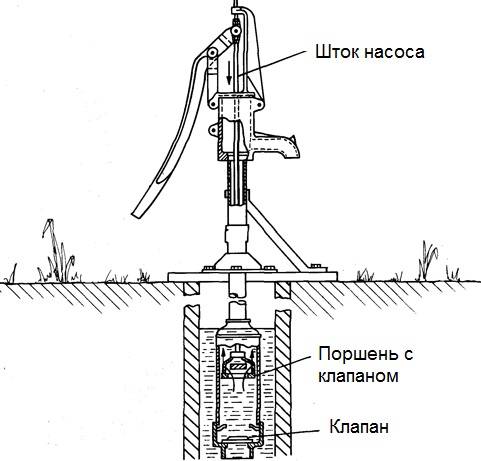

Hand pump

Hand pump

Step four. It remains only to install the pump. The design of a hand pump is extremely simple - a piston installed in a hollow metal cylinder. At the end of the installation, the well is pumped until clean water appears. The base is filled with cement mortar. If desired, the "Abyssinian" can also be connected to the pumping station.

Abyssinian well

The "Abyssinian wells" do not need any special care. Probably, in ten years the water supply will decrease, but this can be easily fixed by cleaning the filter or washing the mine with strong water pressure.

Well pumping

Horizons and types of wells: accessible and not very

Before you start preparing for such a large-scale work, you need to find out where to drill, but without conducting geological exploration, you will not be able to find the exact answer.

Horizons have boundaries

Water is located on different horizons, these sources do not communicate with each other. This is provided by layers of impermeable rocks - clay, limestone, dense loam.

- The shallowest source is perched water, which is provided by precipitation and reservoirs. It can start at a depth of 0.4 m and end at 20 m from the surface. This is the dirtiest type of water, it always has a lot of harmful impurities.

- Having drilled a well up to 30 m deep, you can “stumble” on cleaner groundwater, which is also fed by precipitation. The upper boundary of this horizon can be located at a distance of 5 to 8 m from the surface. This liquid is also recommended to be filtered.

- The underground water source, located in the sandy layer, is already filtered with high quality, therefore it is optimal for water supply. It is this horizon that must be reached by those who want to drill their own well.

- Depth from 80 to 100 m is an unattainable ideal with crystal clear water. Artisanal drilling methods do not allow you to get so deep.

Since the occurrence of horizons is influenced by relief and other factors, the boundaries of perched water and groundwater are conditional.

The whole range of wells

Drilling water wells manually depends on the type of future well. The types of structures cannot be called numerous, because there are only three of them:

- Abyssinian;

- on the sand;

- artesian.

Abyssinian well

This option is optimal when the water in the area is 10-15 m away from the surface. It does not require a lot of free space. Another advantage is the relative simplicity of work, which allows even a beginner who is just learning the science of drilling to cope with the task. This is a well-needle, which is a column constructed from thick-walled pipes.A special filter is arranged at the bottom of it, drilling holes at the end of the pipe. The Abyssinian well does not require drilling as such, since the chisel is simply hammered into the ground. But the most common way to make such a well is still called impact drilling.

Well on the sand

If the aquifer lies at a depth of 30 to 40 m, then it is possible to build a sand well, with the help of which water is extracted from sands saturated with water. Even a 50-meter distance from the surface does not guarantee the purity of drinking water, so it must be given for laboratory analysis. Since in this case there will be no insurmountable obstacles on the way - hard rocks (semi-rocky, rocky), manual drilling of water wells does not imply any special difficulties.

Artesian well

This aquifer can be located at a depth of 40 to 200 m, and water has to be extracted from cracks in rocks and semi-rocks, so it is inaccessible to mere mortals. Without knowledge and serious equipment for drilling, the task of building a well for limestone is an impossible mission. However, it can serve several sites at once, so drilling services ordered together promise significant savings.

What are aquifers

Obviously, you need to drill where there is an aquifer (horizon)

It is important to understand that these layers are distributed at different depths, not evenly, based on the properties of the rock.

According to the depth of occurrence, there are the following types of groundwater:

- Soil - are located almost near the surface.Precipitation adheres to solid parts of the soil and forms soil underground layers. They don't have a waterproof layer.

- Verkhovodka is mainly precipitation that accumulates on top of the aquiclude.

- Ground - is almost everywhere, they are formed by precipitation, waters of lakes, rivers, and other reservoirs. This permanent aquifer lies on the aquiclude.

Important! These three layers have no pressure of their own. If you make a well before them, then the water will not flow

That is why they drill to other interstratal horizons. In rare cases, drilling to groundwater is enough, but this is rather an exception.

Interstratal - this is an aquifer that is sandwiched between two water-resistant horizons. There is pressure here and you can put a well - they are often called artesian. Water from it will rise and beat even without the help of a pump.

Well drilling companies usually know how deep the water is in a particular region. But this does not mean that the water-resistant layer extends to the entire region! It may be that in your area the water lies at 25-30 meters, while the neighbors do not have it at all or it is much deeper.

What to do if you are offered to drill expensive and deep? In this case, it is better to additionally check that there are no other aquifers on the site that are not so deep. You can specify it like this:

- Gather information across multiple companies. If a few specialists insist on deep drilling, then most likely they are.

- There are paid and free databases that indicate the depth of the upper aquifer in different regions. You can get information there.

- You should definitely talk to your neighbors, especially if they already have an operating well.Neighbors can suggest other data on groundwater and its quality.

- For densely populated and well-studied regions, hydrogeological maps and sections are available on the Internet. They are easy to find on the request "aquifers + name of the region."

- Theoretically, information can be obtained from state geological funds.

Types and methods of drilling wells

We will not consider the types of drilling using special mechanisms and industrial equipment, the article focuses only on those that can be done independently using ordinary tools and fixtures. Table

Domestic Well Drilling Techniques

Table. Domestic Well Drilling Techniques

| Drilling method | Brief description of the technology, advantages and disadvantages |

|---|---|

| Hydro drilling | When drilling a well, water is used, it greatly facilitates the process. Water can be supplied under relatively low pressure, only to soften the earth and bring it to the surface. This method is very often used in summer cottages, where only a submersible pump is required for drilling. There is also hydro-drilling with water under high pressure. Water independently makes a well in the ground for water pipes. This method is used quite rarely, it is necessary to have a high-pressure water pump and an open reservoir for its intake. Some summer residents somehow negotiate with firefighters and wash the earth out of the well with the help of a fire truck. Hydrodrilling allows you to get a large diameter well, a casing pipe is lowered into it.The presence of such a pipe makes it possible to use deep-well pumps, they are connected in series to a hydraulic accumulator - the quality of water supply is no different from a centralized urban one. The pump is switched on/off automatically. |

| mechanical drilling | In summer cottages, two methods of mechanical drilling can be used: percussion and screw. In the first case, the pipe is driven into the ground with a load. It rises up and falls on the end of the pipe. Potential energy is converted into kinetic energy, as a result of a strong blow, the pipe is driven into the ground. In terms of labor intensity, they are approximately the same, a competitive choice must be made after analyzing the physical characteristics of soils. If they are sandy or sandy loamy, then it is recommended to make a well with an impact method. The sand is not very hard, smaller weights can be used, and the deepening process proceeds relatively quickly and easily. On heavy clay soils, it is better to drill with a screw method. This technology involves periodically raising the tool to clear it from the ground. If the drill is taken out in sandy soils, then there are high risks of their shedding, the work must be repeated, but the clay perfectly holds the walls of the well. The disadvantage is that if the depth of the well exceeds ten meters, then great efforts must be made to get the tool, various devices have to be made: tripods with cranks, chain hoists, etc. |

Well types

The decision on the choice of drilling method should be made by each owner of a suburban area separately, while always taking into account the approximate depth of the aquifer, the physical properties of the soil, the approximate water flow, the required pressure and your technical capabilities.

The choice of drilling method depends on many factors.

For each method, it is necessary to prepare devices for excavation, drill tips, helical blades, casing pipes, clamps, etc. There are a huge number of different options, each master selects the best one for himself, taking into account the availability of materials and professional skills.

Drilling a well requires special tools and fixtures.

Conclusions and useful video on the topic

Drilling a well with a shock-rope method:

The subtleties of making a screw with your own hands:

Those who want to know how to competently drill a water well by hand, we have given proven methods in practice. It is necessary to choose the optimal method of drilling, to seriously approach the choice of the necessary equipment, and when drilling, strictly follow the advice of experienced craftsmen.

The result of the efforts made will be a self-equipped source of water supply, providing clean water to all households.

Would you like to tell how you drilled a well in your own area? Have questions or interesting facts about the topic of the article? Please write your comments in the box below.