- Methods for self-drilling

- Shock rope

- Auger

- Rotary

- Puncture

- Do-it-yourself drill

- Where to drill?

- Work order

- Assembling a spoon drill

- Types of wells for water

- Features of hydrodrilling

- DIY drilling methods

- Types of wells

- Determining the quality of water

- How to drill a well

- What to drill

- Device characteristics

- Manual well drilling

- rotary method

- screw method

- Option #2 - rotary drilling method

- How to make a homemade earth drill with an engine

Methods for self-drilling

To drill a well for water in a country house, a personal plot, a rural courtyard, it must be taken into account that there are three ranges of depths at which aquifers occur:

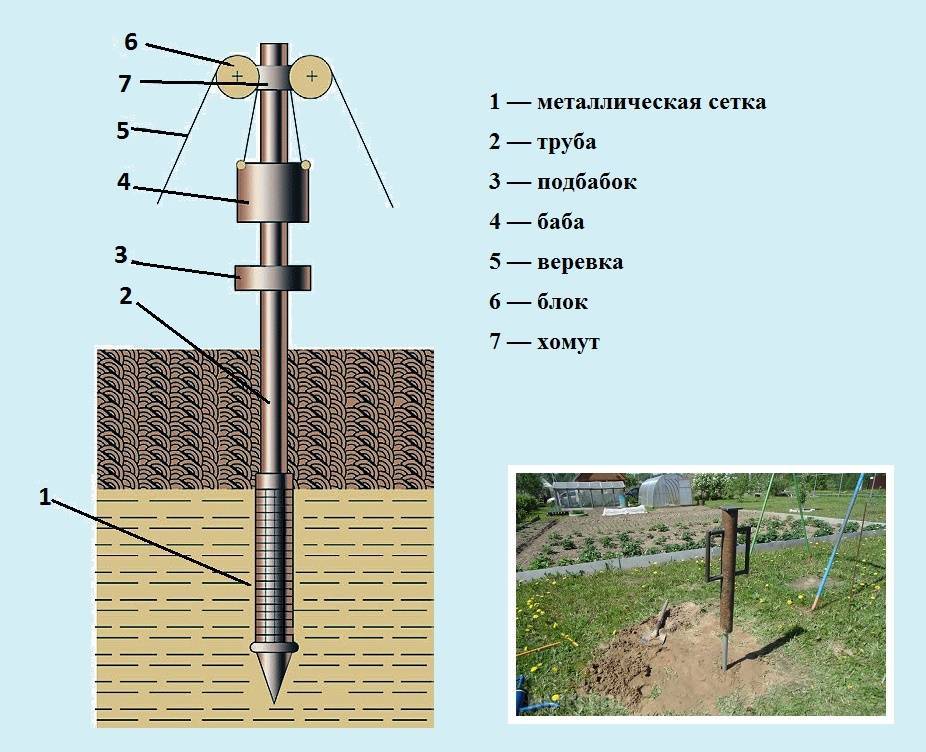

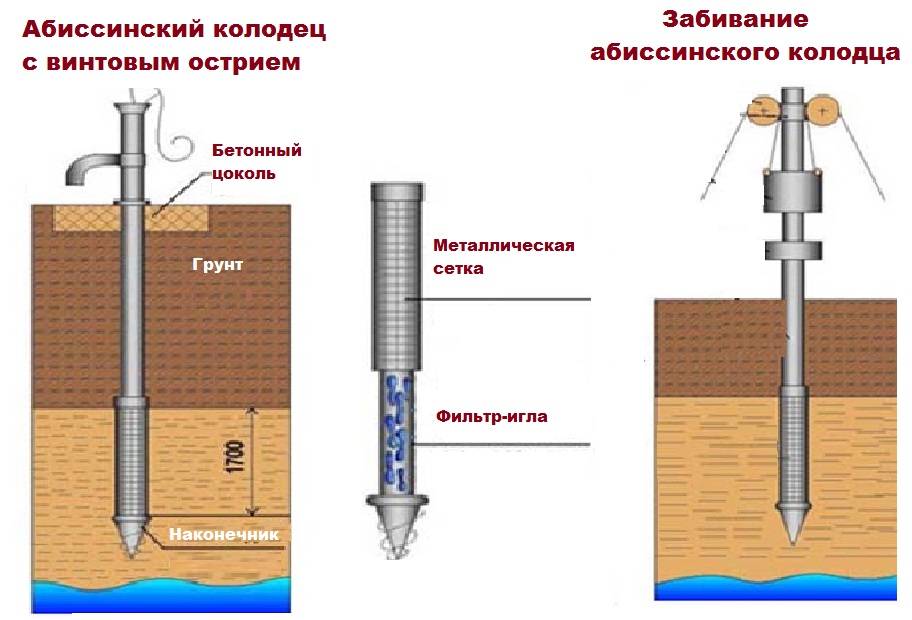

- Abyssinian well. Before the water will have to drill from one and a half to 10 meters.

- On the sand. To make a well of this type, you need to pierce the soil to a mark in the range from 12 to 50 m.

- Artesian source. 100-350 meters. The deepest well, but with the purest drinking water.

In this case, each time a separate type of drilling rig is used. The determining factor is the chosen method of drilling operations.

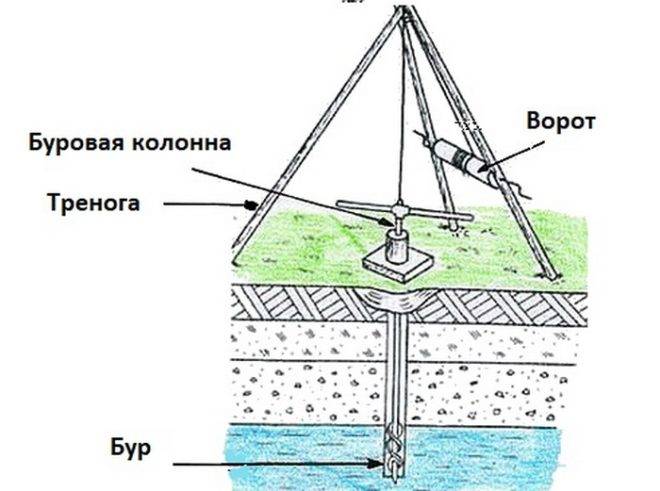

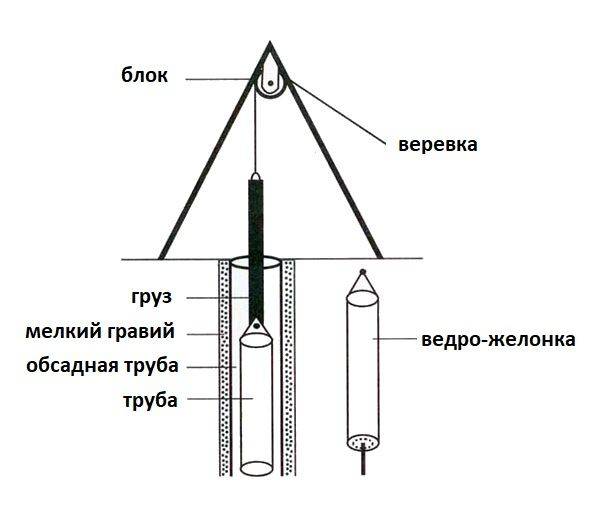

Shock rope

With such drilling of wells for water, the technology of the process involves raising the pipe with three cutters to a height.After that, being weighted with a load, it descends, and crushes the rock under its own weight. Another device necessary for extracting crushed soil is a bailer. All of the above can be bought or made with your own hands.

But before you drill a well with your own hands, you will have to use a garden or fishing drill to make the primary recess. You will also need a metal profile tripod, a cable and a system of blocks. The drummer can be lifted with a manual or automated winch. The use of an electric motor will speed up the process.

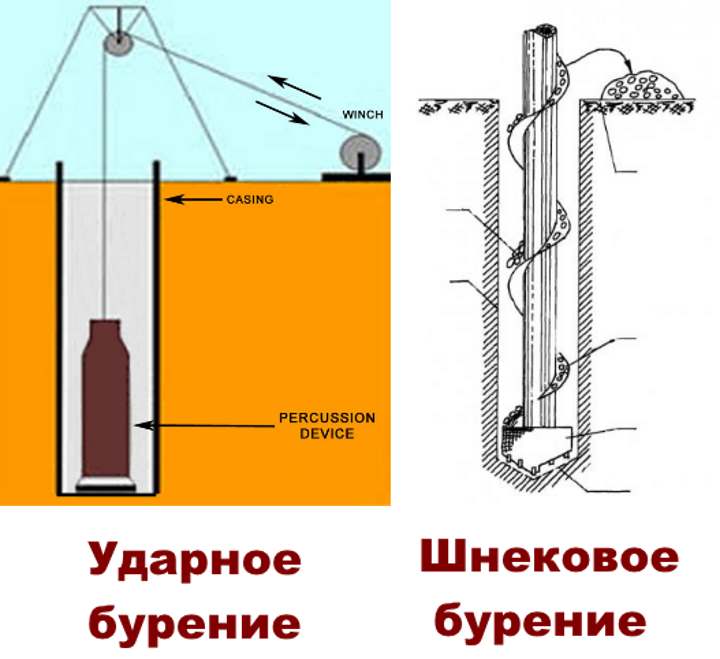

Auger

This technology of drilling wells under water involves the use of a drill, which is a rod with a helical blade. A pipe with a diameter of 10 cm is used as the first element. A blade is welded onto it, the outer edges of which form a diameter of 20 cm. To make one turn, a sheet metal circle is used.

A cut is made from the center along the radius, and a hole equal to the diameter of the pipe is cut along the axis. The design is “divorced” so that a screw is formed that needs to be welded. To drill a well in the country with your own hands using an auger, you need a device that will serve as a drive.

It could be a metal handle. The main thing is that it can be disconnected. As the drill deepens into the ground, it is increased by adding another section. The fastening is welded, reliable, so that the elements do not come apart during the work. After the procedure is completed, the entire structure is removed, and casing pipes are lowered into the shaft.

Rotary

Such drilling of a well in the country is not the cheapest option, but the most effective. The essence of the method is the combination of two technologies (shock and screw).The main element that receives the load is the crown, which is fixed on the pipe. As it sinks into the ground, sections are added.

Before you make a well, you need to take care of the water supply inside the drill. This will soften the ground, which will extend the life of the crown. This method will speed up the drilling process. You will also need a special installation that will rotate, raise and lower the drill with a crown.

Puncture

This is a separate technology that allows you to penetrate the ground horizontally. This is necessary for laying pipelines, cables and other communication systems under roads, buildings, in places where it is impossible to dig a trench. At its core, this is an auger method, but it is used for drilling horizontally.

The pit is dug, the installation is installed, the drilling process begins with periodic sampling of rock from the pit. If water in the country can be obtained from a well separated by an obstacle, a puncture is made, a horizontal casing pipe is laid, and a pipeline is pulled. Everything can be done with your own hands.

Do-it-yourself drill

Making a drill for a well with your own hands is not very difficult. This will require a pipe, a disk from a sawmill, a metal sheet 2-3 mm thick, electrodes for welding. First of all, the working surface of the tool is prepared - knives.

- The disk is cut into two halves.

- A circle is cut from a sheet of iron with a diameter smaller than a disk, but larger than a pipe. A hole is made in it for the diameter of the pipe.

- The circle is cut in half.

- Now the halves are installed to the pipe on opposite sides at a slight angle, but in different directions. Fastening is made by welding.

- On the halves of the disk, landing holes are made, two on each side.

- Each disk is placed on the welded half of the circle, and marks are made through the holes, in which holes are also made.

- Now you need to lay the halves of the disk on the halves of the circle so that their holes match. They are bolted through.

- A threaded sleeve is welded to the opposite edge of the pipe; it will connect the drill rods to each other. Accordingly, to other rods (pipes) it is necessary to weld on the one hand the sleeve corresponding to the thread of the coupling, and on the other hand the coupling itself is welded.

- To rotate a hand drill, you will need to make a special handle. This will be a spur, on which a pipe with a diameter of 20-25 mm will be welded perpendicularly.

Homemade drill

Deep wells cannot be drilled with such a device, but up to 10 m is not a problem. In this case, it will be necessary to drill into the ground a few centimeters (30-40), after which it will be pulled out in order to free it from adhering earth.

A drill glass is also made simply from an ordinary pipe with a wall thickness of at least 2 mm. A piece of pipe is simply taken and sharpened inwards on one side. You can cut teeth at the end with exactly the same sharpening. The opposite edge must be plugged and a hook or eye attached to the end, to which the cable of the drilling rig will be connected. Be sure to make longitudinal grooves through which it will be possible to remove the soil.

Glass-drill

Spoon-drill is made of a thick-walled pipe. On one side, the pipe is cut so that petals form. They must be sharpened, making a sharp edge. A large diameter drill is also welded here. Be sure to make a longitudinal cut through which the soil selected from the well will be removed.

On the opposite side, the drill is muffled and devices are made for suspension to the cable. If you want to drill a well of large diameter, then a drill spoon can be made from a gas cylinder.

Drawing of a spoon-drill

So, the question was sorted out, how to drill a well for water yourself. Several technologies were considered, each of which differs in the working tool used. It is the right choice of tool in accordance with the type of soil that guarantees the quality of the drilling work.

Where to drill?

The general scheme of the formation of aquifers in nature is shown in fig. The verkhovodka feeds mainly on precipitation, lies within the range of approximately 0-10 m. Riding waters can be drinkable without deep processing (boiling, filtration through shungite) only in some cases and subject to regular testing of samples in the sanitary supervision bodies. Then, and for technical purposes, the top water is taken by the well; the flow rate of the well in such conditions will be small and very unstable.

Formation and types of aquifers

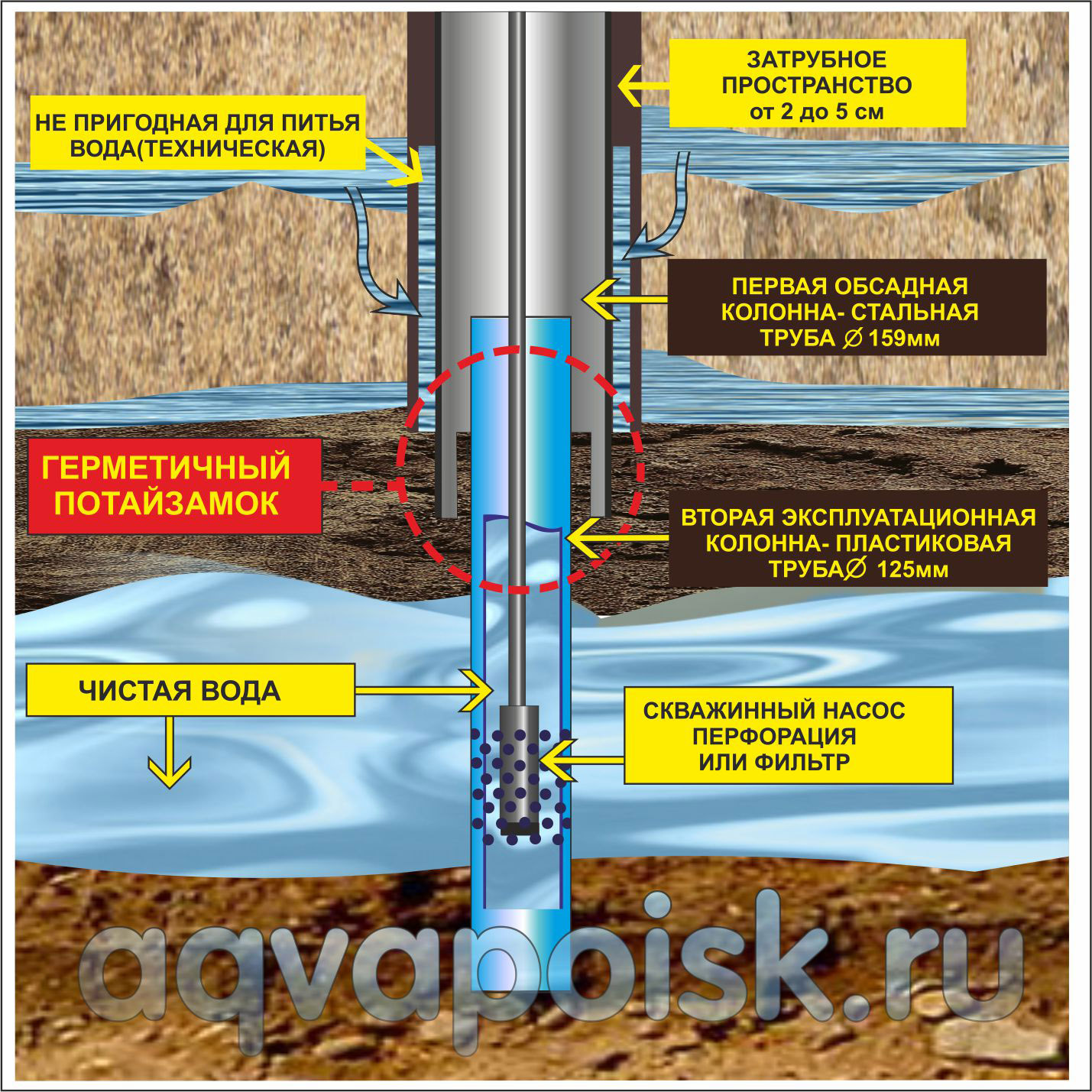

Independently, a well for water is drilled into interstratal waters; highlighted in red in Fig. An artesian well that provides water of the best quality for a very long time cannot be drilled on its own, even if a detailed geological map of the area is available: the depth is usually more than 50 m, and only in exceptional cases the reservoir rises to 30 m. In addition, independent development and the extraction of artesian waters is categorically, up to criminal liability, prohibited - this is a valuable natural resource.

Most often, it is possible to drill a well on their own into a non-pressure reservoir - sand soaked with water on a clay litter. Such wells are called sand wells, although a non-pressure aquifer can be gravelly, pebbly, etc. Non-pressure waters occur approximately 5-20 m from the surface. The water from them is most often drinking, but only according to the results of the check and after the buildup of the well, see below. The debit is small, 2 cu. m / day is considered excellent, and varies somewhat throughout the year. Sand filtering is mandatory, which complicates the design and operation of the well, see below. The lack of pressure tightens the requirements for the pump and the entire plumbing.

Pressure beds are already deeper, in the range of about 7-50 m. The aquifer in this case is dense water-resistant fractured rocks - loam, limestone - or loose, gravel-pebble deposits. The best quality water is obtained from limestones, and such wells last longer. Therefore, water supply wells from pressure layers are called limestone wells. Own pressure in the reservoir can raise water almost to the surface, which greatly simplifies the arrangement of the well and the entire water supply system. The debit is large, up to 5 cubic meters. m / day, and stable. A sand filter is usually not needed. As a rule, the first water sample is analyzed with a bang.

Work order

It is recommended to start with preparatory activities. The first stage is the formation of a platform for mounting a tripod. It is necessary to dig a small pit with a size of 1.5x1.5 m and a depth of up to 2 m. A home-made drilling rig is subsequently installed in this pit.Panel board structures, fixed on the walls of the pit, prevent collapses of loose rocks contained in the surface layers.

The next step is to install a do-it-yourself tripod on the prepared site. At the top of the triangular pyramid, a winch is mounted with a cable, on which a percussion instrument is fixed. A prerequisite is the vertical orientation of the structural parts of the drilling equipment. The slightest deviations will not allow the installation of a casing pipe in a drilled mine.

Subsequent work on drilling wells by the shock-rope method is carried out according to the following algorithm:

- from a height of two meters, a home-made driving glass is immersed into the ground with the help of a shock rod, destroying it;

- with a winch or a well gate, the working body rises to the surface, removing crushed soil particles;

- the projectile is released from destroyed soil fragments, and the procedure is repeated cyclically;

- depending on the characteristics of the rock, the drilling tool is replaced by a bailer or a chisel.

In some cases, the surface layers are moistened by watering the mine with water. In other situations, dry soil is poured into the face.

Assembling a spoon drill

It is necessary to prepare a pipe with a wall thickness of at least 5 mm. An incision is made on the side wall. Its width depends on the type of soil: the looser it is, the smaller the gap. The lower edge of the pipe is rounded with a hammer. This edge is bent so that a helical coil is formed. On the same side, a large drill is fixed. On the other hand, attach the handle.

The spoon drill includes a long metal rod with a cylinder at the end. The cylinder has 2 components, which are located along or in the form of a spiral.A sharp cutting edge is located along the bottom of the cylinder.

Types of wells for water

First of all, the design of the well is determined by the type of aquifer.

You need to find out how deep the water is in your area.

They are like this:

- Verkhovodka: the uppermost and most polluted layer, most often occurring at depths of up to 2.5 m (sometimes up to 10 m). With rare exceptions, the quality of this water does not allow it to be used for drinking and cooking - only for technical needs. It is mined using a regular well.

- Artesian waters: the deepest, cleanest and most productive aquifer. But the extraction of such water, which has an ideal quality, is allowed only with a special license. Yes, and it is impossible to build an artesian well on your own - usually the reservoir lies deeper than 50 m and only in very rare cases goes to a 30-meter horizon.

- Pressure reservoir: the usual depth of occurrence is from 30 to 50 m. The sources of this variety are often called “limestone wells”, although the aquifer can be formed not only by limestone (this is the most desirable option), but also by loams, as well as gravel and pebble deposits .

- Free-flow formation: it is here - to a depth of up to 20 m - that self-taught drillers most often get. As a rule, the formation consists of water-soaked sand, hence the name - sand well. Pebble, gravel structure and some other options are also not excluded. In most cases, the water is of acceptable quality, but it must be taken to the laboratory for analysis. There is no natural pressure, so a submersible pump and a strong plumbing are needed. You will also need to install a sand filter.

Limestone wells have two significant advantages:

- There is no need to install a sand filter at the bottom of the barrel.

- Water due to natural pressure can rise quite high, which facilitates the operation of the well and reduces the requirements for the pump and pipes.

Location of the aquifer

However, despite all the advantages, such a well is very rarely done on its own, since it is too deep.

According to calculations, with a water depth of more than 20 m, it is not advisable to make a well with your own hands - it will be cheaper to hire professionals with special equipment.

If you have reached free-flowing water at around 12-15 m, it is better not to stop, but if possible go deeper to get to the limestone.

A limestone well compared to a sandy one has a number of advantages, including greater productivity (5 cubic meters per day versus 2) and a longer service life - 50 years versus 15.

Features of hydrodrilling

The method consists in extracting the waste rock with water injected into the mine cavity under pressure. The drilling tool for removal of the destroyed layers is not applied.

The technology consists in a combination of 2 processes:

- the formation of a vertical well in the ground through the alternate destruction of soil layers;

- extraction of crushed soil fragments from the wellbore under the action of a working fluid.

The process of mixing the solution for drilling.

The creation of the necessary force required to plunge the cutting tool into the rock is facilitated by the dead weight of the equipment, consisting of a string of drilling rods and equipment for pumping fluid into the well.

To make a washing solution in a separate pit, a small amount of clay suspension is mixed in water, it is stirred with a construction mixer to the consistency of kefir. After that, the drilling fluid is directed into the borehole by a motor pump under pressure.

During hydraulic drilling, the liquid medium performs the following functions:

- removal of fragments of destroyed rock from the body of the water mine;

- cutting tool cooling;

- grinding the internal cavity of the pit;

- strengthening of the mine walls, which makes it possible to reduce the likelihood of the collapse of the working and falling asleep with the dump of the borehole shaft.

From pipe segments 1.5 m long, connected by threaded fasteners, a column is formed, which lengthens due to the growth of fragments as the well is deepened.

Hydrodrilling technology is optimal for rocks with a high concentration of sand and clay. It is not advisable to use this technique for arranging an autonomous source on rocky and swampy soils: massive and viscous soil layers are heavily washed out with water.

DIY drilling methods

- auger drill - as it deepens into the earth, it is built up with new sections of a metal pipe;

- bailer - a device with sharp teeth at the end and a valve that prevents the earth from spilling back into the mine;

- using soil erosion - hydraulic method;

- "needle";

- percussion method.

Using auger drilling technology, it is possible to dig a well up to 100 meters deep. It is difficult to do this manually, therefore, stationary electrical installations are used, and the drill is built up with new sections as it deepens. Periodically it is raised to pour out the soil. To prevent the walls from crumbling, a casing pipe is laid after the drill.

If the drill cannot be built up, a bailer with sharp edges is attached to its base and the drill screws it in a few meters deeper. Next, the pipe is lifted and the accumulated soil is poured out.

The work with the auger can be done on soft ground. Rocky terrain, clay deposits and club mosses are not suitable for this method.

The bailer is a metal pipe with solid steel teeth soldered at the end. A little higher in the pipe there is a valve that blocks the exit to the ground when the device is lifted from a depth. The principle of operation is simple - the bailer is installed in the right place and manually turned, gradually deepening into the soil. The method takes more time than using electrical equipment, but it is economical.

The device needs to be periodically lifted and poured out of the earth from the pipe. The deeper the pipe goes, the harder it is to lift it. In addition, scrolling requires the use of brute force. Most often there are several people working. To make the soil easier to drill, it is washed out with water, pouring it from above into the pipe using a hose and a pump.

Percussion drilling is the oldest method still in use today. The principle is to lower the metal cup into the casing and gradually deepen the well. For drilling, you need a frame with a fixed cable. The method requires time and frequent lifting of the working pipe to pour the soil. To facilitate the work, use a hose with water to erode the soil.

The "needle" method for the Abyssinian well: when the pipe is lowered, the soil is compacted, so it is not thrown to the surface. To penetrate the soil, a sharp tip made of ferroalloy materials is needed.You can make such a device at home if the aquifer is shallow.

The method is cheap and time consuming. The disadvantage is that such a well will not be enough to provide a private house with water.

Types of wells

Drilling a well in the country is not so difficult. Its price will depend on the depth of the water. A sand well will be much cheaper than an artesian well, and this should also be taken into account.

Well on the sand

Done to a great depth. Therefore, it is quite possible to do all the work with your own hands and this will significantly reduce the cost of your venture. Before starting work, you should find out what quality the water is at a shallow depth. To do this, it is best to take a sample from the neighbors and take it for examination and check the quality. We will give the parameters below.

Suitable for the place where you live permanently. This water is of better quality. But the work will cost more. Here it would be better to hire a specialized organization. And immediately it will be necessary to provide for its cleaning. It is located in lime layers and therefore has a high iron content. Immediately provide for proper filtering.

Attention: If you do not live permanently in the country and you only need water for irrigation, then you can safely make such a design

Determining the quality of water

Water in a well or well is considered drinking water in the following cases:

- When the water is clear thirty centimeters deep;

- When nitrate impurities do not exceed 10 mg/l;

- When one liter of water contains no more than 10 Escherichia coli;

- When the taste and smell on a five-point scale, water is estimated at least three points.

To determine these indicators, water must be subjected to laboratory analysis in the sanitary and epidemic service.

How to drill a well

Let's analyze this process from a theoretical point of view:

- Work begins with digging a hole, whose depth and diameter must be at least two meters, or a side of one and a half meters. This measure prevents further shedding of the soil of the upper layer.

- The pit is strengthened with plank shields. Further, with the help of a column and a drilling rig, a well is drilled. The drill column is suspended on a tower at the central point of the future well.

- The drill string consists of several rods, which, with the help of adapter sleeves, are lengthened during the drilling process. The drill head is mounted at the end of the column.

- The tower is mounted from logs, steel pipes, a channel or a corner, which are made into a tripod, at the top of which a winch is attached.

Attention: If the water is shallow, drilling can be done without a tower. In this case, special shortened rods one and a half meters long are used. If you cannot do without a tower during drilling, the length of the rods in this case should be at least three meters

If you cannot do without a tower during drilling, the length of the rods in this case should be at least three meters.

What to drill

The equipment and method of drilling is selected based on the type of soil. The tool used must be made of carbon steel.

We select tools and materials

Drilling is carried out using the following drill heads:

- For drilling in clay soils, a drill is used in the form of a spiral with a base of 45-85 mm and a blade 258-290 mm long.

- In percussion drilling, a drill bit is used.The drill can have a flat, cruciform and other shapes.

- Drilling in loam, sandy clay or clayey sand is carried out using a spoon drill made in the form of a spoon and having a spiral or longitudinal slot. This drill has a diameter of 70-200 mm and a length of 700 mm and deepens for a passage of 30-40 cm.

- Extraction of loose soil is carried out with the help of a drill-bailer using the impact method. The bailers are made from a three-meter pipe and have a piston and ordinary appearance. Inside the bailer should have a diameter of 25-96 mm, outside 95-219 mm, its weight should be 89-225 kg.

Drilling is a cyclic process, periodically accompanied by cleaning of the drilling tool from the soil. Cleaning is carried out with the complete extraction of the drill from the soil. Accordingly, the difficulty of extracting them from the well depends on the length of the hose.

Device characteristics

The first in the list of devices for creating a well is a drilling rig. It is used for digging soil for deep wells. With the help of this design, it became possible to immerse the drill to a great depth. You can also carry out its lifting together with the rods. If you immerse the device for short distances, then you can get it manually, without using a tower.

What are drill rods? They are made from ordinary pipes, which are connected to each other using threads or, in rare cases, dowels. For the manufacture of cutting nozzles, sheet steel with a thickness of 3 mm is used. After their manufacture, it is necessary to sharpen the edges of the nozzles

In this case, it should be taken into account that during the rotational movements of the drill mechanism, they must cut into the ground in a clockwise direction.

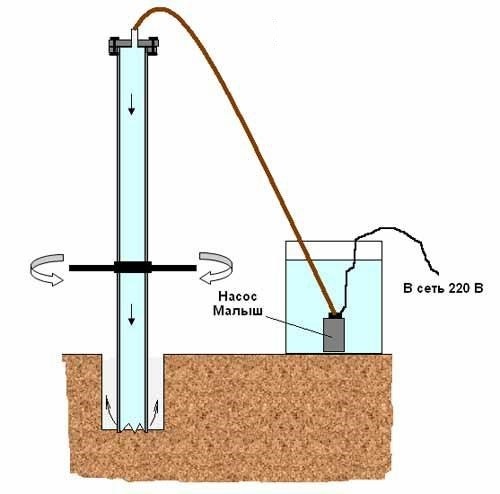

Manual well drilling

Most often, summer residents are interested in how to drill a well with their own hands, and not just a well. You will need such equipment for drilling wells as a drill, a drilling rig, a winch, rods and casing pipes. The drilling tower is needed for digging a deep well, with its help, the drill with rods is immersed and lifted.

rotary method

The simplest method of arranging a well for water is rotary, carried out by rotating the drill.

Hydro-drilling of shallow wells for water can be carried out without a tower, and the drill string can be removed manually. Drill rods are made from pipes, connecting them together with dowels or threads.

The bar, which will be below all, is additionally equipped with a drill. The cutting nozzles are made of sheet 3 mm steel. When sharpening the cutting edges of the nozzle, it must be taken into account that at the moment of rotation of the drill mechanism, they must cut into the soil in a clockwise direction.

The tower is mounted above the drilling site, it must be higher than the drill rod in order to facilitate the extraction of the rod during lifting. After that, a guide hole is dug for the drill, about two spade bayonets deep.

The first turns of rotation of the drill can be done independently, but with a greater immersion of the pipe, additional forces will be required. If the drill cannot be pulled out the first time, you need to turn it counterclockwise and try to pull it out again.

The deeper the drill goes, the more difficult the movement of the pipes.To facilitate this task, the soil must be softened by watering. When moving the drill down every 50 cm, the drilling structure must be taken out to the surface and cleaned from the soil. The drilling cycle is repeated anew. At the moment the tool handle reaches the ground level, the structure is increased with an additional knee.

As the drill goes deeper, the rotation of the pipe becomes more difficult. Softening the soil with water will help facilitate the work. In the course of moving the drill down every half meter, the drilling structure should be brought to the surface and freed from the soil. The drilling cycle is repeated again. At the stage when the tool handle is level with the ground, the structure is extended with an additional knee.

Since lifting and cleaning the drill takes most of the time, you need to make the most of the design, capturing and lifting up as much of the soil as possible. This is the principle of operation of this installation.

Drilling continues until an aquifer is reached, which is easily determined by the condition of the excavated land. Having passed the aquifer, the drill should be immersed a little deeper until it reaches a layer that is located below the aquifer, waterproof. Reaching this layer will make it possible to ensure the maximum inflow of water into the well.

It is worth noting that manual drilling can only be used to dive to the nearest aquifer, usually it lies at a depth not exceeding 10-20 meters.

In order to pump out dirty liquid, you can use a hand pump or a submersible pump. After two or three buckets of dirty water are pumped out, the aquifer is usually cleared and clean water appears.If this does not happen, the well needs to be deepened by about another 1-2 meters.

screw method

For drilling, an auger rig is often used. The working part of this installation is very much like a garden drill, only much more powerful. It is made from a 100 mm pipe with a pair of screw turns welded onto it having a diameter of 200 mm. In order to make one such turn, you need a round sheet blank with a hole cut in its center, the diameter of which is slightly more than 100 mm.

Then, a cut is made at the workpiece along the radius, after which, at the place of the cut, the edges are parted in two different directions, which are perpendicular to the plane of the workpiece. As the drill sinks deep, the rod on which it is attached increases. The tool is rotated by hand with a long handle made of pipe.

The drill must be removed approximately every 50-70 cm, and due to the fact that the more it goes deep, it will become heavier, so you will need to install a tripod with a winch. Thus, it is possible to drill a well for water in a private house a little deeper than the above methods.

You can also use the manual drilling method, which is based on the use of a conventional drill and a hydraulic pump:

Option #2 - rotary drilling method

When drilling deep wells in a rotary way, a special drill pipe is used, in the cavity of which a rotating shaft is immersed into the well, equipped with a tip - a chisel. The weight on the bit is created by the action of the hydraulic installation. This is the most common drilling method, with the help of which any depth of the water well is reached.To wash out the rock (soil) from the well, a drilling fluid is used, which is fed into the pipe in two ways:

- using a pump, it is pumped into the drill pipe, after which the solution with the rock flows out by gravity through the annulus (direct flushing);

- gravity flows into the annulus, and then the solution with the rock is pumped out of the drill pipe using a pump (backwash).

Backwashing allows you to get a greater flow rate of the well, as it is possible to better open the desired aquifer. However, this technology requires the involvement of sophisticated equipment, which affects the increase in the cost of work. Drilling based on direct flushing is cheaper, therefore, most often, owners of private houses order this option for constructing a well for water intake.

You are unlikely to make an artesian well yourself, such drilling is carried out using drilling machines by specialized companies

How to make a homemade earth drill with an engine

If you are interested in a drill that works automatically with minimal human effort, then there are several ideas, for example, from a chainsaw. In this case, you should do everything right so as not to hurt yourself.

First of all, the engine power is calculated. The motor on the chainsaw has a large number of revolutions. If the drill rotates at such a speed, then it is extremely difficult to control such a machine. Moreover, there is a serious load on the motor.

You can learn about all the details of this development by watching the prepared video. It tells in detail about how to make a power drill based on a chainsaw:

Plus, there are craftsmen who use the hammer motor when drilling small wells.

In this case, it is important to make the right nozzle and calculate the size of the drilling rig. Here you can also see the details of this miracle: