- Registration and Permits

- Tips on how to drill a well with your own hands: preparation

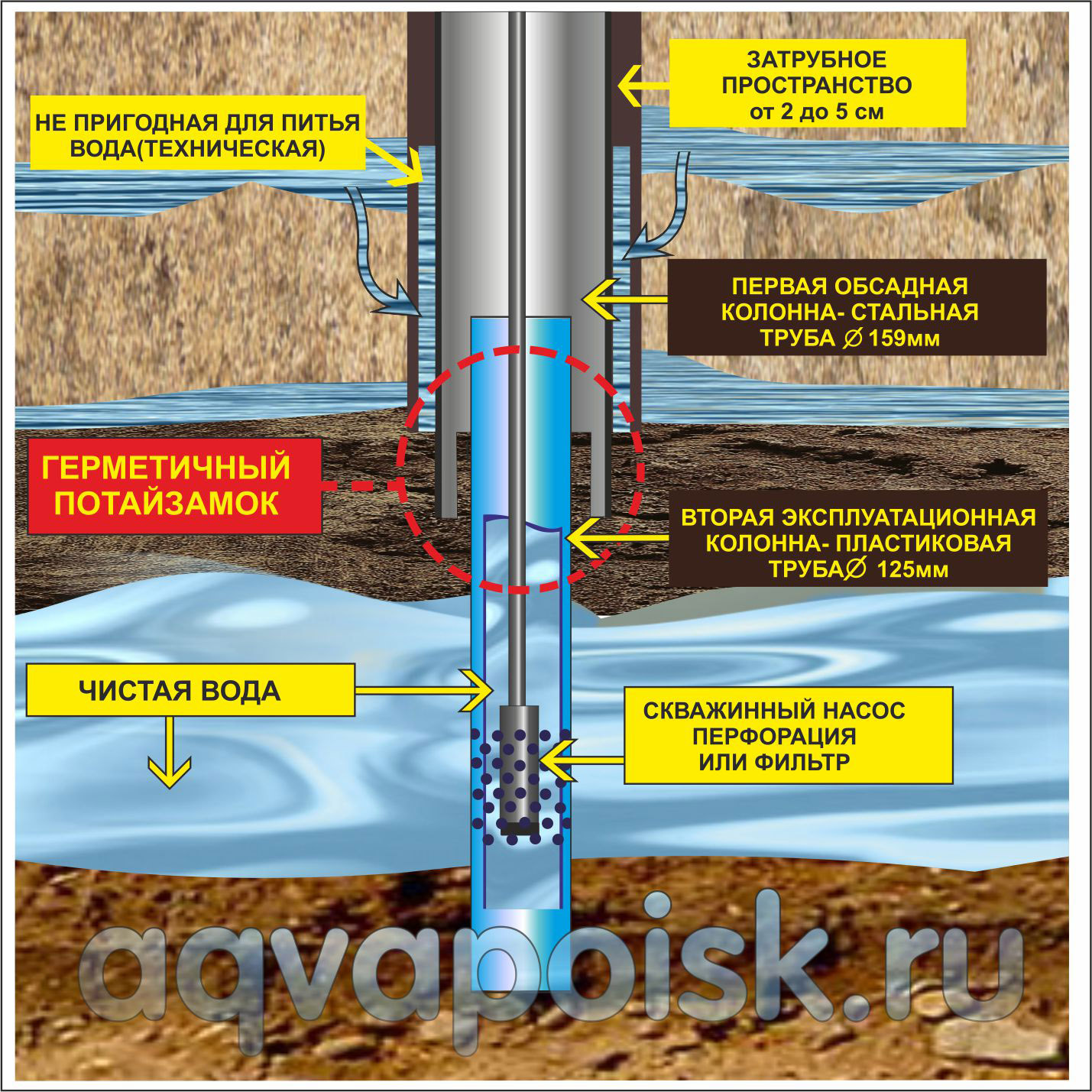

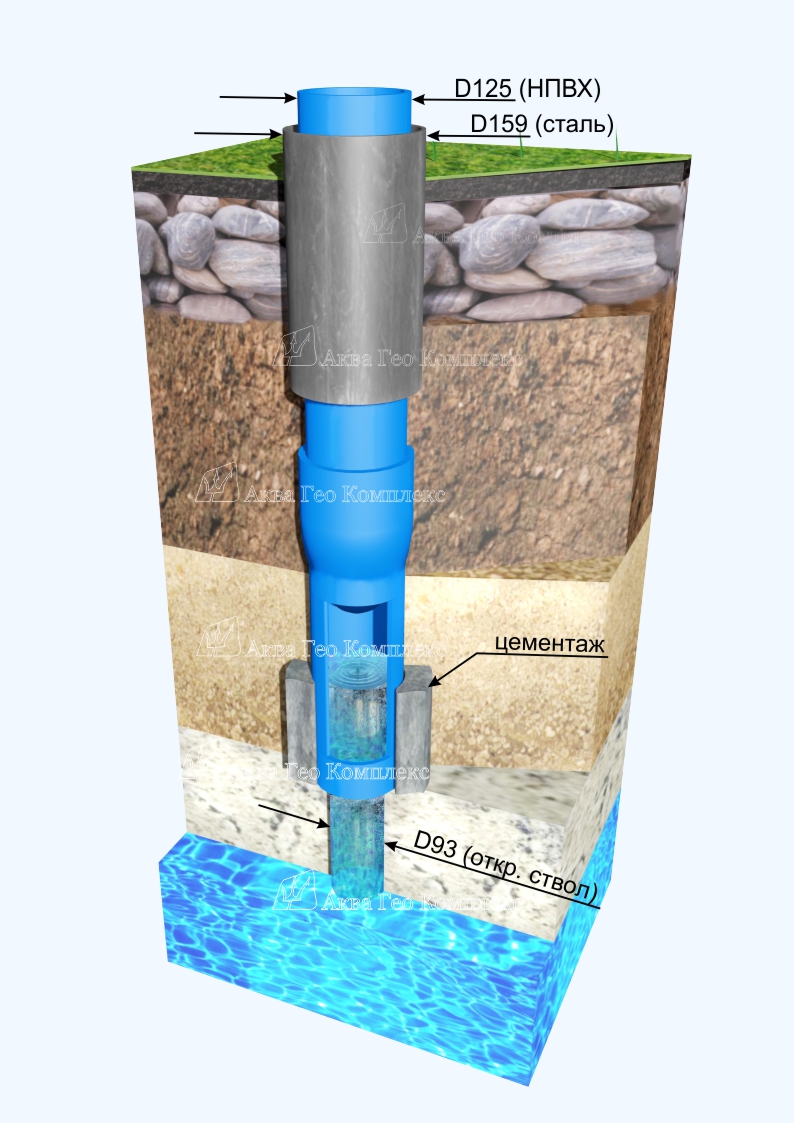

- Device and circuit

- The cost of hydraulic drilling

- How to make a well in the country

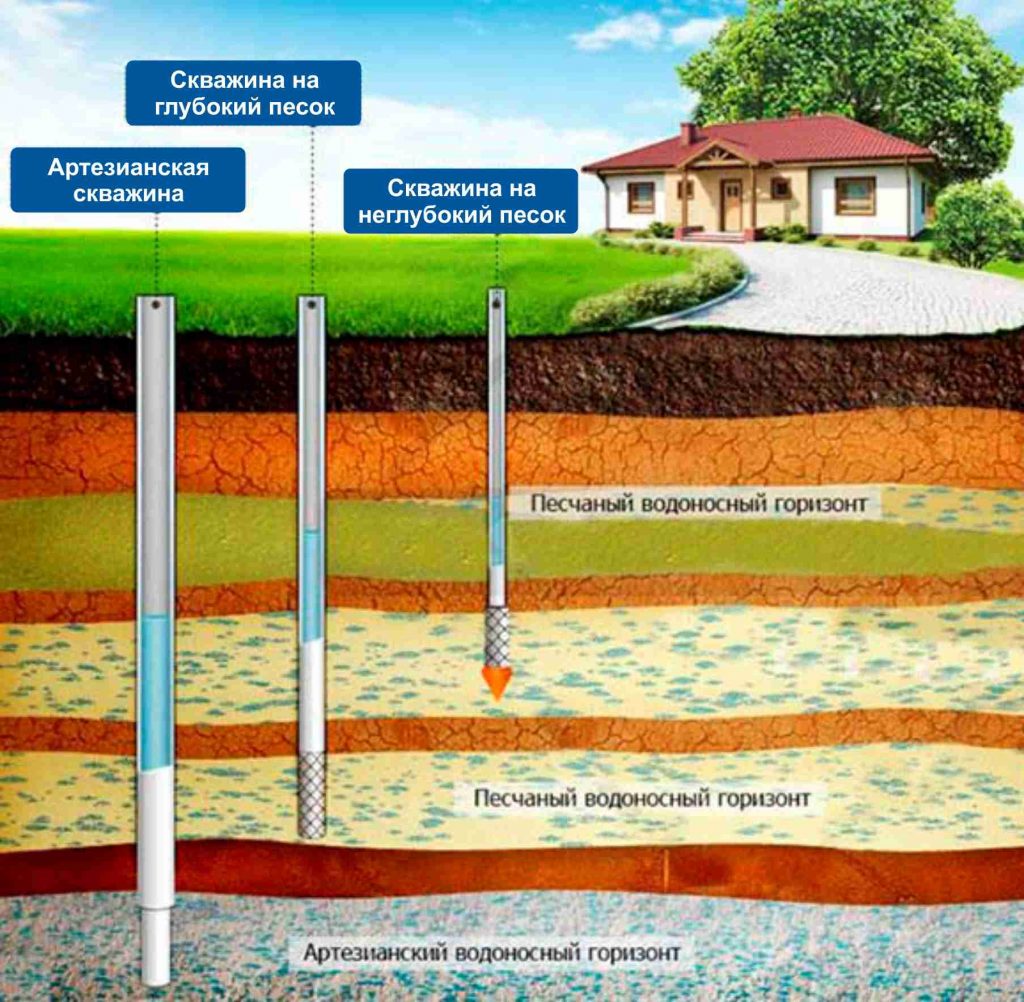

- Before you figure out what water wells are

- Well Installation Instructions

- Filtration of water from a well

- Necessary equipment for work

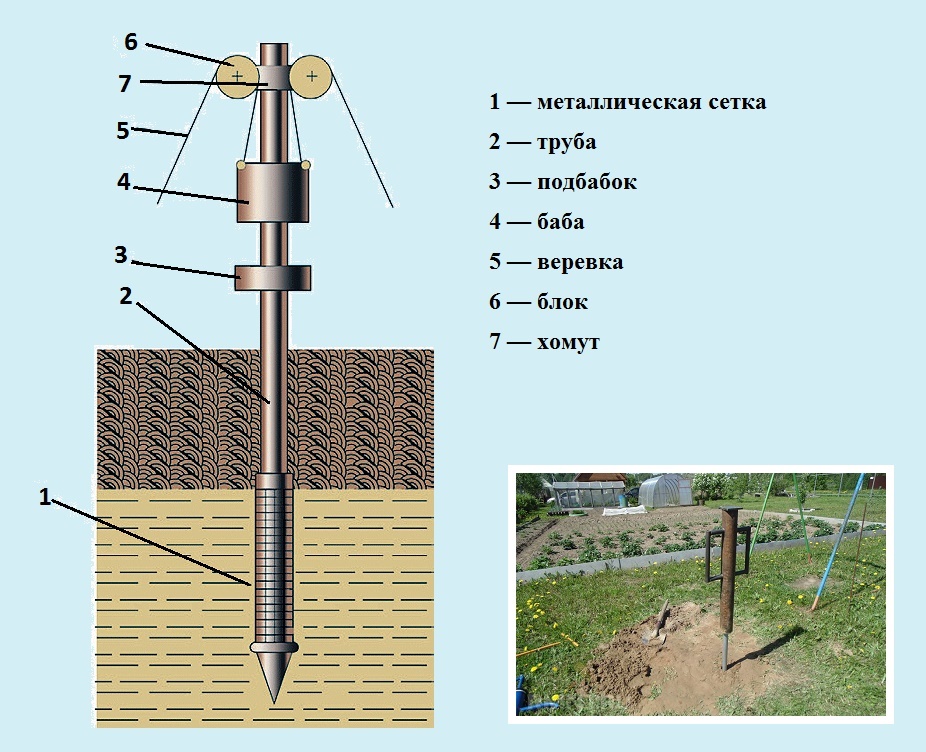

- Do-it-yourself well drilling methods in the country

- Features of the installation of casing pipes

- A simple do-it-yourself water well drilling technology

- Artesian well

- Advantages

- Flaws

- Conclusions and useful video on the topic

Registration and Permits

Activities for opening a business for the provision of water drilling services are carried out in accordance with the following calendar plan:

| Stage/month, decade | 1 | 2 | ||||

| Dec 1 | Dec 2 | Dec 3 | Dec 1 | Dec 2 | Dec 3 | |

| Business registration, opening a current account | X | X | X | |||

| Signing a leasing agreement | X | X | ||||

| Acquisition of technological and auxiliary drilling equipment | X | X | X | |||

| Issuance of permits and approvals | X | X | X | |||

| Installation, commissioning and testing of drilling equipment | X | X | X | |||

| Set of workers | X | X | ||||

| Conclusion of contracts with consumers of services | X | X | X | X | ||

| Start of activity | X |

To register and start this business, you need to collect the following documents:

- License for the right to use the bowels of the earth (the document is issued by the territorial department for the use of natural resources).

- License for the right to operate drilling equipment.

- Contract for drilling works.

The founder should keep in mind that the provision of services is allowed only for those consumers who have:

- Registration documents for the right of ownership (lease) of the land plot.

- Well project.

- Coordination of the well drilling site with the SES authorities and the local department of the geological service.

Depending on the region in which the services are supposed to be provided, the package of documents may vary.

After the project reaches the payback point, it is possible to provide services to consumers in obtaining these permits and conducting approvals for an additional fee.

For this, a specialist working under a contract will be involved.

Tips on how to drill a well with your own hands: preparation

To begin with, the depth of the aquifer is established. Neighbors should be consulted on this matter. If they did not pierce wells, then you should trust the specialists.

To drill a well, you will need special tools. To equip a source of great depth, you will need special equipment - drilling rigs. For small wells, a tripod and a winch are used.

Drilling rig components:

- Drill or coil;

- Column for drilling;

- Rods for drilling;

- Column pipe.

In addition, a caisson, a pump, plumbing pipes, a casing pipe and filters will be required to equip the well. You should also stock up on a shovel. All the necessary elements and tools should be prepared in advance.

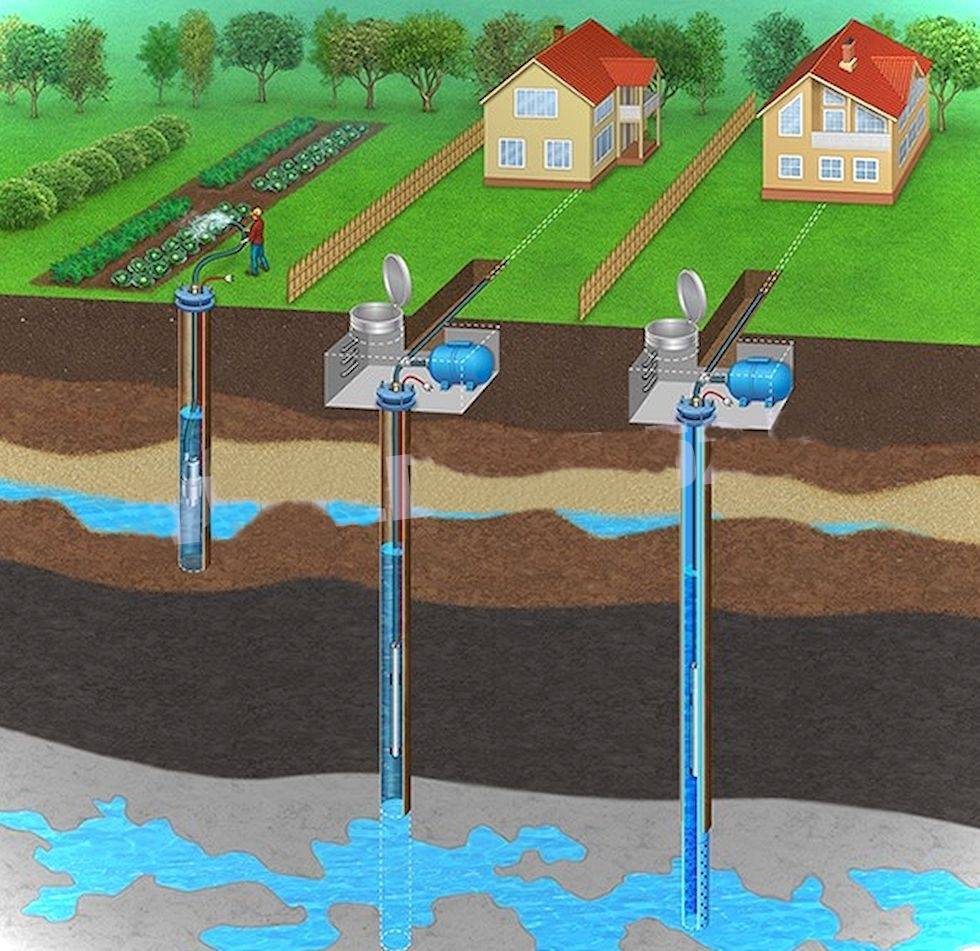

Device and circuit

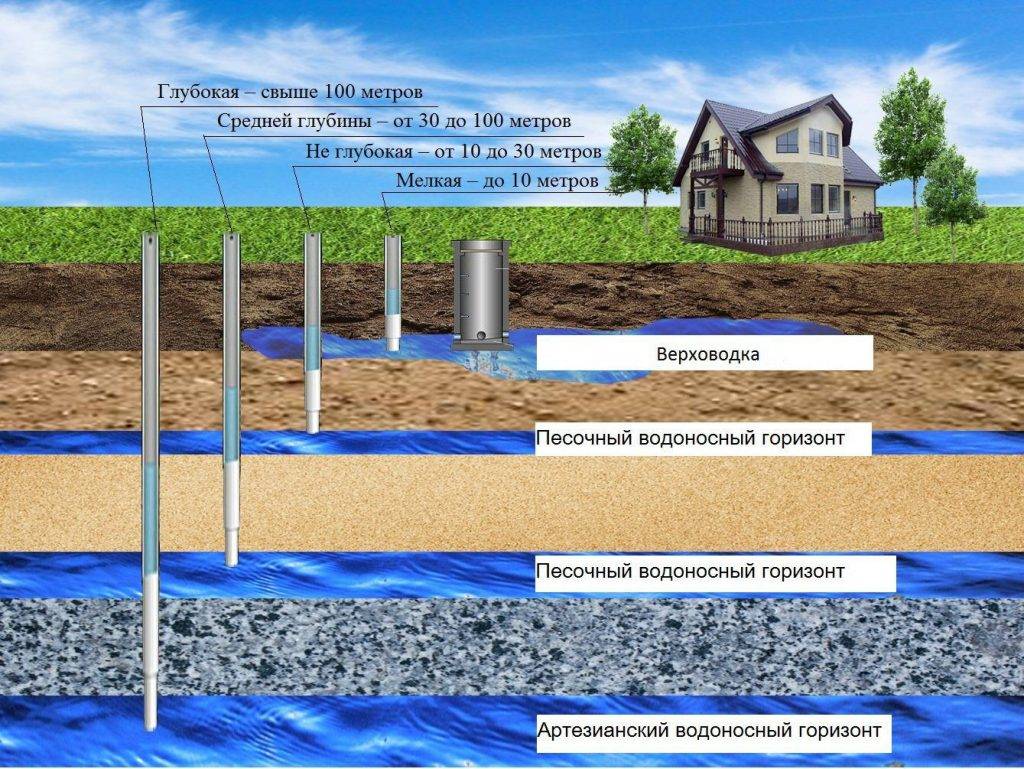

The diagram shows water layers.Verkhovodka is fed by precipitation and lies at a depth of up to 10 meters. The quality of the water allows it to be immediately used for drinking. The source with interstratal waters is made independently. To get better water, an artesian well is made.

According to SNiPs and established standards, the source is protected from any kind of pollution. Distance from the septic tank is 15 meters. Cesspools at least 50 m. From warehouses, industrial enterprises more than 100 meters. The distance from a neighboring source, residential buildings, chicken coops and barns is also taken into account.

The cost of hydraulic drilling

The price for drilling 1 linear meter is 2000-3000 rubles, depending on the region. A number of factors will also affect the formation of the price, such as:

- drilling type;

- materials used;

- distance from the contractor to the customer.

If we make a calculation for a small well, 10 meters deep, then experts will make it turnkey for about 20,000-30,000 rubles. This includes the cost of labor and the cost of materials.

- steel pipes - 10 m (if using perforating technique);

- material for the manufacture of tripods;

- headstock, ropes, rollers;

- pump.

In addition, additional materials will be needed - self-tapping screws, stainless steel mesh, sealant for threaded connections. Even a preliminary calculation of the price shows that it is more economical to break through a shallow well and do it yourself.

But if there is a need for a large debit or artesian water, then you will have to turn to specialists, since this can only be done with special equipment!

How to make a well in the country

Almost every owner of a country house, and even a villager, wants to have a well on his site.Such a source of water from which it would be possible to constantly obtain high-quality water.

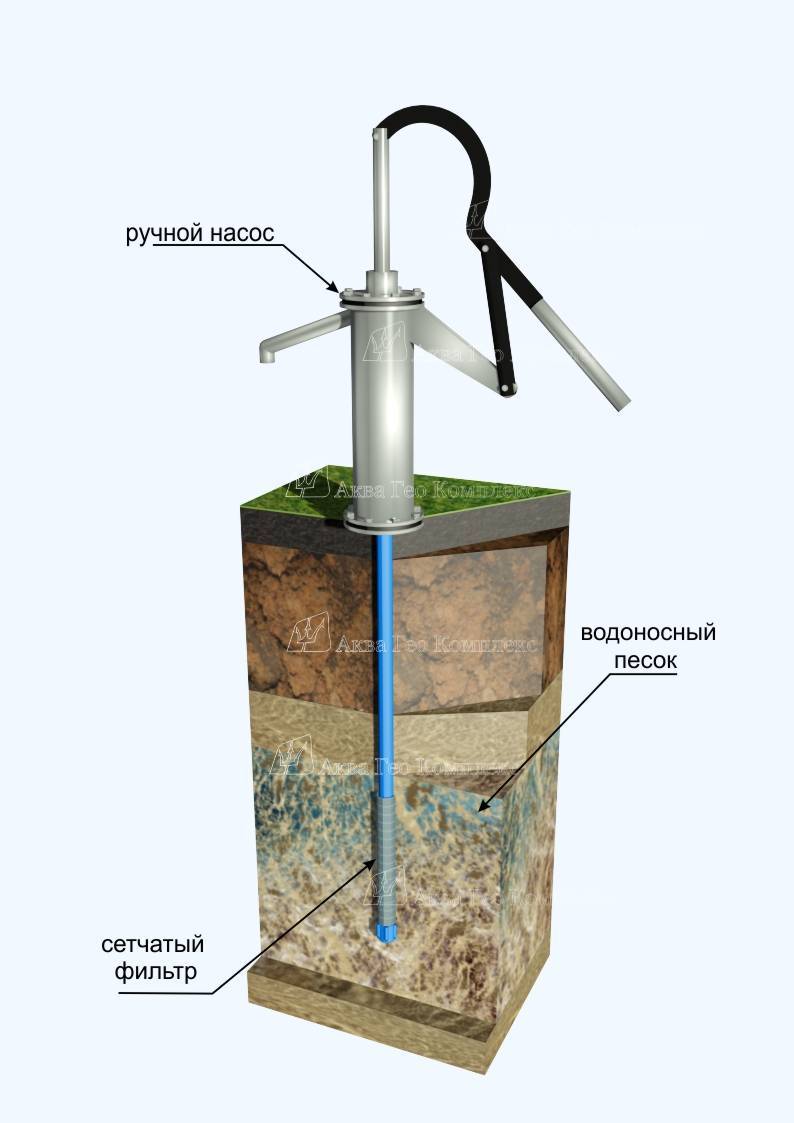

It is worth noting that if the water is at a depth of up to ten meters, then such a well can be drilled independently. This is not such a laborious process as it might seem at first glance. We need a standard pump. It will pump out water and at the same time, in a sense, drill a well.

Video-how to drill a well in the country

Let's move on to the drilling process itself. It should be noted that the pipe that we will lower into the well must be located vertically. Water will be pumped into this pipe using a pump. The teeth should be located at the bottom end of the pipe. Such teeth can be made by hand. Water, which is under pressure from the lower end, erodes the soil. Since the pipe is heavy, it sinks lower and lower, and soon reaches the aquifer.

Video-how to drill a well under water

In order to really get drilling, we need only a steel pipe. The radius of such a pipe must be at least 60 mm (preferably more). Such a pipe will serve as a casing pipe. The length of such a steel pipe must not be less than the depth of groundwater. The end of the pipe, which we close at the top with a flange and a special fitting.

To do this, we use a pass-through fitting. Through this element, water will pump through the hose. We also need to use a welding machine. With it, we will weld four "ears" with special holes. These holes should fit the M10 bolts.

As a water tank, we will take a barrel with a volume of 200 liters.In order for us to somewhat speed up the drilling process, we need to shake the pipe and turn it a little either clockwise or counterclockwise. Thus, we will wash out a large amount of soil. For the convenience of pipe rotation, we can use a gate. To do this, take two metal tubes and attach them to the pipe. For these purposes, we can use special clamps.

For drilling, several people are needed (two are possible). In the place allotted for the well, a hole is dug. The depth of such a pit must be at least 100 cm. A pipe is lowered into this pit. And the jagged end down. Next, using the collar, deepen the pipe. It is worth noting that the pipe must be in a vertical position. Next, we turn on the pump. The hole will fill with water. We scoop it out. Then it can be spilled through a sieve and poured back into the barrel. It is quite possible to drill six meters in a few hours.

Here you can read:

how to drill a well for water, how to drill a well for water video, how to drill a well, how to make a well for water, how to make a well for water on the site video

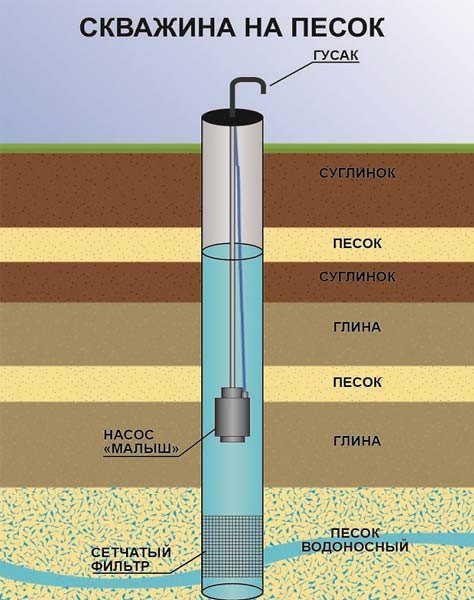

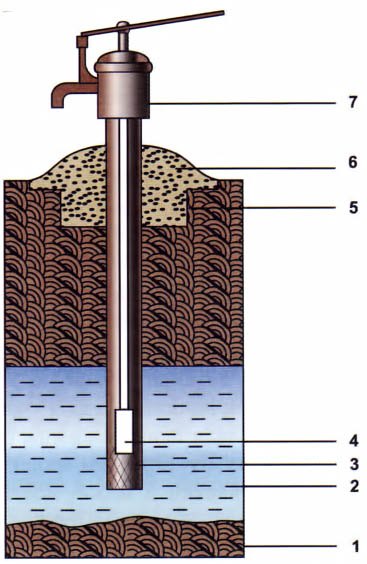

Before you figure out what water wells are

When you start drilling even at shallow depths, the first thing you will encounter is an aquiclude, which is often made of clay slabs, and much less often of rock. If, on the surface of the aquiclude, there is loose and porous soil (limestone, gravel, sand, silt, marl, etc.), and the terrain conditions allow a sufficient amount of water to accumulate in this layer, an aquifer is obtained.

It is from it that water can be extracted at a shallow drilling depth. In its layered structure, the soil resembles the beloved Napoleon cake. Just as the cream is mixed with cakes, so in the ground the aquicludes alternate with loose rock, which causes the formation of an aquifer. By the way, purity and fullness depend on depth. But this is considered a general trend, since the depth of occurrence on a particular land plot depends for the most part on the location and structure of the land, as well as on the terrain and precipitation.

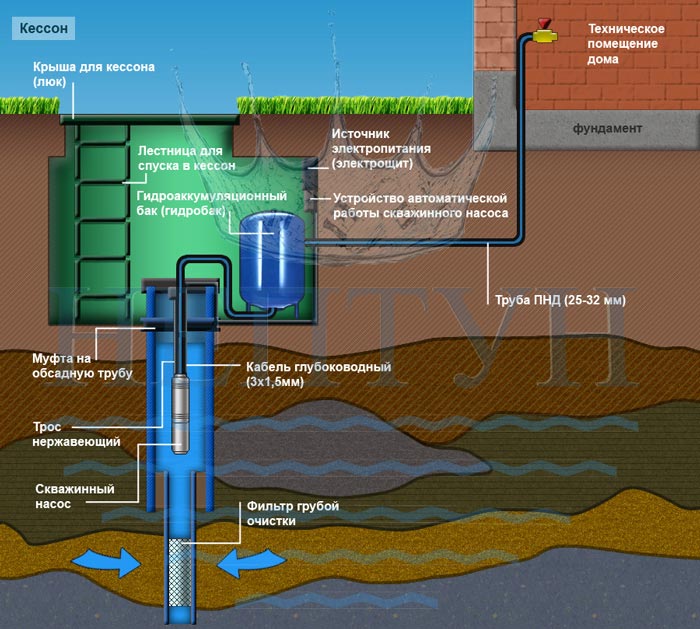

Well Installation Instructions

Drilling wells on your own requires effort and labor. Well drilling instructions:

- You must choose a suitable location. Preferably closer to home. Also, the place should have at least 4 meters in length and width, so that it is convenient for you to work.

- We choose the necessary tool for drilling, these include: drill-chisel, drill-spoon, auger, shock-rope structure. We get to work, we drill a well using the above methods.

- Installation of pipes and pumps. We fill the bottom of the well with sand or small gravel. It must be cleaned with a bailer. We prepare the first pipe in advance, because it will have to be lowered immediately after drilling is completed, otherwise the walls of the pit will crumble. We drill holes in the lower part of the pipe, approximately to a height of 15 centimeters from the edge. This helps her "absorb" more water. A filtration mesh is attached to the end.

- One knee is one hundred percent not enough, its length reaches 2 - 2.5 meters. Installation and maintenance will become difficult with large pipes. Therefore, they are screwed together and threaded. The bottom one should rest against the very bottom of the pit.After installing the pipes inside them, lower the pump.

- Installation of the caisson and equipment. The head of the well must be necessarily covered, insulated. In the caisson, you put the equipment at your discretion. In practice, we mount everything in a chamber, which is more compact, easier to maintain and repair.

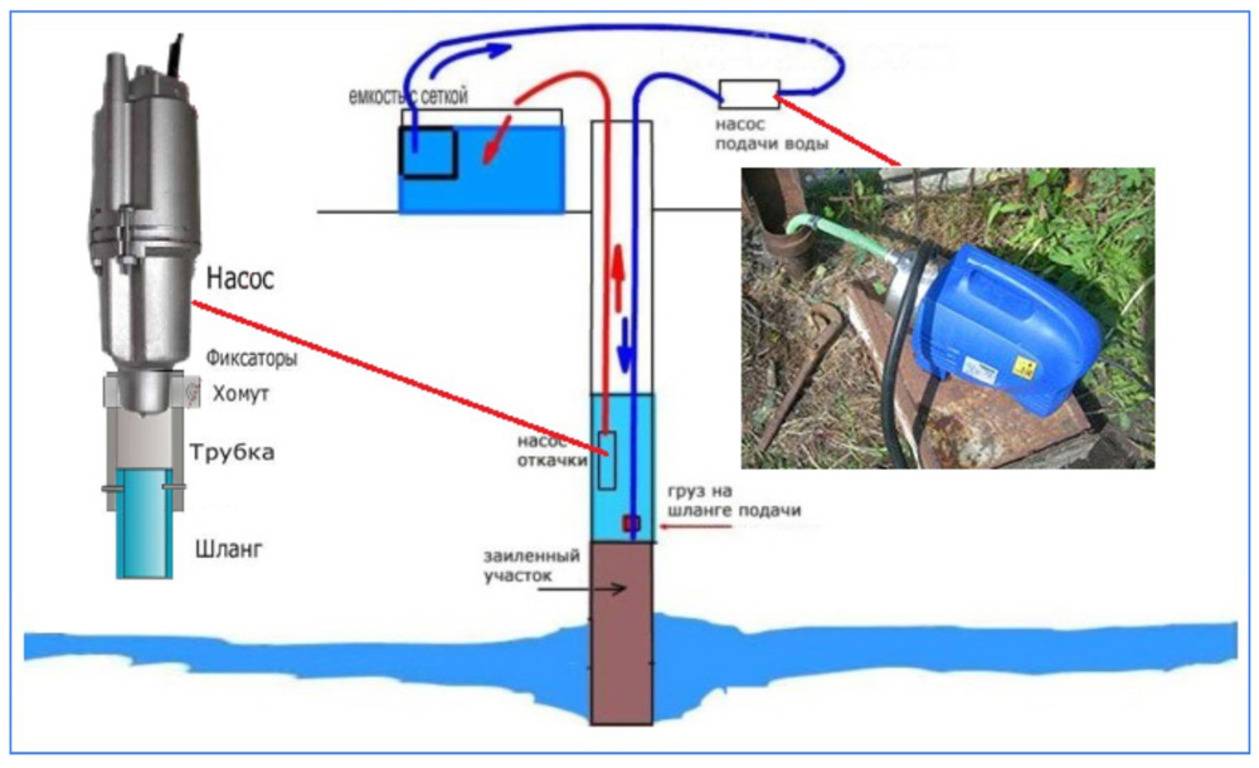

Filtration of water from a well

The drilling process can be considered completed only after the completion of the final stage regulations. Here it will be necessary to take care of protecting the casing with a special head. We fill the space between the casing pipe and the soil with liquid clay, this will prevent the ingress of bacteria, protect it from precipitation and freezing. And of course, we equip the water supply pipe with filters. In the water treatment system for water from a well, coarse and fine filters of your choice are used:

- Mesh filters. In such a filter, foreign particles are retained by the mesh. It allows water to pass through and retains everything superfluous on the surface of the mesh. Periodically, the mesh needs to be cleaned, it's not difficult if you know how. We simply disassemble the filter, remove dirt from the mesh, put it in place and assemble the filter.

- Disc filters. In them, everything extraneous is captured by a package of disks made of synthetic fabric. The efficiency of a disc filter is higher in comparison with a mesh filter, it is also easier to rinse the discs during cleaning, it is disassembled in the same way as a mesh one, it is enough to understand how easy it is, just take the filter in your hands.

- Cartridge filters are fine filters, unlike mesh and disc filters. Such a filter works not only against mechanical suspensions in water, but also fights its bacterial pollution, changes its chemical nature, removing, for example, chlorine and other harmful substances.Water in such filters is purified by replaceable cartridges through which water passes. Filling cartridges copes with the task of deep water purification, the difference between them is in the properties of selectivity to different water pollutants. Cartridges require periodic replacement. And if you wish, you can do this work yourself. Together with the cartridge filter there is a special key, with which we unscrew the flask in which the cartridge is located. There are three of them in the standard filter. We remove the cartridge from the flask, wash the flask, insert another one and assemble it back, not about the sealing gasket in the connection of the flask and the filter housing. So alternately change all three cartridges. We look for water passes, if necessary we tighten it, that's it, the filter is again like new.

- Pressure filters. The most technically complex of all their types, which have found application in everyday life, although until recently they worked only in complex chemical industries. This filter is already a stationary installation with complex automation, where water under pressure and with air supply is cleaned with special fillers to the maximum clean. This device requires maintenance only by trained specialists, but the frequency of routine maintenance is high, once every few years.

We remind you that before servicing the filter, be sure to turn off the water in the system and relieve pressure in it by opening the tap of any plumbing fixture. If we talk about filters, and not only about pressure ones, then it is more reliable to entrust the installation and maintenance of any filters, even mesh ones, to specialists, because no one wants water from a well to turn a house into a pool

Necessary equipment for work

The standard type of hydraulic drilling work is carried out by means of small-sized installations. For your own site, this is a wonderful solution and the best way to get water on your own.

It is necessary to supply the working fluid to the wellbore with a significant pressure, and this requires a pump or motor pump for contaminated fluids.

Sometimes, to increase the breakdown force, shot or coarse sand is added to the working solution. For crushing large pebbles, which can be found in sandy layers, cone and cutter chisels are useful.

If during the drilling of wells or the construction of wells in neighboring areas there were boulders or large pebbles, the starting rod must be equipped with a reinforced drill - a chisel. The tool must be fixed so that it does not interfere with the supply of water to the barrel

The most demanded by the consumer for the purposes of hydraulic drilling are special small-sized MBU units. This is a unit with a height of 3 m and a diameter of 1 m.

This build includes:

- collapsible metal frame;

- drilling tool;

- winch;

- an engine that transmits force to the drill;

- swivel, part of the contour for sliding fastening of parts;

- water motor pump to provide pressure in the system;

- exploration or petal drill;

- drill rods for string formation;

- hoses for supplying water to the swivel from the motor pump;

- Control block.

Among the necessary equipment it is also desirable to have a current converter. It is necessary for the energy supply of the process to be stable. You also need a winch for lifting / lowering casing and stacking pipes.

When choosing a motor pump, it is better to stop at a more powerful device, since large loads are expected.For hydro-drilling, you will also need such a plumbing tool as a pipe wrench, a manual clamp, and a transfer plug.

The hydraulic drilling process from the very beginning to the end of the work includes a constant circulation of the working fluid. With the help of a pump, an aqueous suspension with eroded soil leaves the well, enters directly into the pit, and, after the sedimentation of the suspension, is again fed into the well.

In addition to this procedure, it is possible to carry out hydraulic drilling of shallow wells for water without using a pit. This method does not require a recess for settling the working solution, saves time and makes it possible to drill a well even in garages and basements.

If there is an abandoned pond near the site, then you can also do without the installation of sumps - pits. There are no special requirements for the quality of water supplied to the well

For hydrodrilling, a motor pump is selected that is capable of pumping heavily polluted water. It is advisable to buy a unit with a head of 26 m, a pressure of 2.6 atm and a capacity of 20 m3 / h.

More powerful pump guarantees faster, trouble-free drilling and better hole cleanout

For quality drilling, it is important that a good flow of water always comes from the well.

Do-it-yourself well drilling methods in the country

Drilling technique may vary. It all depends on the type of drilling rig. In total, there are 3 drilling methods.

Well drilling methods:

- Shock-rope;

- screw;

- Rotary.

We drill a well using a percussion rope method through a special load, which is suspended by a cable from the frame. The load is welded with triangular teeth. With the help of raising and lowering the system, the well is drilled.

The auger installation resembles an ordinary garden drill, but is more powerful.Several turns of the screw are welded onto the pipe and the tool is ready. The rotation is done by hand thanks to the long handle. Every half a meter of immersion, the drill has to be removed and cleaned.

The rotary system is considered the most efficient and suitable for any well. A drill column is attached to a drill rod or column. Rotary drilling combines the rotation of the drill and impact on the ground. At the same time, the design of the system allows pumping liquid into the well, flushing it.

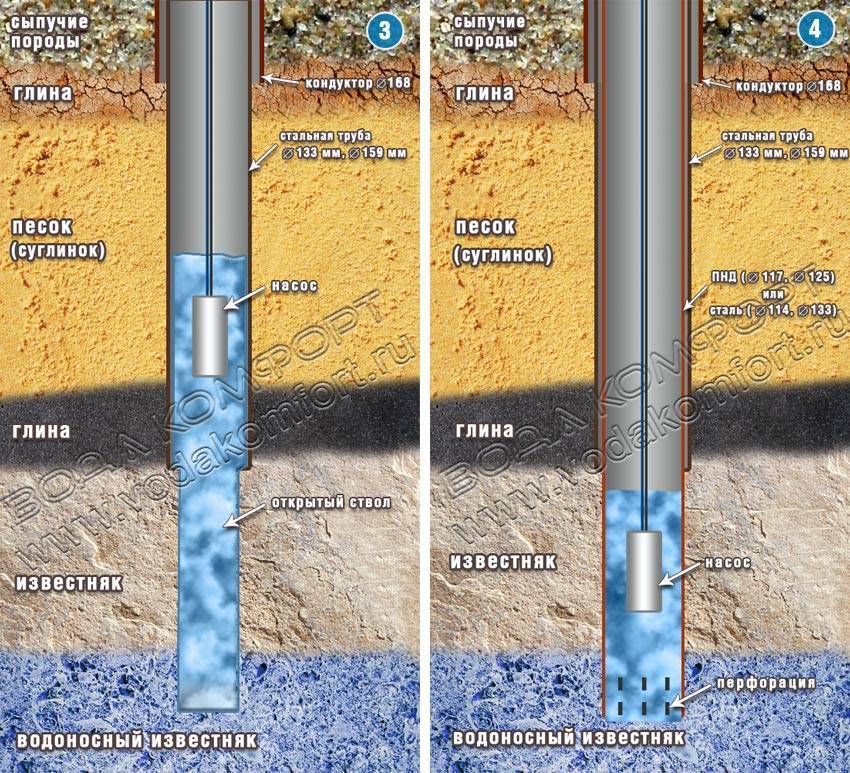

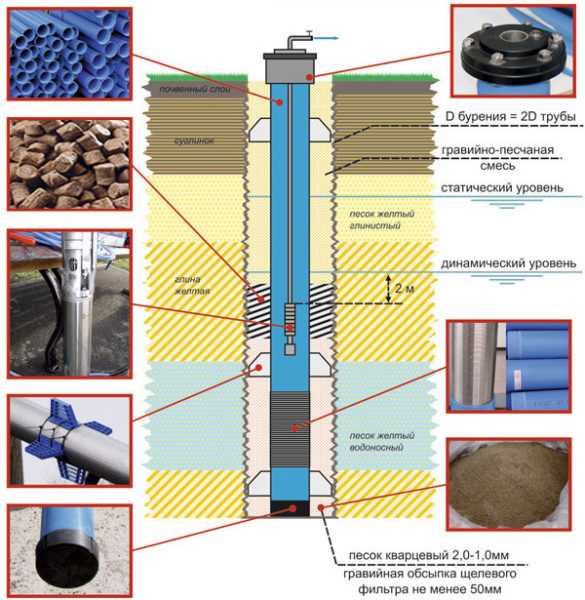

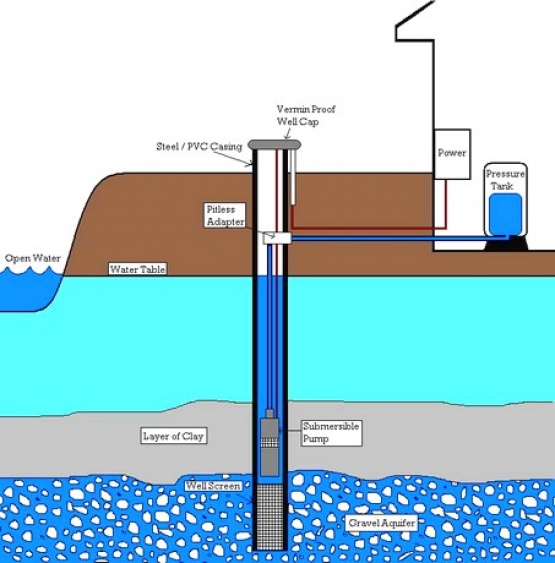

Features of the installation of casing pipes

After flushing the well, the drill rods are carefully removed. It should be borne in mind that if the parts are difficult to lift, then the flushing was insufficient. Now you can install the casing pipes. They can be metal, asbestos-cement or plastic. The latter option is the most widespread, since it is very durable, does not corrode and deform. Most often, pipes with a diameter of 125 mm are installed; for shallow wells, the 116 mm option is suitable. Sufficient wall thickness of parts - 5-7 mm.

For the best quality of the supplied water and additional purification of it from dirt, filters are used: sprayed, slotted or home-made. In the latter case, the simplest option can be considered as follows: with the help of a grinder, cracks are made across the entire casing across. To make a filter of higher purification, many holes are drilled in the pipe, then the part is wrapped with a special mesh or geofabric for better filtration, everything is fixed with clamps. A casing pipe with a filter at the end is lowered into the well.

A well filter of this type can easily be made independently.To do this, holes are drilled in the casing, which are best covered with a layer of geotextile or special mesh on top.

If the installation is difficult due to the presence of a strong water carrier, which quickly “washes out” the wells, you can try the following. Slots are cut or holes are drilled in the tip screwed onto the filter. A head is put on the pipe, to which the pressure hose from the pump is attached. Then the most powerful water pressure is turned on. After these manipulations, the casing should easily enter the water carrier. After installing the casing, half a bucket of gravel can be poured into the column as an additional filter.

The next step is another flushing of the well. This is necessary to wash out the water carrier, which was saturated with drilling fluid during drilling. The operation is performed as follows. A head is put on the pipe, a hose from the motor pump is fixed, and clean water is supplied into the well. After washing, the column is evenly and densely covered with gravel. Now you can lower the pump on the cable and use the well. A small nuance: the mechanism cannot be lowered to the very bottom, otherwise it will fail very quickly. The optimum depth is just below the water column.

The process of hydrodrilling a well for water is quite simple and quite affordable for independent implementation. However, before starting work, you need to carefully study the instructions, and best of all, take part in drilling under the guidance of specialists. Despite the apparent simplicity, there are many nuances known only to professionals.If there is no experience or desire, you can invite specialists who will punch a well quickly and at an affordable cost and equip it. The owner will only have to rejoice at the appearance of an autonomous water supply system in his house.

A simple do-it-yourself water well drilling technology

When the aquifer lies at a depth of more than 10 m, you will have to try to get drinking water. But this technology is not particularly difficult. With the help of simple manipulations, you can equip the well with your own hands.

Stages of drilling technology:

- Using a shovel, you will need to dig a hole 1.5 m deep. The main thing is to remove the top loose layer of earth. The width of the pit can be no more than a meter. It is advised to upholster the walls of the recess with boards for greater convenience.

- Next, you need to prepare a drill. To do this, a steel pipe is taken and teeth are welded on one side of it. They should be in different directions. The other side of the pipe is equipped with a thread for connection to the coupling. With its help, a handle is attached to the drill.

- To work, you need a 200 l barrel, a pump and a hose. The length of the hose should be enough to lower it through the pipe to the ground. It is not easy to perform all the actions on your own, so it is advised to take an assistant.

- The pipe can begin to deepen. Then turn on the pump. Due to the pressure of the liquid, the earth at the base will begin to erode and settle.

- Water enters the barrel from a pipe. It must be pre-filtered. The length of the pipe should be increased by additional sections.

This method is considered the simplest. It does not require expensive equipment and time-consuming. There is no place for complex work like welding, cutting or sharpening.

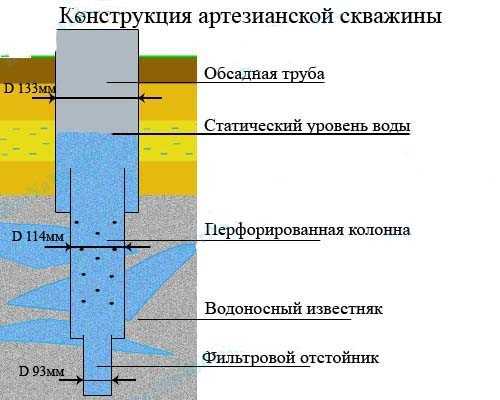

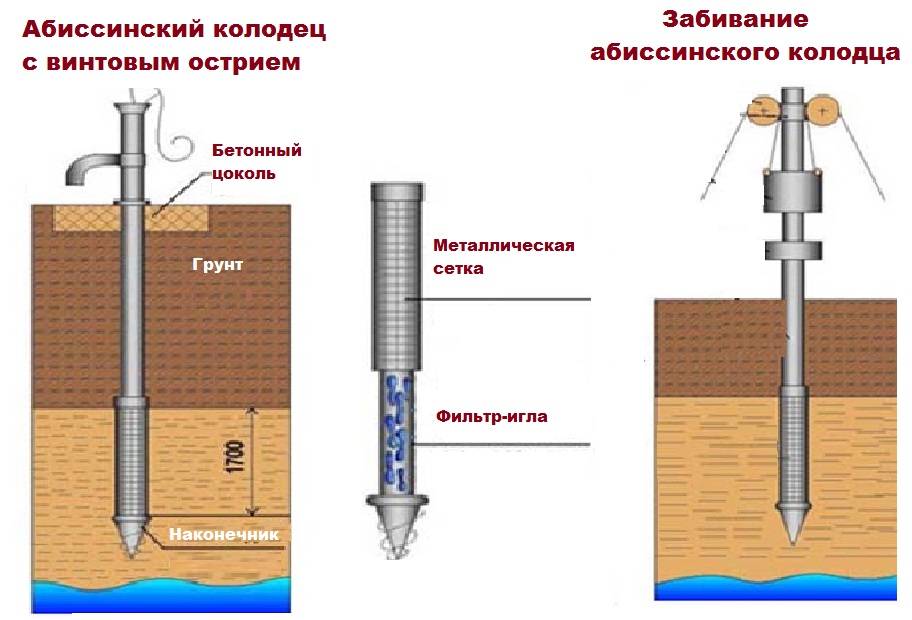

Artesian well

Scheme of an artesian well.

The name of this type of workings comes from the French language - from the place where the first flowing well was drilled: the province of Artois. The large length of the shaft and the solid rocks of the soil crossed on the way to the aquifer require the use of powerful drilling rigs - the auger method will not work.

The construction of the working is preceded by the stage of documentation. Drilling an artesian well is not a licensed activity, but in order to use water from it, many permits and approvals must be issued, including obtaining a license for subsoil use. The process is long and costly.

The main stages: agreement on the location of the site and well, geological survey project, registration of a license for exploration, drilling, drawing up a report and putting reserves on the state balance sheet.

Artesian wells are divided into 4 types:

- A double-cased development - a perforated pipe is mounted in the lower part of the column in the aquifer and a pump is placed in it, the other half is installed on top, reaching the limestone layer. Through the holes in the lower link, water enters the pipe and is pumped out at the mouth with a pump. Used when reservoir pressure is low.

- A water well with a transition is arranged with a variable geological section. 3 casing pipes are mounted - large diameter in the upper part, medium - in stones and sands, small - directly in the productive layer. Used for good water supply.

- The well is classical - with one casing pipe for normal conditions.

- A barrel with a conductor - from 2 casings: in the upper and lower parts.

Drilling technology is complex.The construction of an artesian water intake is carried out by specialized organizations.

Advantages

Advantages of an artesian well.

The main advantages of an artesian well are the remoteness of the water intake from the surface and the occurrence of water in porous limestone, excluding the presence of mechanical impurities in the liquid. This allows you to pump out an underground resource without installing a strainer at the bottom.

As a result, other advantages of artesian wells appear:

- ecological purity of water;

- independence from climatic and weather conditions;

- uninterrupted water supply: groundwater reserves are confirmed by geological surveys.

The source remains inexhaustible for ≥50 years. In this case, you do not need to spend money on periodic filter cleaning: there is none.

Flaws

Associated with costs at the stage of organization of construction and drilling of deep workings. The duration of the period from design to obtaining a passport for an artesian well is 2 years.

It will not be possible to build a water intake in a limited area: the minimum area for a drilling rig is 6x9 m. The water contains mineral formations acquired during filtration through the soil, and is hard.

Conclusions and useful video on the topic

Video #1 A visual demonstration of the rotary drilling process step by step:

Video #2 Analysis of rotary technology and well construction principles:

Video #3 Water circulation during rotary drilling:

The situation with the presence and depth of aquifers can vary greatly from place to place (and somewhere they do not exist at all, as on the island of Madeira).

When designing a well and choosing the optimal method of rotary drilling, the available maps of explored aquifers should be used. This will help you save a lot of money and time.

Tell us about your experience in well development using rotary technology. Share technological nuances that will be useful to site visitors. Please leave comments in the block form below, post photos and ask questions on the topic of the article.