- Fecal sewer pump - principle of operation, device and specifications

- How is the equipment for pumping feces

- The principle of operation of the unit

- Technical characteristics of the device for forced sewerage in a private house

- General description and components of sewage pumps

- Installation and connection rules

- Connection

- Outlet pipeline features

- Inexpensive models (up to 4000 rubles)

- Jeelex Fekalnik 230/8

- CALIBER NPTs-1100U Aqua Line

- JEMIX GS 400

- Brief overview of manufacturers

- Industrial and domestic fecal pumps

- How a sump pump works

- How should I choose a fecal pump?

- Automation, chopper and body material

- Lift height, power and power supply

- The best fecal pumps of the elite class

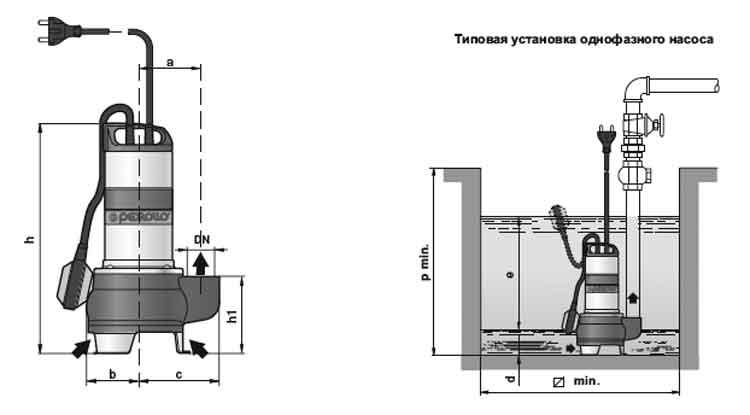

- Pedrollo VXCm 15/50-F - the best stationary sewage pump

- Grundfos SEG 40.09.2.1.502 - the best innovative sewage pump

- Product comparison: choose which model to choose and buy

- Overview of the best brands

- Kinds

- Dressing

- kitchen

- Pedrollo BCm 15/50

- Types of pumps

Fecal sewer pump - principle of operation, device and specifications

This is a small device that allows you to accumulate, grind and move contaminated masses of high viscosity.

How is the equipment for pumping feces

Such units have rather complex structure, consisting of the following elements:

- Frame. It can be made of durable plastic, cast iron or stainless steel. Considering the conditions of use in an aggressive environment, the last option is the best. The ruggedized housing is used on submersible pumps for pumping.

- The stator and rotor - the parts that form the propulsion system, are placed coaxially.

- The shaft connected to the rotor transmits rotation from the electric motor to the working body of the device.

- A sealing system that isolates the inside of the mechanism from an aggressive environment.

- An impeller that directly acts on the pumped substance and sets it in motion from the suction pipe to the outlet.

- A cover that covers the interior of the machine.

- Oil - the chamber protects the mechanism from overheating during operation.

In addition, the device is equipped brackets for fastening rope and hoses.

The principle of operation of the unit

Despite the apparent complexity of the design, the operation of the device is quite simple. During rotation, the impeller carries the fecal effluent towards the inlet pipe, simultaneously crushing its solid fractions.

Under pressure, the mass is fed towards the outlet pipe, on which the hose is installed.

Technical characteristics of the device for forced sewerage in a private house

This, as a rule, is determined by the design features of the building itself, if the forming plumbing fixtures are located in the semi-basements or cellars.

The following specifications are relevant here:

- Pump performance - how much drain can be pumped out per hour of operation (for example, 150-400 liters).

- Power consumption - for a private house, it is enough to use low-power units - up to 400 W / h.

- The depth of immersion or the height of the column - for fecal pumps, the value of this indicator in the amount of 15 meters is sufficient.

- Power - in sewer stations for a private house, equipment with an operating voltage of 220 volts is used.

These are the main features for home fecal station. Equipment parameters are very diverse, but there is always their optimal combination for a particular case.

General description and components of sewage pumps

Sewage pumps are designed for pumping not only polluted water, but also draining basements, pools and cesspools. There are 3 types of data structures:

- Drainage.

2. Fecal.

Drainage pumps only clean water with a small level of pollution. Fecal is able to pump liquid from sewage with a high level of pollution. Sewer stations "take away" drains.

In the general concept, sewer devices are immersed underground in order to pump liquids of a certain degree of contamination. Usually in special stores you can find pumps made of stainless steel, cast iron and plastic. A level sensor is available that controls the automatic activation of the pump.

The float switch is the automatic pump switch. When fecal matter accumulates at a certain level, the key closes or opens. It can be adjusted to different pumping levels of contaminated water.

The float switch consists of a box with air. The container is made of plastic material. Also available is a metal ball, which is placed inside. With the help of electrical contacts, the key is turned on when the mass level reaches its maximum.If the amount of liquid decreases, the “float” turns off - the contacts open, the engine turns off.

Sewer pumps are new. You don't need to turn them on yourself. But these devices have two differences: the shape and type of the impeller.

An impeller is an impeller that pumps liquid. There are several types of impeller:

- multichannel closed type - they distill clean water without various impurities and debris;

- multi-channel semi-closed type - the permissible level of contamination is slightly below average;

- VORTEX - the device pumps out heavily contaminated masses;

- impeller with one channel - masses of medium hardness;

- impeller with two channels - masses containing a large amount of solid fecal matter;

- wheel with a knife - crushes all the garbage that enters the sewage.

Another difference between sewer pumps is the diameter. Drainage pumps that pump exceptionally clean water are 10 mm in diameter - maximum. Pumping stations working with solid fecal matter and garbage in the form of toilet paper and other - up to 100 mm.

Installation and connection rules

Installation and connection toilet pumps and forced pumping of wastewater from different manufacturers occurs according to very similar rules. But before installation, you should read the instructions for a specific product - there may be features.

A sewage pump can stand in the kitchen - to drain drains from the sink and / or dishwasher

Connection

The installation location must be chosen so that the pump can be reached. It does not require special maintenance, but periodically there is a need for cleaning. If to the pump dishwasher and washing machine included, it is better to regularly check whether the sewer installation is clogged with grease, dirt, salt deposits. If necessary, cleaning with mild detergents is possible. Aggressive chemicals should not be used, as they can damage the plastic and rubber parts of the unit.

If the sewer inlet is higher than necessary

So here are the general rules:

- The individual sewer installation must be grounded. Therefore, the outlet must be three-wire with a working ground. (We read about the device of a ground loop in a private house here).

- For safety, a circuit breaker and RCD must be installed on the power line.

-

During installation, the block is fixed to the floor. To reduce the noise level, installation on a vibration-damping base (rubber gasket) is desirable. It is undesirable to press the case against the wall - so that vibration from the pump is not transmitted. These measures are necessary to reduce the noise level.

- The exhaust pipeline is made of rigid plumbing pipes. There are two recommended options - plastic sewer and copper pipes. Fittings are recommended rigid, one-piece.

- Pipelines must be permanently fixed (to walls, floors, etc.).

In general, installing and connecting a sewer pump for a kitchen or toilet is not a very difficult undertaking. But provided that you already have some idea about working with plumbing. In this case, you can do everything yourself.

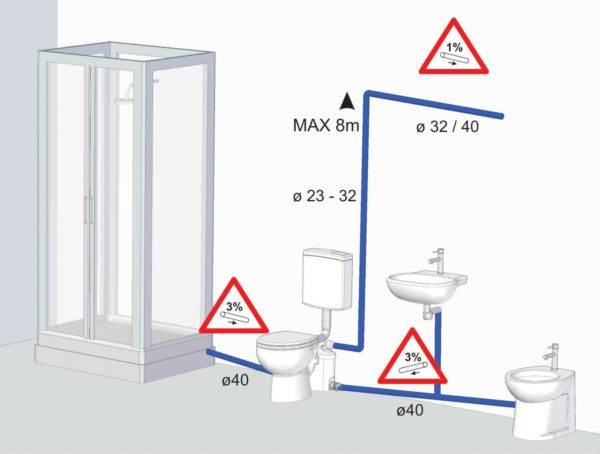

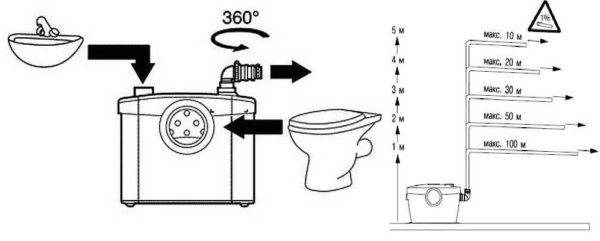

Outlet pipeline features

Compact plumbing toilet pumps can pump drains not only vertically, but can also lift them up. If there is a vertical section in its lower part it is desirable to provide for the possibility of draining - if you have to clear the pipeline from blockage, it is better if the drains are drained in a certain place, and do not start pouring out during work.

The height of the vertical section of the discharge pipeline is determined taking into account the minimum slope of the horizontal section. Each manufacturer (sometimes each model) has its own minimum slope, but in most cases it is 1-4% (1-4 cm per 1 meter).

Sewer pump installation rules

Be careful. The description of the sewage pumps indicates the maximum lifting height of the sewage and the maximum horizontal transport distance. For example: 8 m up, and 80 m horizontally. But this does not mean that by lifting the pipe 4 meters up, it will be possible to transport another 80 meters horizontally. In this case, after a four-meter rise, the length of the horizontal section will be no more than 40 meters. Just lifting 1 meter up “takes away” about 10 meters of horizontal transport

This is important and worth remembering.

Inexpensive models (up to 4000 rubles)

Models with a weight of up to 10 kg are easily installed in various places. cope with pumping groundwater from basement, water supply from the nearest reservoir, etc. Before use septic tank pump bioreagents are used at home - pumps are not equipped with grinders and can hardly cope with thick masses.

Jeelex Fekalnik 230/8

pros

- performance

- the weight

Minuses

- plastic case

- need tightening of mounting bolts before the first start-up

From 3 562 ₽

A good option for a summer residence.With a capacity of 13.8 cubic meters / h, it quickly pumps out the contents of the sewage well. There is no chopper in the pump, so if solid particles (sand, plastic, etc.) get inside, the engine may fail. The body of the unit is made of plastic. Mounting bolts not tight enough.

CALIBER NPTs-1100U Aqua Line

pros

- high performance

- low weight

Minuses

- plastic case

- long wire

From 3 530 ₽

Easy to use - low weight makes it easy to remove for maintenance and use in other places. High productivity - 20 cubic meters / hour. Considering the insignificant price - the best pump for a cesspool or a small septic tank. The model does not cope well with pumping thick masses, so it is necessary to use bioreagents.

JEMIX GS 400

pros

- price

- low weight

Minuses

poor performance

From 1 791 ₽

The low weight makes the model very mobile. Suitable for pumping silt from an artificial pond, groundwater from the basement, water intake for irrigation from natural reservoirs. Before pumping out the contents of the septic tank, it is necessary to add bioreagents to liquefy thick masses - the pump does not cope well with them.

Brief overview of manufacturers

When choosing a fecal pump, preference it is better to give models of well-known manufacturers. They specialize in such equipment, so their equipment is always on top. And in case of breakdowns, parts for repairing such pumps are always much easier to find.

Among the variety of brands for use in the country are suitable:

- Pedrollo Vortex - VXm series with low power (Italy).

- Dzhileks - a series of "Fekalnik" (Russia).

- SFA - compact grinder pumps for the home (France).

- Grundfos (Denmark).

- Marina-Speroni (Italy).

- Calpeda (Italy).

- Whirlwind (Russia).

- Belamos (Russia).

It is worth saying that Russian pumps are in no way inferior to imported counterparts. They were originally developed for domestic realities with voltage drops, etc.

Industrial and domestic fecal pumps

Industrial pumps are used for cleaning sewer systems in agriculture, food complexes, as well as for pumping water from the basement of multi-storey buildings, emergency rescue operations and other large-scale work. Sometimes industrial pumps are used in the private sector to pump out sewage from large drains and cesspools, but given their cost, this solution is rarely advisable.

Industrial fecal pump device

Industrial fecal pump device

Household pumps are designed for pumping and transporting water with organic sewage in the sewer system of an apartment, private house or cottage. And also for draining liquid from storm channels, pools or water intake tanks. More powerful units with grinders can be used to pump fluid from a septic tank, cesspool.

How a sump pump works

Drainage pumps can be divided into two fundamentally different types:

- superficial;

- submersible.

To determine which sump pump is best for a particular job, it's worth understanding the characteristics of each type of device and understanding how a sump pump works under different conditions.

Surface pumps, an example of which can be seen in the photo, are installed above the water, near the pit.Water is pumped out using a hose that is immersed in water and reaches the bottom of the tank. The device can also operate in automatic mode, but it requires a float mechanism to control the liquid level in the tank. The rise of water also raises the float, which acts on the control elements and turns on the pump (for more details: “Drainage pump with a float switch, device and principle of operation“).

The drainage pump must have two pipes: an inlet through which the supply of waste water from the tank is ensured, and an outlet that leads water out of the filling tank. Surface pumps must be protected from water entering the motor, since in this case it may fail. That is why the power of the pump must be sufficient to pump out the liquid at a speed exceeding the rate of rise of water in the pit. Professionals advise using pipes to connect the pump to the sewer, but for this you need to know the exact diameters of the pipes that will be connected.

Surface drainage pumps are quite mobile and easy to maintain. If necessary, the device can be easily transferred to another place where fluid transfer is required, and the resulting malfunctions can often be corrected in the field, since the design is quite simple.

Submersible drainage pumps operate on the same principles as surface pumps, so the differences lie in the design of the devices.Firstly, the very name of submersible devices indicates the need to immerse them in water, and secondly, it is this fact that determines the principle of operation of such devices: the liquid is pumped by the pump itself, without the use of hoses or nozzles. Water is sucked in by the pump through a hole in its bottom, and to protect against solid particles, the structure is equipped with a filter.

These pumps operate automatically, using a float system or a plastic bladder that signals a rising water level and turns on the pump.

Considering the fact that submersible pumps need to work under water, manufacturers create the highest quality electrical insulation in order to reduce the risk of a short circuit to a minimum. You can use these devices both at the household level and in different industries - the technical characteristics of different models of pumps can vary over a very wide range. What are the advantages of submersible drainage pumps? They are highly valued by users for their safety and good performance, which in most cases can be used to the maximum. In addition, submersible equipment is reliable and can last a very long time.

How should I choose a fecal pump?

The passport of the sewer pump for giving contains a lot of technical characteristics. And all of them must be considered when choosing this technique. The first indicator is the operating temperature of the pump, i.e. drain temperature.

Pumping equipment for sewage can be:

- Designed to work only with cold and warm water up to +45°C.

- Designed for pumping wastewater with temperatures up to +90°C.

To pump out water from the cellar and fecal sewage from a street septic tank, a pump of the first category is sufficient. But for uninterrupted functioning as part of a forced sewage system with a mass of plumbing in a country house, you will have to select a model from the second group.

Automation, chopper and body material

Constantly monitoring the status of the fecal pump and managing its operation manually means wasting your time. The cottage is always full of activities. Therefore, the technique should be immediately selected with a float and a thermal relay.

The first one will control the level of effluents in the pumped out pit, turning off / off the pump as necessary, and the second one will prevent the motor from overheating.

Some fecal pumps are able to handle solid waste and pebbles without a grinder, but only the presence of a cutting mechanism guarantees such a technique a long service life.

Some fecal pumps are able to handle solid waste and pebbles without a grinder, but only the presence of a cutting mechanism guarantees such a technique a long service life.

Structurally, the grinder is made in the form:

- two-bladed knife;

- impellers with a cutting edge;

- combined mechanism with several blades.

The impeller is the cheapest chopper option, but pumps with it have the lowest performance. A knife with a pair of blades located perpendicular to each other is more reliable and productive.

However, the most advanced is the combination of three cutting blades and a perforated disc. Passing through such a grinder, solid fecal fractions are converted into a homogeneous ground mass.

According to body material it is best to choose a pump for pumping sewage in the country from metal. Stainless steel and cast iron will last many times longer than plastic.This nuance is especially important for submersible equipment, which is constantly in dirty waters that are aggressive in composition.

Lift height, power and power supply

The higher the performance indicated in the passport, the faster the pump will pump drains. However, the more it will consume electricity. A cesspool in a country house is rarely made voluminous, so a low-power unit is often enough to work in a summer cottage. He will pump out the drains not in 5 minutes, but in 20, but there is nowhere to rush outside the city.

The best option for giving a pump in terms of power is 400–500 watts. This is a performance in the region of 140-160 l / min. Such performance characteristics will make it easy to cope with pumping sewage from a drain or cesspool, and getting rid of excess water in a country cellar.

The pressure figures show the maximum height to which the pumping equipment through the pressure pipe is able to lift liquid with feces. But when calculating this indicator, it is necessary to take into account not only the vertical section of the highway, but also the horizontal one.

In addition, one should take into account the atmospheric pressure, the material of manufacture and the cross section of the pipes, as well as the temperature of the effluents and the size of the impurities in them. In a simplified calculation of the required pressure, the footage of the horizontal section is divided by ten and added to the length of the vertical pipe section, and then all this increases by 20–25% - the resulting figure should be less than that indicated in the data sheet (+)

In a simplified calculation of the required pressure, the footage of the horizontal section is divided by ten and added to the length of the vertical pipe section, and then all this increases by 20–25% - the resulting figure should be less than that indicated in the data sheet (+)

In a simplified calculation of the required pressure, the footage of the horizontal section is divided by ten and added to the length of the vertical pipe section, and then all this increases by 20–25% - the resulting figure should be less than that indicated in the data sheet (+)

Some models of sewer pumps are designed to be powered by a single-phase network, while others are powered by a three-phase one. The first group is cheaper. As a rule, it is recommended to choose just such a fecal pump for giving. It will cause less problems with connecting to the mains. And if necessary, it can be powered from a portable generator.

The best fecal pumps of the elite class

Pedrollo VXCm 15/50-F - the best stationary sewage pump

Pedrollo VXCm 15/50-F is a weighty cast iron submersible unit. Equipped with a single-phase motor with thermal protection, as well as wet rotor pump and VORTEX impeller.

With the help of a float, 2 hinges and a flange, respectively, it automatically works and stops when running dry, it is permanently installed vertically and connected to the pipeline. It plunges to a depth of 10 m, the head creates 11.5 m.

Pros:

- wear resistance, extreme strength and long service life: components and parts are made of stainless steel and thick cast iron;

- high efficiency and productivity: with a power of 1.1 kW, the supply is 36 m3 / h;

- protection against overheating, jamming and idling;

- the use in Pedrollo VXCm 15 / 50-F of a special design impeller - type VORTEX;

- large sizes of milled inclusions: 50 mm.

Minuses:

- heavy weight (36.9 kg);

- high price: 49.3-53.5 thousand rubles.

Grundfos SEG 40.09.2.1.502 - the best innovative sewage pump

Grundfos SEG 40.09.2.1.502 is an innovative submersible unit with a modular design. At the device, the motor and pump housing are connected by a clamp, the shaft has a cartridge connection, the flanged outlet is located horizontally.

The machine turns on by default at a liquid depth of 25 cm. At the inlet, it cuts particles Ø 10 mm. Characteristics: power 0.9 kW, capacity 15 m3/h, immersion depth 10 m, lifting height 14.5 m.

Pros:

- ease of use: the built-in level switch is used (AUTOADAPT system), the use of a remote control is allowed;

- in Grundfos SEG 40.09.2.1.502 the gap between the casing and the impeller is adjustable;

- strength and reliability: new technologies are combined with durable wear-resistant materials - cast iron and stainless steel;

- total protection, including against dry running and overheating: thermal sensors are built into the stator windings;

- well-thought-out design (even in small things): a long power cord (15 m), a specially designed handle.

Minuses:

- high cost: 66.9-78.9 thousand rubles;

- significant weight: 38.0 kg.

Product comparison: choose which model to choose and buy

| Product Name | |||||||||||||||

|  |  |  |  |  |  |  |  |  | ||||||

| average price | 12480 rub. | 4860 rub. | 7220 rub. | 5919 rub. | 6580 rub. | 2630 rub. | 7870 rub. | 3970 rub. | 10530 rub. | 5990 rub. | 2692 rub. | 3154 rub. | 9309 rub. | 11003 rub. | 8790 rub. |

| Rating | |||||||||||||||

| Additional Information | the content of sand in the water is not more than 180 gr. in. cube m. | the pump is not designed for pumping particularly thick masses | |||||||||||||

| Guarantee period | 2 y. | 365 days | 1 year | 5 years | 1 year | 1 year | 1 year | 1 year | 1 year | 1 year | 1 year | 1 year | |||

| Type of | submersible borehole | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal | submersible fecal |

| Power consumption | 800 W | 590 W | 1200 W | 1400 W | 450 W | 750 W | 800 W | 250 W | 750 W | 250 W | 400 W | 750 W | 900 W | 450 W | |

| Bandwidth | 2.7 cu. m/hour | 13.8 cu. m/hour | 19.8 cu. m/hour | 24.96 cu. m/hour | 12 cu. m/hour | 13.5 cu. m/hour | 15.6 cu. m/hour | 8.4 cu. m/hour | 18 cu. m/hour | 9 cu. m/hour | 7.5 cu. m/hour | 13.5 cu. m/hour | 14 cu. m/hour | 18 cu. m/hour | 16 cu. m/hour |

| Mains voltage | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V | 220/230 V |

| Max head | 60 m | 8 m | 12 m | 11 m | 7 m | 8 m | 10 m | 6 m | 11 m | 7.5 m | 5 m | 8 m | 12 m | 12 m | 12 m |

| Water quality | clean | dirty | dirty | dirty | dirty | dirty | dirty | dirty | dirty | dirty | dirty | dirty | dirty | dirty | dirty |

| Permissible liquid temperature | 1°C to 40°C | up to 35°C | 1°C to 35°C | up to 35°C | 1°C to 35°C | 1°C to 35°C | up to 35°C | 1°C to 35°C | up to 35°C | up to 40°C | up to 35°C | 1°C to 40°C | |||

| Pump installation | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical | vertical |

| Permissible ambient temperature | 1°C to 40°C | from 1°C | 1°C to 35°C | ||||||||||||

| Protection | from overheating | from dry running | from dry running | from dry running | from dry running | from dry running | from dry running, from overheating | from dry running | from dry running | from dry running | from dry running, from overheating | from dry running, from overheating | from dry running | ||

| Power cord length | 35 m | 7 m | 10 m | 10 m | 10 m | 10 m | 7 m | 7.5 m | 10 m | 10 m | 7.5 m | 5 m | |||

| Immersion depth | 80 m | 8 m | 8 m | 7 m | 8 m | 8 m | 8 m | 5 m | 5 m | 8 m | 5 m | 5 m | |||

| Pump diameter | 75 mm | ||||||||||||||

| The weight | 5.2 kg | 7.9 kg | 8.1 kg | 5.03 kg | 14.85 kg | 4.095 kg | 5.03 kg | 17.8 kg | 20.5 kg | ||||||

| Life time | 10 years | 10 years | 3650 days | 1095 days | |||||||||||

| Automatic water level control | float | float | float | float | float | float | float | float | float | float | float | float | float | float | |

| Size of passed particles | 35 mm | 37 mm | 40 mm | 35 mm | 35 mm | 35 mm | 15 mm | 35 mm | 27 mm | 35 mm | 35 mm | 36 mm | 12 mm | 42 mm | |

| Dimensions (WxHxD) | 22×40 cm | 24.5×56.5×30.5 cm | |||||||||||||

| Pump mechanism | centrifugal | centrifugal | |||||||||||||

| Outlet thread diameter (G) | 2″ | 1″ | 1½» | 1¼» | 1″ | 1½» | 2″ | ||||||||

| cutting attachment | there is | there is | |||||||||||||

| Rated power | 1300 W | ||||||||||||||

| Number | Product photo | Product Name | Rating |

|---|---|---|---|

| 2.7 cu. m/hour | |||

| 1 | Average price: 12480 rub. | ||

| 13.8 cu. m/hour | |||

| 1 | Average price: 4860 rub. | ||

| 19.8 cu. m/hour | |||

| 1 | Average price: 7220 rub. | ||

| 24.96 cu. m/hour | |||

| 1 | Average price: 5919 rub. | ||

| 13.5 cu. m/hour | |||

| 1 | Average price: 2630 rub. | ||

| 2 | Average price: 3154 rub. | ||

| 12 cu. m/hour | |||

| 1 | Average price: 6580 rub. | ||

| 18 cu. m/hour | |||

| 1 | Average price: 10530 rub. | ||

| 2 | Average price: 11003 rub. | ||

| 15.6 cu. m/hour | |||

| 1 | Average price: 7870 rub. | ||

| 8.4 cu. m/hour | |||

| 1 | Average price: 3970 rub. | ||

| 9 cu. m/hour | |||

| 1 | Average price: 5990 rub. | ||

| 7.5 cu. m/hour | |||

| 1 | Average price: 2692 rub. | ||

| 14 cu. m/hour | |||

| 1 | Average price: 9309 rub. | ||

| 16 cu. m/hour | |||

| 1 | Average price: 8790 rub. |

Overview of the best brands

The modern market opens wide horizons for selection of fecal pumpsequipped with grinders. Italian, German, Spanish and other equipment is offered to customers, and each manufacturer puts up an impressive range of models for sale.

Imported products, which are present in large quantities on the modern market. The main suppliers of fecal pumps are German, Italian, Spanish companies

grundfos. Among the best manufacturers, the first place in the ranking is the company. The Germans have succeeded in the development and production of pumps for various purposes. Not without German ideas in the production of fecal equipment with a grinder.

Their Grundfos Seg model, made for professional use, is well suited for ordinary private households. Despite the cast-iron body of the device, it is easy to transport from one place to another.

The electric motor of the device is endowed with a sensitive system of protection against overheating and short circuits. There is a regulator of speed of rotation of a rotor of the electric motor. With a maximum operating power of 0.9 kW, it gives a pressure of at least 15 meters. Dives to a depth of 10 meters.

The Grundfos brand is famous for producing a wide range of garden pumps. In the line presented to the buyer submersible pumps are dominated by models for pumping clean and dirty water

Gilex. German equipment attracts the buyer with technology, but pushes it away with a high price. It was the affordable cost, combined with good quality, that brought Dzhileks Fekalnik to second place.

The development of Russian engineers also belongs to the category of professional equipment. The effectiveness of the action and quality indicators in the work were appreciated by many users of this equipment.

"Dzhileks Fekalnik" is made of stainless steel. It can be submerged to a depth of 8 meters. The power of the device is 0.4 kW, and the productivity is 160 l / min. A reliable hermetically sealed housing, equipped with a thermal protection system, also attracts simple maintenance.

Herz. The next best representative of liquid pumping devices is another German invention, this time from Herz. Model WRS25/11 is in high demand due to its reliability, durability and wear resistance. A feature of the model is the design for use in extreme conditions.

Fecal pumps of the German manufacturer Herz attract with excellent performance, practicality and a wide range that allows you to choose equipment for pumping any volume.

The development from Herz provides a capacity of up to 260 l / min., creates a head up to 14 meters and can dive to a depth of 8 meters. The weight of the pump is 31 kg due to the cast iron body and steel working parts. The motor winding has insulation class "B".

Vortex. The well-deserved fourth position in the ranking of the best is occupied by the Whirlwind fecal pump. The FN-1500L model showed good results in operation. Efficient pumping and efficient shredding of large debris. Fully automatic control of the water level in the working chamber - switching on and off when the set parameters are reached.

Device for pumping faeces brand "Whirlwind". The pump equipped with a grinder is manufactured by a Russian company.The technique has received clear recognition from users. Demand for Whirlwinds exceeds supply

The pump is capable of lifting a column of liquid up to 18 meters. The productivity of the device reaches the value of 24 cubic meters / hour. Throughput on crushed particles - 15 mm. Maximum power - 1.5 kW. Material - a steel blade of a chopper knife and a cast-iron casing of the pump itself.

A fecal pump with a self-sharpening chopper from Italian manufacturers is designed for operation in extreme conditions. The design allows diving to a depth of 20 meters. During operation, a pressure of up to 40 meters is created. Productivity indicator - 16 cubic meters / hour.

A powerful device from an Italian manufacturer is the Calpeda GMG fecal pump with a grinder, which is endowed with a self-sharpening mechanism. Equipment, the service life of which depends only on the natural wear of parts

This is how the rating of the best pumping equipment from the group of fecal systems looks like. Of course, this list should be taken only conditionally. The range of pumping equipment is very large, and only five models are not able to show the situation in full. But in the case of choosing a pump for everyday life, it is quite logical to focus on the designated list.

Kinds

Conventionally, these devices are divided into two categories:

- household;

- Industrial.

Household appliances are used for pumping wastewater and can be installed not only in country houses, but also in apartments. Industrial - used in apartment buildings and substations that are connected to the sewer.

Household units differ in the place of installation and purpose. They also differ in the type of construction.There are devices that are installed for use by one consumer, and there are pumps used for forced sewage of an entire house.

Pumps for sewerage in the apartment are produced in the following versions:

- For a toilet bowl with a grinder;

- For kitchen without chopper.

Dressing

box, the dimensions of which correspond to the dimensions of the drain barreltoilet

The color of the body of the device is selected to match the color of the toilet bowl. During the drain, the device filled with water, with the help of blades, begins to grind waste water and toilet paper. Larger debris, such as personal care products, cannot be handled.

Such a unit can pump wastewater, the temperature of which is from +35 to + 50 degrees. Many models have additional holes for connecting a shower or bidet.

Therefore, when choosing a unit, water temperature plays an important role. If it is higher than the specified indicators, then the equipment may deteriorate. In some models, a relay is installed that turns off the device after half an hour, after pumping hot water.

In addition to such fecal pumps, there are built-in devices with grinders that are used for wall hung toilets. They are distinguished by their compact size, which allows them to be hidden behind drywall partition wall.

There are models in which the toilet and the pump are combined. In this design, there is no drain tank. It connects directly to the water supply and takes up little space.

kitchen

Models for installation in the kitchen are called sanitary. Their purpose is to pump dirty water. There are no choppers in the design of sanitary pumps, therefore, large fractions should not be contained in the water.

Kitchen sewer pumps have several inputs for connecting several drains from:

- sinks;

- bathroom;

- shower room;

- Washbasin.

When choosing a unit for the kitchen, you need to pay attention to the temperature of the wastewater. The maximum temperature of some models is +90 degrees, which allows you to connect a washing machine and dishwasher to them

Important: kitchen equipment is covered with a layer of grease from the inside, so it is important to take the time to clean them periodically.

Pedrollo BCm 15/50

Main characteristics:

- Maximum pressure - 16 m;

- Throughput - 48 cubic meters. m/hour;

- Power consumption - 1100 W.

Frame. The body and main parts are made of cast iron and stainless steel, which allows the pump to be operated in a chemically aggressive environment with abrasive inclusions.

Engine. A single-phase electric motor with built-in thermal protection consumes 1100 W, which is enough to pump out a viscous mixture in the amount of 48 m3/hour. This flow corresponds to a discharge nozzle diameter of 2½’. To exclude the option of working in dry mode, the pump is equipped with a float switch that opens the power circuit when the liquid level drops to a critical level.

Water pump. The double impeller of the pump creates a sufficiently large pressure equal to 15 meters and successfully replaces the chopper. The removable cover allows you to quickly get to the pump for revision or cleaning in case of clogging.

Device Pedrollo BCm 15/50.

1. Pump housing.2. Pump base.3. Impeller.4. Engine housing.

5. Engine cover.6. Motor shaft.7. Double mechanical shaft seal with intermediate oil chamber.

8. Bearings.9. Capacitor.10. Electric motor.11. Power cable.12.External float switch.

Application. The design of this model is designed for immersion in water up to a depth of 5 meters, so the length of the power cable is 10 meters. The pump is designed for pumping fecal matter and other liquids with a temperature not exceeding 40°C. The diameter of solid particles must not exceed 50 mm. At width 250 mm and height 450 mm, it easily fits into a standard size inspection hatch.

Pros of Pedrollo BCm 15/50

- Quality materials.

- Reliable shaft seal.

- High performance and high pressure.

- Low noise level.

- Protection against dry running and engine overheating.

Cons of Pedrollo BCm 15/50

- Heavy.

- Expensive.

Types of pumps

All pumps used in everyday life can be divided into two groups: surface and submersible.

Surface pumps are placed at the edge of a water tank or reservoir. They can be used both for drainage and for pressurizing the pipeline.

Submersible pumps, as the name implies, sink directly into the water. They are used for water supply and sanitation. Submersible pumps, according to their function, are divided into:

- drainage;

- fecal;

- wells;

- borehole.

Drainage pumps are used both for pumping water of various impurities at a depth of up to 7-10 meters, and for taking water from reservoirs or tanks.

Fecal pumps have much in common with drainage. At the same time, they are more powerful and durable, and can be equipped with a cutting nozzle. They are designed for pumping dirty water with inclusions, sewage water, fecal matter.

Well pumps are used to pump clean water (inclusion no more than 5 mm) from wells with a depth of more than 7 meters.

Downhole pumps are used for lifting water from great depths. They are distinguished by high power, pressure force and high performance.