- right time

- Preparatory stage

- How to heat "problem" stoves

- Step-by-step instruction

- Fuel briquettes or ordinary firewood: what to choose?

- What to do if you are drawn to the bottom?

- The principles of the furnace furnace

- Secrets of Kindling the Stove

- Prepare firewood ahead of time

- What fuel is suitable for a home stove

- Firewood

- Table: the required amount of fuel depending on the type of firewood

- A new type of fuel - eurowood

- How to make a sawdust briquette with your own hands

- Photo gallery: devices for the manufacture of fuel briquettes

- Tips from experienced bakers

- Advantages and disadvantages of systems

- Advantages of ovens

- A Few Disadvantages

- Design features of Russian stoves

- A few tips to make your firebox even more efficient

- What are the main differences in heating systems on coal and on wood

- A coal boiler is right for you if…

- A biofuel boiler is right for you if…

- What can't be done?

- Not recommended:

- Furnace firing process

- Reload

right time

It should be said right away that harvesting firewood is a long process that is accompanied by a lot of physical work. In order to provide yourself with high-quality forest for the whole year, so that it is warm in the house and hot in the bath, you should properly chop and dry firewood, as well as provide them with decent storage conditions.If you do not plan to cut wood with your own hands, you can buy the required amount of wood.

Since ancient times, all the inhabitants of the village have known that the best time for logging is considered to be early winter, or the latest autumn, when it is still warm and dry on the streets. This time of the year was not chosen by chance, because it is more convenient to carry out many works in autumn and winter, in particular:

- It is much easier to chop and cut trees that have shed their leaves for the winter.

- It is also easier to chop frozen logs in winter, well, or in autumn, when the first frosts have already arrived.

- In addition, the movement of juice in the winter period inside the trees slows down, which allows you to get drier wood.

- Drying wood is a long process, the forest felled in winter dries during spring and summer, and only by autumn, or better by next winter, is it fully ready for use.

The felled forest cannot be used immediately, it must be dried. If you heat the stove with raw firewood, from freshly cut down trees, then they will burn badly, smoke and smoke heavily. In addition, such a forest will give off much less heat than after thorough drying. Modern technologies make it possible to dry fresh wood, but it is still better to resort to natural drying.

The felled timber is being prepared for transport

By the way, let's look at how the calculation for firewood is carried out, because we need to know how much wood we need. If we assume that in winter you will always be in the country and heat the stove, then you can use the average calculation option.

Based on this simple math, it's easy to calculate how many cubic meters of wood you need to heat your home.Next, add some firewood for kindling baths on weekends, if any, and a small reserve for unforeseen cases will not hurt.

Note that a firewood harvester, usually ZIL or KAMAZ, is capable of simultaneously converting about 5 cubes of wood. So calculate how many cars you need.

Preparatory stage

When you are going to make the first kindling of the season, it is recommended to carry out a number of measures before it, thanks to which trouble-free operation of the stove will be ensured throughout the entire cold period.

The activities are as follows:

visual inspection: you should carefully examine the body of the furnace and the chimney for cracking. If cracks are found in the brickwork, they should be repaired with clay mortar, the repair of the metal case is carried out by welding;

before the start of the season, all flues and chimneys must be cleaned of soot

Otherwise, your rustic stove will become worse at giving off heat, and the soot in the chimney may ignite and cause a fire in the house;

pay attention to the tightness of the firebox and blower doors, their free play and the operability of the locking mechanisms. The same requirement applies to views (latches);

preparation of fuel of proper quality.

How to heat "problem" stoves

These, for example, include heating devices that have not been used for a long time. In addition, in winter, it is more difficult to flood any stove appliance. First, let's figure out how to heat a bathhouse or a house with firewood after a long break.

Step-by-step instruction

- We inspect the equipment to make sure it is in good working order.

- Warm up the chimney. To do this, set the maximum thrust, open the views and the blower door.Roll a tube out of cardboard or paper. We introduce it into the cleaning window, set it on fire. We warm up the pipe until a characteristic hum appears.

- We close the cleaning window, put flammable material into the chamber: sawdust, paper scraps. We set fire to them until they burn out, once again we check the quality of the chimney.

Fuel briquettes or ordinary firewood: what to choose?

What to give preference to: ordinary firewood or fuel briquettes? To answer this question, it is necessary to study the advantages and disadvantages of both.

We list the most important advantages of fuel briquettes:

- A fuel briquette, when compared with ordinary firewood, burns 4 times longer than the latter, which contributes to the economical consumption of such fuel.

- After the combustion of pellets, very little ash remains - about 1% of the total mass of used fuel. When using conventional firewood, this figure can reach up to 20% of the total mass of fuel used. The ash left after the combustion of wood briquettes or any other type can be used as a fertilizer containing a large amount of potassium.

- The amount of thermal energy released during the combustion of eurofirewood is almost twice as much as when using ordinary firewood.

- During combustion, fuel briquettes emit heat almost all the time, which cannot be said about ordinary firewood, the heat output of which decreases rapidly as it burns.

- During combustion, fuel briquettes practically do not spark, emit a minimum amount of smoke and smell. Thus, this type of fuel does not create discomfort and does not harm the environment.In addition, when burning firewood infected with mold or fungus, toxic smoke is formed, which is excluded when using eurofirewood, for the production of which carefully dried sawdust or shavings are used.

- When using wood briquettes as fuel, much less soot is deposited on the walls of chimneys than when using conventional firewood.

- The compact dimensions that distinguish eurofirewood allow more economical use of the area for storing such fuel. Moreover, when storing fuel briquettes, usually placed in a neat package, there is no garbage and wood dust, which are necessarily present in places where ordinary firewood is stored.

Compact storage is an indisputable advantage of fuel briquettes

Naturally, this type of fuel has certain disadvantages:

- Due to the high density of the internal structure, fuel briquettes flare up for a long time, it will not be possible to quickly warm up the room with the help of such fuel.

- The low moisture resistance of eurofirewood can cause them to simply deteriorate if the required storage conditions are not provided.

- Fuel briquettes, which are compressed sawdust, are characterized by a rather low resistance to mechanical damage.

- When burning fuel briquettes, there is no such beautiful flame as when using ordinary firewood, which somewhat limits the use of pellets as fuel for fireplaces, where the aesthetic component of the combustion process is also very important.

Comparison of the main parameters of various types of solid fuels

To make a choice between fuel briquettes and ordinary firewood, the advantages of the latter should also be taken into account.

- When burning ordinary firewood, as mentioned above, more heat is generated, respectively, with the help of such fuel it is possible to quickly warm up the heated room.

- The cost of ordinary firewood in comparison with fuel briquettes is much lower.

- Firewood is more resistant to mechanical damage.

- When burning firewood, a beautiful flame is formed, which is an especially important quality for fireplace fuel. In addition, when burning firewood, essential oils contained in wood are released into the surrounding air, which has a beneficial effect on the nervous and respiratory systems of a person who is in a heated room.

- The characteristic crackle that firewood emits during combustion also has a beneficial effect on the nervous system.

- The ash left after burning ordinary firewood does not have such a tart smell as the product of burning pellets.

What to do if you are drawn to the bottom?

“The main feature by which one can judge the bottom relief is the flow and speed of water, its direction and the “pattern” that it gives to waves and vibrations. It only seems at first glance that everywhere and everything is the same, but still, if you look closely, you begin to notice that in some areas the ripples are not the same, the flow speed is different and the direction of the flow is different, ”says Sergey Fedchenko, who has worked for many years in search and rescue rapid response unit.

So, for example, a steep bank of a river always has a great depth and may well have a pit due to the uneven spread of washed (crumbled) soil by a stream of water.

“It is easy to understand that you are in a hole.You will feel how the bottom leaves from under your feet and you fall through, - says Sergey Fedchenko. - And when you get into the whirlpool, you will begin to be pulled to the bottom. In both cases, in order not to drown, you need to take in air and, plunging into the water, row to the side with all your strength.

Rescuers advise, once in a whirlpool or in an area of a strong circular current, try to overcome the possible panic that usually accompanies unforeseen events on the water.

Rescuers are armed with special boats. Nadezhda Kuzmina

“Often a person who finds himself in the water exaggerates the danger of the situation and begins to take actions that aggravate the situation. Save your strength and don't try to fight the circular current. Your task is to get out of the whirlpool with the least effort. If you feel that you are being pulled in a circle, try to row in the direction of the rotation of the water, methodically swimming away from the center of the funnel, advises Sergey Fedchenko. - If you are pulled into the center of the funnel with great force, and you feel that you can not cope with the current, take a lot of air into your lungs and dive. While under water, look for a current that does not go in a circle, but brings it to the surface and to the side. This current, as a rule, is always present in the whirlpool at a certain depth, so your task is not to get confused, but to take advantage of such an upward flow.

Related article

Dangerous swimming season. How to help a drowning child

If you are at a relatively shallow depth, then, once in the funnel, be extremely collected. The bottom in such places is usually strewn with snags and stones, which are easy to injure when getting out of the whirlpool.If you feel that you are being carried by a swirling stream to a tree trunk or boulder sticking out of the water, try to put your legs forward and group yourself so as not to hit your head or other vital organs on an obstacle. Follow the main rule - in any situation, keep composure, composure and self-control.

The principles of the furnace furnace

"How to heat the stove correctly?" - a question that worries many city dwellers who move outside the city for the summer. Yes, and people who constantly live "in nature" and use the stove also ask this question.

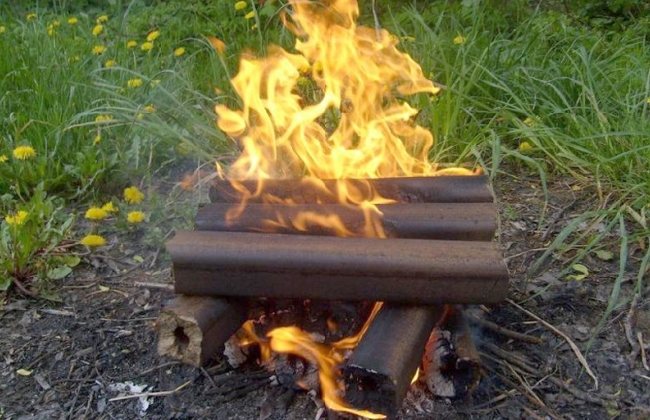

Warm and cozy next to the stove, in which firewood crackles

An efficient and safe furnace has “three pillars” on which this process rests: the serviceability of the furnace itself, the use of high-quality fuel and skillful ignition.

We must say right away that if the furnace is used improperly, negative consequences can be expected:

- increase in fuel consumption (you will have to use 20% more fuel);

- clogging of the elements of the furnace;

- failure of the heating device;

- insufficient heating of premises with considerable fuel consumption.

So that all of the above does not concern you, you should know the principles of furnace furnace:

- Always check the condition of all components of the oven before using it.

- To increase the influx of fresh air and better combustion of fuel, it is necessary to clean the grate-grate and the ash container.

- After a long break in using the stove, you must first warm up the chimney (to do this, light a mini-bonfire in the furnace), and only then proceed to the stove in the usual way.

- Place the fuel strictly in the middle of the firebox, preventing it from shifting to the back of the device; it is better to put coal, firewood or briquettes closer to the door.

- Regulate the supply of fresh air to the furnace with doors from the blower and the furnace.

- To improve draft, use a chimney damper and a view (a device at the turn of the chimney and combustion chamber).

- You should not "gut" the fuel until more than half of it has burned.

Secrets of Kindling the Stove

Many people tend to mistake fuel for its ease of ignition. It will not work to set fire to coal without firewood, in addition, the ignition process itself must be carried out correctly. This contributes to a long service life of the furnace.

The stove must be inspected externally every time you are going to fire it up. Substances or objects that are easily flammable and have been accidentally placed nearby are removed at a sufficient distance beforehand. Before kindling, the chamber and ash pan must be cleaned by removing unburned products. To prevent small particles of ash from flying around the room, it is recommended to pour a little water into the ash pan.

Coal is usually stored indoors, but moisture ingress is not ruled out. In this case, it must first be dried. When burning wet coal, all the water in the form of steam goes into the chimney. A large amount of soot settles on wet surfaces of the pipe walls.

Crumpled old newspapers are stacked on the grate. Small wood chips can be placed on top of them. Wood logs are stacked in a hut or well, depending on your habits. After that, we melt the stove by closing the firebox door and opening the blower.

When the firewood begins to burn through and the first red-hot firebrands form, you can fill in a portion of fine coal, after which larger pieces are gradually added. When burning coal, cover the chimney damper, this will save heat.But remember that with a closed damper, there is a high probability of filling the room with carbon monoxide. Watch the flame, the blue tint indicates that it's time to open the damper.

Prepare firewood ahead of time

Bring the firewood into a warm room 2-3 days before lighting to increase its initial temperature.

The warmer the firewood is initially, the:

- They spend less heat on their own heating and more on space heating. You use heat more usefully.

- Firewood reaches the optimal combustion mode faster, which further increases its calorific value and reduces the amount of soot emitted. This is because the resin, creosote, tar, essential oils and other substances that make up the wood do not burn at low temperatures and settle on the walls in the form of soot. And in the optimal mode, the combustion temperature is sufficient for them to burn out completely and release additional heat.

The difference between the burning of “warm” and “cold” firewood is immediately noticeable: cold firewood emits a lot of smoke, which characterizes incomplete combustion. And warm dry firewood burns almost without smoke.

What fuel is suitable for a home stove

In order to heat the stove, you can use firewood, coal, peat. Modern manufacturers also offer new types of fuel - eurofirewood, various types of pressed briquettes.

Firewood

Birch in this regard has always been considered the best. Such logs do not shoot, do not spark and completely burn out, have a high heat transfer. But if you overdo it and make too much fire, a fire can happen.

Birch firewood is the best for a home stove

- Oak firewood burns for a long time, gives a lot of heat. Heat transfer is higher than that of birch by about 20%. But they are very expensive.With constant use, the brick burns out quickly enough, the walls become thinner.

- Pine and spruce firewood is inferior to birch and oak in terms of heat transfer. Due to the presence of resin, they crackle strongly, shoot. Not only sparks can fly out to the floor, but also hot coals. Therefore, the wooden floor must be covered with a sheet of metal, floor tiles or other non-combustible materials. Pine and spruce firewood gives a lot of ash, burns out for a long time. If you close the chimney opening before all the coals go out, you can burn yourself.

- Aspen firewood burns slowly. Heat dissipation is 50% lower than that of birch. But aspen helps to clean the chimney from soot and soot, so it is recommended to put them in a red-hot stove at the end of the firebox in a small amount.

Aspen firewood is often used not for the purpose of generating heat, but as a means of cleaning the chimney from soot.

Firewood from alder quickly flares up, practically does not form smoke, like aspen, cleans the chimney from soot. It has long been considered "royal" firewood.

Pine, birch and spruce, although they have good heat dissipation, form a lot of soot during combustion. This means that the chimney will have to be cleaned more often.

Table: the required amount of fuel depending on the type of firewood

| wood species | Birch | Aspen | Pine | Spruce | Alder | Oak |

| Fuel volume (m³) | 1,0 | 1,5 | 1,2 | 1,3 | 1,2 | 0,75 |

A new type of fuel - eurowood

Eurowood is produced from sawdust and wood dust, compressing them on special presses under high pressure and at high temperature. The density of fuel briquettes is 3 times greater than that of firewood, which means that heat transfer is higher. They burn with a high, even flame, with virtually no smoke.They burn completely and leave very little ash. The thermal conductivity of eurofirewood is approximately the same as that of coal, but their cost is much higher.

Eurowood is an environmentally friendly alternative to conventional fuel

How to make a sawdust briquette with your own hands

As an alternative to expensive eurofirewood - briquettes made by hand. If it is possible to purchase sawdust, then if you have free time and desire, you can make them yourself. Husk for seeds, finely torn paper, dry leaves, straw, cardboard will be used. For a bunch, you can take clay or any wallpaper paste. The manufacturing process consists of several stages:

- Soak sawdust in water.

- Mix thoroughly with either clay or glue in a ratio of 1:10. There should not be too much water. The main thing is to moisten the sawdust.

- Place the resulting mixture in a special mold and squeeze with your hands, compress.

- Lay the briquette to dry outside, preferably under a canopy.

To speed up the process, you can make a special press.

Of course, such briquettes, due to the low degree of pressing, cannot compete with eurofirewood. Their heat transfer will be lower, and manufacturing will take a lot of time.

Photo gallery: devices for the manufacture of fuel briquettes

Homemade sawdust briquettes - cheap fuel with good heat dissipation

The sawdust press gives the briquettes a certain shape

Double sawdust press can be made independently

Instead of sawdust for the manufacture of fuel briquettes, you can take paper or husks of seeds

Tips from experienced bakers

If you have a stove or boiler in your house that runs exclusively on coal fuel, you still have to kindle the heater with paper and wood.Only after the required temperature has been reached in the firebox, it will be possible to fill in the coal itself. If it is not known how much to take, then you need to focus on a layer of about 5-6 centimeters.

When this volume of material flares up well, it will be possible to add the remainder in such an amount that the layer is already 15 centimeters. With this approach, you can be sure that the stove will ignite well, and there will be a sufficient temperature in the house.

When kindling, the pipe valve should be slightly moved away, and the coal itself should be placed on the grate. At that moment, when the fuel has already flared up well, it is necessary to open this valve to the maximum.

At the next stage, it is worth laying a portion of fine coal (if it is large, you will have to split it). Its layer will be about 5-8 centimeters, and the area should correspond to the grid. When the bookmark is completed, the firebox door should be closed, and at the same moment the blower should be opened. After the material flares up, the volume is increased to 12-20 cm.

As for the subsequent portions of coal that will be laid after the burnout of a batch of material, here you should follow some rules:

- A new bookmark is made only when you are convinced that the previously filled coal has already flared up quite well.

- Before pouring in a new portion of coal, if the firebox doors open at this time, it is necessary to cover the blower.

- You should not allow the material to burn out up to the grate, the combustion should be uniform throughout the layer.

If you pay attention, you can see that the purchased coal is not only large pieces. It may also contain small particles, as well as typical dust.To prevent its association into a single layer during combustion, the material should be moistened with water before laying.

To prevent its association into a single layer during combustion, the material should be moistened with water before laying.

The same applies to those who use fatty coal of the PZh or Zh grades. However, the volume of water should not be large, because the material burns better in a dry form. When kindling the furnace, fuel grades PS and SS, where small elements predominate, must be moistened with a slightly larger volume of liquid.

There is also lean coal, which is marked with the letter T, it is it that should be moistened abundantly, but long-flame material is only sprayed to remove dust. As for the Anthracite brand, it does not need to be moistened at all, only if it is in dust, slightly irrigated with water.

When the combustion process itself is underway, the door of the combustion chamber must be closed. It should be opened only when it is planned to throw in a new batch of coal. Unlike firewood, it is not necessary to turn this material over so often, because otherwise the firebox will cool down, and part of the material will fall through the grates.

Now it becomes clear what is better to heat the stove and how to do it correctly. Of course, the process may not work the first time, but do not despair, because after two or three attempts, all actions will be performed automatically, and the house will be filled with comfortable warmth and a pleasant crackle of burning coal or firewood.

Advantages and disadvantages of systems

In most European countries, as well as in the United States of America, wood pellet heating systems have been used for heating private homes for many years.

Such popularity is primarily due to the harmlessness of this method of heating a house for its residents, while, for example, solar heating boilers cannot boast of environmental safety.

Advantages of ovens

One of the most significant advantages of pellet stoves-fireplaces is the autonomy of their work - they are absolutely independent of external energy sources (electricity, gas). In addition, the cost of such equipment is several times lower than that of alternative options.

Since the process of space heating is almost completely automated, a large supply of pellets can be loaded into the bunker of the furnace in advance so that the system heats the house for a long period of time without human intervention. In addition, in the manufacture of absolutely all metal elements of the system, they are coated with special compounds that protect the furnace from corrosion.

It is also worth highlighting the following advantages of pellet stoves:

- if suddenly the system runs out of fuel or the door accidentally opens, the oven will automatically turn off;

- similar furnaces can be used for commercial or industrial premises;

- pellets are much more efficient in terms of heat transfer than similar types of solid fuels.

A Few Disadvantages

It is also worth listing several disadvantages of such systems:

- the high cost of furnaces in comparison with gas or electric equipment;

- in houses and dachas remote from the city, it is quite difficult to provide after-sales service for devices;

- old generation models must be thoroughly cleaned at least once every 2 weeks;

- imported stoves are often not designed for operating conditions in our country - severe winters or constant voltage drops in the network can quickly disable equipment.

Design features of Russian stoves

They consist of three main elements:

- furnaces;

- chimney;

- pipes.

The combustion chamber, an obligatory part of any unit, is a compartment designed for solid fuel. A blower is arranged under the firebox, which provides the supply of oxygen necessary to maintain the combustion process, and in addition, ash from burnt wood accumulates in it.

The purpose of the chimney is to remove smoke and excess heat energy collected in the furnace of a Russian stove. During its construction, several turns of a zigzag shape are laid out inside to heat one of the walls of the house. The surface inside the chimney should be smooth so that it is less covered with soot and dust.

With the help of a pipe, smoke is removed to the outside into the atmosphere. It should be well insulated, as it heats up to a high temperature.

Also, at the very bottom of the Russian stove there is a pod or podpechek - a special compartment for storing a supply of firewood. The undercoat was often used for dishes. The sixth is intended for the convenience of cooking.

A few tips to make your firebox even more efficient

Figure 6

The furnace furnace in the furnace process will be even more effective if you pay attention to the following points:

- wet wood can cause the flame to go out after a while; the reason is the formation of a large amount of carbon monoxide inside the chamber; it is better to forget about undried fuel altogether, but if an unpleasant situation has arisen, you need to close the furnace damper and open the chimney and damper - for 10-20 minutes; after that, you can also open the outer door (chambers) for a while;

- logs that have not burned at least 50% are not recommended to move;

- it is advisable to rake the coals formed before the others to the center of the furnace bottom and overlay with burning fuel and hot coals;

- it is better that the temperature in the firebox exceeds 200 degrees; in this case, soot almost does not settle on the chimney walls.

What are the main differences in heating systems on coal and on wood

Coal is still a fairly cheap product, and coal-fired boilers are the cheapest of all modern devices. Hard coal burns slowly, giving off enough heat so that the problem of loading a new batch into the boiler does not bother you too often. Coal-fired boilers can also burn wood, but with less efficiency. Coal in the house is a constant source of dirt. Burning coal harms the environment.

Wood is considered an ecological fuel, when it is burned, no harmful compounds are formed. The cost of firewood can be very low. However, the price of certain types of wood fuel - briquettes or pellets - is still quite high. Harvesting firewood is a rather laborious and time-consuming process. Wood-fired boilers are more expensive than coal-fired boilers. Modern wood pellet boilers are almost fully automated and do not require special maintenance.

A coal boiler is right for you if…

There is coal mining in your area, or for some other reason, coal is cheap and relatively easy to order. In regions where coal is not traditionally used for heating, the use of such a boiler is completely unreasonable. When both coal and wood are available and you are looking for an inexpensive automated boiler, a coal-fired boiler is definitely your choice. Automated boilers for pellets and briquettes are still quite expensive, unlike the same coal-fired boilers

Such a choice will allow not to spend a lot of time and effort on loading fuel, which is quite important for a rural resident.

A biofuel boiler is right for you if…

- You prefer cleaner fuel. Having a coal boiler in the house, one has to put up with the constant pollution of space with coal dust. In this case, even the purchase of specially prepared portions of coal will not save. It is clear that cleaning the boiler room is not among the priorities, not to mention the fact that we breathe this dust, which does not improve our health in any way. Even simple firewood, from which sawdust and bark falls, is much more pleasant to use than coal. Pellets and briquettes do not pollute your house at all, they do not emit harmful compounds into the air. Ash from burning wood, in contrast to the waste of the combustion process of coal, is a valuable mineral fertilizer.

- You have access to cheap wood. In the "forest" regions of Russia, getting cheap firewood is not a problem. You can completely minimize costs if you harvest firewood yourself.Each household has the right once a year to receive a plot for firewood for very little money, however, this right is rarely used by anyone, since buying a standing forest involves a lot of time and effort. It is easier to buy already chopped firewood, which will be brought to your gate. If the question is not worth the money, then it is better to use pellets or briquettes for heating.

- Your priority is the ease of maintenance of the heating system. Although coal boilers are automated, nevertheless, pellet devices are much more advanced in technical terms. Some pellet boilers can be loaded once a week. The kindling of such a boiler is an easy task at all - due to its small size, the pellets ignite well. Most boilers are equipped with electric ignition, which is controlled by a controller, a well-thought-out air supply system to the burner, and even an automatic device for removing combustion waste.

What can't be done?

When burning coal in a furnace, it is prohibited:

- use pieces of bitumen, plastic, construction, household waste as kindling material;

- at the same time leave open the blower and the furnace door;

- when igniting, use gasoline, kerosene, alcohol, and other flammable substances.

It should be remembered that adults must constantly monitor the combustion process and in no case transfer this function to children.

To ensure maximum heat transfer, it is necessary that the coal is in the form of not too large pieces. It is not recommended to use excessively wet fuel, since a lot of steam will be released from its surface during combustion, which will significantly reduce the efficiency of the combustion process.

Not recommended:

- Use gasoline and other flammable liquids to kindle the stove. This may cause an explosion and fire.

- Burn garbage, polymers, roofing felt, roofing material, old shoes, etc. in the stove. This leads to clogging of the stove with hard-to-remove tarry soot and an unpleasant smell in the house.

- Burn with raw wood. Up to 40% of heat can be spent on the evaporation of moisture contained in firewood. In addition, damp firewood produces a large amount of soot. Firewood is considered dry if it has been stored under a canopy for 1 year. If there is no dry firewood, then it is good to dry a two-three-day supply of raw firewood in the house (near the stove).

- Close the stove roof (or Russian stove bench) with combustible materials. This leads to fires. You can put something on the stove only 2-3 hours after the furnace has stopped, that is, when the stove starts to cool down.

- Reheat ovens. The temperature of the furnace walls should not exceed 70 °C.

We invite you to read: Installation chimney sandwich pipes through the roof: detailed instructions

Furnace firing process

Regardless of whether coal or firewood will be used as the main fuel, ignition is carried out in the same way. First you need to clean the ash chamber and the firebox using a poker, shovel and broom. After cleaning, do not forget to remove the remaining ash from the door porches with a broom, otherwise they will not close tightly.

To ignite the stove, you must act according to the instructions:

- put on the grate a few crumpled sheets of paper and a few thin torches. It is unacceptable to use liquid fuel for kindling;

- from thin logs make a bookmark for about 2/3 of the volume of the furnace. Firewood can be folded "house" or crosswise, making gaps for air. This is where the shorties, which were mentioned earlier, come in handy;

- open the view about halfway, open the blower door a quarter;

- through the open door of the main chamber, set fire to the paper, then close it. Well, when you have a panorama glass furnace installed, then the process is clearly visible. If there is no glass, the door is left slightly ajar and the combustion is observed by adjusting the air supply with the ash pan door. Usually, at first it is opened halfway, and when the wood flares up, it is covered.

Reload

Solid fuel long-burning appliances are designed in such a way that one bookmark is enough for a long time. For ordinary wood-burning stoves, one portion is enough for a short time. At best, not 6-8 hours. Therefore, to maintain the operating mode, it is necessary to re-bookmark. It is performed when the tree is almost burned out, but a bluish light flame remains.

In the process of laying a new portion, two important conditions are observed. First, carbon monoxide must not be allowed to enter the room. Secondly, you need to maintain a high temperature, which will greatly facilitate re-kindling. Therefore, do everything as quickly as possible. They begin with the fact that the smoldering remains of firewood and coals are carefully raked into the center of the chamber. So that they are in the middle of the new bookmark. Then everything is done in the same way as the first time.