- To install a new disk, after cleaning the casing, you must perform the following steps:

- Saw blades for angle grinders

- Peeling

- For metal, concrete, wood and other materials

- How to change a disk on a grinder without a key?

- Peculiarities

- Recommendations of specialists for certain types of work

- Chainsaw chain sharpening

- Pipe cutting

- cutting moldings

- Sharpening a circular saw blade

- Cutting wheels for grinders, in turn, have their own subspecies, such as:

- Cutting discs

- About diamond tools

- What is required to install the disk?

- Which side to put the disc on the grinder?

- Types of discs for grinders

- Cut-off

- Cutting (abrasive) wheels for metal

- For wood

- Diamond

- Grinding and roughing

- Is there a significant difference from the direction of rotation

- Stuck nut - how to unscrew?

- Disc replacement by reverse rotation

- open end wrench and socket head

- Heat

- With a nail

- With a gas wrench

- Perforator or drill in chiseling mode

- Nut tapping

- Destruction of the cutting wheel

- Summing up: how to choose a disc for a grinder?

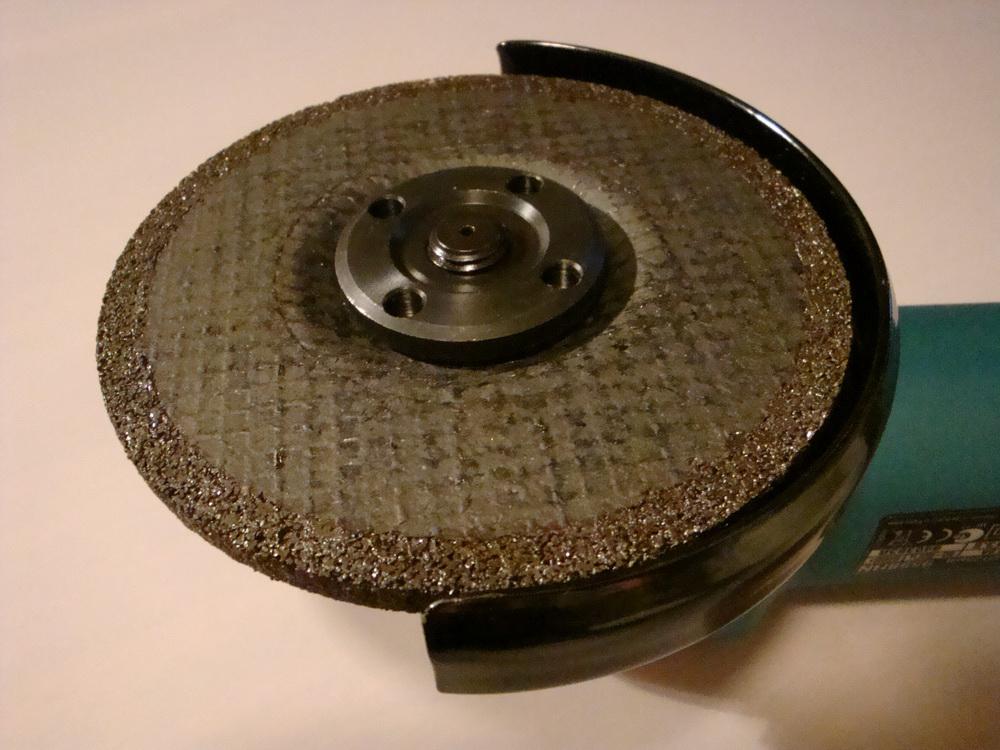

To install a new disk, after cleaning the casing, you must perform the following steps:

- We install the bottom flange in its place;

- We put a special gasket on top of it (if gaskets are not provided, you can cut them yourself. Cardboard or tin will serve as the optimal material).

- Installing the disk

- We put the second gasket;

- From above we install the upper flange;

- We wrap the upper flange by hand in the opposite direction from the rotation of the grinder circle, while holding the disk itself;

- Next, press the lock button again and scroll the flange with your hand until you feel resistance;

- At the final stage, we make the final fixation using the same open-end wrench. To do this, insert the key into the holes and scroll a little more.

After all the actions taken, you can safely continue to do the work.

One of the most frequently asked questions about the installation / dismantling of angle grinder equipment is: “Which side to put the disk on the grinder?”.

Usually, inexperienced masters ask such a question. Is it possible to set the circle with the wrong side - yes. Firstly, if the disk is not flat, but, for example, petal, then you will not be able to install it incorrectly, if the petals are not positioned correctly, you just need to twist the casing and the handle on the grinder. That is, the question disappears by itself.

If the circle is still flat, then you should focus on its label, the so-called "shirt".

If the angle grinder rotates towards itself, the disk should be installed with the “shirt” outward, if the disk rotates away from itself, then, accordingly, it must be installed with the “shirt” inside.

If you do not adhere to this algorithm, there is a high probability that the disk will fail very quickly or immediately deform.

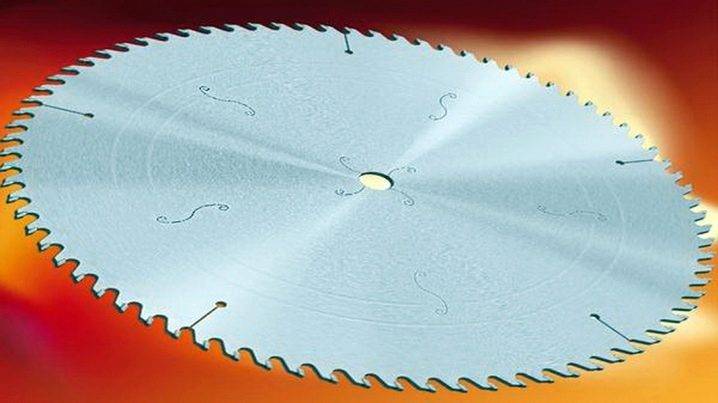

Saw blades for angle grinders

Wood saw blades for angle grinders were developed by various manufacturers and, accordingly, have several varieties.The simplest and definitely the most budgetary option is to install a circular disk of the appropriate size on the grinder - both the outer diameter and the diameter of the inner mounting hole. For a grinder, which, according to its dimensional characteristics, is classified as small, a circle of 125x22 mm is suitable.

Technically, a disk with a diameter of 230 mm can also be installed on a small angle grinder, but for this you will have to remove the protective cover, which is absolutely unacceptable. An angle grinder user's hands are in close proximity to the rotating work surfaces and any abnormal situation can cause serious injury. The use of such a circle on an angle grinder can cause serious safety violations and is strongly discouraged for beginners.

Any misalignment, including those associated with the uneven structure of the wood, can cause the disc to jam and, as a result, a sharp jump in the entire unit to the point that it can escape from the hands and make a dangerous unpredictable flight. saw blade not intended for circular such fast revolutions that the grinder spindle gives out, this results in its excessive heating, which affects the strength of the steel. As a result, when skewed, the saw wheel can be destroyed with fragments flying at high speed in unpredictable directions.

Special attachments for sawing wood, designed for UMSh, have significant differences from the circular saw blade. Consider the most common nozzle options for sawing wood. On sale you can find saw blades similar to circular saws, which have an increased tooth set, which significantly reduces the likelihood of jamming.In addition, the difference for the manufacture of such a disc is that other alloys are used, which reduces the risk of destruction of the disc when it is heated.

Further attempts to secure the disc from jamming led to the combination of circular and chain saws in one product. The chain, similar to the chainsaw chain, moves freely along the working surface of the disc, which absolutely eliminates jamming. There are quite a few modifications of such a hybrid. Craftsmen with the help of such a combined saw successfully saw branches and can even saw not very thick trees.

A completely new direction in the evolution of circular discs was marked by the invention of a special nozzle that is suitable for working on various materials. Such a universal disc is made of a special composition - tungsten carbide. There are no teeth on this saw blade at all. This type of blade allows you to cut a variety of materials well, it can be considered the safest blade for sawing wood of all that are used on angle grinders.

Peeling

It is worth mentioning right away that roughing and grinding discs go hand in hand, and in many stores in the “type” parameter of the nozzle it can be written: “grinding roughing disc”. In our article, we will break this “couple” into two types. Peelers in this context are a nozzle for freeing the structure being processed from the outer layer, for example, from rust. There are such peeling nozzles:

Roughing discs. Peeling discs, like cord brushes, can be flat and bowl-shaped. They are intended for cleaning welds and preparing metal surfaces for grinding.

For metal, concrete, wood and other materials

For efficient processing of any material, it is important to choose the right power to match the diameter of the tool and its thickness. In addition, the consumable must be suitable in terms of characteristics for processing a particular type of workpiece material.

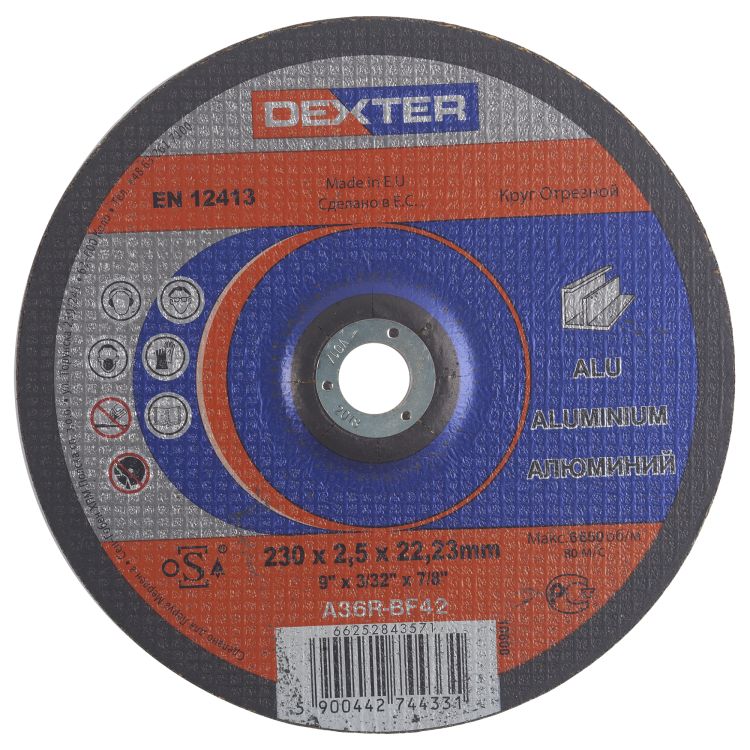

The main difference between discs for steels, cast iron, non-ferrous metals in the composition of fillers. For processing alloyed steels in the composition of the material disc is added a very strong additive that can overcome the resistance of alloy steel. When processing non-ferrous metals, on the contrary, a soft filler is added, which works effectively when processing viscous materials.

Disc for aluminum

For processing concrete (tiles, paving slabs), diamond discs are used (actually, these are metal circles with diamond coating).

Disc for tiles

Processing wood with an angle grinder is not recommended due to the high risk of injury. If, nevertheless, such a need arises, then the best option would be a grinder with a disc with a diameter of 125 mm. As a working tool, special angle grinder disks for wood should be used.

wood disc

How to change a disk on a grinder without a key?

Method 1. Use a gas key

Grasp the nut with a pipe wrench and carefully unscrew it without applying much force. Disadvantage: you can crush the nut, break the rotation lock

Method 2. Make a homemade key for the grinder. To do this, you need a long nail (at least 100 mm). It is necessary to cut off the hat, the tip and give the nail a U-shape. It should be bent in such a way that the “tool” racks fall into the holes of the flange.If the nut is tightened tightly, insert any metal bar between the nail posts and, holding it with both hands, rotate the structure in the direction of the circle. At this time, you need to press and hold the spindle lock button. The method is safe, but it takes time and additional tools - a hacksaw, a vice, a hammer.

Method 3. Tapping with a chisel. Before changing the disc, you can treat the spindle shaft with WD-40 fluid and wait at least 15 minutes. Then put the tip of a thin chisel at an angle to the hole of the flange nut and gently tap on the entire surface of the hole with a metal hammer. Sooner or later, due to slight tapping, the nut will break, and it will be possible to unscrew it manually. The disadvantage of this method is that the holes can be damaged and the flange damaged.

Method 4. Heat the nut. If it is difficult to unscrew the angle grinder nut with your hands, you can heat it up a little with a gas burner or autogenous. You need to unwind the flange with gloves so as not to burn yourself. This is the most risky of the proposed methods. It is possible to overheat the bearings and oil in the gearbox of an angle grinder.

Finally, I would like to mention a few important points regarding the replacement of the disc in the grinder.

- On the angle grinder, you need to install circles of a suitable size. It is necessary to strictly observe safety precautions and in no case do not remove the protective cover in order to install a disc of a larger diameter. When choosing a disc, you need to take into account the model of the power tool, its power, spindle speed.

- Due to the disc rotating at high speed, hardening is formed on the protective cover of the angle grinder. Therefore, when changing the disc, remove and clean the casing.

- Washers are provided in some models of angle grinders so that the disc does not get stuck between the flanges. At least the support flange can be equipped with a rubber washer. Instead of factory fasteners, gaskets can be cut out of cardboard, rubber or plastic. You need to use 2 gaskets: between the support flange and the disc, between the disc and the nut.

- Do not forget: if the circle rotates clockwise, then the nut is also unscrewed clockwise and twisted against.

- If you don’t want to buy a new key, install a Bosch quick-lock nut on the angle grinder - you can easily unscrew it by hand.

The main thing is that when changing a disk on an angle grinder, do not violate safety precautions and perform all manipulations with the tool turned off from the network.

Peculiarities

Consider what a cutting wheel for an angle grinder is. In fact, this is the main device in the process of cutting or processing material. The engine in the grinder spins a diamond blade, which has a certain amount of cutting crystals. It is these strong crystals that cut the surface.

The cutter can be designed for different types of work, depending on the material with which it is necessary to work, and according to its functional purpose. There are cutting wheels for metal, wood, plastic and even stone. Over time, the circle gradually grinds and becomes smaller.

Recommendations of specialists for certain types of work

Next, we will tell you how to work with an angle grinder with various metal products.

Chainsaw chain sharpening

Photo No. 12: sharpening the chainsaw chain with a grinder

The chain is sharpened on the arrow of the chainsaw. For work, a grinding disc with a thickness of 2.5 mm is used. It is necessary to mark the first tooth that you will process.With competent actions, you can update the chain 4-7 times before it finally fails.

Pipe cutting

Photo No. 13: cutting pipes with a grinder

It is better to start cutting thick metal with a grinder from the edges. If you start from the middle part, the disc can jam and bend. During processing, apply force to the lower part of the cutting tool, which ensures efficient cutting.

cutting moldings

Photo No. 14: cutting corners with a grinder

To cut metal corners, you can use worn discs or a tool with a small diameter

It is important to remember that the work is phased: first, one part of the molding is cut, then the second.

Sharpening a circular saw blade

Photo number 15: sharpening the circle of a circular saw with a grinder

Start by fixing the angle grinder with clamps, leaving access to the rotating part of the tool. Then bring the saw blade to the grinding wheel without much force. The circle must pass along the product tangentially. When working, make sure that the sharpening plane is observed.

Cutting wheels for grinders, in turn, have their own subspecies, such as:

- Cutting wheels for metal work;

- Abrasive wheels for working with stone;

- Circles for woodworking;

- Diamond discs (which were mentioned above).

The purpose of each type of disk usually corresponds to its name.

Among the grinding discs, there are four main subtypes - flap, wire, diamond and bakelite-based grinding discs (straight, profile T41 and dish-shaped, profile T27).

- The petal disc is made from sandpaper. Its main purpose is the elimination of an existing coating, such as old paint, primer or a layer of paintwork.Also, discs of this type are used for grinding wooden products.

- Wire discs are used by craftsmen to remove rust. They can also remove other types of persistent pollution.

- Diamond discs are used for polishing stone work.

- Disc discs are made of plastic or rubber and are used for polishing metal surfaces.

Cutting discs

Cutting discs are most commonly used when working with a grinder. The following nozzles are distinguished by purpose:

For metal. These cutting wheels are made from electrocorundum or crystalline corundum. In this case, a bakelite bond is often used inside the product. Depending on the thickness and size, the disc can cut metal profiles, stainless steel, heating pipes, etc. GRAFF GADM 115 10 is one of the inexpensive discs for metal.

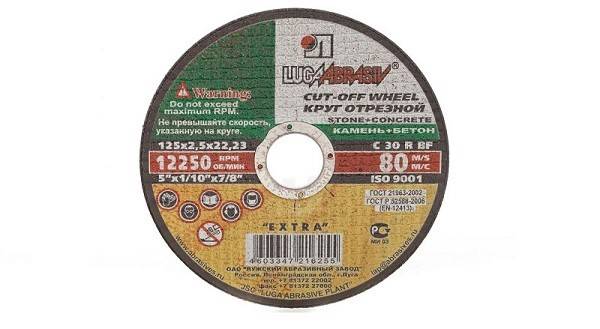

For stone and concrete. Wheels for cutting stone and concrete are made of silicon carbide

Please note that the disc is designed for relatively "non-hard" materials such as white brick and slate (harder ones will need a diamond wheel)

For ceramic tiles and concrete. This attachment is designed for cutting paving stones, ceramic tiles, red bricks, cutting strips for chasing, etc. The disc itself is made of metal with diamond grit applied to the cutting edge. There are solid all-metal and segmented discs. The former are designed for wet cutting (cooling with water), as they get very hot during the process. Segmented ones are convenient for dry cutting, and they are the most popular among diamond blades.Here, for example, is a high-quality durable Makita B-28086 segmented disc for cutting concrete and stone products.

For a tree. Discs for processing wooden structures are tungsten carbide carbide or metal with abrasive coating. The first are designed for sawing hard and soft wood, drywall, gas silicate and MDF. The second one can also cut metal and even wood with nails (but this must be verified empirically). Bison Professional 36859-125 is just such a representative of the "nail saw".

Universal. These nozzles can cut almost all types of materials (for wood, it is better to take a nozzle for direct use). In particular, they are convenient to use when you have to cut different materials in one working day, and you don’t want to waste time changing the nozzle. Universal models cut even reinforced concrete. However, they are often quite expensive, and sometimes it is more profitable to buy two discs for different types of processed materials. Of the good universal wheels, we can recommend Wolverine 100125, which is suitable for both wet and dry cutting.

About diamond tools

" Back

Most specialists in repair and construction work today they are well acquainted with an angle grinder or, as it is also called by the people, a grinder. It is used to process a variety of materials, including stone, reinforced concrete, concrete, marble and many others.For beginners, at first, a number of questions may arise, among which the most frequent ones are: how to properly install the disc on the grinder, how to fix the disc on the grinder, which side to put the disc on the grinder and in which direction the disc on the grinder should spin. Let's try to briefly answer all these questions.

What is required to install the disk?

Installing a disc on an angle grinder is usually a fairly simple process in which you need to follow a few rules. In order to produce it, it is necessary to arm yourself with the appropriate tool - a key that will be needed to unscrew the nut. The next step after it has been untwisted will be the replacement of the grinder disk or its initial installation. If it happened that the disc was clamped in the grinder, to remove it, you will have to crumble it and remove the remnants from the gap between the support flange and the nut with a flat screwdriver or chisel.

Which side to put the disc on the grinder?

Which side to put the cutting disc on can depend on several factors. Firstly, if the disk is not flat, then there is only one way to put it, and the question disappears by itself. Secondly, if the circle is still flat, you can focus on the label - if the angle grinder is spinning away from itself, then it is set with the label inward, if towards itself, then, respectively, outward. If this principle is not followed, then undesirable results can be expected - disc breakage during sawing or simply its rapid wear.

As for the direction in which the disk rotates on the grinder, this is primarily a safety issue. It is believed that it is necessary to cut concrete in the direction of rotation of the disk or towards itself.In the ideal position, the sparks should fly to the side to the left of the one who works with the tool. If this does not work, then you can use another position when a sheaf of sparks is sent down. In any case, situations should not be allowed when sparks fly from the user, since in the event of a sharp jamming of the disk, the angle grinder will be directed towards him.

In other words, it is extremely unsafe to cut materials against the direction of rotation of the disk or away from you, since in the case of a wedge, the angle grinder is thrown sharply in the direction of the one who is working. By the way, if you have additional questions about how to install a disk on an angle grinder, you can also watch training videos, which are more than enough on the Internet today.

If you have any questions or need advice on changing and installing discs, just leave a request on the website or call the specified contact phone number, and our experts will tell you how to proceed. The entire range of our diamond blades is presented in the diamond blades section.

Types of discs for grinders

Angle grinder is widely used in construction and repair technological operations. Discs for grinders differ from each other:

- dimensions of outer diameter and thickness;

- material and method of manufacture;

- purpose and maximum speed.

The choice of disks for an angle grinder implies knowledge and consideration of the features of not only the workpieces being processed, but also the capabilities of the tool itself.

Cut-off

The most used wheels for angle grinders are also called abrasive. They are classified according to different criteria. There are discs for working with metal, stone, wood.There is also a diamond disc, which is used to work with the most durable and hard materials (reinforced concrete, porcelain stoneware, tiles, marble, granite and other natural and artificial stones).

We give a brief description of each type.

A common feature for all cutting discs is the classification according to the outer diameter and thickness. The outer diameter is:

- 115 mm for small household grinders;

- 125 and 150 mm for medium-sized angle grinders in terms of power and weight;

- 180 and 230 mm for powerful professional tools.

The thickness of the discs varies from 1 to 3.2 mm. It depends on the size of the nozzle: discs with a large diameter are thicker; discs medium and small - any. The choice of disc thickness is influenced by:

- speed of rotation of the working body of the grinder;

- expected load.

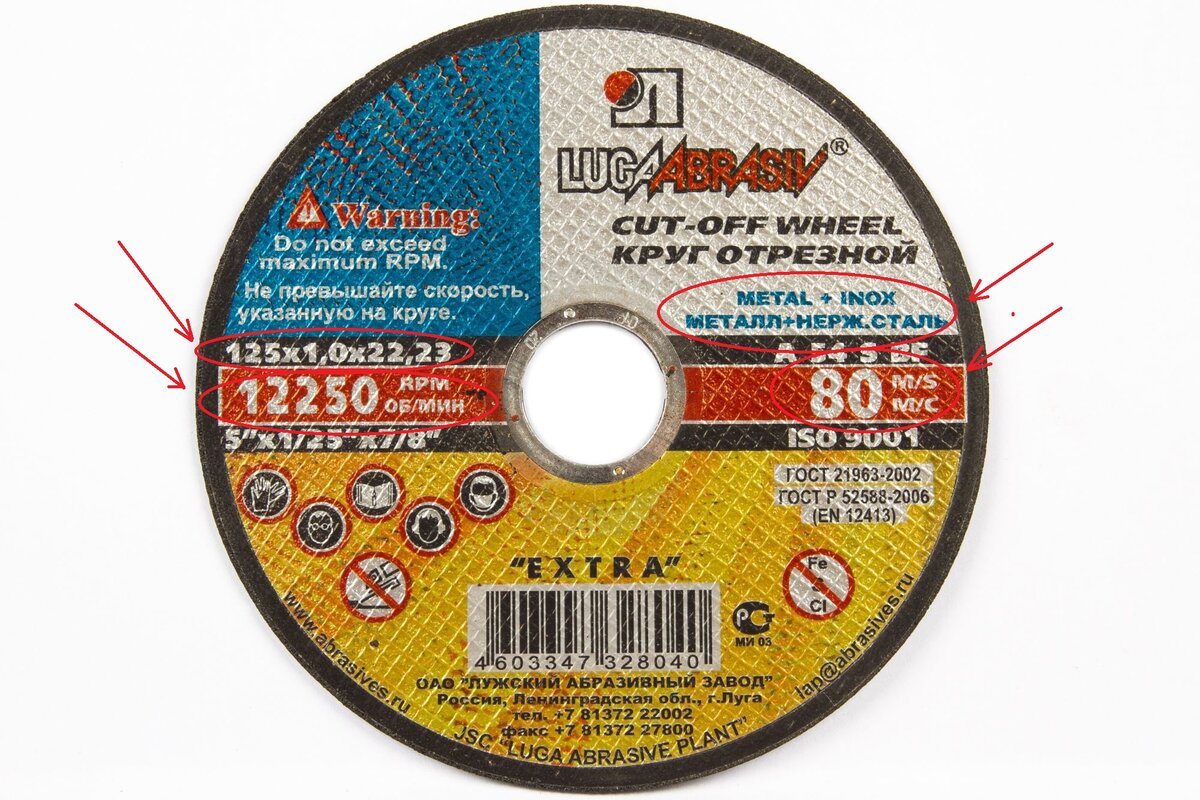

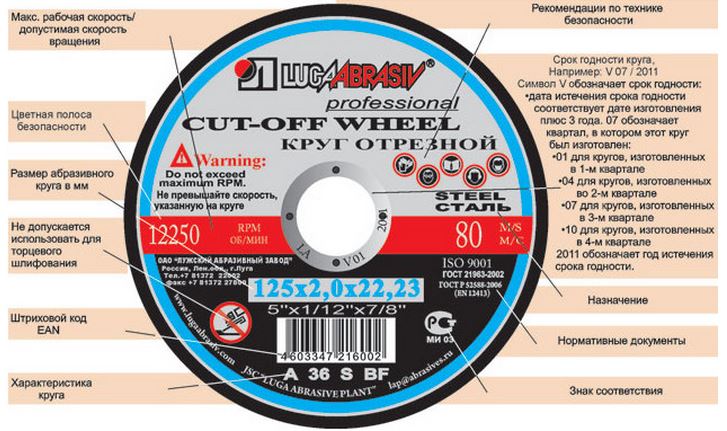

Cutting (abrasive) wheels for metal

These wheels are used to work with body sheet steel (disc thickness from 1 to 1.6 mm) and rolled steel: rebar, round timber, channel, angle and other types (disc thickness from 2.5 to 3.6 mm). There are special nozzles for working with stainless steel, aluminum, cast iron and other metals.

Cutting disc for metal grinder

Information about this is available on the surface of the disk in the form of a printed marking and a colored strip. Abrasive discs are several layers of fiberglass mesh, on which under great pressure bakelite abrasive material (silicon carbide, corundum, electrocorundum) is pressed on both sides. The reinforced abrasive discs are then placed in a heat treatment oven to gain strength. The set heating temperature is 200 degrees. There, the mass is sintered and becomes strong and resistant to destruction into fragments.

They are absolutely identical to discs for metal and differ only in the abrasives used.

Circle for stone

For wood

They are made of high-strength steel and equipped with sharp teeth on the outer diameter. These nozzles work on the principle of a circular and are quite dangerous in operation. It is recommended to permanently fix the angle grinder with a special tool.

Cutting disc for wood for grinders

Diamond

They are used for cutting high-strength materials made of natural and artificial stone.

Diamond disc for stone grinder

There are different types of diamond blades for concrete, reinforced concrete, stone. Between themselves, they differ in fractional diamond coating and the type of cutting edge - solid, with large or small slots, notches

It is important to know that the diamond blade is not used to work with metal blanks. In appearance, it is difficult to understand the purpose of diamond discs.

The best option is to consult a sales assistant before buying or carefully study the application to the package.

Some manufacturers of diamond blades paint the front side with paint, depending on the material for which they are intended:

- green - for granite;

- yellow - for plaster and tiles;

- blue - for marble and concrete;

- gray - for granite ceramics and tiles;

- orange - for bricks.

A diamond blade with a segmented cutting blade is used for cutting stones in a dry way. Wheels with a solid cutting edge require water cooling. Slotted turbo discs run at a higher rotational speed than segmented blade discs.

Grinding and roughing

Grinding wheels are divided into four types:

Petal (emery) nozzles remove old paint, primer or varnish, polish wooden products.

This is what a petal disk looks like

Rust is eliminated with special wire wheels and stubborn dirt is removed.

Diamond modifications in the form of a bowl are used to polish stone products.

Disc discs from plastic or rubber metal surfaces are polished. Replaceable discs with sandpaper, felt, sponge, cloth can be attached to the plates.

Most grinding discs work with special pastes or liquids, including finely ground abrasives. These nozzles polish surfaces of any materials, including car body parts in car services.

Is there a significant difference from the direction of rotation

The direction of rotation of the cutting wheel can be either “toward” or “away from you”. Each of them has its own advantages and disadvantages. So when the disk rotates “away from itself”, dust and sparks fly onto the operator, which creates additional difficulties in work, is associated with possible burns to the eyes, skin, and clothing flashes. The rotation of the disk "on itself" is devoid of this drawback. But in this case, there is a higher risk of injury. After all, if the disc is clamped, then the tool will fly with force into the face of the operator. There is no single rule in which direction the cutting wheel should rotate.

If this is important, then the information must be indicated on the instrument. In all other cases, the direction of rotation is chosen by the operator, taking into account the type of surface to be treated, convenience and work experience.

Stuck nut - how to unscrew?

It is not so easy to remove a disc on a grinder if it is bitten, especially without damaging the cutting element or tool. We will also consider several options for action.

Disc replacement by reverse rotation

This method has several advantages - it can be done without a key and with a broken spindle lock. Beginners in working with angle grinders mistakenly believe that if the stopper is broken, it is almost impossible to unscrew the nut. However, this is not the case. You don't even need keys.

The bottom line is that the abrasive wheel needs to be rotated in different directions. Putting on thick gloves, you need to hit the cutting edge of the circle several times. This is what you will provide variable movement in different directions. As a rule, a couple of sharp blows are enough so that the nut can be easily unscrewed.

open end wrench and socket head

In this case, you will have to slightly modify the existing standard tools - an open-end wrench for 17 and a socket head for 24 mm. The thickness of the key is ground down to 4 mm. 4 protrusions are machined on the head, falling into the holes of the fixing nut.

After preparation, the key is placed in the space under the disk, and the head is put on the angle grinder flange and rotated in the opposite direction to the rotation of the circle. After that, it can be easily removed and put a new one.

Heat

This is one way to remove a disc from a grinder without a key. The fixing nut is heated with an industrial hair dryer or a gas burner. After that, the flange will unscrew much easier. However, there is a risk of damage to the plastic parts of the grinder or gearbox.

With a nail

For these purposes, a 100 mm nail is best suited. It should be bent into a U-shape so that the ends fit freely into the holes in the clamping flange.The tip and cap are removed. By inserting a nail into the holes, the latch is turned away. If the efforts of the hands are not enough, then add a nail or a screwdriver in the form of a lever.

With a gas wrench

The use of this tool is justified by the increase in the applied moment of force due to the increased shoulder. It will be much easier to unwind a jammed connection with a gas wrench

However, when eliminating jamming, it is important to remember that applying excessive force can damage the spindle lock or clamping nut.

Perforator or drill in chiseling mode

You can unscrew the disc on the angle grinder without a key using a drill or puncher, after switching it to the jackhammer mode. A suitable drill is used as a working nozzle, most often 6 millimeters. Rest the drill against the edge of the hole of the clamping nut, fix the movement of the spindle and briefly turn it on to move it. This method allows you to turn away even very complex bites.

Nut tapping

This method is similar to the previous one, only you can use a suitable metal rod or chisel. With the spindle head fixed, tap along the edges of the clamp holes in the direction of the wheel movement. Slightly moving the latch off the dead center, you can unscrew it with your hands. However, the method is not the most harmless for the tool - the mounting holes for the standard key are damaged.

Destruction of the cutting wheel

You can unscrew the jammed nut by completely destroying the disk. If there is already damage, then you can break it with your hands, but most often this will not work. Better take a hacksaw or sheet metal and cut. As a result, you will be left with a central ring and hard-to-reach pieces.Having found a suitable plate, holding it in a vice, grind off the remnants of the abrasive on it to a metal ring. After that, it will be easily unscrewed with a standard key.

The most radical way to unscrew a jammed clamping nut is to cut it. It is advisable to resort to it only in extreme cases. Of course, you can find a new one, but you will have to spend your time and money. It is not uncommon for spare clamping elements to be included in the delivery set of the angle grinder.

Summing up: how to choose a disc for a grinder?

To correctly buy a disc for an angle grinder, you must:

- Know the maximum disk size your angle grinder can handle. Do not take discs larger than the device allows.

- Know the maximum speed of the grinder. The higher the speed of the angle grinder, the smaller the size of the disks it can work with.

- Processed material. For wood, metal and stone their discs. There are universal ones that can cut almost anything.

- Seat size. The size of the seat of the circle must correspond to the same parameter in the angle grinder.

- Manufacturer. Do not buy frankly cheap discs or products from unknown manufacturers - they will "disperse" like hot cakes in the school cafeteria, and the savings will be minimal.

- 6 dangerous mistakes when working with a grinder, which are better not to make.

- We lay the wiring in the house: how to choose the right wire?