- original solutions

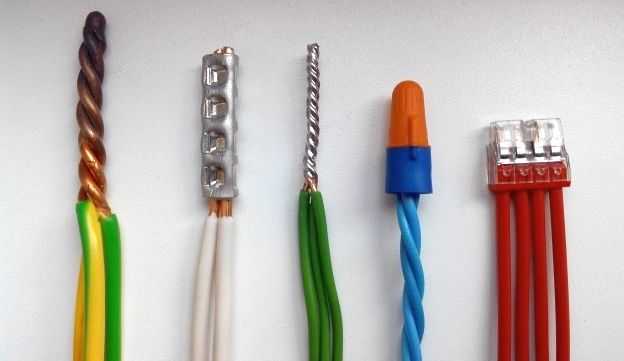

- Types of twists. Twisting errors

- Various twist options

- Twisting

- Terminal clamps

- Terminal block

- Terminals on plastic blocks

- Self-clamping terminals

- stranded wires

- Parallel twist

- Sequential stranding

- Bandage twist

- Soldering as a reliable alternative to twisting

- Types of electrical wire connections

- Splicing stranded wires without twisting

- Connecting wires with a diameter of less than 1 mm with a twist

- Connection of copper wires in any combination by soldering

- Tips to help you

- Conclusions and useful video on the topic:

original solutions

It is not necessary for everyone to know how to make the correct twist using non-standard solutions, but in some cases it is such knowledge that helps to cope with the work. For example, how to make a twist in which it is necessary to connect not two or three cores, but several dozen pairs? For this, a special mechanical device is used - manual press equipment. Both stranded and single-core wires of the same metal are twisted with such a press.

Sometimes, on the contrary, it is necessary to decide how to properly twist for low-voltage installations: power cords, LEDs, telephones, etc.For this, special connectors are used, which are plastic caps for twisting wires, inside of which a metal alloy plate in a special solution is placed. It is a hydrophobic gel that prevents rust and protects the contact from oxidation and moisture ingress.

If you find an error, please highlight a piece of text and click Ctrl+Enter

.

Types of twists. Twisting errors

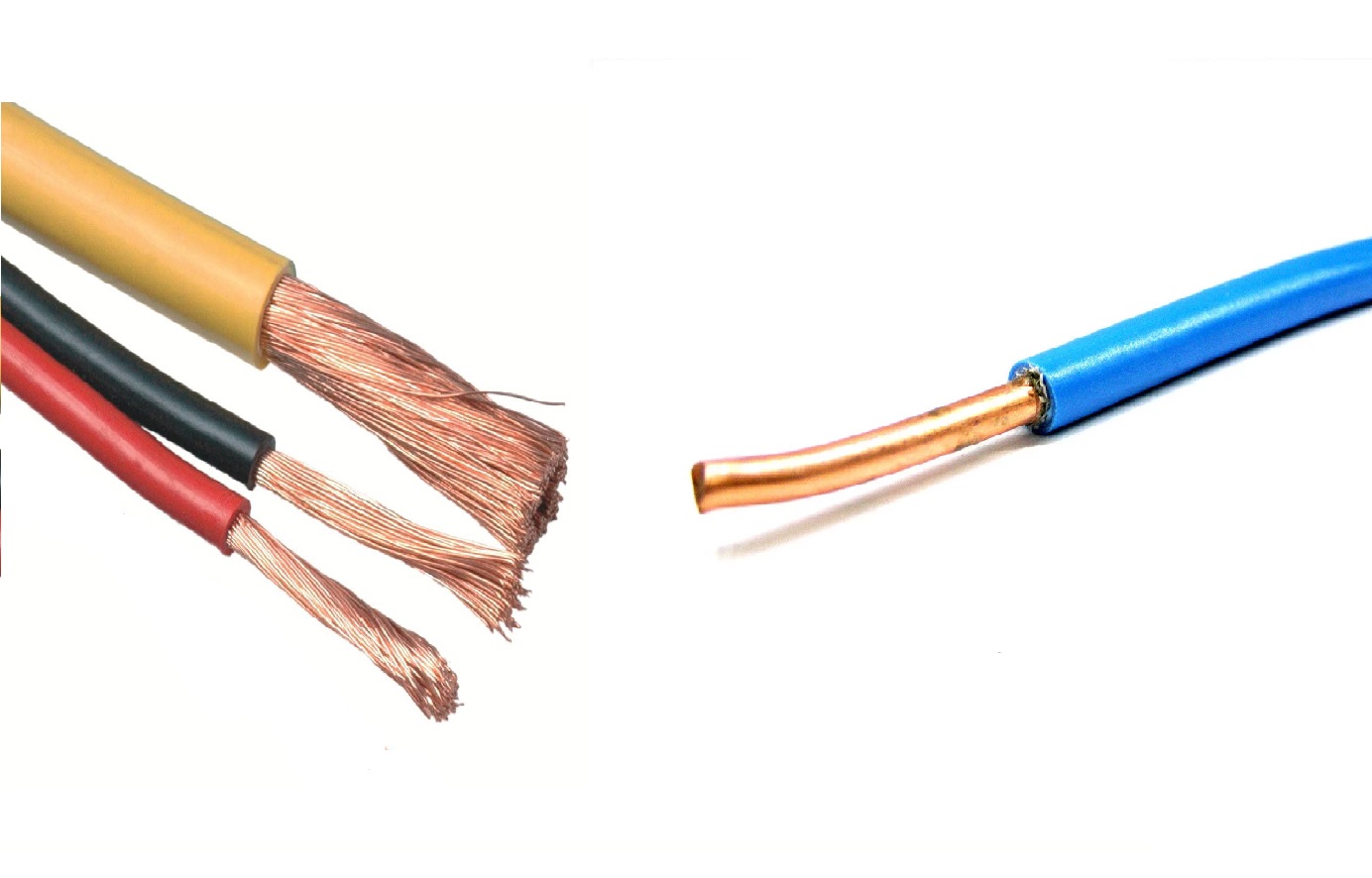

First, let's remember that wires are aluminum and copper. Copper wires are divided into solid (one solid core) and stranded (flexible).

Monocore is used for stationary connection of equipment. Once laid under the plaster, behind the drywall and forgot about them. Wiggling and bending such wiring is no longer required.

Stranded ones are used for mobile devices or temporary connection of electrical equipment. Where the wiring constantly needs to be moved from place to place, change its location. These are home carrying, household appliances plugged into sockets. They are also used in the assembly of switchboards, where there is a shortage in free space, and the cores have to be significantly bent in order to lead the devices into the terminals.

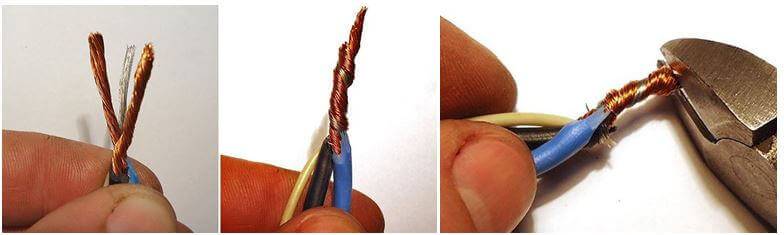

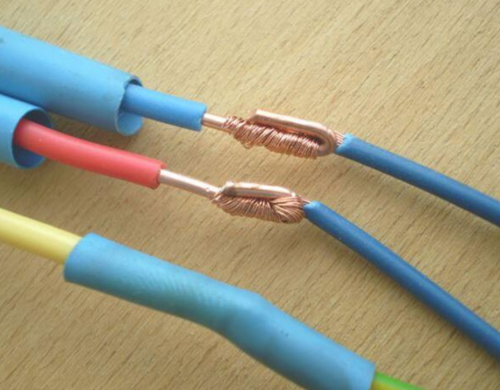

Consider first how to properly twist the wires from the monocore. The process here is not intricate and is known to everyone. Two wires are taken, stripped at the ends and begin to twist together.

The main features and rules in this process:

- wires must be of the same material (copper or aluminum)

- clean the core by at least 3-4 cm, thereby increasing the usable contact area

- wires run parallel to each other

- both wires must be twisted evenly among themselves

- when twisting with some pliers, hold the place where you start stripping the insulation, and twist at the end with others. The insulated parts of the conductors must not be twisted together.

- the number of turns that should be obtained in the end - from five or more

The twists of aluminum and copper wires are performed in the same way. The difference is that you can spin and twist copper several times, and aluminum 1-2 times. After which they will break off.

And if you need to twist more than two wires, say 4-5? The process is no different:

- with your hands, slowly twist the wires only giving them the shape of a future twist

- take two pliers and, holding the twist at first, tighten the veins at the end

- the length of the stripped areas should also be 3-4cm

There are situations when it is necessary that the twist takes as less as possible places. Either there is not enough space in the junction box, or it must then be pulled through a narrow hole. In this case, the technology is slightly different.

- put the stripped strands of wires cross on the cross, in the middle of the stripping place

- and begin to twist them so that the ends after folding are equidistant from each other

For quality and reliability such twists are inferior to ordinary ones.

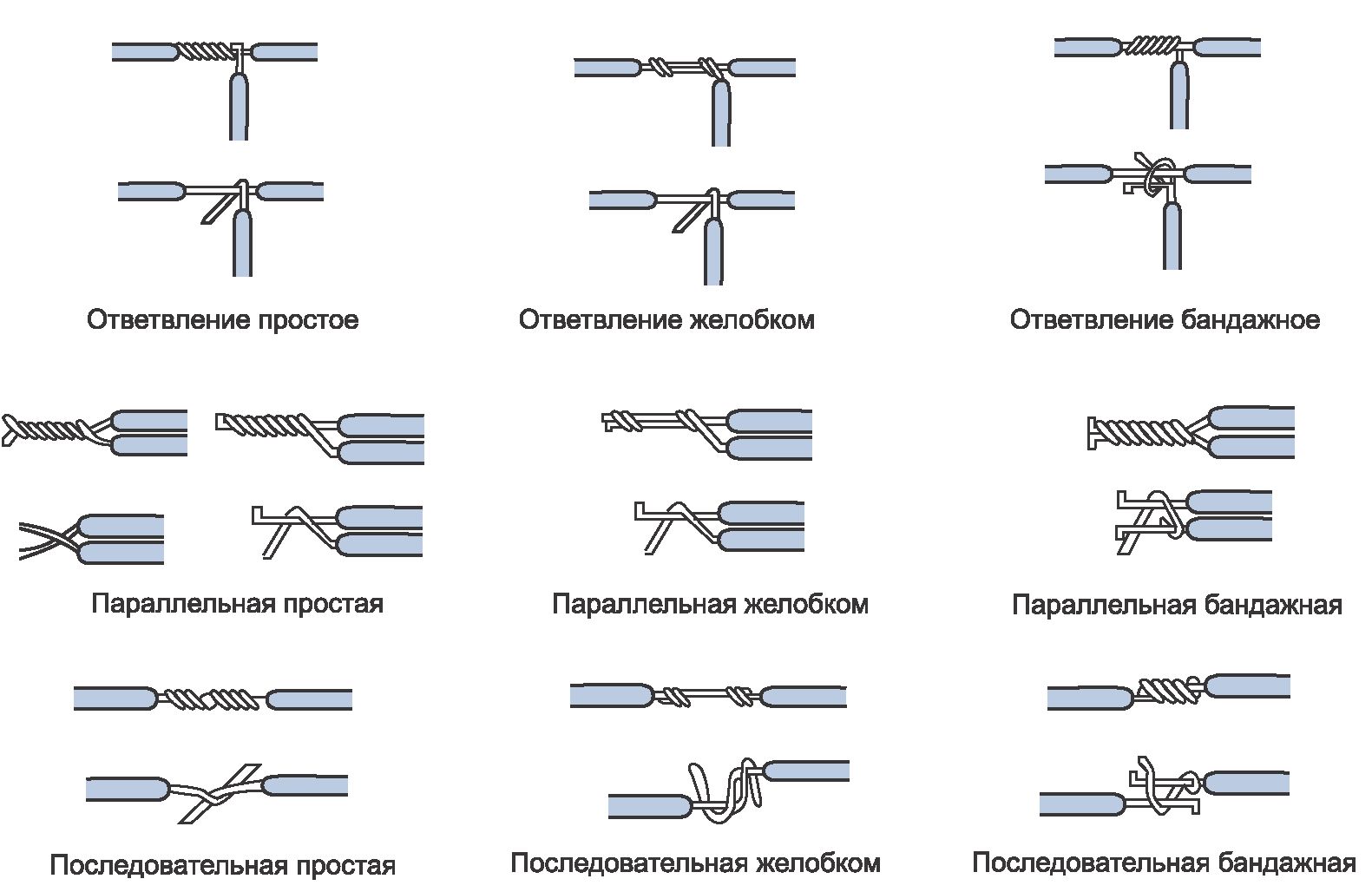

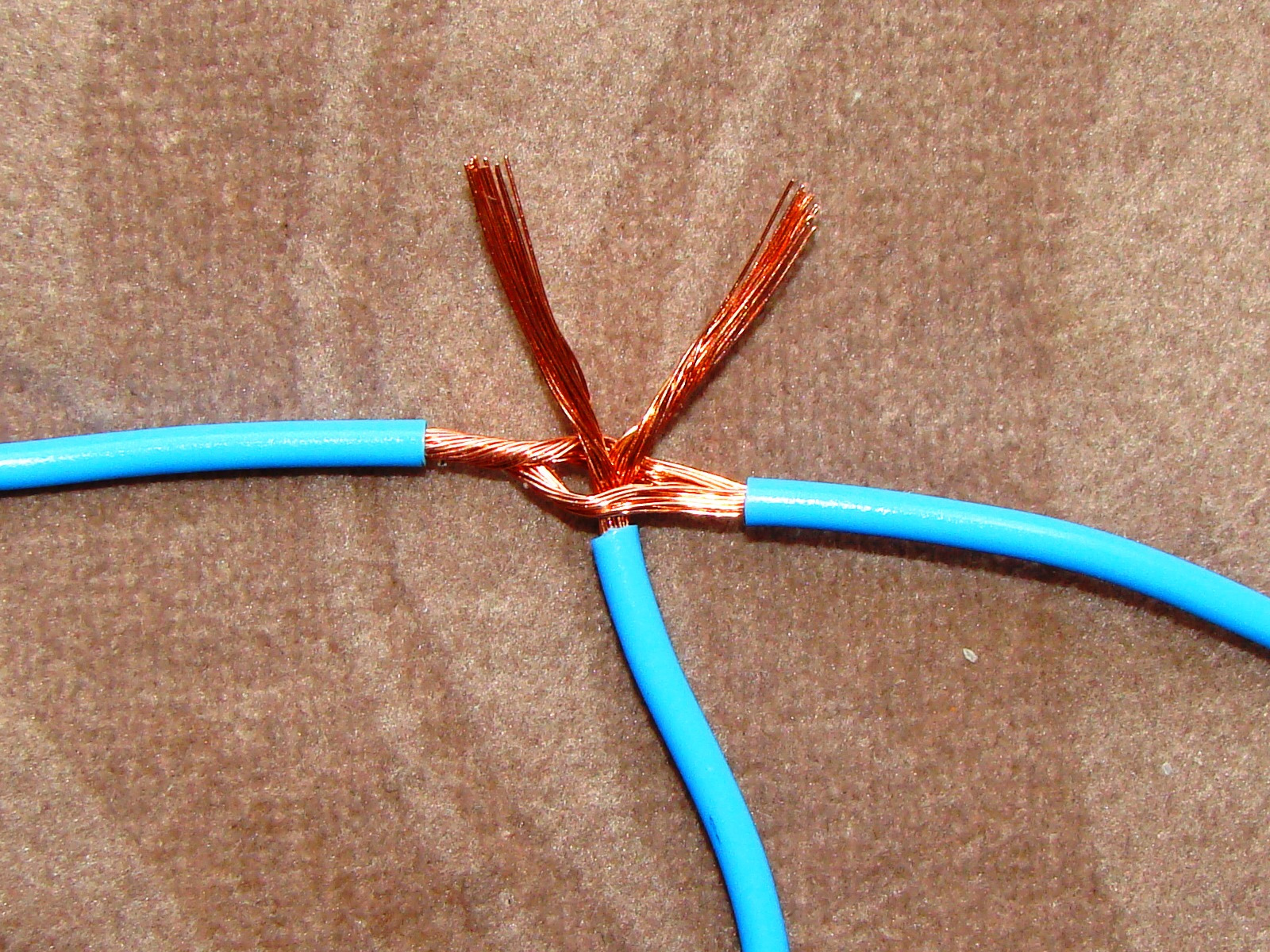

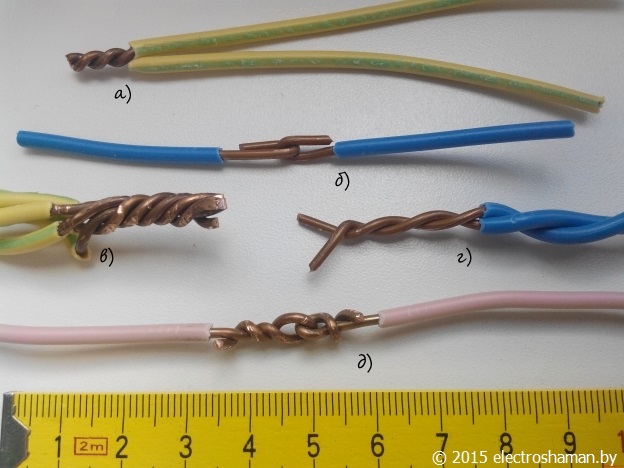

Various twist options

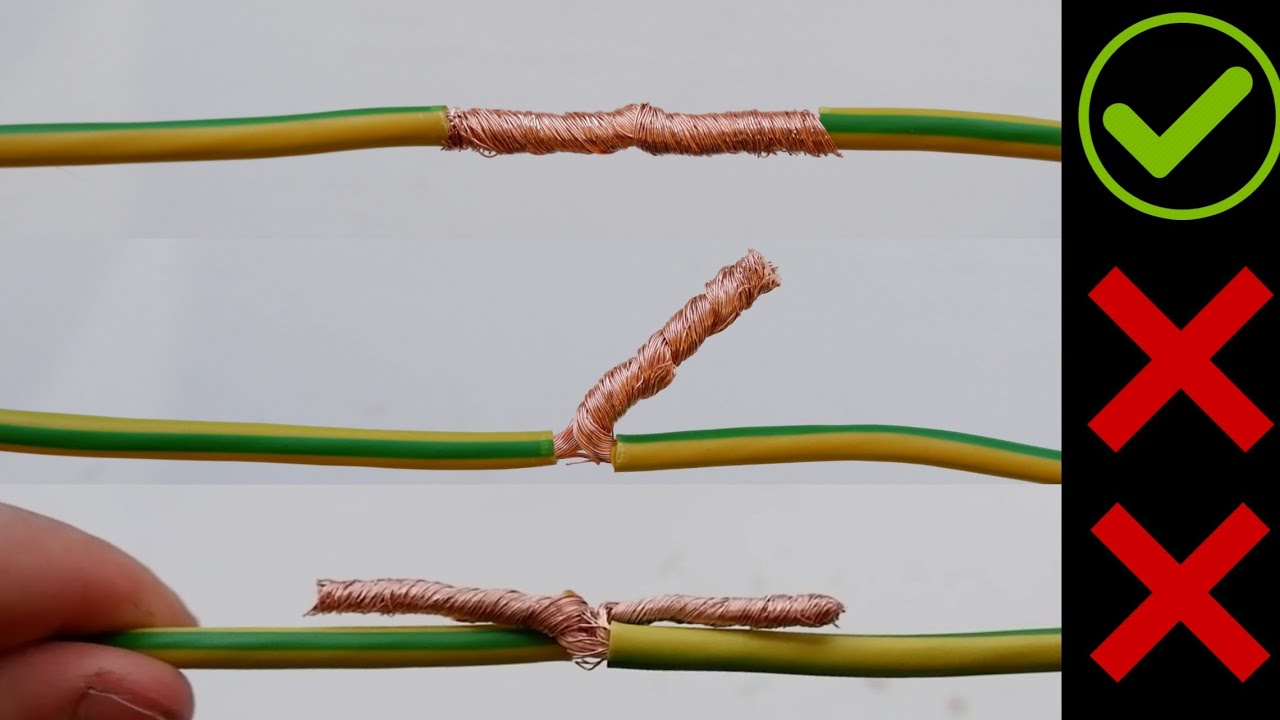

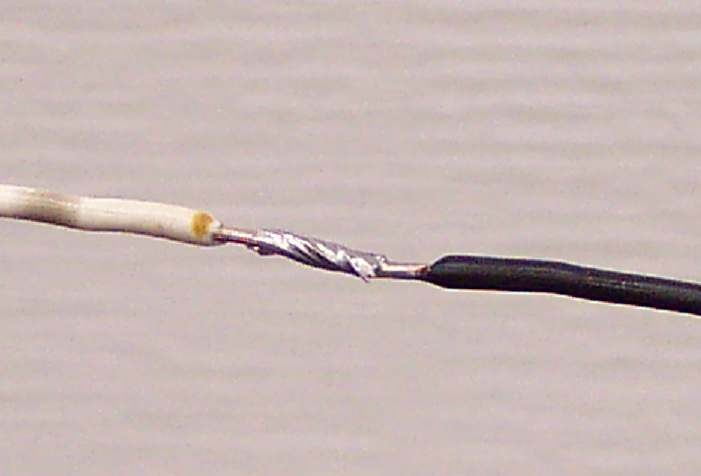

Unprofessional connection. This is a twisting of a stranded wire with a single-core. This type of connection is not provided for by the rules, and if such a connection of wires is discovered by the selection committee, then the facility will simply not be accepted for operation.

However, twisting is still used, and here you need to know how the correct twisting of stranded wires is performed.It is often used in emergency cases when it is not possible to professionally make a connection, and the service life of such a connection will be short. And yet, twisting can temporarily be used only for open wiring, so that you can always inspect the junction.

Bad wire connection

Bad wire connection

Why is it impossible to connect the wires with a twist? The fact is that when twisting, an unreliable contact is created. When the load currents pass through the twist, the place of the twist heats up, and this increases the contact resistance at the junction. This, in turn, contributes to even more heating. Thus, at the junction, the temperature rises to dangerous values, which can cause a fire. In addition, a broken contact leads to the appearance of a spark at the place of twisting, which can also cause a fire. Therefore, in order to achieve good contact, it is recommended to connect wires with a cross section of up to 4 mm2 by twisting. Details about the color marking of wires.

There are several types of twists. When twisting, it is necessary to achieve good electrical contact, as well as the creation of mechanical tensile strength. Before proceeding with the connection of wires, they should be prepared. Wire preparation is carried out in the following sequence:

- from the wire, the insulation is removed at the junction. The insulation is removed in such a way as not to damage the wire core. If a notch appears on the wire core, then it may break in this place;

- the exposed area of the wire is degreased. To do this, it is wiped with a cloth dipped in acetone;

- to create a good contact, the fat-free section of the wire is cleaned with sandpaper to a metallic sheen;

- after connection, the insulation of the wire must be restored. For this, insulating tape or heat shrink tubing can be used.

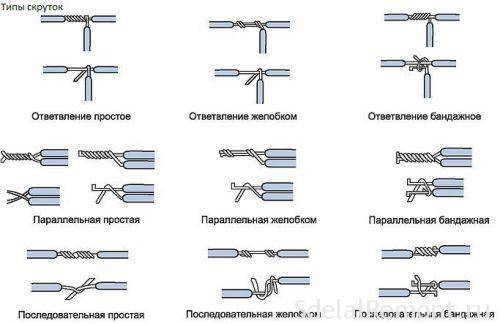

In practice, several types of twists are used:

-

simple parallel twist. This is the simplest and most common type of connection. With a good parallel twist at the junction, a good quality of contact can be achieved, but the mechanical forces to break will be minimal. Such twisting can be weakened in the event of vibration. To properly perform such a twist, it is necessary that each wire wrap around each other. In this case, there must be at least three turns;

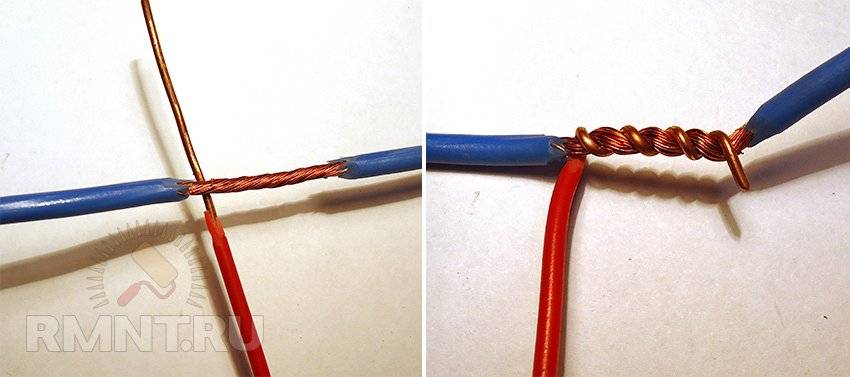

- winding method. This method is used if it is necessary to branch the wire from the main line. To do this, the insulation of the wire is removed at the branch section, and the branch wire is connected to the bare place by winding;

Connecting the wire to the main

Connecting the wire to the main

- bandage twist. This type of twist is often used when connecting two or more solid wires. With bandage twisting, an additional conductor is used from the same material as the wire cores. First, a simple parallel twist is performed, and then a bandage from an additional conductor is applied to this place. The bandage increases the mechanical tensile strength at the junction;

- connection of stranded and solid wires. This type is the most common and simple, first a simple winding is performed, and then clamped;

Connection of stranded and solid copper wire

Connection of stranded and solid copper wire

other various connection options.

In detail, about the methods of connecting single-core wires

Twisting

You can make a twist in one of three ways:

- simple twist;

- bandage;

- groove twist.

The first method is most often used in everyday life. Properly chosen tool, the use of PPE caps allows you to get good contact.

In this way, the ends are connected in the junction box.

Bandage twist is used to make large diameter wire connections. To ensure a strong connection of aluminum conductors, twisting with a groove is used.

If the connection technology in the junction box is performed accurately, then the contact can serve for a long time and reliably.

All of the listed types of twisting require a certain skill in work.

With a wire cross section of 6 squares and above, PPE caps in the junction box are not used.

To strengthen the bandage twist, soldering is used. Technological instructions do not allow simple twisting of aluminum and copper wires.

Such connections can be made after preliminary tinning of copper.

All of the above methods are used to connect multicore cables and wires. All operations in the junction box must be done carefully. Especially in the case when there are more than three cores in the cable.

If you want to make an additional tap on a certain section of the line, then all actions are performed according to a standard and familiar pattern.

To make a reliable twist of aluminum wires, the electrician requires theoretical training and practical skills.

With enough experience, he can quickly complete any connection. In this case, the place of twisting must be cleaned. Aluminum oxide has insulating properties.

If the contact at the place of twisting heats up, then it is most likely that the stripping of the aluminum wire was not done well. It's no secret that you need to do all the operations correctly.

This law is strictly applied in electrical engineering. The fitter's tool must be good and the exam on rules for the operation of electrical installations He must submit within a certain time frame.

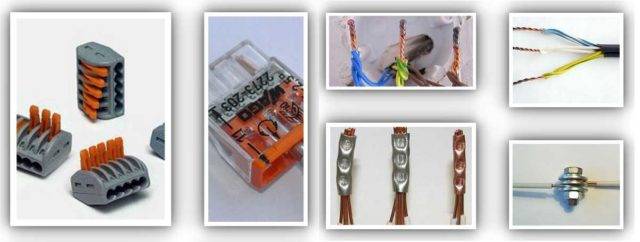

Terminal clamps

Terminal blocks for connecting wires give one indisputable advantage, they can be used to connect wires from different metal. Both here and in other articles, we have repeatedly reminded that it is forbidden to twist aluminum and copper wires together. The resulting galvanic couple will result in the occurrence of corrosive processes and the destruction of the connection.

And it doesn't matter how much current flows at the junction. Sooner or later, the twist will still start to heat up. The way out of this situation is precisely the terminals

The way out of this situation is precisely the terminals.

Terminal block

The simplest and cheapest solution is polyethylene terminal blocks. They are not expensive and are sold in every electrical store.

The polyethylene frame is designed for several cells, inside each there is a brass tube (sleeve). The ends of the cores to be connected must be inserted into this sleeve and clamped with two screws. It is very convenient that as many cells are cut off from the block as it is necessary to connect pairs of wires, for example, in one junction box.

But not everything is so smooth, there are also disadvantages. Under room conditions, aluminum begins to flow under screw pressure. You will have to periodically revise the terminal blocks and tighten the contacts where the aluminum conductors are fixed.If this is not done in a timely manner, the aluminum conductor in the terminal block will loosen, lose reliable contact, as a result, spark, heat up, which can result in a fire. With copper conductors such there are no problems, but it will not be superfluous to make a periodic audit of their contacts.

Terminal blocks are not intended for connecting stranded wires. If stranded wires are clamped into such connecting terminals, then during tightening under pressure of the screw, the thin veins may partially break, which will lead to overheating.

In the case when it becomes necessary to clamp stranded wires into the terminal block, it is imperative to use auxiliary pin lugs

It is very important to choose the right diameter, so that the wire is not jumped out. The stranded wire must be inserted into the lug, crimped with pliers and fixed in the terminal block. As a result of all of the above, the terminal block is ideal for solid copper wires.

With aluminum and stranded, a number of additional measures and requirements will have to be observed

As a result of all of the above, the terminal block is ideal for solid copper wires. With aluminum and stranded, a number of additional measures and requirements will have to be observed.

How to use terminal blocks is shown in this video:

Terminals on plastic blocks

Another very convenient wire connector is a terminal on plastic pads. This option differs from terminal blocks by a smooth metal clamp. In the clamping surface there is a recess for the wire, so there is no pressure on the core from the twisting screw.Therefore, such terminals are suitable for connecting any wires in them.

In these clamps, everything is extremely simple. The ends of the wires are stripped and placed between the plates - contact and pressure.

Such terminals are additionally equipped with a transparent plastic cover, which can be removed if necessary.

Self-clamping terminals

Wiring using these terminals is simple and quick.

The wire must be pushed into the hole to the very end. There it is automatically fixed with the help of a pressure plate, which presses the wire to the tinned bar. Thanks to the material of which the pressure plate is made, the pressing force does not weaken and is maintained all the time.

The internal tinned bar is made in the form of a copper plate. Both copper and aluminum wires can be fixed in self-clamping terminals. These clamps are disposable.

And if you want clamps for connecting reusable wires, then use terminal blocks with levers. They lifted the lever and put the wire into the hole, then fixed it there by pressing it back. If necessary, the lever is raised again and the wire protrudes.

Try to choose clamps from a manufacturer that has proven itself well. WAGO clamps have especially positive characteristics and reviews.

The advantages and disadvantages are discussed in this video:

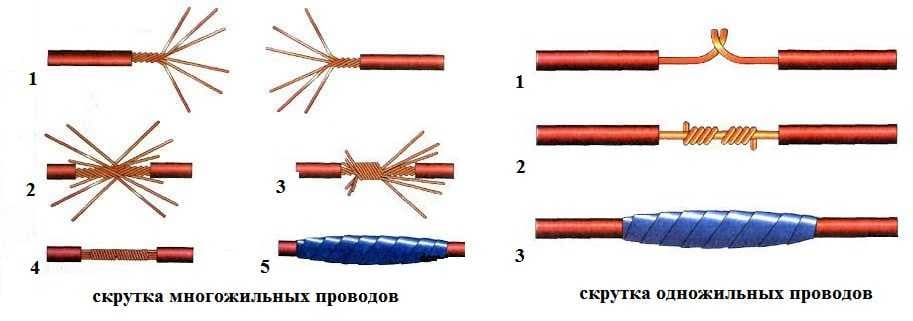

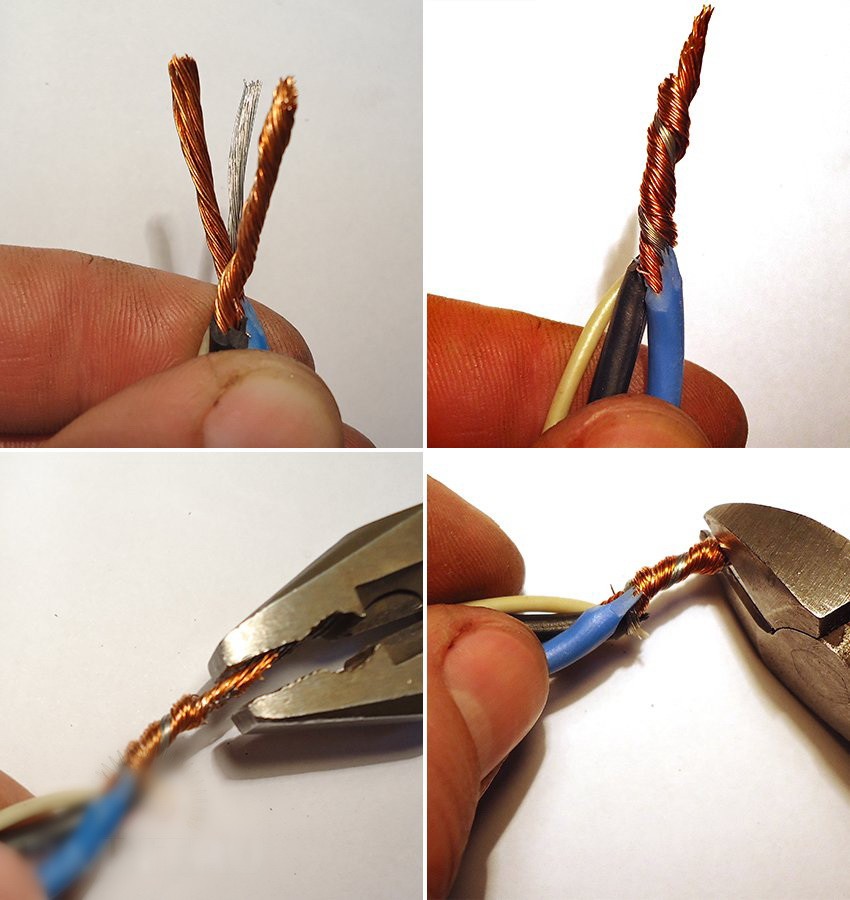

stranded wires

Twisting stranded electrical wires can be done in different ways.

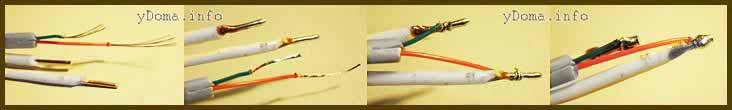

Parallel twist

Most simple method - parallel twisting, when both stripped wires are crisscrossed over each other at the stripping point and twisted at the same time. Such a connection gives reliable contact, but it will not tolerate the applied force to break and vibration.

This method is best used for copper wires, when one of them is solid and the other is stranded. A monolithic wire must be stripped of insulation a little more than a stranded one. After twisting, an additional bend is made from the remaining copper monolithic tail in the direction of twisting, due to this, the connection is more reliable. This method is also suitable for twisting aluminum conductors with different cross sections.

The advantage of parallel stranding is that it can be used to connect more than two wires at the same time.

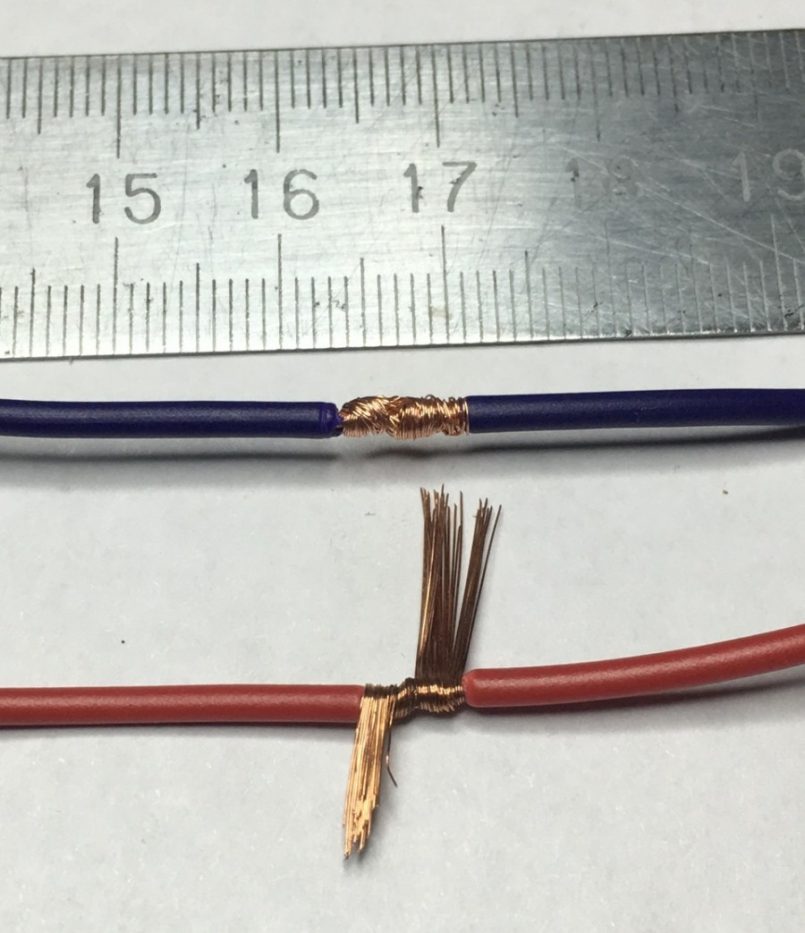

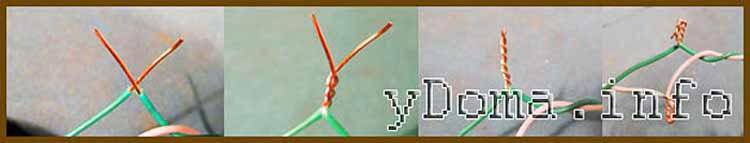

Sequential stranding

In the serial method, each wire connected is wound onto another. The reliability and contact of such a connection will be optimal, but this twist can only be used for two wires, no more.

Fold the stripped strands crosswise on top of each other approximately in the middle of the bare area and start twisting. One wire goes around the other wire, just wrap the second wire around the first.

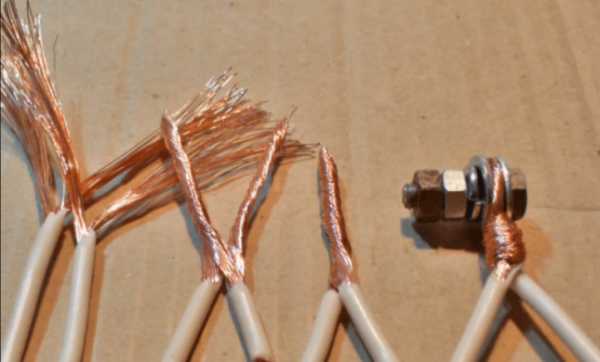

Bandage twist

Stranded wires can be connected to each other by the method of bandage twisting. In this case, the wires to be connected are stripped to the same length and applied parallel to each other. In this position, they are fixed with a third wire, which is tightly wound onto the bare surface of the connected cores.

Please note that with the help of such a twist, you can connect hard stranded wires, but you must use a soft (flexible) wire as a fixing wire. The tighter you make the winding of the fixing wire, the more reliable the contact connection will be.

More than two conductors can be connected using a bandage twist.

Soldering as a reliable alternative to twisting

The closest alternative to twisting, which is prohibited for electrical installations, is the connection of wires by soldering. It requires special fixtures and consumables, but provides absolute electrical contact.

You will need an electric soldering iron with a power of 60-100 W, a stand and tweezers (thin-nose pliers). The tip of the soldering iron should be cleaned of scale and sharpened, having previously selected the most suitable tip shape in the form of a spatula, and connect the body of the device to the ground wire. From the "consumables" you will need solder POS-40, POS-60 from tin and lead, rosin as a flux. You can use solder wire with rosin placed inside the structure.

If you need to solder steel, brass or aluminum, you will need a special soldering acid.

- The cores stripped of insulation should be irradiated, for which the tips heated with a soldering iron are placed in a piece of rosin, they should be covered with a brown-transparent layer of flux.

- We place the tip of the soldering iron tip in the solder, grab a drop of the molten one and evenly process the wires one by one, turning and moving along the tip blade.

- Attach or twist wires together, fixing motionless. Warm up with a sting for 2–5 s. Treat the areas to be soldered with a layer of solder, allowing the drop to spread over the surfaces.Turn the connected wires over and repeat the operation on the reverse side.

- After cooling, the soldering points are isolated by analogy with twisting. In some compounds, they are pre-treated with a brush dipped in alcohol and varnished on top.

Types of electrical wire connections

There are about a dozen ways to connect wires. In general, they can be divided into two groups: those that require special equipment or specific skills and those that any home master can successfully use - they do not require any special skills.

Don't know how to connect two wires? Choose the most suitable way

The first group includes:

- Soldering. When connecting wires of small diameter in the amount of -2-3 pieces - a very reliable method. True, it requires a soldering iron and some skills in owning it.

- Welding. We need a welding machine and special electrodes. But the contact is reliable - the conductors are fused into a monolith.

- Crimping sleeves. Sleeves and special pliers are needed. Sleeves are selected according to certain rules that you need to know. The connection is reliable, but in order to remake it, it will have to be cut off.

All these methods of connecting wires are performed mainly by specialists. If you have the skills to handle a soldering iron or a welding machine, after practicing on unnecessary scraps, you can make them yourself.

Some wiring methods are more popular, others less so.

Ways to connect wires that do not require any specific skills are becoming more and more popular. Their advantage is quick installation, reliable connection. The disadvantage is that “connectors” are needed - terminal blocks, clamps, bolts.Some of them cost quite decent money (Wago terminal blocks, for example), although there are inexpensive options - screw terminal blocks.

So here are the ways to connect wires, which are easy to perform:

- Terminal blocks. They are easy to install and low cost. All you need is a screwdriver to connect the wires. The disadvantage is that the bolted connection can loosen over time.

- Spring clips like Wago. Very easy installation, easy but rather high cost. Another disadvantage is a large number of fakes.

- PPE caps. Fast installation, good contact, can be installed several times. The disadvantage is a lot of low quality products.

-

Bolted connection. Reliable connection with low cost. Typically used when changing from aluminum to copper. Disadvantage - bulky, inconvenient.

Among professionals there are two opposite opinions. Some believe that new ways of connecting wires - clamps - the best way out, as they speed up installation without compromising the quality of the connection. Others say that the springs will someday weaken and the contact will deteriorate. In this matter, the choice is yours.

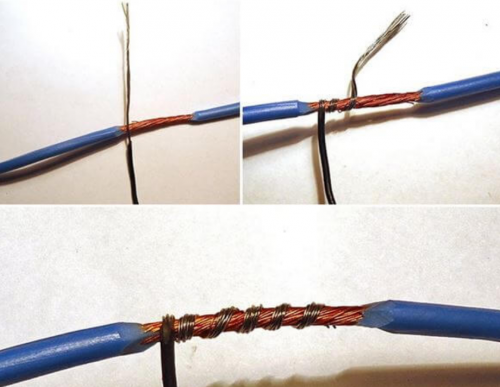

Splicing stranded wires without twisting

You can splice stranded wires in the same way as single-core ones. But there is a more perfect way, in which the connection is more accurate. First you need to adjust the length of the wires with a shift of a couple of centimeters and strip the ends for a length of 5-8 mm.

Fluff the slightly cleaned areas of the pair to be joined and insert the resulting “panicles” into each other.In order for the conductors to take a neat shape, they must be pulled together with a thin wire before soldering. Then lubricate with soldering varnish and solder with solder.

All conductors are soldered. We clean the places of soldering with sandpaper and isolate. We attach on both sides along the conductors one strip of electrical tape and wind a couple more layers.

This is what the connection looks like after being covered with electrical tape. You can still improve the appearance if you sharpen the places of soldering with a needle file from the side of the insulation of adjacent conductors.

The strength of the connected stranded wires without soldering is very high, which is clearly demonstrated by the video. As you can see, the weight of the monitor is 15 kg, the connection can withstand without deformation.

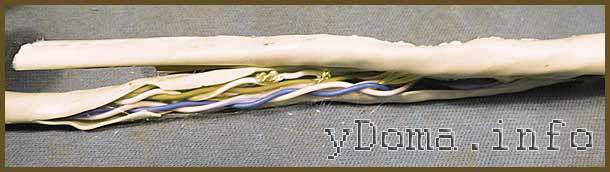

Connecting wires with a diameter of less than 1 mm with a twist

We will consider the twisting of thin conductors using the example of splicing a twisted-pair cable for computer networks. For twisting, thin conductors are released from insulation for a length of thirty diameters with a shift relative to adjacent conductors and then twisted in the same way as thick ones. Conductors must wrap themselves around each other at least 5 times. Then the twists are bent in half with tweezers. This technique increases the mechanical strength and reduces the physical size of the twist.

As you can see, all eight conductors are connected with a sheared twist, which eliminates the need to insulate each of them individually.

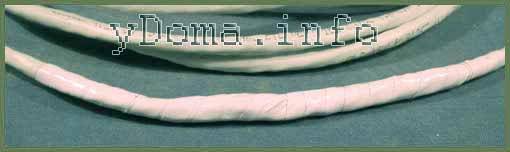

It remains to fill the conductors in the cable sheath. Before refueling, to make it more convenient, you can pull the conductors with a coil of insulating tape.

It remains to fix the cable sheath with insulating tape and the twist connection is completed.

Twisted pair cable splicing technology is covered in a separate article "Twisted Pair Cable Extension".

Connection of copper wires in any combination by soldering

When connecting and repairing electrical appliances, it is necessary to lengthen and connect wires with different cross-sections in almost any combination. Consider the case of connecting two stranded conductors with different cross sections and number of cores. One wire has 6 conductors with a diameter of 0.1 mm, and the second has 12 conductors with a diameter of 0.3 mm. Such thin wires cannot be reliably connected with a simple twist.

With a shift, you need to remove the insulation from the conductors. The wires are tinned with solder, and then the smaller wire is wound around the larger wire. It is enough to wind a few turns. The place of twisting is soldered with solder. If you want to get a direct connection of wires, then a thinner the wire is bent and then the junction isolated.

Using the same technology, a thin stranded wire is connected to a single-core wire with a larger cross section.

As is obvious from the technology described above, it is possible to connect any copper wire any electrical circuits. At the same time, one should not forget that the permissible current strength will be determined by the cross section of the thinnest wire.

Tips to help you

If you want to be sure of the quality of the connection you made, we advise you to read the following recommendations:

- Twisted wires, but twisting does not seem reliable to you? Use soldering or welding! Such a connection will simply become inextricable and you definitely won’t have to worry about the quality of the contact between the cores. By the way, this option is most acceptable when the cores of the wires have a large cross section.

- Use terminals, for example - WAGO. They will not only provide a reliable connection, but also allow you to make it much faster.Which is also very convenient - with the help of terminals it is quite possible to connect several wires, both with different cross-sections, and even made from different metals. Contact in this case will be more reliable nowhere. Terminals are also a great option for connecting wires in a chandelier or outlet.

-

Use PPE clips. Their task is not only to make the connection reliable, but also to increase its security. In addition, these PPE caps are not at all inexpensive.

- Twisted the wires together? Do not rush to hide the connection in the junction box! Let the new electrical circuit node run for some time. After that, you will need to check the temperature of the wires at the place of their bonding. If you feel that the wires are heating up, it is definitely worth redoing the twist!

Use these tips, they definitely will not interfere with you when performing any electrical work where there is a need to connect wires to each other

What is important to pay attention to - the above methods do not allow you to make the twist waterproof. So if you decide to fasten the cores in the wall under a layer of plaster (besides without a box), be sure to isolate the junctions with cambric

Conclusions and useful video on the topic:

Comparative analysis of various switching methods:

As you can see, equipping electrical wiring, you can completely do without soldering and welding.

There are enough modern devices on the market to ensure the switching of conductors using safe and efficient technologies. The choice of the method depends on personal preferences and financial capabilities.

If you have rich experience in electrical work, in particular, connecting conductors without using soldering and welding tools, please leave useful recommendations for beginners and additions to our material below under the article.