- Selecting the method of connecting conductors

- Connection of stranded and solid conductors

- Connecting wires with a cross section of different diameters

- Connecting larger wires

- Connecting broken wires in the wall

- Combination of copper and aluminum

- Why do you need a good twist?

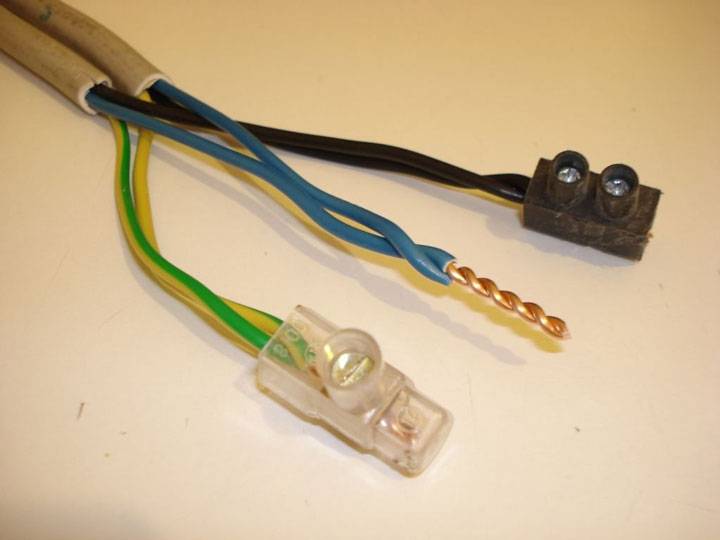

- Twisting

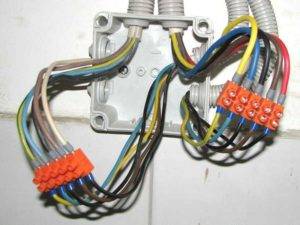

- Twists for junction boxes with welding

- Where are stranded wires used?

- How to connect headphone wires

- Wago

- ZVI

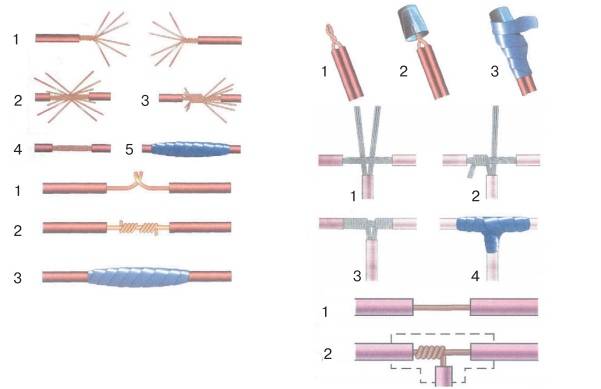

- Methods for connecting wires or cables to each other

- Crimping

- Bolted connection

- Terminal blocks

- Types of terminal blocks for multi-core and single-core cables

- Terminals in junction box (copper or metal)

- Self-clamping terminal blocks WAGO

- Use of tips

- Soldering wire lugs

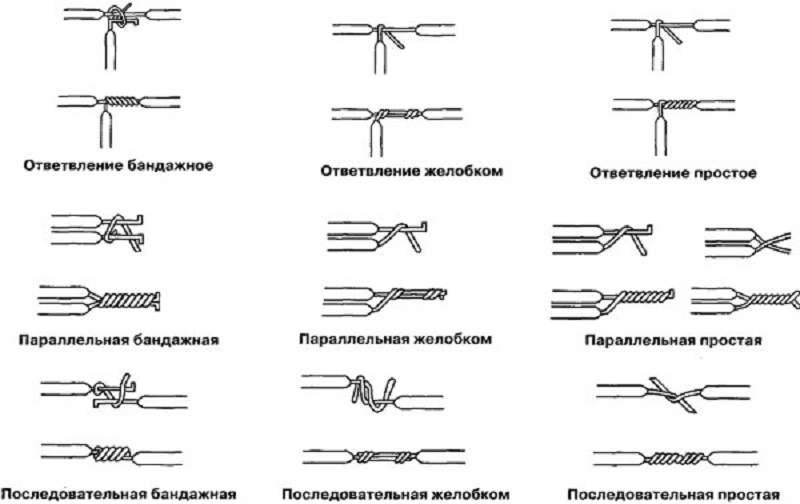

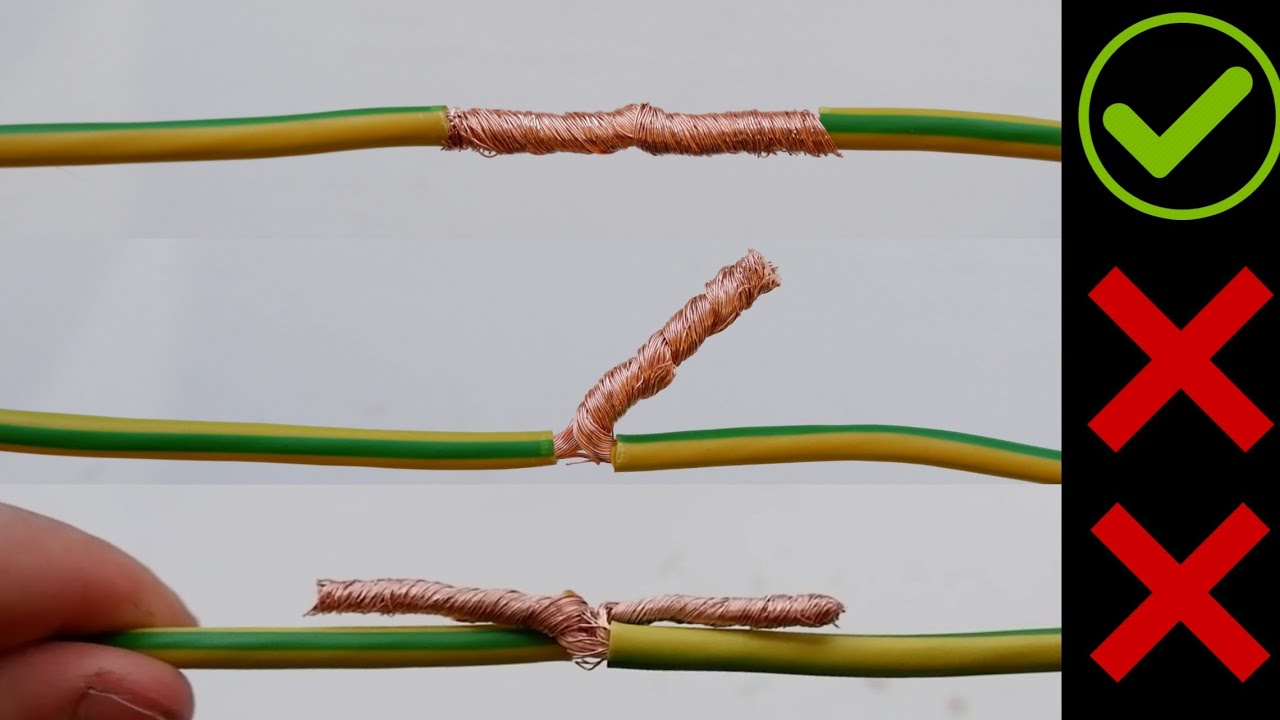

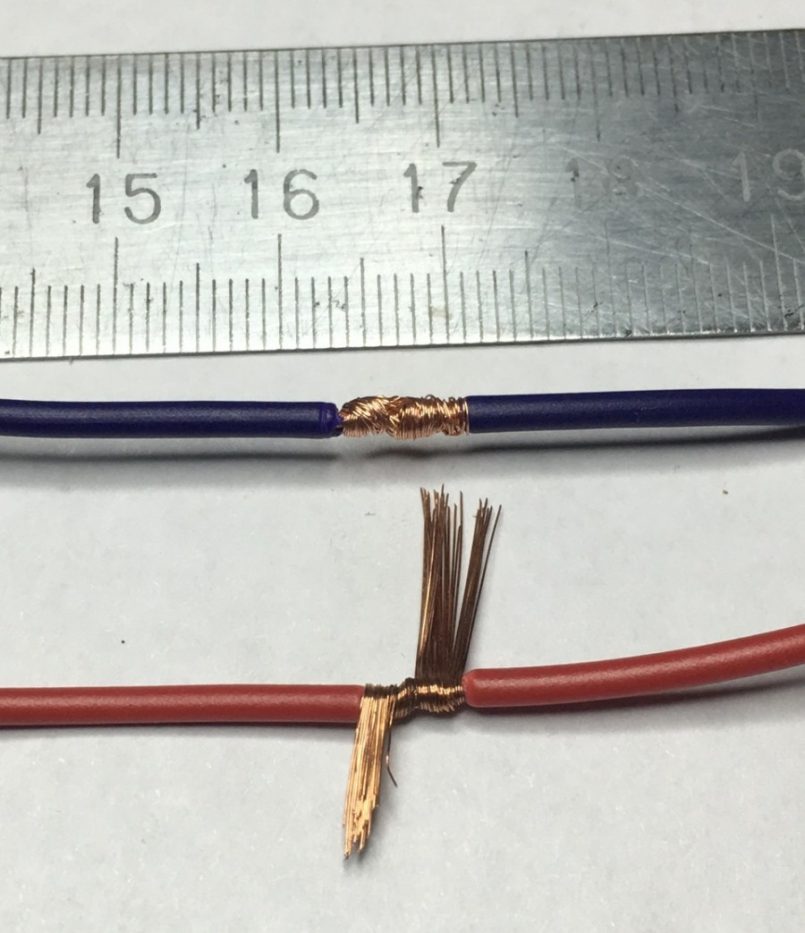

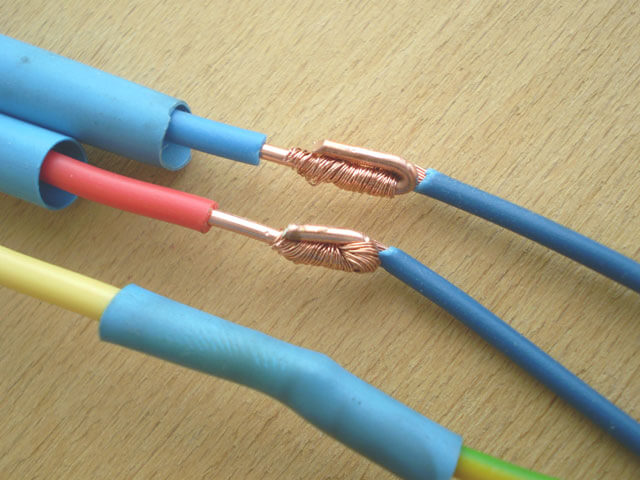

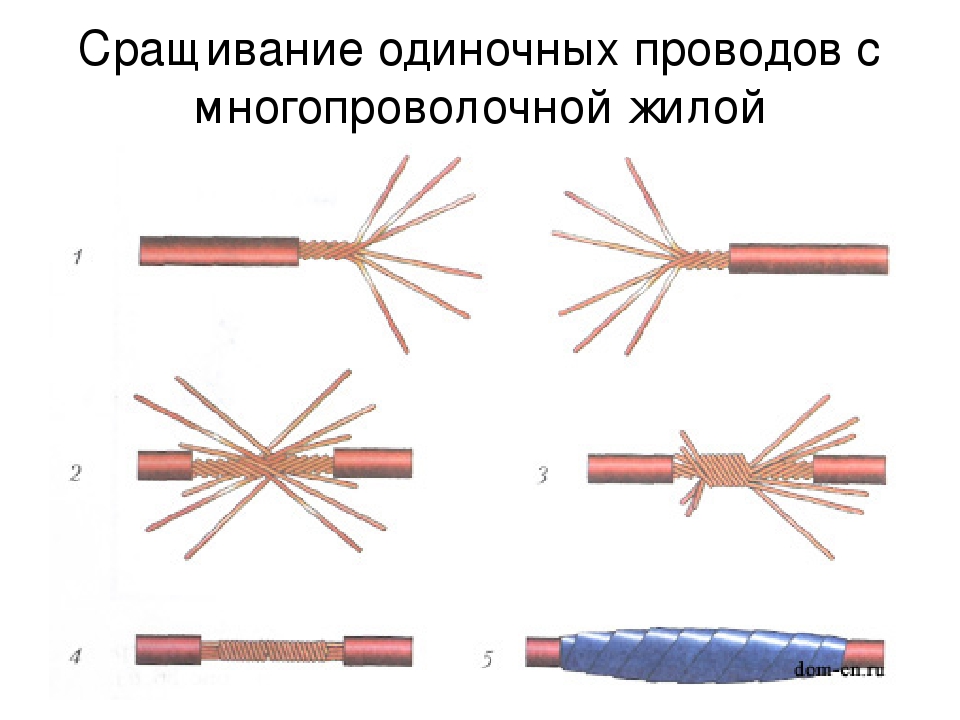

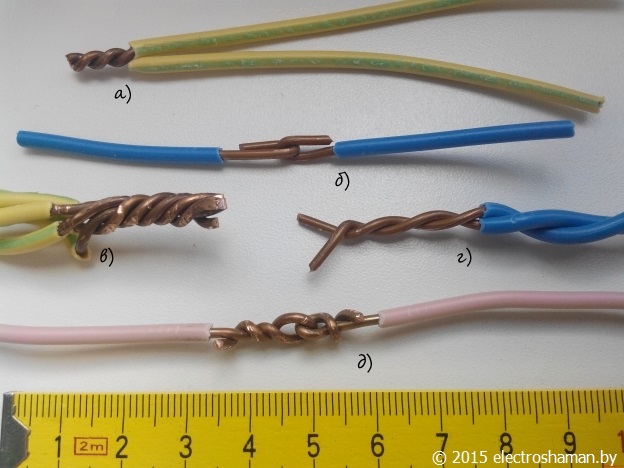

- Stranded wire twisting options

- Parallel connection

- Sequential seam type

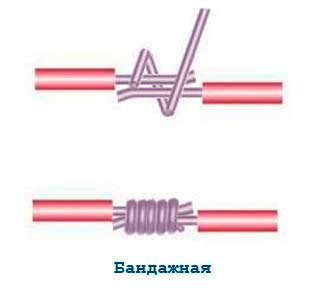

- Bandage twist

- Twisted connection

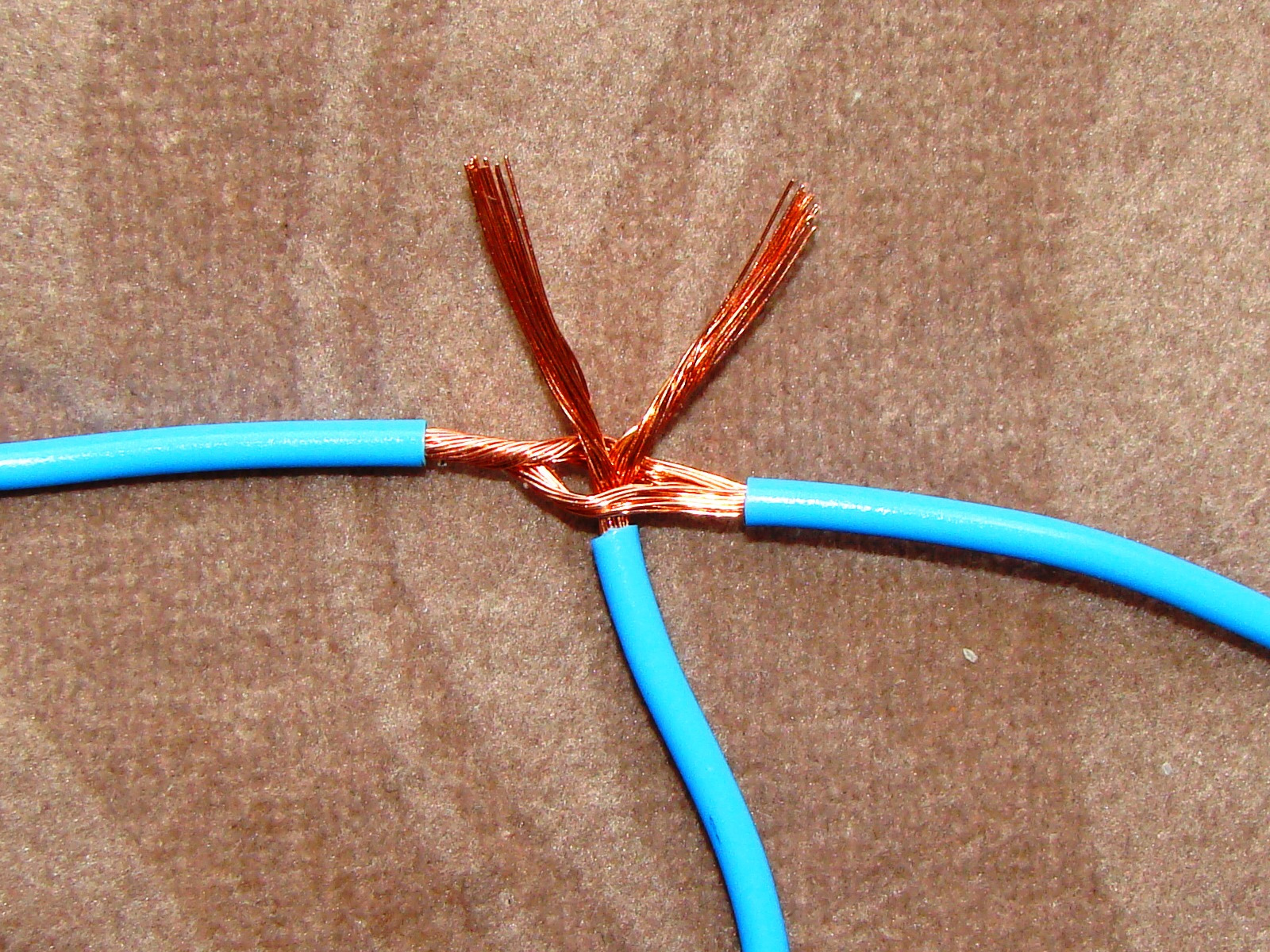

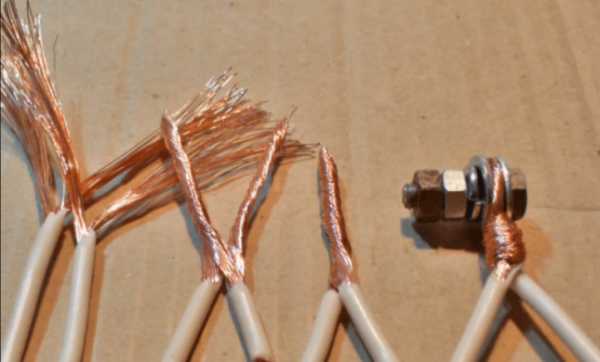

- What if there are several cables?

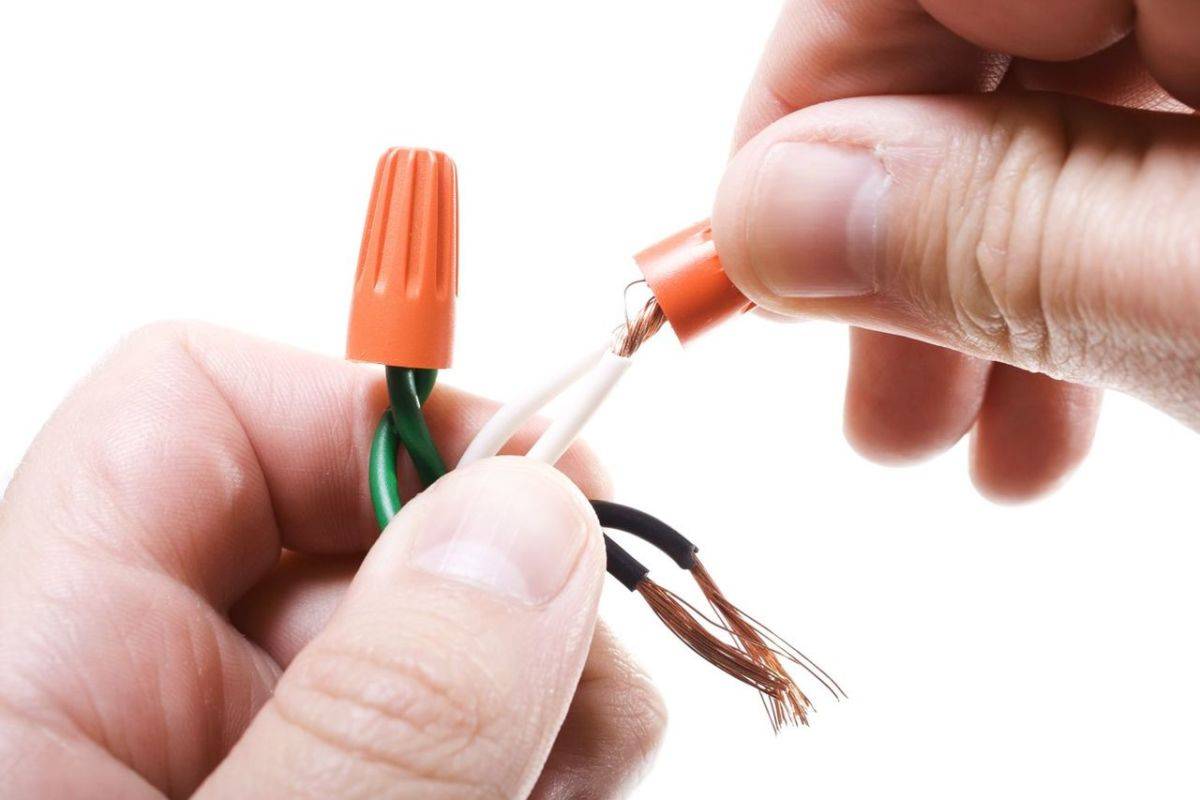

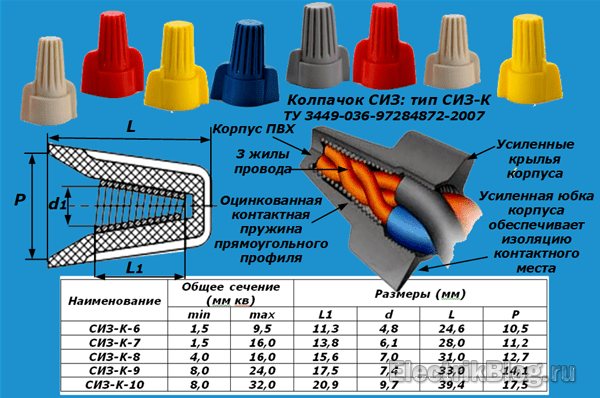

- PPE caps: why electricians constantly argue about them

Selecting the method of connecting conductors

There are many ways to connect conductors. You need to choose the possible option taking into account the situation. So, if you need a temporary connection, you can simply twist or clamp the conductors between the bolt and nut. Shaped or winding wires of large cross section are best fixed by welding or soldering.

Watch this video on YouTube

Watch this video on YouTube

Splice sleeves or sleeves are ideal for splicing cables. Connecting insulating clamps are well suited for fixing small wires and with the right clamp size. Terminal blocks are needed to assemble the circuit. Piercing and branch clamps are used to connect an additional load to an existing network.

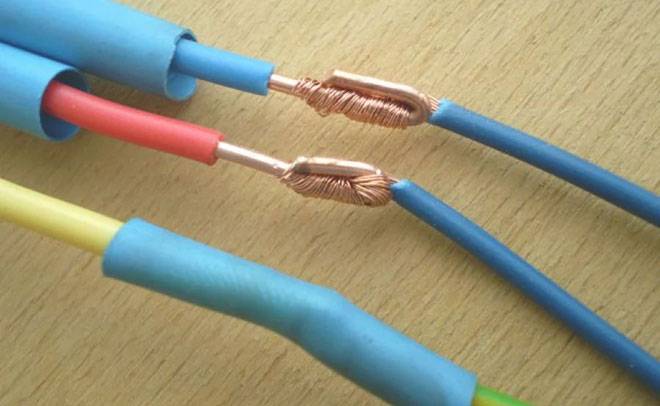

Connection of stranded and solid conductors

This connection begins with a selection of the cross-section of a stranded wire to a single-core one. A stranded conductor must not be less than the cross section of a single conductor, otherwise it will burn out at the junction. They are fixed by soldering or welding, or by crimping when using cable sleeves.

When soldering, the wires are cleaned of insulation, then the stranded wire is wound onto a single-core wire, and then soldering is performed. Then the place of soldering is protected by insulation. When crimping, the contact points are cleaned, a sleeve is put on, which is crimped with crimping press tongs in several places.

Connecting wires with a cross section of different diameters

The connection of wires with a cross section of different diameters is possible when calculating the current density in the sections, if the density in the sections is acceptable, then they can be connected by soldering, twisting, terminals or bolted connections. Connection technologies do not differ from the process of connecting wires with the same cross section and were discussed above.

Connecting larger wires

This method of connection is quite complicated with a large contact area. If the cross section of rectangular wires is too large, fixing is possible only by welding and often it is impossible to do it at home due to the need to heat the conductors to a high temperature.After welding the conductors, a mandatory test of the resulting contact is necessary.

When connected stranded wires or cables large cross-section, you can use the connecting cable sleeve already mentioned above.

Connecting broken wires in the wall

Often in everyday life there are situations when there is a breakdown of electrical wiring in the wall. Often this happens during repair work. Initially, the electrical wiring must be de-energized and the plaster dismantled at the repair site.

After that, the insulation is stripped from each end of the damaged wire, and the ends are coated with molten lead-tin solder. using an ordinary soldering iron. Isolation for the place of soldering is immediately thought out. It is good to use heat-shrinkable tubing, given the size of the area to be repaired. The tube is put on one of the ends of the conductors.

Next, a wire with a cross section not less than the broken wire is selected, it is cut off and soldered first to one end of the wire, then to the other. At the same time, the length of the extended conductor must ensure the strength of the contacts. It should not be too small or long. In conclusion, a tube is put on the area, which, when heated with a hairdryer, tightly wraps around the soldered area.

Combination of copper and aluminum

How to connect copper and aluminum wire is discussed in more detail in our article. The connection of dissimilar wires is possible by the bolted connection discussed earlier. However, most often fixation is performed using copper-aluminum sleeves (CAM) for crimping. On the one hand, the sleeve is made of aluminum, on the other hand, copper. The aluminum side of the sleeve is larger because aluminum has a lower current density than copper.The sleeve is put on the ends of the wires with the same metal and crimped with a press.

Why do you need a good twist?

Imagine that two wires to be connected are twisted together just as if. Those who are familiar with electrical engineering know that a contact resistance arises at the point of contact between two conductors. Its value depends on two factors:

- surface area at the point of contact;

- the presence of an oxide film on the conductors.

To perform twisting, the core is exposed, the metal interacts with atmospheric oxygen, as a result of which the surface of the conductor is covered with an oxide film, which has a decent value of resistivity.

example of poor-quality twisting: the twisting point heats up, the insulation melts

Accordingly, if the twisting is performed poorly, the contact resistance increases, which in turn, when an electric current passes through the junction, will cause heating. As a result, the place of twisting may heat up so that the electrical wiring will ignite. Surely everyone had to hear the phrase in their life that the fire occurred due to a malfunction in the electrical network.

To prevent this from happening, the contact connection of the wires must be as strong, reliable and safe as possible. That is, the twisting must be performed with such high quality that the contact resistance is stable and does not change over time.

Twisting

More a few years ago not there was an alternative to connecting wires with a twist. To make it, it is enough to have only pliers and a knife with you. The twisting of wires is carried out in depending on their diameter.

- wrap one conductor around another;

- twist aluminum wire with copper.

If it is nevertheless necessary to connect copper to aluminum wire, then copper should be tinned with solder.

The connection of wires in the box using twisting can be done in some variations:

- with different sections;

- from different metal;

- single-core with multi-core.

Up to 6 wires can be twisted in the box. If you plan to connect a stranded conductor, then it must be converted to a single-core by means of solder.

There is another way to connect the two wires with a cross section of more than 1 mm. It involves splicing two pairs of wires. In most cases, this method is used when:

- the conductors are broken;

- they need to be increased when changing the location of the switch or outlet.

The splicing process itself consists of the following steps:

- the implementation of the shift of the ends of the conductors in length by 2-3 cm;

- removal of insulation up to 20 wire sections;

- twisting the conductors is accompanied by the creation of two turns on each wire.

When placing a twist under a layer of plaster, it must be soldered. Solder buildup is removed with sandpaper. Otherwise, they may break the insulation. Due to the fact that the twisted wires have shifted, it makes no sense to isolate them separately. The insulating tape is wound in three layers. When laying wires in plaster, you need to use a PVC tube.

The connection of electrical wires with a cross section of less than 1 mm is carried out by twisting the conductors more than 5 times. The twist in half is bent with tweezers. The use of this method leads to a reduction in the dimensions of the twist and an increase in its mechanical strength.

Despite its popularity, the twisted wire connection often does not withstand the maximum loads in the electrical network. As a result, the conductors expand and a gap appears in the twist. The wires oxidize, which leads to the loss of contact between the wires.

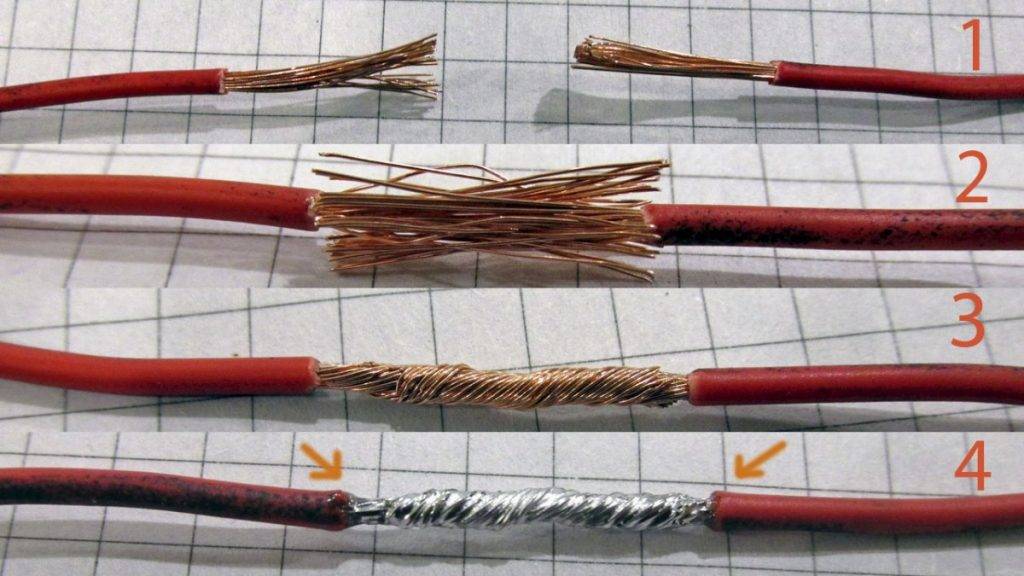

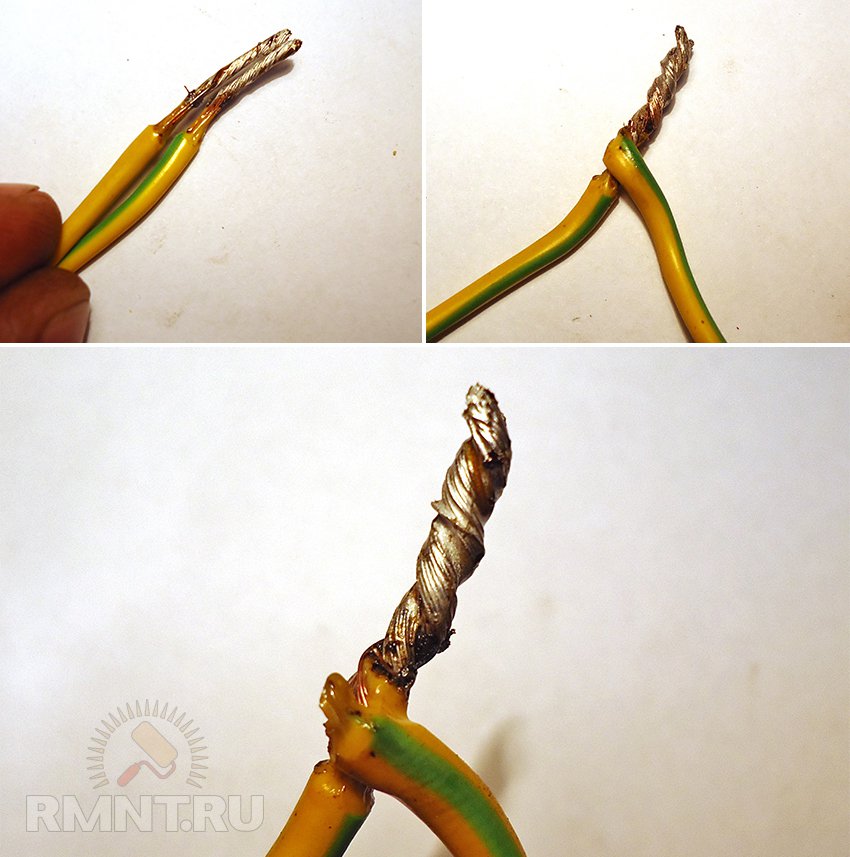

Twists for junction boxes with welding

If we need to connect two or more solid copper wires and hide them in a junction box, then for a reliable connection it is better to weld the contacts. To do this, we additionally need a special welding machine with carbon electrodes. For example, the TSS Compact-160 welder is suitable for such a task. You will also need graphite electrodes (you can take rods from AA batteries or a graphite bar from the engine) and flux.

First, we twist two cores, as in the picture, starting from the tips and ending with the base.

Then, using a welding machine, we weld the ends (only them, you don’t need to weld them along the entire length).

After that, you need to isolate the twists with electrical tape / heat shrink and carefully fold them into the junction box.

Of course, welding takes more time than, for example, WAGO clamps or other terminal blocks, but such twists last for decades, and your grandchildren will already change them.

Where are stranded wires used?

Any stranded conductor contains at its base a large number of thin wires. The use of a multi-core cable is relevant in areas that require a large number of bends or, if necessary, pull the conductor through too narrow and long enough holes.

The scope of application of stranded conductors is presented:

- extended tees;

- mobile lighting fixtures;

- automotive wiring;

- connecting lighting fixtures to the electrical network;

- connecting switches or other types of leverage to the electrical network.

Flexible stranded conductors can be repeatedly and easily twisted, which does not negatively affect the functionality of the system. Among other things, it is this type of electrical wiring that is distinguished by plasticity, and greater flexibility and elasticity is given to the wire by weaving a special thread, which is a bit like nylon in strength and composition.

How to connect headphone wires

Sometimes the cable breaks off near the plug for working headphones, but there is a plug from the defective headphones. There are also other situations in which it is necessary to connect the wires in the headphones.

For this you need:

- cut off a broken plug or unevenly cut cable;

- strip the outer insulation by 15–20 mm;

- determine which of the internal wires is common and check the integrity of all conductors;

- cut the internal wiring according to the principle: do not touch one, common by 5 mm and the second by 10 mm. This is done to reduce the thickness of the joint. There can be two common conductors - each earpiece has its own. In this case, they are twisted together. Sometimes a screen is used as a common conductor;

- strip the ends of the wires. If varnish is used as insulation, it will burn out during the tinning process;

- tin ends to a length of 5 mm;

- put a piece of heat shrink tubing on the wire 30 mm longer than the expected connection length;

- put on pieces of a thinner heat shrink tube 10 mm long on the long ends, do not put on the middle (general) one;

- twist the wires (long with short, and medium with medium);

- solder twists;

- bend the soldered twists outward, to the unprotected edges, slide pieces of a thin heat-shrink tube over them and heat it with a hairdryer or a lighter;

- slide a larger diameter heat shrink tube over the junction and warm it up.

If everything was done carefully, and the color of the tube was chosen according to the color of the cable, then the connection is imperceptible and the headphones will work no worse than new ones.

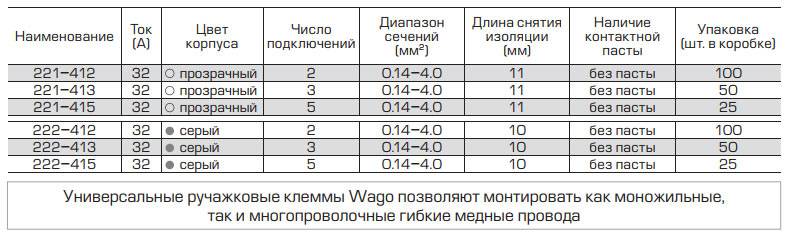

Wago

The next view is the Wago terminal blocks. They also come in different sizes, and for a different number of connected wires - two, three, five, eight.

The next view is the Wago terminal blocks. They also come in different sizes, and for a different number of connected wires - two, three, five, eight.

They can join together both monocores and stranded wires.

For multi-wire, the clamp should have a latch-flag, which, when open, allows you to easily insert the wire and clamp it inside after snapping.

These terminal blocks in home wiring, according to the manufacturer, can easily withstand loads up to 24A (light, sockets).

There are separate compact specimens on 32A-41A.

Here are the most popular types of Wago clamps, their markings, characteristics and for what section they are designed:

There is also an industrial series for cable sections up to 95mm2. Their terminals are really large, but the principle of operation is almost the same as that of the small ones.

When you measure the load on such clamps, with a current value of more than 200A, and at the same time you see that nothing is burning or heating, many doubts about Wago products disappear.

If your Vago clamps are original, and not a Chinese fake, and at the same time the line is protected by a circuit breaker with a correctly selected setting, then this type of connection can rightfully be called the simplest, most modern and easy to install.

Violate any of the above conditions and the result will be quite natural.

Therefore, you do not need to set wago to 24A and at the same time protect such wiring with an automatic 25A. The contact in this case will burn out during overload.

Always choose the right vago terminal blocks.

Automatic machines, as a rule, you already have, and they protect primarily the electrical wiring, and not the load and the end user.

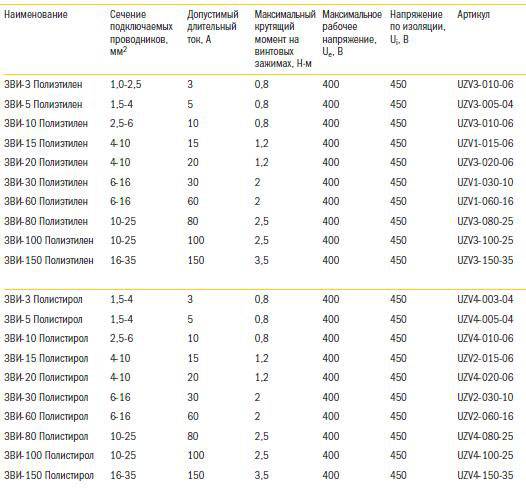

ZVI

There is also a fairly old type of connection, such as terminal blocks. ZVI - insulated screw clamp.

There is also a fairly old type of connection, such as terminal blocks. ZVI - insulated screw clamp.

In appearance, this is a very simple screw connection of wires to each other. Again, it happens under different sections and various shapes.

Here are their technical characteristics (current, cross section, dimensions, screw torque):

However, ZVI has a number of significant drawbacks, due to which it cannot be called the most successful and reliable connection.

Basically, in this way you can connect only two wires together. Unless, of course, you don’t specifically choose large pads and shove several wires there. What to do is not recommended.

Such a screw connection is well suited for solid conductors, but not for stranded flexible wires.

For flexible wires, you will have to press them with NShVI lugs and incur additional costs.

You can find videos on the network where, as an experiment, the transient resistances on different types of connections are measured with a microohmmeter.

Surprisingly, the smallest value is obtained for screw terminals.

Methods for connecting wires or cables to each other

The connection points of two conductors must meet the following requirements:

- reliability;

- mechanical strength.

These conditions can also be met when connecting conductors without soldering.

Crimping

This method requires special equipment. Crimping of wires with sleeves is carried out for both copper and aluminum wires of different diameters. The sleeve is selected depending on the section and material.

Pressing algorithm:

- stripping insulation;

- stripping wires to bare metal;

- the wires must be twisted and inserted into the sleeve;

- conductors are crimped using special pliers.

The selection of the sleeve causes the main difficulties. An incorrectly selected diameter will not be able to provide reliable contact.

Bolted connection

Bolts, nuts and several washers are used for contact. The junction is reliable, but the design itself takes up a lot of space and is inconvenient when laying.

Bolts, nuts and several washers are used for contact. The junction is reliable, but the design itself takes up a lot of space and is inconvenient when laying.

The connection order is:

- stripping insulation;

- the cleaned part is laid in the form of a loop with a diameter equal to the cross section of the bolt;

- a washer is put on the bolt, then one of the conductors, another washer, the second conductor and the third washer;

- the structure is tightened with a nut.

A bolt can be used to connect several wires. Tightening the nut is done not only by hand, but also by a wrench.

Terminal blocks

The terminal block is a contact plate in a polymer or carbolite housing. With their help, any user can connect the wires. The connection takes place in several stages:

The terminal block is a contact plate in a polymer or carbolite housing. With their help, any user can connect the wires. The connection takes place in several stages:

- stripping insulation by 5-7 mm;

- removal of the oxide film;

- installation of conductors in sockets opposite each other;

- bolt fixing.

Pros - you can connect cables of different diameters. Disadvantages - only 2 wires can be connected.

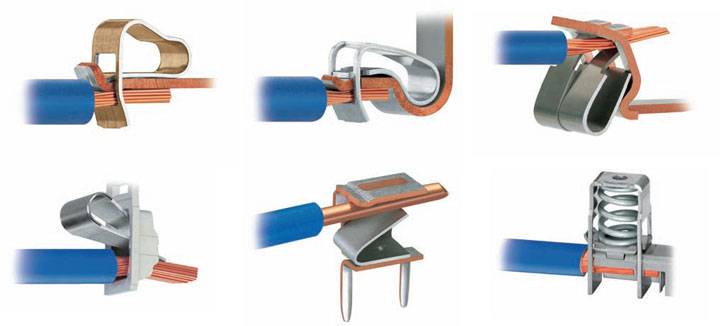

Types of terminal blocks for multi-core and single-core cables

In total there are 5 main types of terminal blocks:

In total there are 5 main types of terminal blocks:

- knife and pin;

- screw;

- clamping and self-clamping;

- cap;

- walnut grips.

The first type is rarely used, they are not designed for high currents and have an open design. Screw terminals create reliable contact, but not suitable for multicore cable connections. Clamp terminal blocks are the most convenient devices to use, no special equipment is needed for their installation. Caps are also used frequently, but unlike clamping devices, caps can be used repeatedly. "Nut" is practically not used.

Terminals in junction box (copper or metal)

Terminals are the most common connection method in a junction box. They are cheap, easy to install, provide a secure contact, and can be used to connect copper and aluminum. Flaws:

- cheap devices are of poor quality;

- only 2 wires can be connected;

- not suitable for stranded wires.

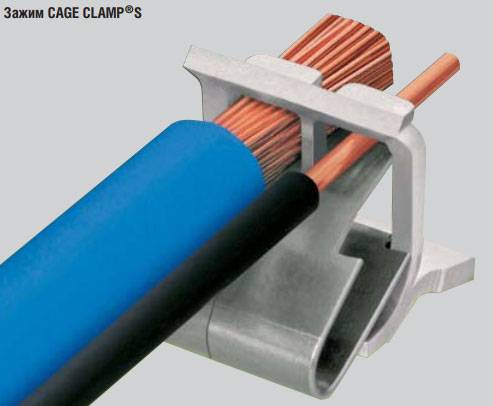

Self-clamping terminal blocks WAGO

2 types of Vago terminal blocks are used:

2 types of Vago terminal blocks are used:

- With a flat-spring mechanism - they are also called disposable, since reuse is impossible. Inside is a plate with spring petals. When installing the conductor, the tab is pressed out, and the wire is clamped.

- With lever mechanism. This is the best connector. The stripped conductor is inserted into the terminal, the lever is clamped. Re-installation is possible.

With proper operation, Vago terminal blocks work for 25-30 years.

Use of tips

For connection, 2 types of tips and sleeves are used:

- in the first, the connection is made inside the product;

- in the second, the termination of two electrical wires occurs with different tips.

The connection inside the sleeve or tip is strong and reliable.There are also special sleeves for connecting copper and aluminum wires.

Soldering wire lugs

The tips are connected to the wiring using a press. If not, contact can be made by soldering.

The tips are connected to the wiring using a press. If not, contact can be made by soldering.

The electrical wire and the tip are tinned inside, the stripped cable is brought inside.

The entire structure on the contact must be wrapped with fiberglass tape, heated with a burner until the tin melts.

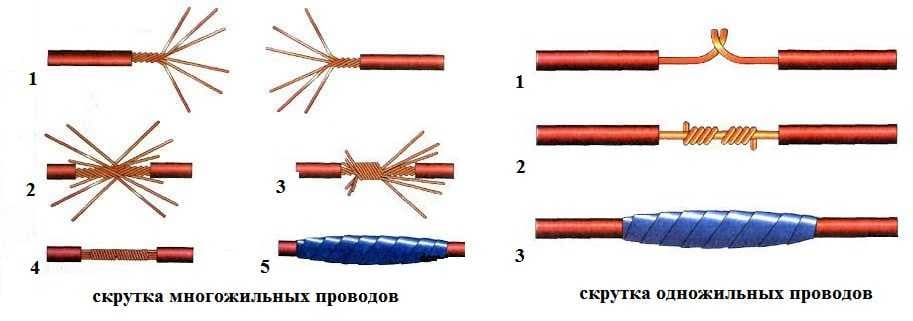

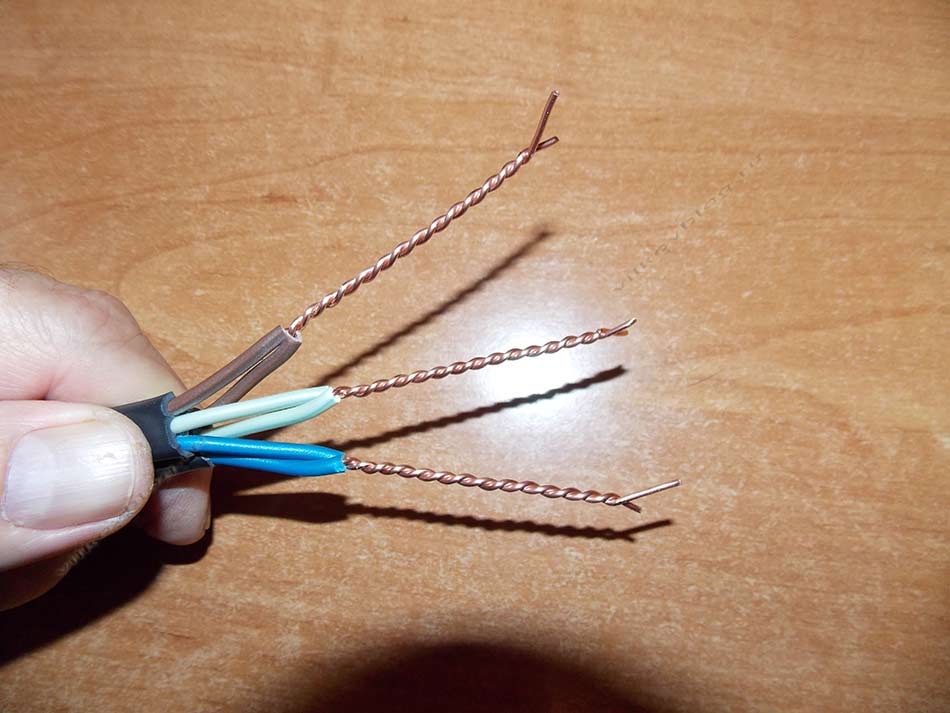

Stranded wire twisting options

Stranded is a wire with a metal central part in the form of thin wires. The elements are intertwined with each other, forming a lay with external insulation. Manufacturers can cover the wiring with polyurethane, add nylon threads to improve strength. Protection complicates the process of removing the insulating layer.

Stranding insulated stranded wires performed in several ways.

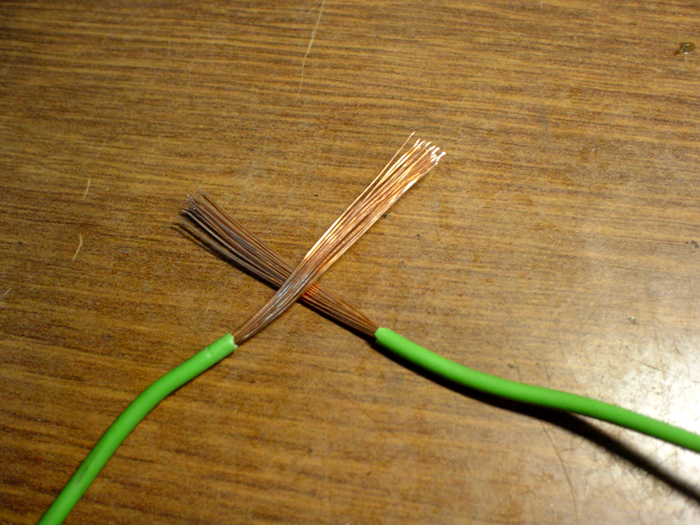

Parallel connection

The simplest option is when two stripped cores are laid cross-by-cross one by one. Only the area without insulation is allowed to be twisted. Parallel twisting provides reliable contacts, but does not protect against breaks with force.

The technology is suitable for copper conductors - one solid and one stranded. Aluminum conductors with different cross-sections can also be connected in parallel. In the case of a solid wire, more insulation will need to be removed than with a stranded one.

After twisting, a segment should remain, from which an additional bend is created in the direction of fixation. This technique enhances the strength of the connection.

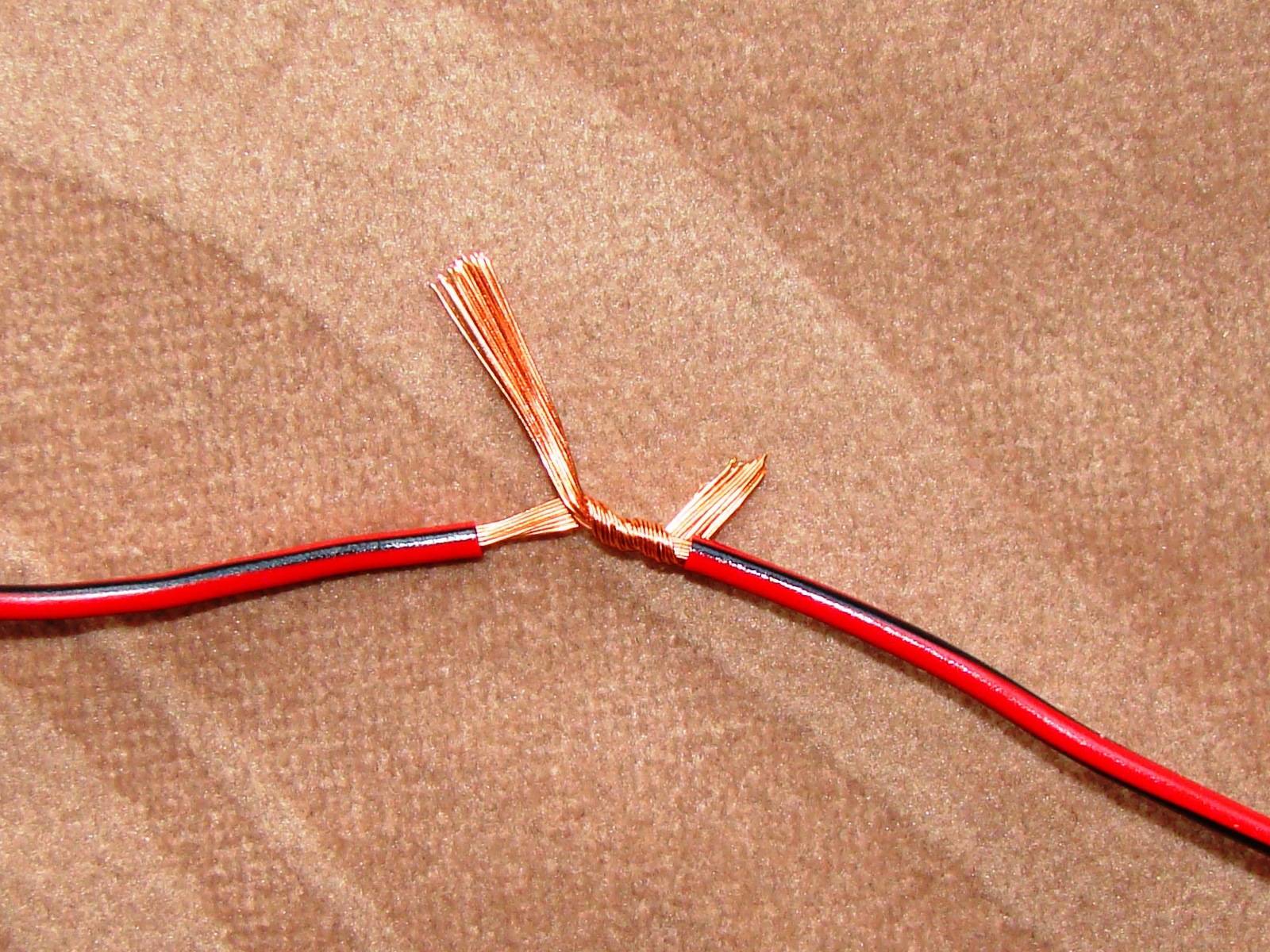

Sequential seam type

Fasten the wires together so that each of them overlaps the other:

- the cores are cleaned from the insulating coating;

- the cleaned elements are stacked on top of each other;

- twisting starts from the center so that one wire wraps around the second;

- the second contact is twisted in the same way.

Due to the minimum reliability, the connection is suitable for two cables.

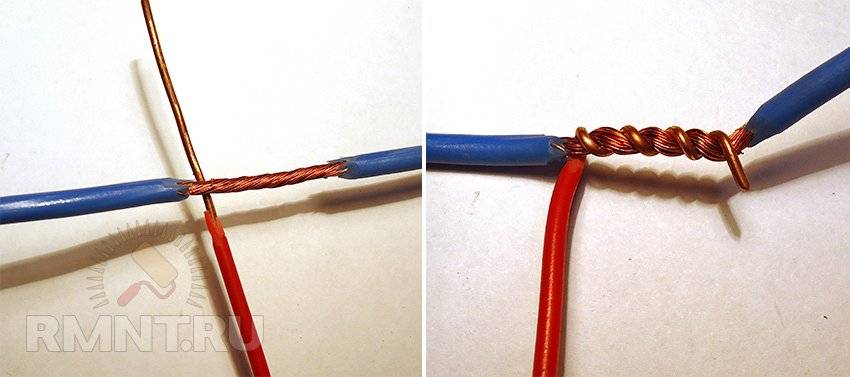

Bandage twist

The best way to fasten a stranded wire:

- two types of wire are selected - hard for fixing and soft for winding;

- insulation is removed from the cores so that the length of the bare sections is the same;

- conductors are laid in parallel;

- to fix the cores together, a third stripped wire is used.

More than 2 rigid cables should be chosen as twisted products. The winding is organized using a flexible soft wire.

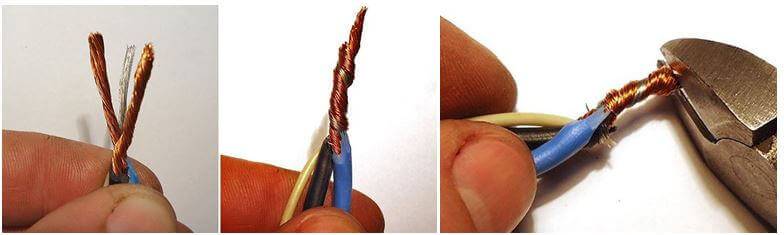

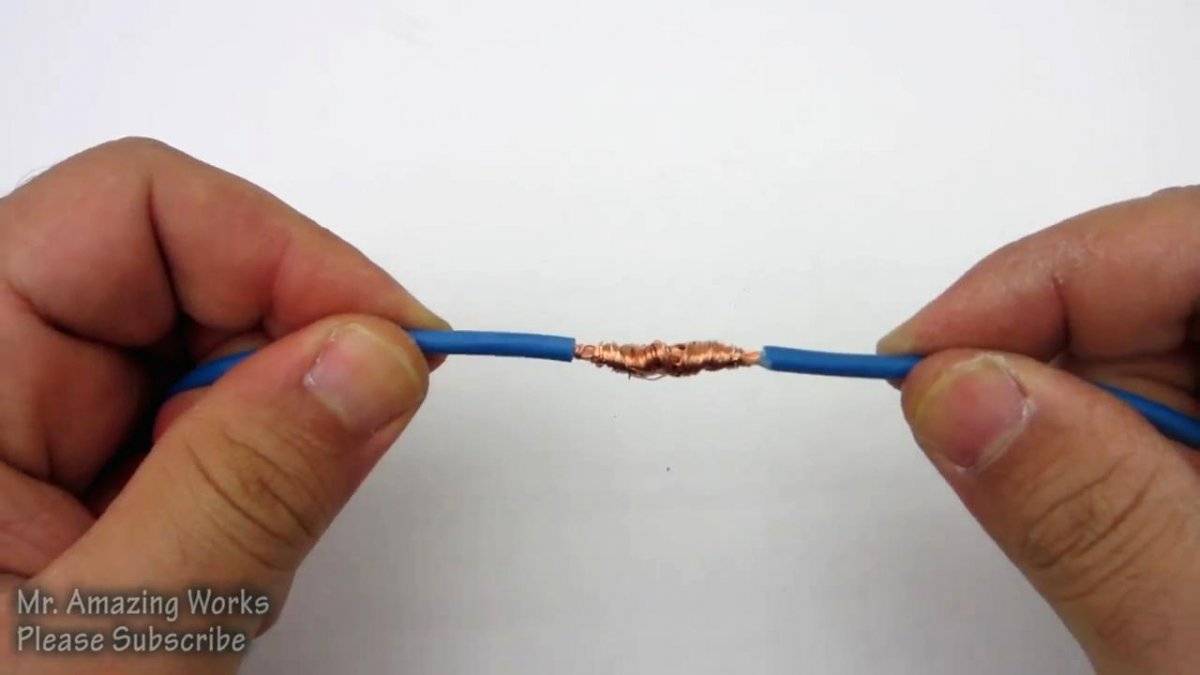

Twisted connection

If for some reason you do not have the opportunity to use other methods of connecting electrical wires, you can use twisting, just do it with high quality. Very often it is used as a temporary option and is subsequently replaced by more reliable switching methods.

How to connect wires with a twist? To begin with, the veins are cleaned by 70-80 mm. The main thing is to twist all switched conductors into one single twist at the same time, and not wind one around the other.

Many mistakenly begin to twist the cores together from the place where the insulating layer ends. But it is better to clamp both wires in this place with one pair of pliers, and with the second, grab the ends of the wires and perform rotational movements in a clockwise direction.

If the wire section is small, you can twist it by hand.Align the conductors with the insulation shear and hold them firmly in this place with your left hand. Bend all switched tips into one single bend at an angle of 90 degrees (a bend length of 10-15 mm will be enough). Hold this fold with your right hand and rotate it clockwise. This must be done firmly and firmly. If it is already difficult to twist with your hands at the end, use the pliers, as described above. As soon as the twist becomes even and beautiful, you can cut the bend.

You can also connect several wires in this way, but then, to make it easier to twist them, make the bend longer, somewhere around 20-30 mm.

How to properly twist the wires is shown in this video:

There is also a way to twist wires with a screwdriver, see about it here:

For twisting wires with a special tool, see here:

Now the resulting twist must be carefully insulated. For this, electrical tape is used. Do not spare it, wind it in several layers, and isolate not only the connection itself, but also step 2-3 cm over the core insulation. Thus, you will ensure the twisting of insulating reliability and protect the contact connection from moisture.

You can also insulate the connection of wires with the help of thermotubes. The main thing is not to forget to put the tube on one of the wires to be connected in advance, and then put it on the place of the twist. Under heat, the thermal pipe shrinks, so slightly heat its edges, and it will firmly wrap around the wire, thereby providing reliable insulation.

If the twisting is done with high quality, it is likely that it will serve you for many years, provided that the load current in the network is normal.But still, it is better not to stop at this stage and strengthen the junction by welding or soldering.

What if there are several cables?

The following methods are suitable for connecting more than two cores:

twist. The maximum number of cores is 6. They are straightened and folded parallel to each other, then twisted with pliers;

PPE. The connector allows you to splice 4 wires, but only with a cross section of 1.5 square meters. mm. With a larger cross section - only two cores;

bolted connection. You can put on a bolt as many wires as you like, as long as its length is enough;

welding;

soldering;

sleeve pressing. On one side of the sleeve, several cores are started

It is important to choose the right cross section of the product: it should only slightly exceed the total cross section of the cores - then the connection will be of high quality;

terminal block. There are products with multiple wire connectors

Also, several wires can be fixed in one terminal if they have the same cross section.

Wires with different cross-sections cannot be connected to the same terminal: the smaller one will be pressed with insufficient force.

PPE caps: why electricians constantly argue about them

The basis for creating an electrical contact here is the same twist, but it is performed in a short section and reinforced with compressed coils of a spring, immediately closed with a dielectric cap.

Similar connectors came to us from the west. They are now massively used in frame construction: installation is easy and fast, stipulated by the rules.

At first glance, the design is ideal for an electrician: the work is done quickly, does not require significant effort. But there are many complaints about PPE caps (squeeze insulated). Let's dwell on them.

Caps are not universal.They are created for a specific wire size. A thinner section will not allow the spring to compress the twist normally, although it is made in a conical shape.

Careless installers make twisting with pliers, and the cap is simply put on it as insulation. Since it is poorly fixed by springs, it often flies off, exposing metal that is energized, which is dangerous.

Initially, the twist must be prepared, but the main pressing force is created by the springs when the body is manually screwed in clockwise.

Simple PPE caps have an insufficiently strong spring, a satisfactory dielectric body. Manufacturers improved their shortcomings by releasing the SIZ-K model, specified by the technical conditions of the TU 3449-036-97284872-2007 series.

They allow you to mount three cores in one housing due to the use of a special galvanized spring with a rectangular section profile, which has increased adhesion to the metal of the conductors.

Reinforced wings on the body facilitate installation, reduce the hand force that must be applied when screwing. The design of the lower part of the skirt has increased protection of the contact connection.

The insulation of PPE caps is designed for voltages up to 600 volts.

However, many electricians try to use this design only in lighting networks with small current loads, for example, when using LED lamps.

Independent tests under maximum loads do not show reliable PPE results. In addition, the market was flooded with beautiful fakes made using simplified technology.