- Ways to combat electrochemical corrosion

- Permanent connection

- Welding

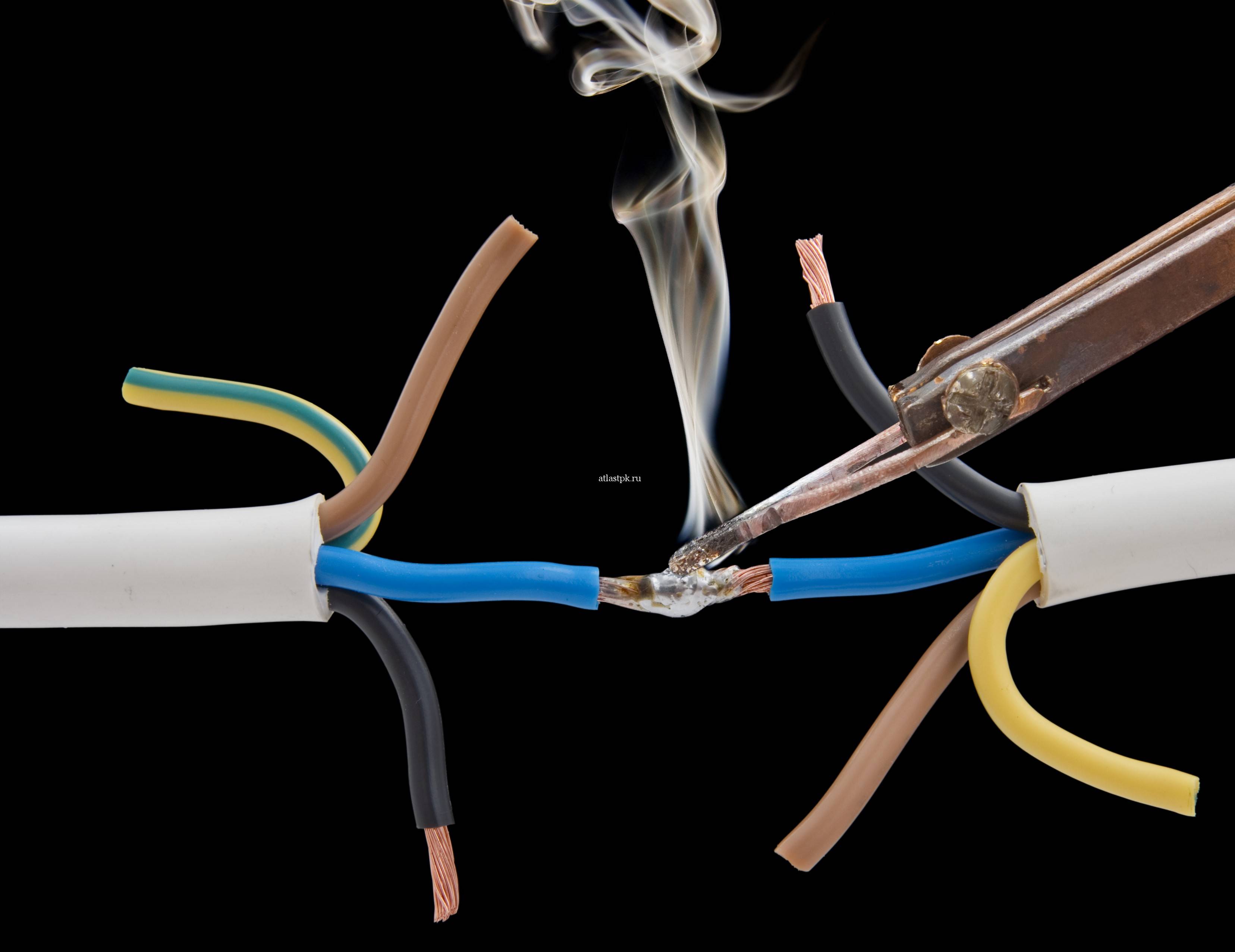

- Soldering

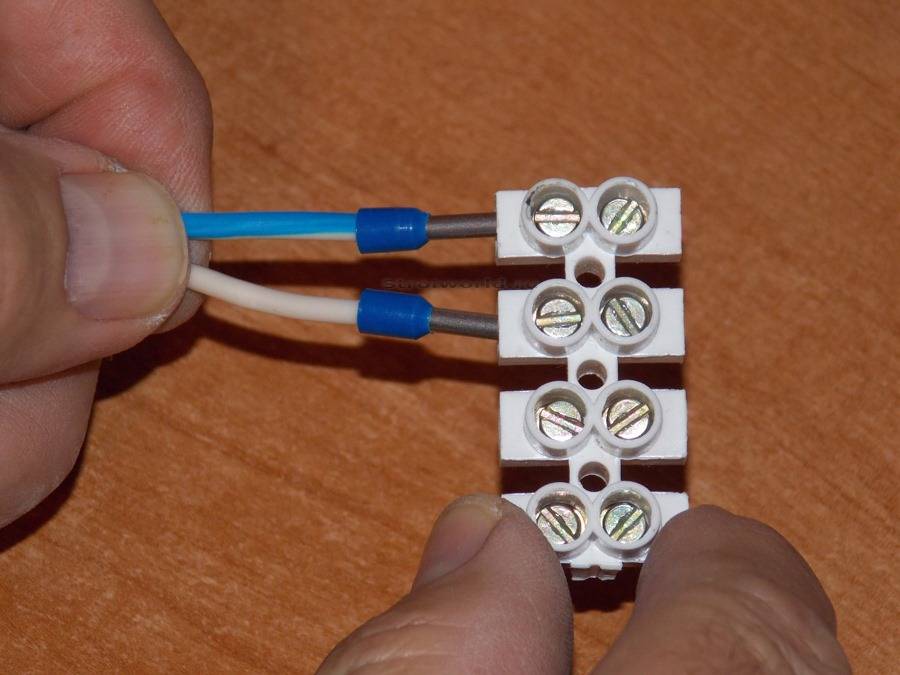

- Crimping

- Is it possible to twist copper wire with aluminum

- Features of aluminum wires

- What is their feature

- Connection options

- Features and secrets of using the crimping method

- Helpful Tips

- Connection of aluminum and copper wires

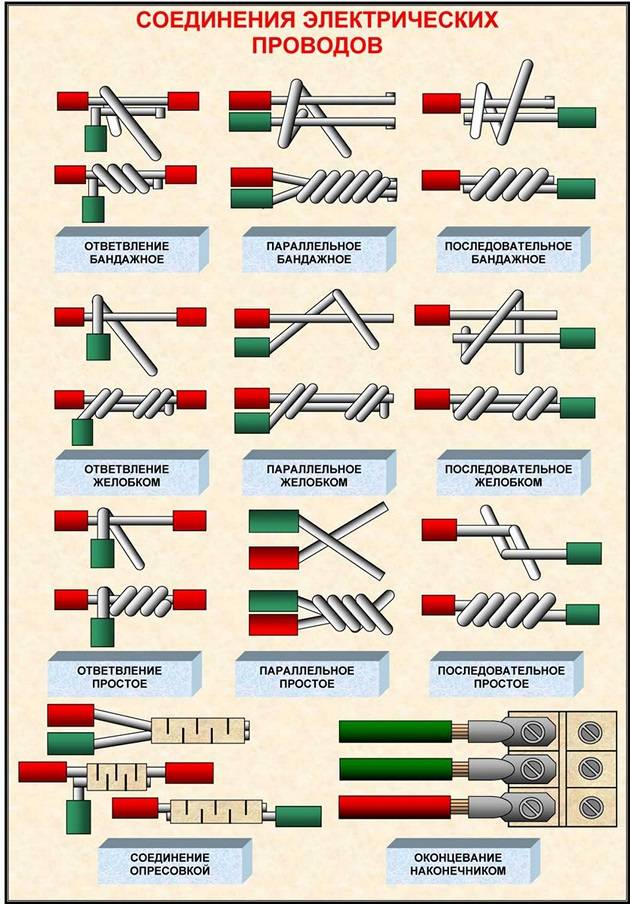

- Existing methods of connecting conductors

- Tips from experienced installers

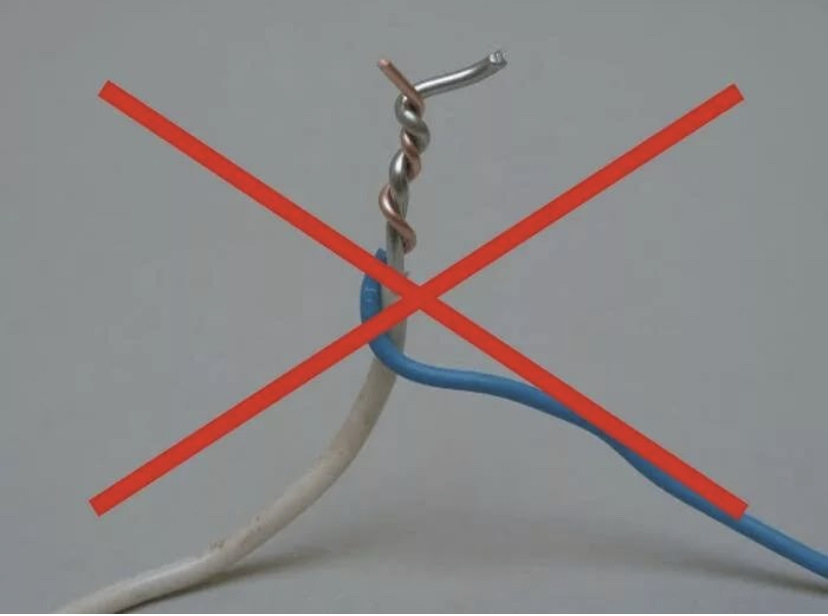

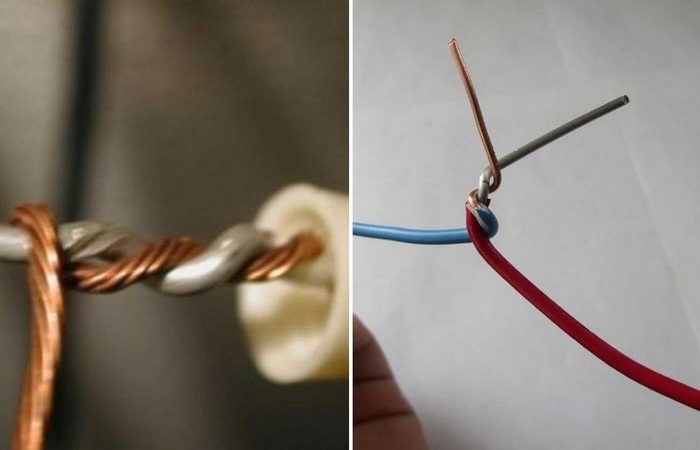

- Twisting

- How to connect aluminum wire with aluminum one-piece way

- Table of electrochemical potentials (mV) arising between connected conductors

- What is the best way to connect aluminum cable conductors?

Ways to combat electrochemical corrosion

To suppress the corrosion processes of wires, two approaches can be used.

- blocking the access of air to the contact zone, which reduces the intensity of the chemical reaction to almost zero;

- physical separation of copper and aluminum conductors, which completely eliminates the cause.

Any of the methods of this group is highly efficient and allows you to get a splice of minimum dimensions, but it is technically difficult to implement.

Therefore, at home, simpler approaches of the second group are used, for the implementation of which various purchased elements or simply improvised means are involved.

Permanent connection

Several methods fall into this category, namely:

- Crimping.

- Soldering.

- Welding.

Each of these methods has its place. Several factors influence the choice:

- Availability of suitable tools and equipment.

- Estimated current load.

- Wire diameter.

- Availability of consumables.

- Having relevant skills.

Consider each method of permanent connection separately.

Welding

Fast and reliable connection method. Moreover, this technology is relevant if a large number of connections should be made. However, for this you need to have a welding transformer and skills.

wire welding

wire welding

The welding process is as follows:

- The wires are twisted together.

- Apply a special flux to the end.

- After that, carbon electrode welding takes place for up to 2 seconds.

- As a result, a drop should form at the end of the twist.

Flux

Flux

- The drop should be treated with a solvent, and then varnished.

- When the varnish is dry, the connection is isolated.

Soldering

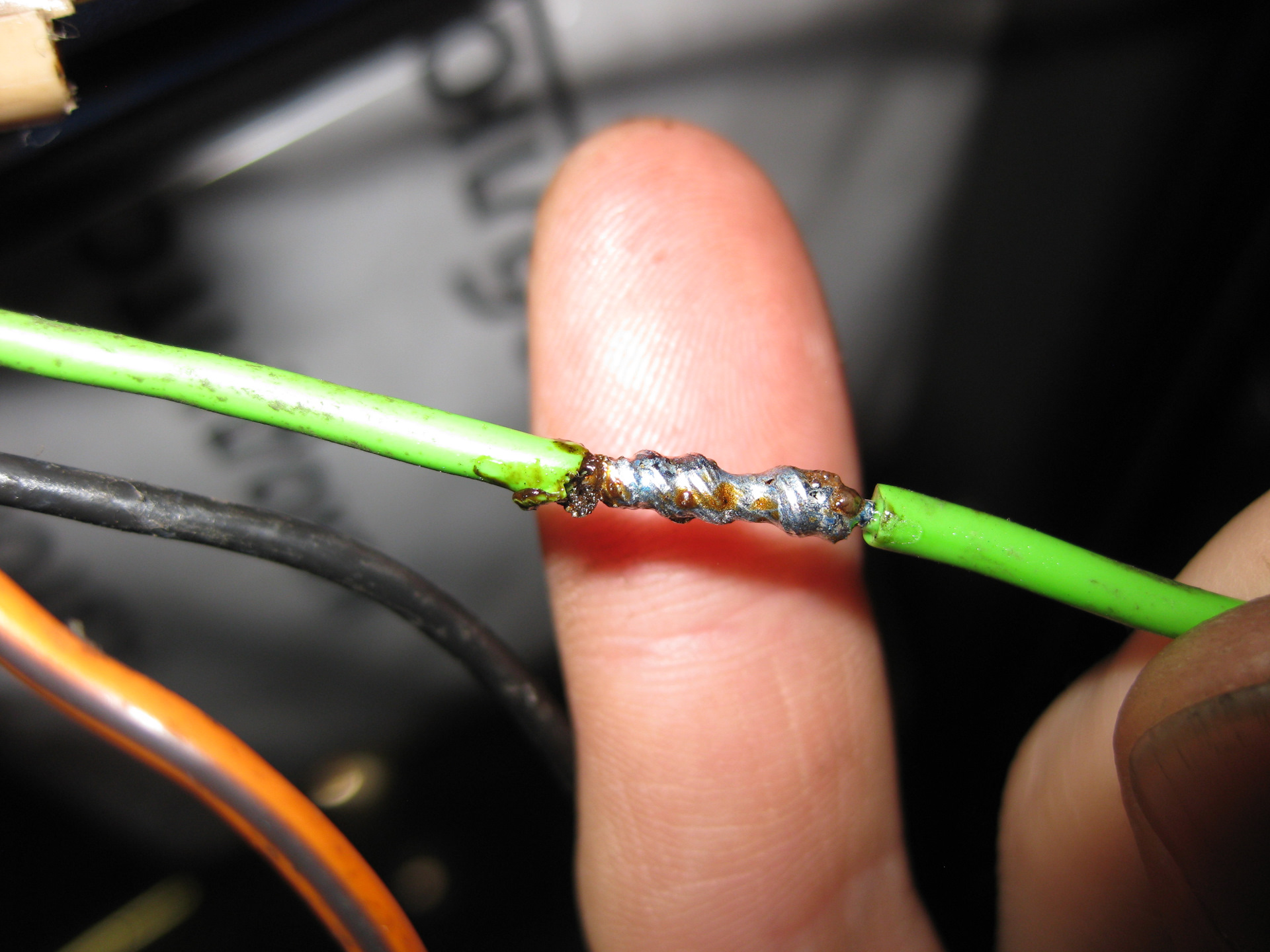

The method of soldering the connection is simple. This will require components such as rosin, a soldering iron, solders and additional elements. So, the wire is twisted, and then apply solder to them with a soldering iron.

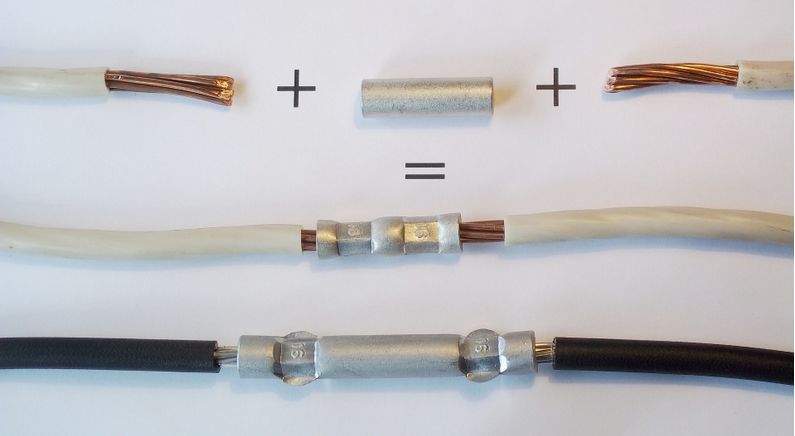

Crimping

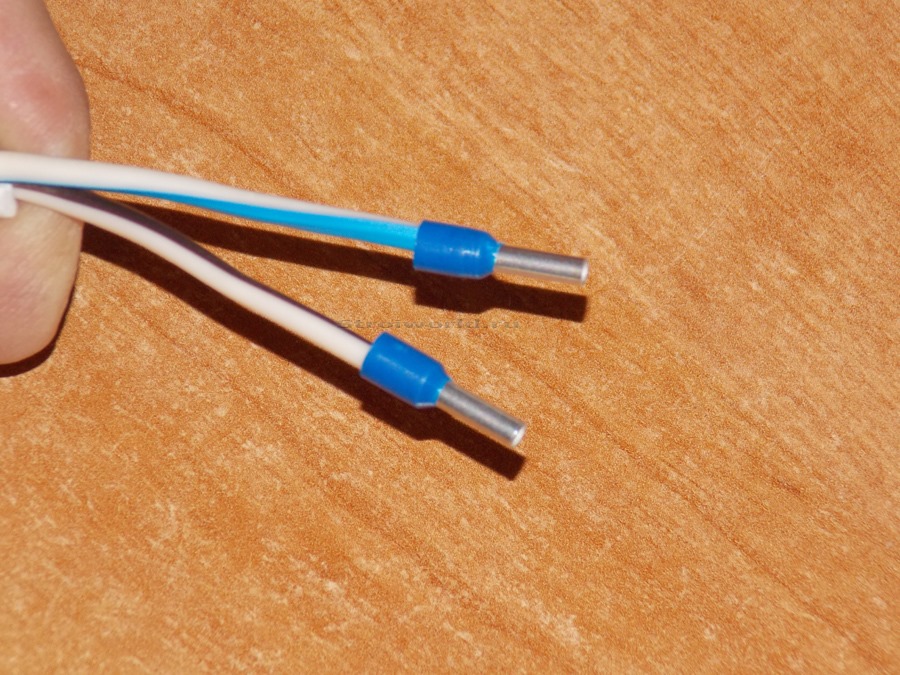

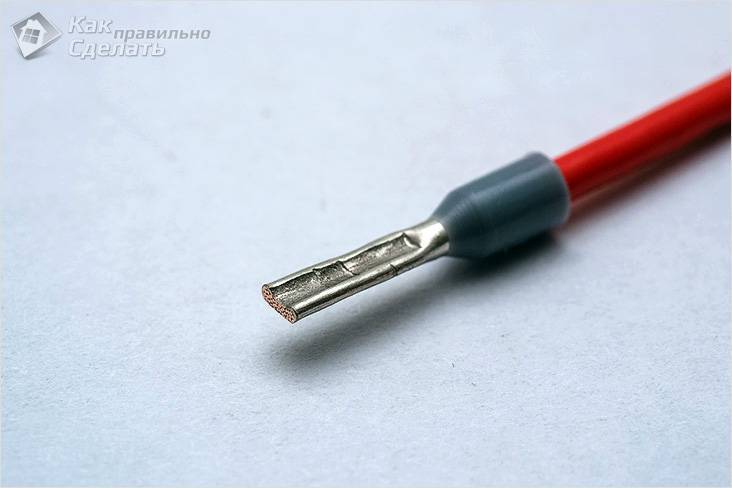

For such a connection, special press tongs and sleeves, which are hollow rods, will be required. For crimping, you clean the ends of the wire, insert them into the sleeve and perform crimping in three places. You can also twist the wires additionally.

Crimping set

Crimping set

Is it possible to twist copper wire with aluminum

Let's start with the fact that is it possible to connect aluminum wires to copper, and will such a connection not lead to a fire? The answer is yes, you can. But let's first get acquainted with these materials.

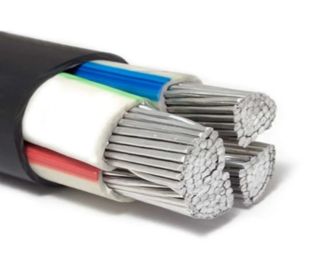

If you ask yourself which wiring is better, copper or aluminum, then the choice is of course copper. This comes from the technical characteristics of copper, the cross section of the aluminum wire under the same conditions has to be taken more. There are also disadvantages, copper is more expensive. It is easier to distinguish copper wire from aluminum by color, copper has a reddish tint, aluminum is gray, white.

Looking at the electrical performance of metals, there is no question of what conducts current better. Here are some details:

- Resistivity: copper - 0.017 Ohm mm² / m, aluminum - 0.028 Ohm mm² / m.

- Heat capacity: copper - 0.385 J / gK, aluminum - 0.9 J / gK.

- The elasticity of the material: copper - 0.8%, aluminum - 0.6%.

So why can't you twist copper and aluminum wires, because twisting, especially with a small cross section, is the cheapest option in terms of both money and time? The thing is that, when these materials are connected, they create a galvanic pair.

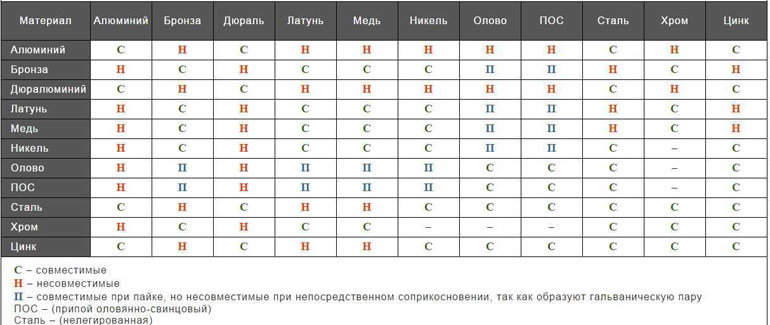

Galvanic couple - 2 metals of various kinds, the combination of which will lead to increased corrosion. Copper and aluminum are such a galvanic pair. The electrochemical potentials of the two metals are too different, so rapid corrosion will increase the resistance at the junction and its heating will follow. For more details on the compatibility of metals, see GOST 9.005-72. Below is a table with some data on metals:

Galvanic compatibility of meltals

There are many ways to achieve high-quality contact between two conductors (soldering, using a simple terminal block, more expensive WAGO terminals, or an ordinary bolt with a nut).

Features of aluminum wires

According to the norms of the PUE, it is forbidden to use aluminum conductors during installation in residential premises.

Aluminum wire is a cheap solution that has an order of magnitude lower price than copper wire. It is not subject to corrosion, as it is instantly covered with a thick oxide film. Has a low specific gravity.

The main disadvantage is the low electrical conductivity of aluminum. It is 37.9 µS×m, which is almost two times worse than copper, which has 59.5 µS×m. The low flexibility of the conductor makes it impossible to install in places where it is subjected to repeated mechanical stress.

There are four types of wire connections: crimping, squeezing, welding, soldering. Crimp sleeves and terminal blocks provide easy and quick installation of the cable in places where high mechanical resistance is not needed. Soldering and welding will give the most durable and reliable connection, but require skill and the use of special tools.

What is their feature

Aluminum has special metal properties that can make joining difficult. Due to oxidation, an oxide film forms on aluminum, which prevents the passage of electric current. This film will melt only at a temperature of at least 2000 ° C, and this figure is higher than the melting temperature of aluminum itself. Moreover, if you clean the oxide film mechanically, then after a while it appears again.

If you want to solder aluminum, then this film will prevent the solder from adhering to the core. Also, during welding, the film forms inclusions that adversely affect the quality of the contact. Among other things, aluminum belongs to the category of metals that are characterized by high fluidity and brittleness. As a consequence, the contact must be fully protected against possible mechanical influences.For example, if you connect aluminum with a bolt clamp, then you need to regularly tighten the contact, since aluminum, figuratively speaking, “flows out” from under the contact, which, in turn, weakens.

Are there ways to reliably connect aluminum wire then? Let's take a look at a few common methods and decide how best to get the job done.

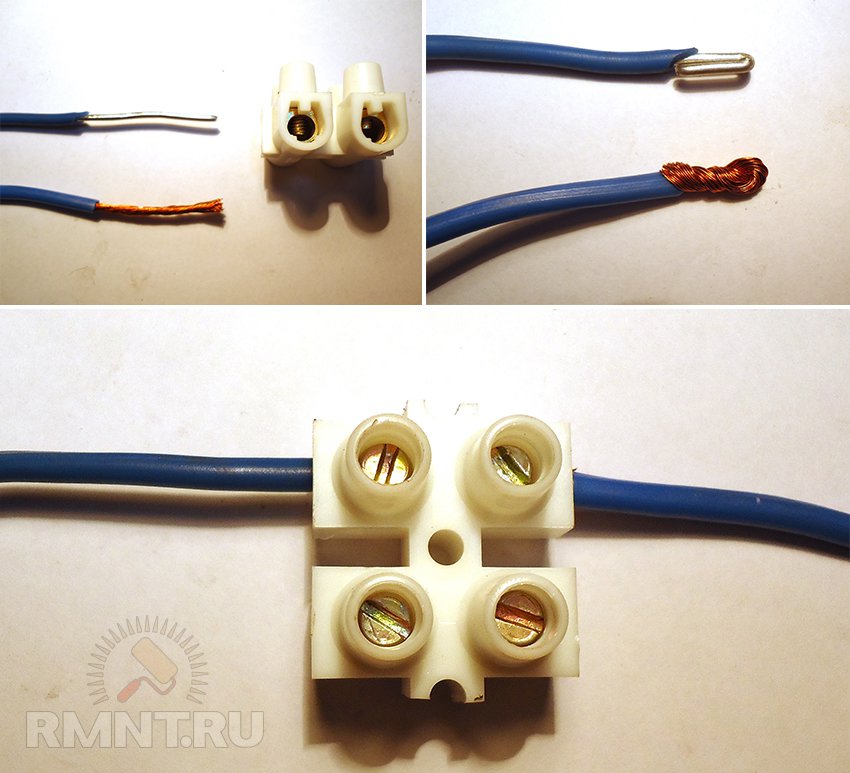

This connection method is very simple. It is necessary to strip the wire from insulation by 20 mm. After the vein, it is recommended to clean it with a fine-grained sandpaper. Next, twist the bare core into a ring and insert it into the clamping screw, which should be tightly tightened.

Screw connection kit

Screw connection kit

The disadvantage of this connection method is that, due to the fluidity of aluminum, the contact must be tightened from time to time. Therefore, the connection point must be in an accessible place.

In this case, special terminal blocks are used. Due to the presence of a special spring, there is no need to regularly tighten the contact. The inserted stripped aluminum wire is securely held. There are terminal blocks both disposable and reusable. Disposable used to connect wires without further disconnection. The wire is inserted into the hole of the clamp, do not pull it back. As for the reusable connection, the wire is easily pulled out by pressing the special lever holding the wire.

In rare cases, aluminum wire can be connected by twisting. It should be noted right away that this method is very unreliable, even though it was used relatively often in Soviet times.This is partly due to the fact that in the past the number of household appliances and, accordingly, the load on the wiring was less. Now the picture looks different.

Moreover, the duration of such a connection depends on various factors, such as current load, humidity and temperature. If the temperature rises, the metal expands, which widens the gap between the wires. This can lead to contact resistance, the contact point will heat up and after that oxidation will form and, in the end, the contact will be completely broken. However, this process continues for a long time, so for temporary connections, the twisting method is acceptable.

When joining aluminum in this way, it is important to adhere to the following rules:

- The wires should evenly wrap around each other.

- If the wire is thick, then there should be no more than three turns, and for a thin one, at least five.

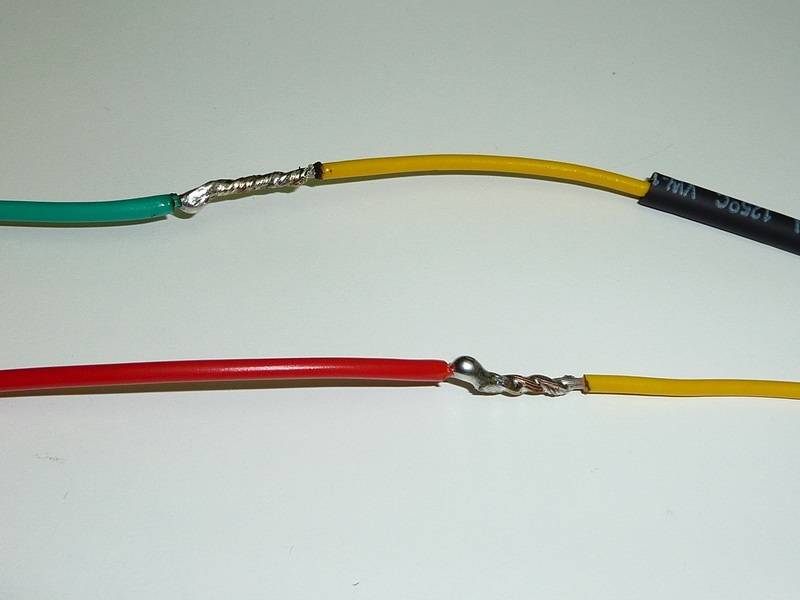

- If copper and aluminum wire are connected, then copper must be tinned.

- It is recommended to use heat shrink tubing as contact insulation.

Connection options

There are many options for how to connect aluminum wires to each other.

One of the most common methods is the usual twisting of stripped contacts. Most people who do not have special knowledge in the field of electrical engineering use this method to connect aluminum wires, considering it reliable. This is an erroneous opinion. Not all types of cable can be twisted, so how can they have a different section, which will create a weak spot in the wiring after they are connected, as well as a different brand of these cores. For a branch of an electric line, this method is not suitable.

This method has a low level of reliability, as well as a high degree of fire hazard.When this method existed, there was not yet such a large number of various household electrical appliances that consume a lot of energy (washing machines, air conditioners, water heaters, two-compartment refrigerators, etc.). The simultaneous use of several powerful energy-intensive devices significantly increases the load on the network. Contacts with a small cross section will not withstand increased voltage. For this reason, the twisting method has lost its relevance. It can be used for temporary connection.

Soldering. For connecting or branching aluminum wires, this fastening method is considered one of the safest. To do this correctly, you need to tin the wire contacts.

To do this, they are treated with molten rosin, and then carefully sanded with fine sanding paper. Then the ends of the cables are pressed tightly against each other, and then rosin is gradually added

Soldering must be uniform to prolong the service life.

Welding. This connection method is not available to everyone. To do this, you need to have special knowledge and skills, to have special equipment, access to which is not available to everyone. This method is very reliable, but it is highly recommended for experienced welders.

Contact clamps. In this way, it is best to make a connection of aluminum conductors. In the same way, you can follow if you need a branch wire. To do this correctly, strip the contacts from the braid by 2-3 centimeters, and then strip the metal with fine sandpaper (suitable 0 and 1 grain). The bare part will need to be rounded off. The cross section of this circle must be similar to the diameter of the clamping terminal.The resulting circle is put on the mover and tightened tightly.

A separate fastening method is a connecting fitting or clamp type COAC for steel-aluminum and aluminum cables. The oval clamp SOAC can be used to fasten two groups of wires: with a current load and mechanical tension along them, or only with a current load. Various brands of COAC clamp can be used according to the brand of wire, its dimensions, strength and weight. In addition to СОАС, the САС type can be used for fastening steel-aluminum conductors. For each type of such devices, there are special tables with the corresponding indications and values.

SOAS-IP is used for overhead power lines. Uninsulated wires can be connected by twisting using a SOAS-IP type clamp. The oval SOAC clamp is a fairly common type and can be purchased from most specialty stores, as well as ordered online.

Features and secrets of using the crimping method

Sometimes in the process of installation and laying of electrical wiring, it becomes necessary to obtain a high-quality connection of wires. In this case, the connection of aluminum wires with copper is carried out by crimping using sleeves. Often such a need appears at the stage of entry into electrical cabinets, switchgear or during the connection of the cable to an already installed unit, where there is no possibility of replacing copper with aluminum, and vice versa.

The presented type of connection of conductors is characterized by high costs, since it involves the use of specialized equipment and tools.However, in the process of performing repeated similar work, professionals often prefer this particular method.

Note! It is not recommended to fold conductors made of copper and aluminum in a parallel direction to each other, in other words, overlap. The fact is that in such a case, copper and aluminum are in direct contact.

In addition, it is better not to use untinned copper sleeves in combination with a cable made of aluminum.

A reliable connection of aluminum wires with copper can be obtained using the crimping method using sleeves.

Thanks to the crimping of wires with sleeves, a more durable and reliable contact is guaranteed. In a similar way, aluminum and copper conductors are fastened in production, even with powerful consumers.

To perform such work, special aluminum-copper sleeves will be required. If a manual hydraulic press is not available, they can be compressed using a standard hammer and aluminum pads.

On a note! Such a compression is recommended to be used when performing crimping not only with sleeves, but also with tips. By the way, they can also be made half of aluminum and copper. This allows you to connect an aluminum wire to various devices with terminals or copper leads.

Often, aluminum-copper sleeves are used to connect the cores of cables that have a large cross section. If the cross section is insignificant, a pair of conductors is crimped with a single sleeve. In this case, it is better to start the wires end-to-end - on both sides.

Crimping of cable cores with a small cross section is carried out with one sleeve.

Crimping of cable cores with a small cross section is carried out with one sleeve.

Helpful Tips

When working with electrical wires, they must be de-energized, even if the voltage is not high. After completion of work, bare contacts must be insulated with a special tape, placed in a rubber sheath or in a protective sleeve. In masses with high humidity, the mount will not last very long, and there is also a risk of getting an electric shock.

When working with the COAC clamp, you need to use special tools for twisting the cores together. You need to carefully consider the marking of the oval clamp SOAC, since a mismatch in the parameters can lead to unforeseen consequences.

Connection of aluminum and copper wires

Disposable terminal blocks allow you to connect solid conductors with a cross section of 1.5-2.5 mm 2. According to the manufacturers, such blocks are allowed to be used for connecting cables in systems with currents up to 24 A. However, professional electricians are skeptical about this statement and do not recommend applying loads higher than 10 A to the terminals.

We use modern pads with spring clips

Reusable pads are equipped with a special lever (usually it is painted orange) and allow you to connect cables with any number of cores. The permissible cross section of the connected conductors is 0.08-4 mm2. Maximum current - 34A.

To connect using these terminals, do the following:

- remove 1 cm of insulation from the conductors;

- raise the terminal lever up;

- insert the wires into the terminal;

- lower the lever.

Leverless terminals simply click into place.

They are designed to connect any type of single-core wires, including copper wires with aluminum wires with a cross section of 1.5 to 2.5 mm2

As a result, the cables will be securely fixed in the block. The cost of making such a connection will be more significant, but you will spend much less time on the job and save yourself from the need to use any additional tools.

In a flat-spring clamp, the wire with stripped insulation is simply inserted into the hole of the Wago terminal until it stops

Electrical connectors with mortise contact

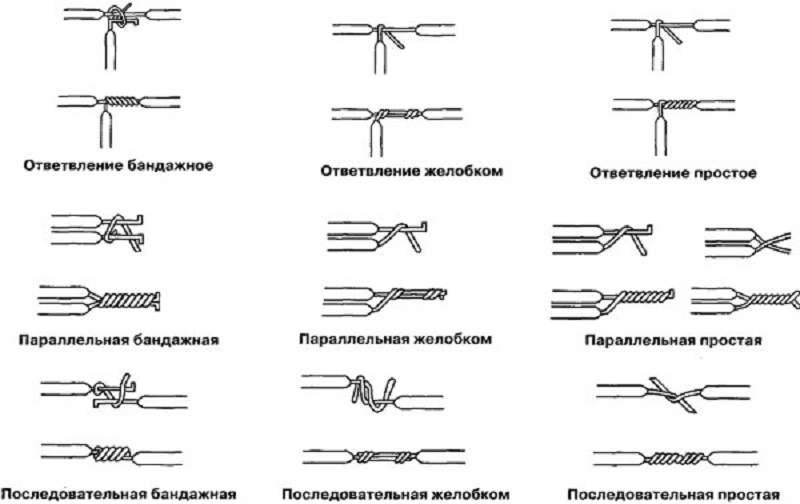

Existing methods of connecting conductors

The main methods of connecting conductors in a house or apartment

To connect the wires can be done in several ways:

- welding is the most reliable method, providing high reliability of the connection, but requiring skills and the presence of a welding machine;

- terminal blocks - a simple and fairly reliable connection;

- soldering - works well if the currents do not exceed the normative ones and the connection does not heat up to temperatures above the norm (65 ° C);

- crimping with sleeves - requires knowledge of technology, special pliers, but the connection is reliable;

- the use of spring clips - wago, PPE - quickly installed, subject to operating conditions provide good contact;

- bolted connection - easy to perform, usually used in difficult cases - if it is necessary to switch from aluminum to copper and vice versa.

The specific type of connection is selected based on many factors. It is necessary to take into account the material of the conductor, its cross section, the number of cores, the type of insulation, the number of conductors to be connected, as well as the operating conditions.Based on these factors, we will consider each of the types of connections.

Tips from experienced installers

There are many controversial issues both in connection methods and in the use of individual mounting products. But a number of rules apply to absolutely all craftsmen who are engaged in electrical installation.

For example, it is strictly forbidden to twist aluminum conductors with copper conductors. The rapid oxidation process leads to the destruction of the connection and the appearance of a dangerous point, which at any time can spark or flare up.

A few more important rules:

If the conductor is covered with an oxide film, it must be carefully removed either with contact paste or fine sandpaper. It is better to select the diameters of sleeves, tips, caps according to size.

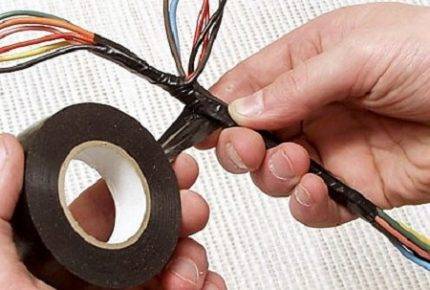

When using electrical tape, overlap the coils. One layer is not enough, it is better to walk along the connection 2-3 times, be sure to make the last turn on the insulation

When using electrical tape, overlap the coils. One layer is not enough, it is better to walk along the connection 2-3 times, be sure to make the last turn on the insulation

Single conductors in screw terminals are held loosely. Therefore, it is recommended to bend the stripped end in half or make an arbitrary loop out of it.

At the end of the work, be sure to check the reliability of the connections - lightly pull the wires. It happens that the switching is unsuccessful, and the core simply slips out of the terminal block.

If the volume of the junction box allows, for example, the shields can accommodate a lot of wires and devices, then leave the cable with a margin. Sometimes switching is required and the extra length is useful if the connections are one-piece or burnt.

We also have other articles on the site on conductor connectors, connection methods wires of different sections and selection advice best connector:

- Ways to connect electrical wires: types of connections + technical nuances

- Terminals for connecting wires: which terminal blocks are better and how to work with them

- Wire Connectors: Best Connector Types + What to Look for When Choosing a Connector

Twisting

In rare cases, aluminum wire can be connected by twisting. It should be noted right away that this method is very unreliable, even though it was used relatively often in Soviet times. This is partly due to the fact that in the past the number of household appliances and, accordingly, the load on the wiring was less. Now the picture looks different.

Moreover, the duration of such a connection depends on various factors, such as current load, humidity and temperature. If the temperature rises, the metal expands, which widens the gap between the wires. This can lead to contact resistance, the contact point will heat up and after that oxidation will form and, in the end, the contact will be completely broken. However, this process continues for a long time, so for temporary connections, the twisting method is acceptable.

When joining aluminum in this way, it is important to adhere to the following rules:

- The wires should evenly wrap around each other.

- If the wire is thick, then there should be no more than three turns, and for a thin one, at least five.

- If copper and aluminum wire are connected, then copper must be tinned.

- It is recommended to use heat shrink tubing as contact insulation.

How to connect aluminum wire with aluminum one-piece way

The one-piece type connection is endowed with all the advantages of a threaded one.The difference is only in a few points:

- the ability to disassemble and reassemble the connections without breaking the rivet;

- the need for the presence of special devices for the implementation of the rivet.

To date, rivets have found wide application for permanent connections of thin-walled structural elements in the process of creating partitions. Efficiency, low price and strength are the main advantages of the presented type of permanent connection.

The essence of the functioning of the riveter is quite simple. It retracts and cuts steel rods threaded through a tubular aluminum head rivet. The rods have a thickening, and during the retraction of the rivet into the tube, it expands.

With the help of a riveter, you can not only make permanent connections of thin-walled elements, but also reliably connect electrical wires. Note! There are rivets of various types, diameters and length variations. Therefore, everyone can choose the best option for personal tasks.

With the help of a riveter, you can not only make permanent connections of thin-walled elements, but also reliably connect electrical wires. Note! There are rivets of various types, diameters and length variations. Therefore, everyone can choose the best option for personal tasks.

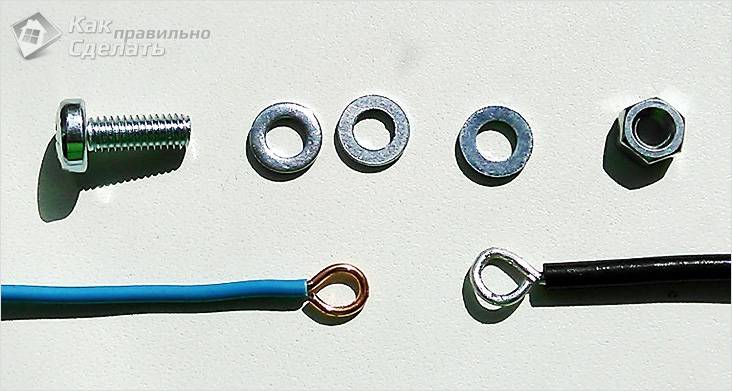

To connect conductors with a rivet, you will need to prepare them in the same way as for a threaded connection. Ring diameter should be a little morethan the rivet diameter. The optimal size is 4 mm.

The parts are put on the rivet in the following order:

- aluminum conductor;

- spring washer;

- copper conductor;

- flat washer.

Then the steel rod is inserted into the riveter and its handles are pressed until it snaps into place. This sound indicates the trimming of excess steel rods. That's it, the connection is made.

The degree of reliability of both one and the second type of connection presented by means of a rivet is quite high.A similar connection method can be successfully used to splice damaged areas during the repair of conductors in the wall. However, it must be ensured that excellent insulation of bare joints is ensured.

Since there are different types, diameters and lengths of rivets, everyone can choose the appropriate option.

Since there are different types, diameters and lengths of rivets, everyone can choose the appropriate option.

Table of electrochemical potentials (mV) arising between connected conductors

| Metal | Copper, its alloys | Lead-ol. solder | Aluminum | Duralumin | Steel | stainless steel steel | Zinc coating | Chrome plating | Silver | Carbon (graphite) | Gold Platinum |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Copper, its alloys | 0,00 | 0,25 | 0,65 | 0,35 | 0,45 | 0,10 | 0,85 | 0,20 | 0,25 | 0,35 | 0,40 |

| Lead-ol. solder | 0,25 | 0,00 | 0,40 | 0,10 | 0,20 | 0,15 | 0,60 | 0,05 | 0,50 | 0,60 | 0,65 |

| Aluminum | 0,65 | 0,40 | 0,00 | 0,30 | 0,20 | 0,55 | 0,20 | 0,45 | 0,90 | 1,00 | 1,05 |

| Duralumin | 0,35 | 0,10 | 0,30 | 0,00 | 0,10 | 0,25 | 0,50 | 0,15 | 0,60 | 0,70 | 0,75 |

| mild steel | 0,45 | 0,20 | 0,20 | 0,10 | 0,00 | 0,35 | 0,40 | 0,25 | 0,70 | 0,80 | 0,85 |

| stainless steel steel | 0,10 | 0,15 | 0,55 | 0,25 | 0,35 | 0,00 | 0,75 | 0,10 | 0,35 | 0,45 | 0,50 |

| Zinc coating | 0,85 | 0,60 | 0,20 | 0,50 | 0,40 | 0,75 | 0,00 | 0,65 | 1,10 | 1,20 | 1,25 |

| Chrome plating | 0,20 | 0,05 | 0,45 | 0,15 | 0,25 | 0,10 | 0,65 | 0,00 | 0,45 | 0,55 | 0,60 |

| Silver | 0,25 | 0,50 | 0,90 | 0,60 | 0,70 | 0,35 | 1,10 | 0,45 | 0,00 | 0,10 | 0,15 |

| Carbon (graphite) | 0,35 | 0,60 | 1,00 | 0,70 | 0,80 | 0,45 | 1,20 | 0,55 | 0,10 | 0,00 | 0,05 |

| Gold Platinum | 0,40 | 0,65 | 1,05 | 0,75 | 0,85 | 0,50 | 1,25 | 0,60 | 0,15 | 0,05 | 0,00 |

According to the requirements of the standard, mechanical connection between materials is allowed, the electrochemical potential (voltage) between which does not exceed 0.6 mV. As can be seen from the table, the reliability of contact when connecting copper with stainless steel (potential 0.1 mV) will be much higher than with silver (0.25 mV) or gold (0.4 mV)!

And if the copper wire is covered with tin-lead solder, then you can safely connect it with aluminum in any mechanical way! After all, then the electrochemical potential, as can be seen from the table, will be only 0.4 mV.

What is the best way to connect aluminum cable conductors?

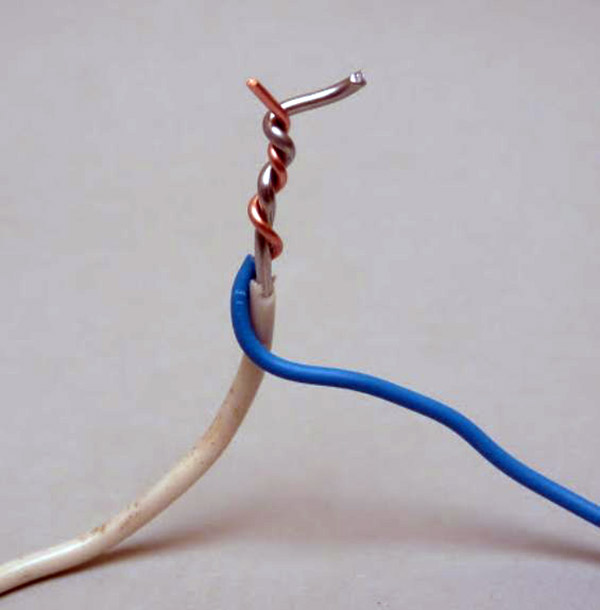

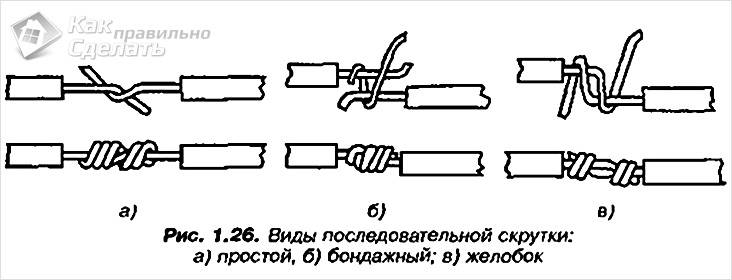

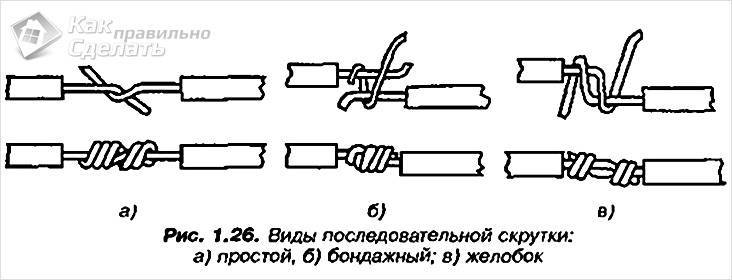

Twisting aluminum wires - with proper winding, this connection method will last at least 50 years. The twisting of wires can be different, for example, in such a way as in the pictures. The second connection method is certainly much better and more reliable.

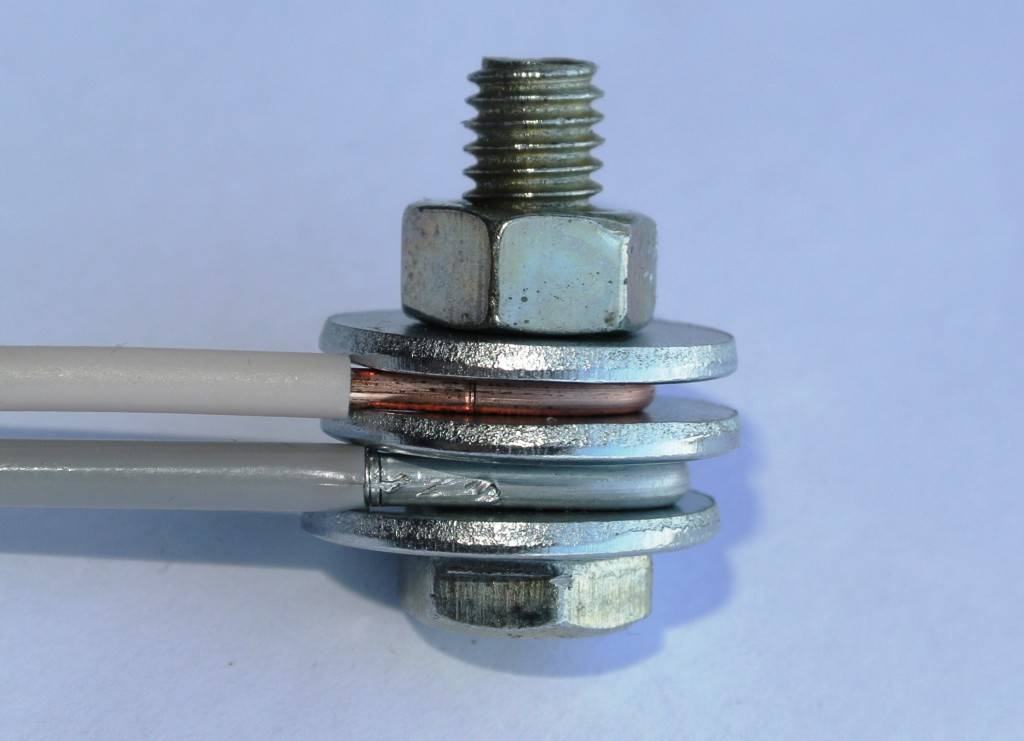

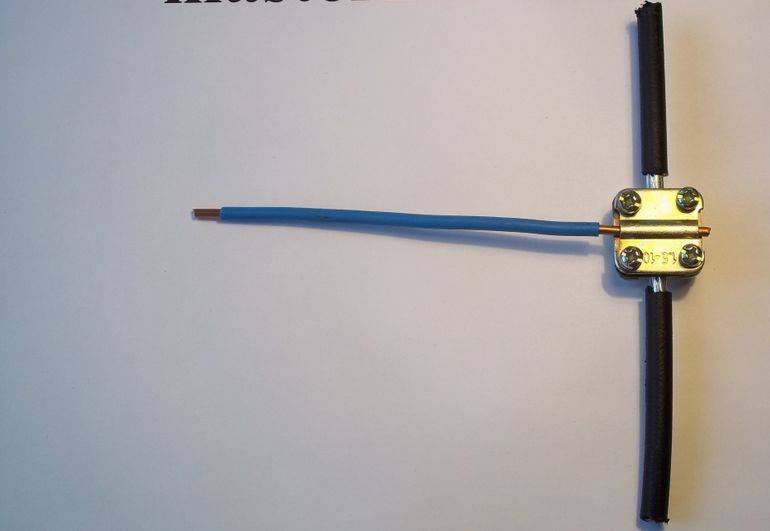

Bolted connection - a long bolt is taken, one end of the aluminum wire is wound on it, closer to the head.Then a washer is put on the bolt, and the end of another wire is wound behind it. After that, everything is tightened with one or two washers. With bolts, washers and nuts, it is best to connect wires made of dissimilar metals, such as aluminum and copper.

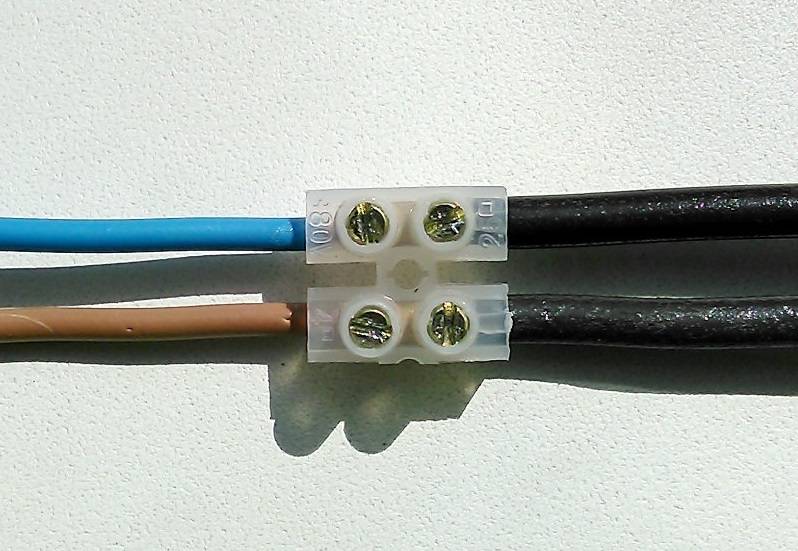

Terminals and pads are an equally popular way to connect aluminum wires. This method is fast and reliable, as well as the ability to connect copper wires and aluminium. Today, there is a wide variety of terminal blocks, for example, Wago, and simpler in design.

Sleeve connection - with this method, two wires are twisted together, and then crimped using a cable sleeve. For greater reliability, the sleeve is crimped not with pliers, but with specially designed for this purpose press tongs.

To make a sleeve for connecting two wires, you can use a copper tube to connect the air conditioner. The sleeve must have a length of at least 5-7 cm, and its diameter depends on what section of the cable will need to be connected (crimped).