- Device Features

- Protective equipment

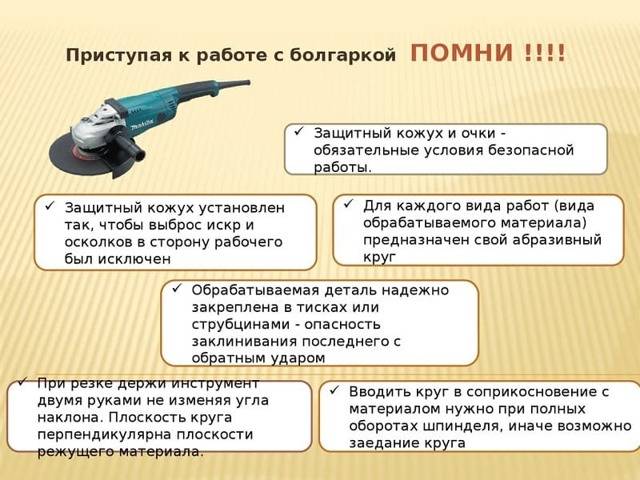

- Safety precautions when working with a grinder. How to work as a grinder!!!

- Is it possible to cut porcelain stoneware with a grinder? Types of cutting ceramic products

- Straight cut or straight cut

- Curly cutting or curly cut

- Cutting rectangular holes in tiles

- Cutting circles (round holes)

- 45° bevel cutting

- How to cut with a grinder: requirements and recommendations

- Cutting grinder glass products

- Preparing to work with a grinder

- Methods and techniques on how to work as an angle grinder

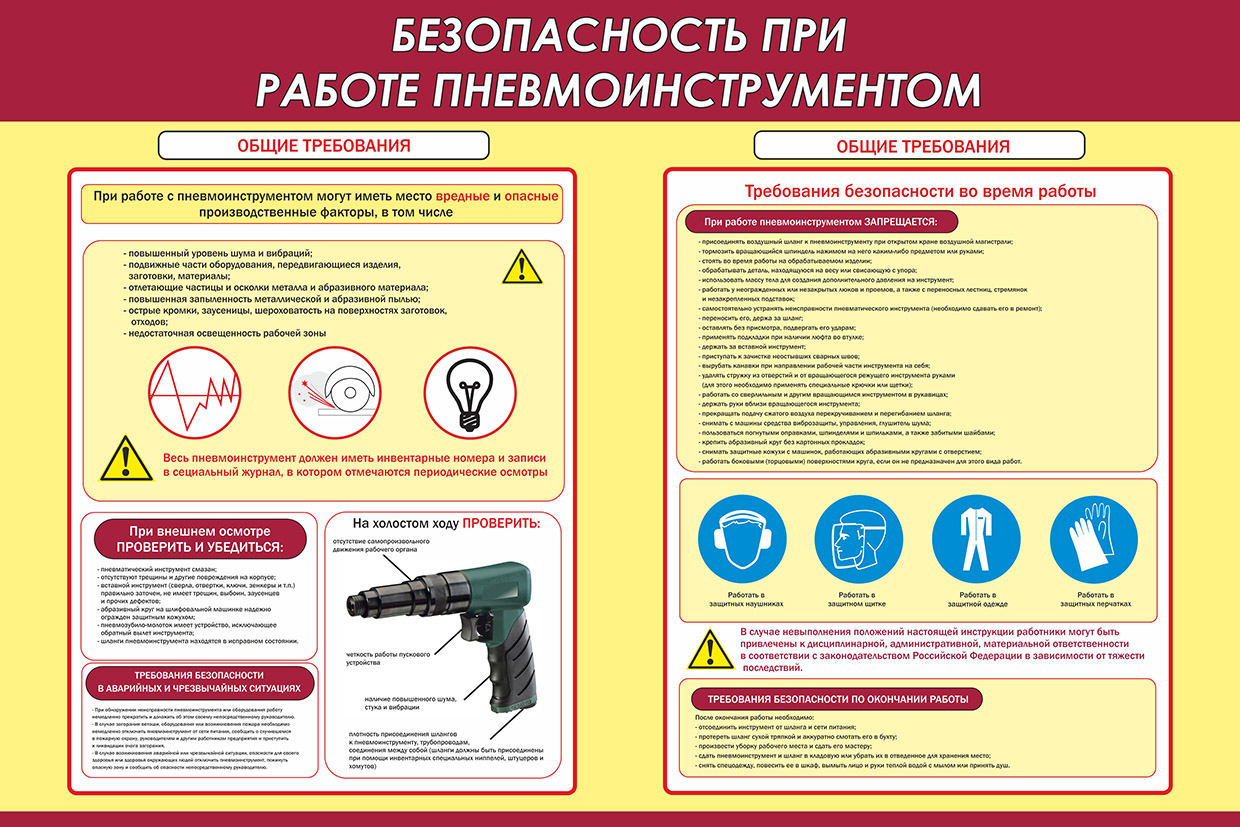

- GENERAL REQUIREMENTS FOR LABOR PROTECTION

Device Features

The simple design of the angle grinder does not prevent it from being one of the most popular and necessary tools in the household. The principle of operation is an electric motor that starts the shaft through an angular gearbox, on which a special disk is attached.

The main advantage of this technique is its versatility, because when using different discs, cutting, polishing or grinding off excess material is performed. There are discs designed to work with wood, but they cannot be used for metal. As a polishing consumable, discs with an abrasive base of different grain sizes are used.

Bulgarians are classified into several types:

- Professional;

- Small, medium and large power;

- Without handles;

- household;

- With one or two handles.

Low-power equipment is powered by a simple 220 V household outlet, but powerful angle grinders are connected to a 380 V network. Regardless of power, all machines perform manipulations for cutting, grinding and polishing wooden, concrete, metal and plastic materials.

Low-power equipment is powered by a simple 220 V household outlet, but powerful angle grinders are connected to a 380 V network. Regardless of power, all machines perform manipulations for cutting, grinding and polishing wooden, concrete, metal and plastic materials.

The only difference is the operating time. Powerful appliances are able to work longer without overheating, but household equipment has to be given a rest. If necessary, the angle grinder serves as the basis for creating a small machine. To do this, the grinder is fixed permanently and parts, drills, cutters are turned and knives are sharpened.

The grinder is an indispensable technique for construction and rescue work in auto repair shops and economic activities.

There are several reasons why the grinder is classified as a dangerous tool:

- Working with an angle grinder often takes place on an unstable surface, where it is impossible to find support for a stable position.

- Despite the protection, most of the spinning disk is not protected.

- Abrasive polishing discs often break during operation into medium and small pieces, which scatter in different directions at high speed.

Protective equipment

Picking up an angle grinder, the user must already be equipped with personal protective equipment:

- Glasses. Translucent protection will protect your eyes from scale, dust and other inclusions flying in different directions. A protective shield acts as an alternative to glasses. Thanks to him, not only the eyes are protected, but the entire face.

- Gloves.Thanks to the thick fabric, the gloves allow you to grab onto workpieces heated during cutting, as well as sharp edges of rolled metal and other materials.

- Jacket with long sleeves. You need to protect your hands not only with gloves, because they cover only the area of \u200b\u200bthe wrists. A long sleeve will cover the entire forearm from scale. Without this, it will not be possible to use the grinder correctly.

- Face mask/respirator. Respiratory protection is especially important when cutting rolled products with traces of corrosion. Rust easily rises into the air, which allows it to freely enter the lungs. Metal oxides can provoke the development of many diseases.

- Earplugs. During the processing of workpieces, a strong noise arises, the long-term impact of which can subsequently affect the general well-being. Earplugs allow you to level the negative effect of noise on the auditory system.

Now you can consider the instructions on how to properly work with the grinder.

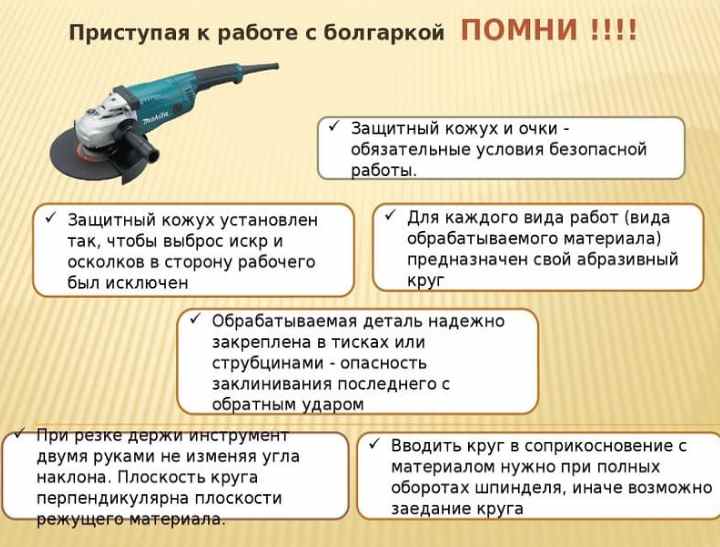

Safety precautions when working with a grinder. How to work as a grinder!!!

Again, twenty-five, again I see how builders and finishers who have been working with construction tools for more than a year cannot handle them correctly: drill, cut with a grinder correctly, and only about the safety of working with a grinder in the distant echoes of the past, and besides that all the work it is worth producing with glasses, no one knows anything!

I already had the honor to present you an article on how to drill correctly, installation of a dust-free strobe using a grinder, as well as no less interesting information about what could fail when working with a grinder. An important article on how to work with a puncher. And so let's get started:

How to work as a grinder?

Before you start working with a grinder, you should initially assemble and equip it correctly. First of all, let's deal with the protection against the angle grinder. If you are left-handed, then the protection should be rearranged. All protection when buying on a grinder is under the right hand, but the protection under the left hand is simply twisted:

- it is worth pressing the clamping nut and twisting the protection so that when you start working as a grinder holding it with your left hand, you can see the whole grinder disk, and not vice versa. We also attach protection under the right hand.

An important point when fixing the protection: - on the grinder it should be slightly inclined towards you, so that the chips would fly out from you, and not hit your hands! This rule of working with an angle grinder just refers to the safety of working with an angle grinder.

The second not unimportant nuance when completing the grinder is to fit a key for clamping the disc on the electric cord for the grinder. The key for clamping the disc to the angle grinder for convenience and safety, you need to wrap it on electrical tape on the fourth part of the electric cord of the angle grinder, from the side of the plug. This will ensure convenient operation when changing the discs of the grinder and the key will not interfere. Now you can start working as a grinder.

The very first rule when working with a grinder, and indeed with any tool, is to let the tool make a cut on its own, and in no case do not put pressure on it with force. Your task is simply to correct the stroke of the tool and sometimes lightly press it, if necessary. Such a nuance will save your instrument, even if it is the cheapest

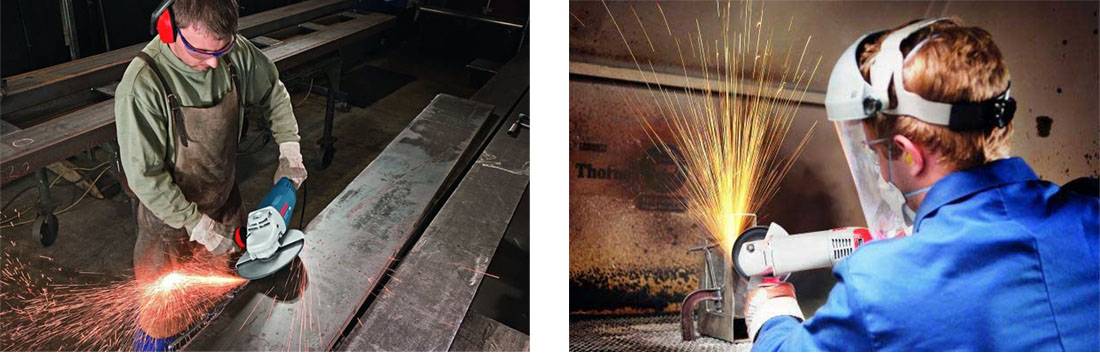

Bulgarian, safe and sound, and she will serve you, good, and long service. But in the photo on the right side of the article, you can clearly see how not to work with an angle grinder.The photo shows how the shavings from cutting with a grinder flies to the person working with the grinder on clothes and in the face. With a side cut with a grinder on weight, the grinder must be kept protected towards you, and the visible cutting side away from you.

Safety precautions when working with a grinder.

Power Tool Safety, and in particular with a grinder must always be respected! The first and indisputable safety rule when working with a grinder:

1) Protect your eyes by wearing goggles;

Safety precautions when working with a grinder include one more nuance:

2) Cut the grinder away from you, which will allow, in case of clamping the disk, the grinder to fly out in front, and if you pulled it towards you, it will fly to your feet, especially if these are medium or large grinders.

3) It is also worth knowing that the grinder mode is no more than a meter and we do not stretch forward and do not climb under ourselves, trying to cut off more, after which we must 4) turn it off and start moving, correct the cord of the grinder there. It is this point in safety precautions when working with a grinder that is important because the worker will begin to correct or tighten, fold back the cord from the grinder at a reflex level, and the grinder itself will continue to work at this moment. And this is fraught with consequences:

- There were cases when the wire, with such a throw back, fell under a working grinder disk and cut its legs, crippled those close to it, spoiled the counter, which costs from 1500, due to a short circuit.

A little higher, we discussed the clamping key from the grinder, which must be tied near the grinder fork. Let me clarify this point.This is due to the fact that when you cut with a grinder on the floor, the key tied in the middle or close to the handle of the grinder clings to your leg during work and you, again, frantically begin to correct it, etc., etc., since he just gets in the way.

So you and I went through the course of a young fighter in such a necessary topic as - safety precautions when working with a grinder.

Is it possible to cut porcelain stoneware with a grinder? Types of cutting ceramic products

In addition to ceramics, which is used in the improvement of bathrooms, there is also porcelain stoneware, natural stone tiles. They are more durable and reliable, therefore they are used for laying in public places, industrial premises, modern interiors of residential buildings.

These types of tiles are also processed with a grinder. The general principle of operation will not change. The only difference is that, due to the higher strength, it is recommended to use exclusively segmented diamond-coated metal discs: due to better cooling, there is less chance of overheating. The wet method will help to make the work more efficient and reduce the amount of dust.

The advantage of a grinder over a tile cutter is that the latter only cuts in a straight line. LBM performs complex forms. What types of cutting will the master face?

- A straight cut is more convenient and faster to make with a tile cutter. But if you don't have one, then an angle grinder will do.

- The curly oval neckline is a complex variety. Used for decorative purposes.

- Rectangular hole.

- Round holes.

- At an angle of 45°.

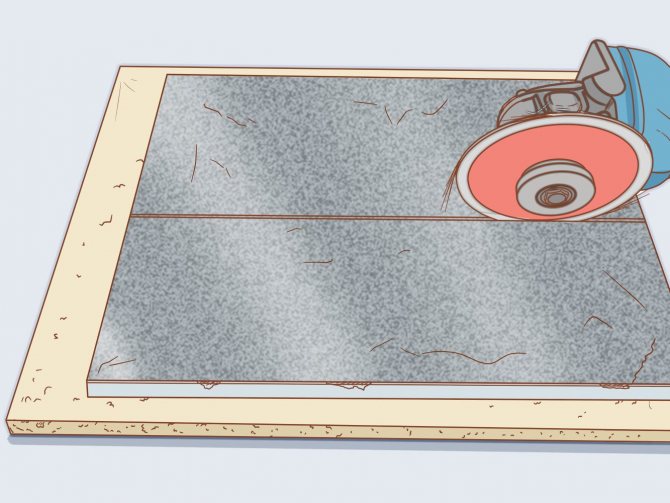

Straight cut or straight cut

The standard, easiest way, which we advise non-professionals to initially master.

- We prepare the workpiece: for this we take a marker, a ruler, draw a line along which we will make a cut.

- We place the workpiece on a straight surface, remove all unnecessary that may interfere. To ensure accuracy, we fix the workpiece with a vise.

- Let's start drinking. It is necessary not to saw through the ceramics, but to make an incision 1-5 mm deep (depending on the thickness of your workpiece). Remember that when entering the material, the number of revolutions decreases, later it can be increased. We lead the tool evenly, at the same speed, away from us. We do not drive back and forth in a circle along the intended line. We stick to the planned trajectory as far as possible. When the cutting edge exits, we slow down again to avoid chipping.

- We break the workpiece into two parts. If necessary, clean the cut with the appropriate tool.

Curly cutting or curly cut

The most complex variety, demanding on the skill of the worker. It is recommended to entrust its execution to a professional if you do not consider yourself an experienced user. Unlike a straight cut, a curly cut cannot be made with a tile cutter: a grinder is necessary in this case.

So you make an oval hole:

- We make markings on the workpiece with a marker.

- We fix the workpiece on a flat surface, fix it for the greatest reliability.

- We start working with angle grinders: you need to make short serifs, cutting off excess material.

- At the end of sawing, irregularities will remain at the cut points. To finish the curved cut, change the cutting disc with an abrasive wheel, process the cut until the result resists you.

Cutting rectangular holes in tiles

For this type of sawing, you will need a drill with a drill bit (recommended diameter - 5 mm) on the tile!

- We outline the contours of the figure that we will cut out.

- We fix the workpiece using a flat surface (this can be a large solid table or a special workbench).

- Using a drilling tool, within the outlined contours, we create holes in the corners of the proposed rectangle.

- Using the angle grinder, we cut the lines following the marked contour.

- Delete the inner part of the figure.

- If necessary, we refine the resulting area with an abrasive.

Cutting circles (round holes)

Before starting cutting the circle, prepare a drill, a carbide drill (3–4 mm is a suitable diameter), compasses. Let's get started:

- We put a marker on the workpiece. This will be the center point of the circle.

- Using a compass, draw the outline of a circle of the size you need.

- Drill create a hole in place of the center point.

- With an angle grinder, we make through cuts from the inside of the contour of our circle.

- We process irregularities with an abrasive or sandpaper.

45° bevel cutting

This type of cut is considered complex. To improve the quality of the result, we advise you to do the work with a branded metal circle reinforced with diamond coating.

- We mark the place of the cut with a marker along the ruler.

- We locate and, if possible, fix the disc.

- We place the blank with the outer side to the bottom.

- Using an angle grinder, cut off the back side of the workpiece at an angle.

- Following the marked line, we perform a second cut. This will allow you to achieve the most accurate and even result.

- If necessary, adjust the cut point.

How to cut with a grinder: requirements and recommendations

The grinder is on alert, the workplace is cleared of extraneous things and people, the workpiece is securely attached and marked - this is exactly the moment when you can start working. The grinder must be held with both hands, firmly and confidently. It must be taken so that in the event of a wheel jamming, the tool is not pulled out of the hands, and in the event of a reverse impact, it does not lead to a strong displacement. The kickback is one of the most dangerous moments of working with an angle grinder. This is a sudden and sharp rejection of it as a result of jamming of the disk in the workpiece.

The position of the body during work must be stable, one should stand so that sparks do not fly to the legs, clothes, and even more so to the face. The power cord of the angle grinder must be out of reach of the rotating disc so that it does not get caught. And if you need to move to another object, turn off the tool and drag the cord to a new safe position. You should also turn off the grinder if there are power outages.

To the question: “How to cut with a grinder correctly,” manufacturers unequivocally answer: “So that the direction of rotation of the disk and the movement of the tool itself coincide.” In this case, a jet of sparks will cover the markings along which the cut is made, so this operating rule is often ignored, but in vain. It is necessary to bring the disc into contact with the surface at full speed of the spindle so that the wheel does not jam.

Rules for cutting with a grinder:

- It is necessary that the cut line passes by the working person, and does not rest against him. And in the event of a disc jamming, the jet movement of the tool will take place away from the operator.

- The protective cover will provide protection if it is located between the circle and the worker.

- There is no need to forcefully press the tool. The grinder will cope with the task under her own weight, and overloading will only lead to a distortion of the circle.

- You can not turn on the grinder if the disk is located in the cut of the workpiece.

- It is necessary to start cutting profiles from the place with the smallest cross section.

- When cutting stone, concrete or tiles, a lot of dust is generated, which must be protected from the respiratory system and which must be disposed of. There are special casings with a nozzle for a vacuum cleaner. You can also suppress dust with water by directing the water jet into the cut.

- When cutting walls, you must be prepared for the fact that a cable, pipe, fittings can get under the circle, which can lead to a kickback and therefore it is better to stay away from a possible tool displacement line.

- goggles or mask;

- anti-dust respirator;

- special protective clothing;

- thick leather gloves;

- construction vacuum cleaner;

- suitable fittings.

Cutting grinder glass products

Glass processing always creates quite a lot of difficulties. In this case, you can use a special hard-coated wheel as a nozzle.

Working with a grinder with natural and artificial stone Stone is considered another difficult material to process. To work with it, a special steel disc with a coating is used. A feature of the cutting nozzle for stone can also be called the presence of separate segments.

Cutting glass with a grinder

Dividing the cutting edge into several segments improves the cooling efficiency. The nozzle is used to work with granite, marble and other stone.

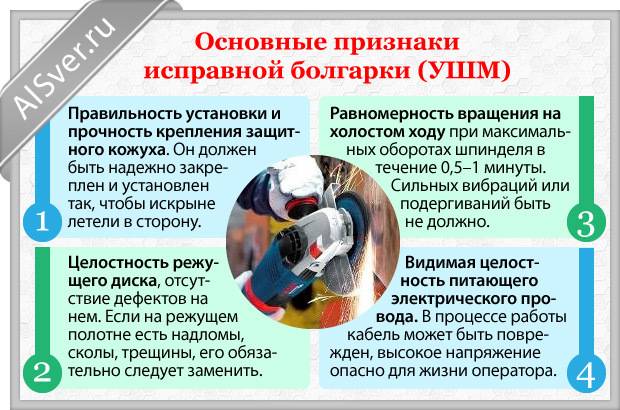

Preparing to work with a grinder

Recommendations on how to properly work with a grinder would not be complete without a description of the preparatory stage. First of all, you need to prepare and tune in to work.If safety precautions are not followed, the angle grinder becomes a very dangerous tool. Therefore, it is better not to pick it up, being sick, too tired, and even more so drunk. Fatigue and lack of concentration lead to negligence, which in the case of an angle grinder can cost health and even life.

To work with a grinder, goggles are a must.

You need to prepare protective equipment. Protective goggles and a casing must be present. Without them, cutting with a grinder and performing other manipulations is prohibited. Fragments, sparks, scale and so on - all this inevitably appears when working with a grinder. And getting these particles in your eyes can cause serious injury.

The mask or goggles must be of a closed type. The flight path of fragments and sparks is non-uniform. If the mask or goggles are open, sparks can fly behind them. It is better that the mask was with a safety net, because. an unreinforced product may break at some point.

The protective cover is a barrier between the circle of the grinder and the operator. During operation, the circles break quite often. Almost everyone who periodically uses a grinder had to deal with this. In most cases, the cause of the destruction of the circle is its jamming in the slot. The protective cover is installed in such a way that fragments and sparks do not fly towards the operator. If the circle breaks during operation, the casing will protect the person working with the grinder. The opening in the casing defines the fragmentation sector and protects the operator from injury.

The casing must be fixed so that there is no possibility of its spontaneous rotation.Sometimes it is very inconvenient to work with the installed casing, but it must not be removed in any case, otherwise the consequences for the health of the operator may be the most unfavorable.

In addition to glasses, it is necessary to have other protective equipment, in particular, gloves or mittens.

While working with the grinder, the operator keeps his hands very close to the rotating circle, it is important to protect them from metal fragments, sparks and other particles that form. The best option is thick leather gloves.

Cotton products do not guarantee reliable protection of hands from sparks.

When sawing stone materials, you need to wear an anti-dust respirator.

When processing stone materials in the absence of dust extraction devices, the operator must wear a dust mask. You need to work in well-tucked, not wide clothes

It is important to eliminate all dangling parts so that during operation they are not tightened by a rotating circle.

Working circles for grinders deserve special attention. Each type of material is processed using a wheel specially designed for it. It is impossible to use circles that are not intended for processing the existing material.

It is forbidden to install larger circles on the tool than indicated in the instructions. Small size grinders operate at a higher rotational speed than larger sizes. During operation, large circles may not withstand high speeds and collapse. When rotating a large circle, the bearings will experience an increased load, which will lead to their faster wear and, in general, will reduce the life of the grinder.In addition, to install a wheel of an unacceptably large size, you will have to remove the casing, which is also prohibited.

When working with a grinder, you should use only whole discs without visible damage.

It is forbidden to install damaged and deformed wheels. This can provoke a kickback and lead to the destruction of the circle. Possible injury to the operator.

After the tool is installed, the angle grinder will need to be checked at maximum speed for at least 1 minute. The circle should rotate freely, and the vibration should not be stronger than usual.

Thus, in addition to the grinder itself, you will need:

Having mastered all the features of preparation, you can begin to understand how to work as a grinder.

Methods and techniques on how to work as an angle grinder

1. The workplace must be completely clear of foreign objects that may interfere with your free movement and cause awkward movement.2. The grinder must be held firmly with both hands due to the risk of a jerk at start-up and during operation.

You can not let it out of your hands until the rotation of the wheel or grinding brush stops completely.3.The question of how to cut with a grinder is one of the most highlighted in professional recommendations, but at the same time, many people forget, due to the inconvenience when working in a confined space, that cutting according to safety rules is possible only when the disk moves away from you. the workpiece to be sawn must be transverse with the maximum prevention of jamming of the disc during the cutting process. In the case of working with the disc position tangentially or bending, there is a risk of clamping, which is accompanied by a sharp kickback of the tool and a break in the cutting wheel. In such cases, the angle grinder is often pulled out of your hands, which completely eliminates control over the tool. Before using the tool for the first time (turning it on), in order to understand how to properly hold the grinder, you need to manipulate it in front of you for the possibility of cutting paths outside your body. Be sure to consider cases of “leaving” the tool to the side, forward, back. A sheaf of sparks serves as a sure guide for determining how to properly saw with a grinder.

Sparks should not be directed upwards or towards the master. Do not forget that sparks and a directed dust stream are small particles of material that, due to the high ejection speed, can quite easily damage not only the skin, but also other easily destroyed materials. massive parts use wider discs.4. It is unacceptable to use interchangeable wheels and nozzles for other purposes: The cutting wheel is used only for cutting off parts, and not for grinding surfaces, because.

pressure on it at an angle or on its side surface deforms the wheel with an increase in the likelihood of destruction. The grinding wheel is not applicable for cutting off parts due to the large width. Depending on the model of the grinding wheel, it is unacceptable to carry out grinding on non-working surfaces that do not have a grainy structure like emery. Additional nozzles must have operational features, how to properly use the grinder when installing them. Before using the nozzle, it is definitely recommended to clarify its working surfaces and the direction of movement of the tool. Due to the large structural and raw material difference, cutting and grinding wheels have different non-interchangeable purposes. - this is a simplified, long-standing popular name for an angle grinder. It is used everywhere: in construction, in agriculture, and in private household work.

Designed for grinding and cleaning surfaces of various kinds, for cutting metals of any thickness, stones and other materials. This power tool got its unofficial name due to the country of origin - Bulgaria. The working element of the grinder is a special disk, the configuration of which is selected depending on the material being processed.A nozzle disk moving at a huge speed, with the slightest inaccurate movement of the master, can lead to at least wounds or cuts, and in more serious cases, to severe injuries. Unobserved safety precautions make the angle grinder an extremely dangerous tool, so the rules defined for working with it should always be strictly followed.

GENERAL REQUIREMENTS FOR LABOR PROTECTION

1.1. To perform work with a manual electric angle grinder, workers are allowed at least 18 years old who have undergone a medical examination and have no contraindications for health reasons, who have the necessary theoretical and practical training, who have passed introductory and primary workplace safety briefings and training according to a special program, certified by the qualification commission and granted permission for independent work using an electrified tool. 1.2. When performing work using a manual electric angle grinder, the employee must undergo special instruction and receive group I on electrical safety. 1.3. An employee working with a hand-held electric angle grinder must periodically, at least once a year, undergo training and testing knowledge of labor protection requirements and obtain a permit for work of increased danger. 1.4. A person working with a manual electric angle grinder, regardless of qualifications and length of service, must undergo a re-instruction on labor protection at least once every three months. 1.5. An employee who has shown unsatisfactory knowledge and skills of safe work with a manual electric angle grinder is not allowed to work independently. 1.6.The employee is prohibited from performing work for which he is not authorized in accordance with the established procedure, as well as using tools and equipment with which he does not have safe handling skills. 1.7. While working with a manual electric angle grinder, an employee can be adversely affected, mainly by the following dangerous and harmful production factors: - electric current, the path of which, when closed, can pass through the human body; - unprotected rotating working tool; - sharp edges, burrs, roughness on the surface of the power tool and workpieces; - increased noise and vibration levels during the operation of the electric drive of the tool and during the processing of parts; - increased dust content in the air of the working area; - physical activity (for example, during prolonged work with a hand-held power tool). 1.8. An employee working with a hand-held electric angle grinder should be aware that, according to the degree of protection, the power tool is produced in the following classes: I - a power tool in which all live parts are insulated and the plug has a grounding contact; II - a power tool in which all live parts have double or reinforced insulation; III - a power tool with a rated voltage not exceeding 42 V, in which neither internal nor external circuits are under a different voltage. 1.9. A worker who works with a Class 1 power tool must wear personal protective equipment. 1.10.To prevent the possibility of a fire, an employee must comply with fire safety requirements himself and prevent violations of these requirements by other employees; Smoking is allowed only in specially designated areas. 1.11. The employee is obliged to comply with labor and production discipline, internal labor regulations; it should be remembered that the use of alcoholic beverages, as a rule, leads to accidents. 1.12. If an accident occurs with any of the employees, then the victim must be given first aid, report the incident to the manager and maintain the situation of the incident, if this does not create a danger to others. 1.13. The employee, if necessary, must be able to provide first aid, use a first aid kit. 1.14. In the immediate vicinity of the workplace, in a visible and accessible place, there should be a first-aid kit, equipped with medicines and dressings with an unexpired shelf life. 1.15. To prevent the possibility of illness, an employee working with a hand-held electric angle grinder should follow the rules of personal hygiene, including washing their hands thoroughly with soap and water before eating. 1.16. Eating and smoking is allowed only in designated areas. 1.17. An employee who has committed a violation or non-compliance with the requirements of an instruction on labor protection is considered as a violator of industrial discipline and may be subject to disciplinary liability, and, depending on the consequences, to criminal liability; if the violation is associated with causing material damage, then the perpetrator may be held liable in accordance with the established procedure.