- Alternative thermal insulation options

- Why is outdoor insulation needed?

- Types of thermal insulation materials

- Mineral wool

- glass wool

- polyurethane foam

- Foamed polyethylene

- Other heaters

- Kinds

- Mineral wool

- polyurethane foam

- Features of the use of heaters

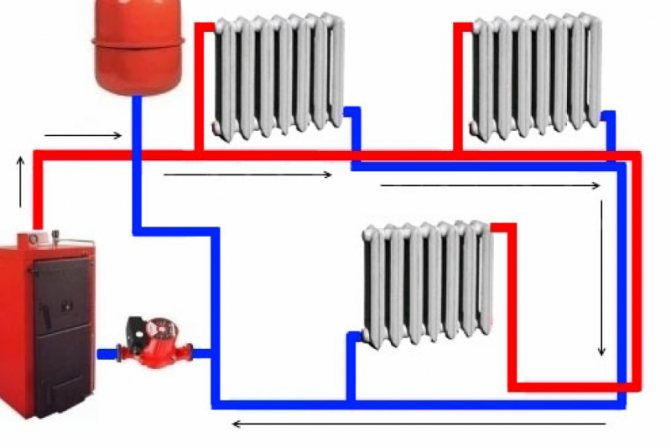

- Thermal insulation of heating pipes

- Ways to insulate water pipes

- Ways to reduce heat loss

- Who should pay for the replacement of pipes in the basement -

- The need to insulate heating pipes

- Why is it necessary to insulate heating pipes?

- K-FLEX

- Do I need to insulate the plumbing?

- Applied thermal insulation materials

- glass wool

- Basalt insulation

- Styrofoam

- polyurethane foam

- Foamed polyethylene and artificial rubber

- Thermal insulation paint

- 3 Types of overlays

- How to perform thermal insulation of polypropylene pipes

- How to insulate heating pipes with your own hands

Alternative thermal insulation options

There are alternative methods of thermal insulation that prevent the occurrence of adverse effects. They are not applicable in all cases. First, you can remove all the water from the system - no water, no problem. This method is applicable for houses not used during the winter. It will help protect the system from damage in case of freezing of water pipes.

Secondly, you can ensure the constant movement of water in the pipeline by opening a tap a little. This is not difficult to do with permanent residence. But the option is dangerous - all of a sudden you have to leave home for a couple of days, and upon returning you will expect a surprise in the form of a damaged water supply.

Insulation helps to get rid of condensate, which has a positive effect on extending the life of metal pipes

In addition to the ajar tap, there are other ways to ensure constant pressure in the pipeline. For example, use a special pump to increase the water pressure in the system, or add another element - the receiver. It should be cut into the pipe immediately near the pump. The operation of the receiver will maintain a constant pressure, which will protect the system from freezing.

Why is outdoor insulation needed?

The answer to this question is simple. It is rather not about insulation, but about the thermal insulation of heating systems on the street. The overall efficiency of all heating will depend on the quality of the insulation.

Video

The main thing is not what materials the insulation was carried out, but how well the installation was done!

Thermal insulation should close the entire pipeline from negative natural phenomena and mechanical damage. The insulation will protect pipes located in the open air from premature destruction and the negative effects of ultraviolet rays.

Polymer samples are resistant to corrosion, but they require good frost protection, as they are prone to freezing, mechanical damage and abrasion, while metal samples, which are more rigid and reliable at first glance, quickly oxidize and become unusable.

Another disadvantage of metal is its high thermal conductivity, which is not very good for heating systems. Proper heat and waterproofing (insulation) will eliminate the above disadvantages without wasting heat.

Everyone chooses a heater according to their own parameters, based on personal preferences and wishes.

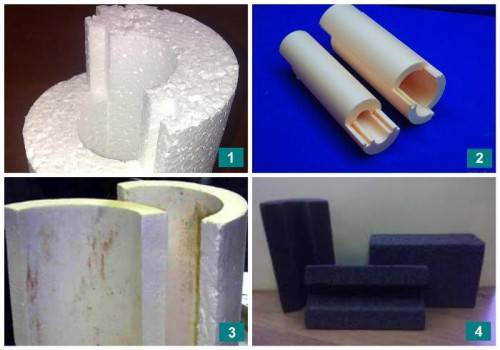

Types of thermal insulation materials

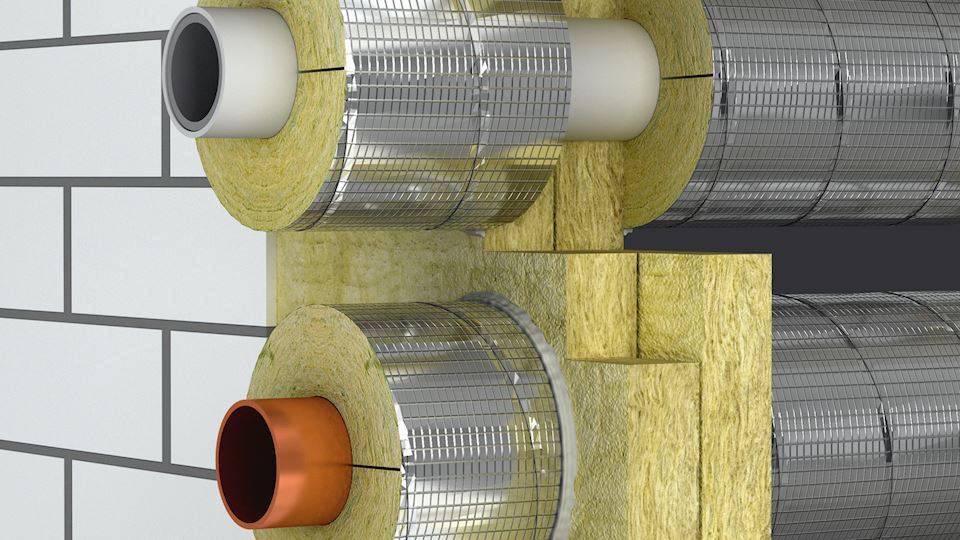

Mineral wool

Mineral wool is especially well suited for the insulation of large diameter pipelines.

Due to their high efficiency, heat insulators consisting of mineral wool are very popular. Among their advantages are the following:

- a sufficient degree of heat resistance (up to 650 C), while the material, when heated, does not lose its original mechanical and thermal insulation characteristics;

- chemical resistance to solvents, alkalis, acids, oil solutions;

- slight water absorption - due to treatment with special impregnating compounds;

- mineral wool is considered a non-toxic building material.

Insulation for heating pipes based on mineral wool is ideal for thermal insulation of heating and hot water pipelines in public, industrial and residential buildings. It is often used for installation on pipes that are subjected to constant heating, for example, on stove chimneys.

There are several types of mineral wool heat insulators:

- stone wool - made from basalt rocks (you have already read about it above);

- glass wool (fiberglass) - the raw material is broken glass or staple fiber made from quartz sand. Glass insulation, unlike stone, is not so heat-resistant, so the areas where it can be used are somewhat narrower.

glass wool

Felt glass wool for pipes

Glass mineral insulation is produced with a thickness of 3-4 microns in rolls 1550-2000 mm long. Glass wool has a low density and can be used for pipelines whose heating temperature is not higher than 180 C.

The insulation is suitable for thermal insulation of ground communications. Among its positive properties:

- resistance to vibration;

- resistance to biological and chemical influences;

- long service life.

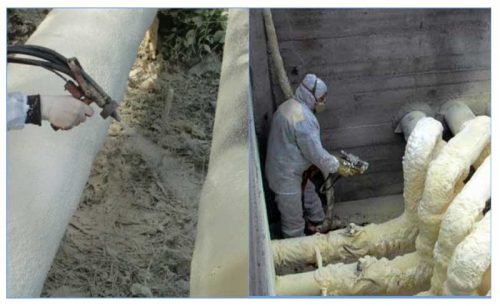

polyurethane foam

Polyurethane foam insulation

A polyurethane foam heat insulator is a rigid structure consisting of ribs and walls. Insulation is cast under production conditions using the "pipe in pipe" method. Another name for such an insulator is a heat-insulating shell. It is very durable and retains heat well inside the pipeline. It is especially worth noting that polyurethane foam insulation:

- has a neutral odor and is non-toxic;

- resistant to decay;

- safe for the human body;

- very durable, which prevents possible pipeline breakdowns associated with external mechanical loads;

- has good dielectric properties;

- chemically resistant to alkalis, acids, plasticizers, solvents;

- withstands various weather conditions, so it can be used to insulate heating pipes on the street.

But polymer insulation has one significant drawback - the high price.

Foamed polyethylene

Cylinders for polyethylene foam insulation

Environmentally friendly, harmless to humans, resistant to humidity and sudden temperature fluctuations, polyethylene foam is in great demand as a heat-insulating material. It is made in the form of a tube of a certain diameter, equipped with an incision.It can be used for insulation of heating pipes, as well as cold and hot water supply.

It retains its characteristics when interacting with various building materials (lime, concrete, etc.).

Other heaters

Several other types of heaters are also available:

- Styrofoam.

The insulation is made in the form of two connecting halves. The connection takes place using the tongue-and-groove method, which prevents the formation of so-called "cold bridges" in the heat-insulating layer.

- Styrofoam.

A low degree of moisture absorption and thermal conductivity, a long service life (50 years or more), good sound insulation and heat resistance, as well as resistance to ignition, make polystyrene an indispensable insulation used in industrial construction.

Expanded polystyrene, polystyrene, penoizol, foam glass - the best heaters for heating pipes

- Penoizol.

It is similar in its properties to polystyrene, differs only in that it is produced in liquid form. When applied to pipes, it does not leave “gaps” and ensures the tightness of the system after drying.

- Foam glass.

It is an absolutely safe insulation, as it consists of glass of a cellular structure. The insulation is non-shrinking, strong and durable, non-flammable, resistant to chemical environments and vapors, easily endures rodent invasions.

Insulation of heating pipes with foam glass is not difficult even for beginners, while you can be sure of its long service life.

Kinds

There are a lot of heat-insulating materials - these are not only mineral wool, fiberglass, but also various polymers, foamed materials.

Mineral wool

Cotton wool with mineral additives is a traditional, cheap, time-tested insulation that has several varieties. Stone wool is created with the addition of basalt rocks. Its features:

- can withstand up to +650°С without losing its properties;

- does not lose shape;

- has high chemical resistance to oils, solvents, acids, alkalis;

- non-toxic;

- special impregnation achieves its low water absorption.

It withstands high temperatures, it is used inside boiler rooms, in hot water supply networks, heating, as well as for pipes that are heated (chimney, stove).

Glass wool (fiberglass) - wool with glass spatula fiber made of quartz sand and glass grains. It has indicators much lower than that of stone. Glass wool features:

- fiber thickness 3–4 µm, ribbons 1550–200 mm;

- low density;

- operating temperature - up to 180°С;

- high resistance to vibration, biologically, chemically active environments. Long service life.

It is used in somewhat limited areas, it is recommended for above-ground pipelines. Differs in high vibration resistance.

polyurethane foam

The disadvantage is the high cost. It has technical characteristics such as weather resistance, solvent resistance, acid resistance, non-toxicity, decay resistance and strength. Polyurethane foam is odorless and does not electrify.

This is a rigid heat insulator used for pipes with walls and ribs. The product is created by the method of pouring "pipe in pipe" in an industrial environment. It is also called heat-insulating shells.The joints between the shells are insulated with a special heat-resistant polyethylene tape and couplings.

Polyurethane foam shells are often additionally sheathed. Sheathing can be polymeric or rigid. The first protects the insulation from dampness, mechanical stress, and eliminates corrosion and dispersion.

Rigid protection is used for steel galvanized heating pipes with spiral seams. They have a tin heat-insulating protective shell, in which there is a polyurethane layer. Mostly used for large above ground pipelines. The advantages of insulation are simple installation and dismantling, reusability, the ability to use on damaged sections of the pipeline.

Features of the use of heaters

Thermal insulation materials contribute to the supply of heat at a higher temperature. Therefore, when applying them, you need to follow these rules to eliminate the occurrence of errors:

- Carrying out work with your own hands, it is better to choose insulating materials that have an adhesive layer.

- If you want to use only aluminum foil as a heater, heat loss will not be reduced, since it conducts heat well.

- If the soil of the site is unstable, then you need to select light heaters (rock wool, polystyrene).

- Thermal insulation products of a rigid structure do not fit well on narrow or wide pipelines.

- The use of heavy insulation implies a fastening system due to the increased load on the structure.

Using insulating materials, you can reduce heat transfer from heating pipes many times over. If you sealed the pipe correctly, you can expect to reduce heating costs.

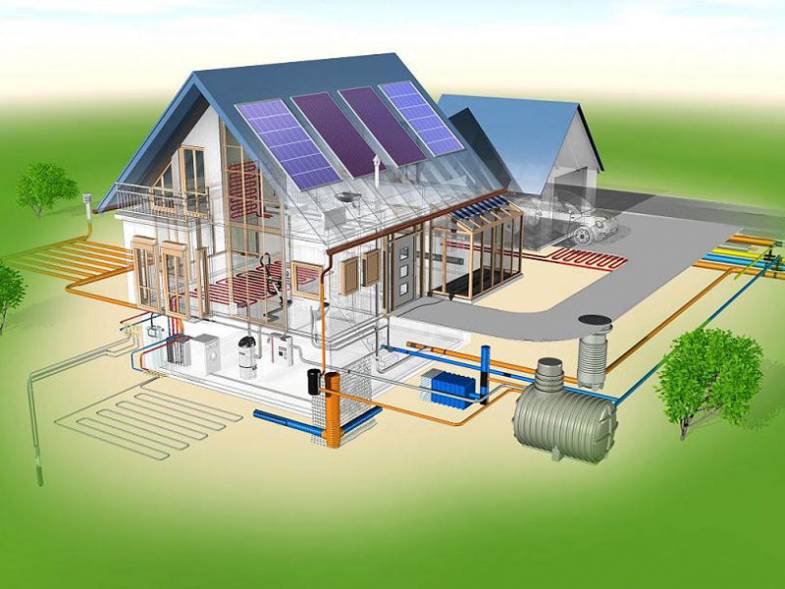

Thermal insulation of heating pipes

The main heat losses in heating occur in the main pipelines passing on the street, but these are not the only places; heat leaks can also be present in an apartment or a private house. You need to isolate the following places:

- Supply and return of poorly heated rooms. In the attic, basement or attached garage.

- When installing cottage heating systems, when the central line is embedded in the screed.

- When laying pipes behind plasterboard partitions or other products that are used for flush mounting.

If the first point can be dealt with, then the rest need to be dealt with. Heating of living rooms in a country house occurs due to radiators, the rest of the pipe is used to transport heat to heating appliances. If the line is built into the floor, then the pipes must be insulated with isoproflex or other similar material. This is due to the fact that part of the generated heat will be used to heat the surrounding structures, but this is not necessary.

Advice! It is important to choose the right thickness of the insulation when embedding polypropylene pipes in the screed. In this case, thermal insulation acts as a damper, compensates for the expansion of the material when heated.

The mains that are behind the protective screens will release heat to warm up the enclosed space, which reduces the efficiency of the heating system for a country house. To prevent possible heat loss, it is necessary to isolate such pipelines without fail.

Ways to insulate water pipes

So that the frost does not damage the water pipes in a private house / cottage / cottage, you have to worry about their thermal insulation in advance.

It is important even at the stage of laying communications to consider options for insulating pipes, and not only water pipes. If this is done in a timely manner, the costs will be minimal.

There are a lot of options for pipe insulation - it is important to choose high-quality material among the mass of offers, not focusing too much on price. The cheapest option is money thrown to the wind. Among the methods of insulating a pipeline for supplying water to a house among homeowners, the most popular are:

Among the methods of insulating a pipeline for supplying water to a house among homeowners, the most popular are:

- stretch the pipeline 0.5 m below the freezing level;

- use a heating cable;

- insulate with heat-insulating material;

- provide an air gap;

- buy a finished factory pipe;

- apply multiple methods.

Most often, more than one method is used. So, if the water pipes are deep, then the area responsible for the entrance to the house still needs to be insulated. Therefore, the most optimal option is selected for it in order to secure the local water supply system.

The depth of the pipeline depends on the region. To find out, you can use special reference tables by finding your region or check it empirically

The heating cable is widely used due to the ease of installation and the high-quality performance of the functions assigned to it.

Depending on the type of installation, there are 2 types of cable:

- outer;

- interior.

The first is mounted on top of the water pipe, and the second - inside. It is securely insulated and made of safe materials. It is connected through a heat shrink sleeve to a regular cable with a plug or to a machine.Read more about heating cable for plumbing.

The heating cable comes in different capacities. Most often found between 10 and 20 watts

There are a lot of thermal insulation materials on the market. They all differ in their properties, quality, price, complexity of installation and service life.

Which one to choose depends on the specific situation.

Among the heaters, polyethylene and polyurethane foam semi-cylinders - shells are especially easy to install.

The air gap method is also often used. It is a water pipe placed in a cheap smooth plastic or corrugated pipe of a larger diameter.

Inside there is free space for the circulation of warm air coming from an insulated basement or heated in another way.

Warm air perfectly protects the water pipe from freezing. Although often it is additionally insulated with polypropylene or other material

Another option is to buy ready-made insulated pipes of factory origin. They are sold fully assembled.

They are 2 pipes of different diameters placed inside each other. Between them is a layer of insulation. Often this method of insulation is called pre-insulation.

The option with ready-made pipes does not always satisfy the needs of a particular user - the diameter, type of material and cost can become a real problem for their purchase

The use of several methods of thermal insulation of pipes is due to the fact that all methods are imperfect and it will not be possible to apply them in all cases. The conditions of use in various households located in all regions of the country are radically different from each other.Therefore, you have to choose the option that suits your specific requirements.

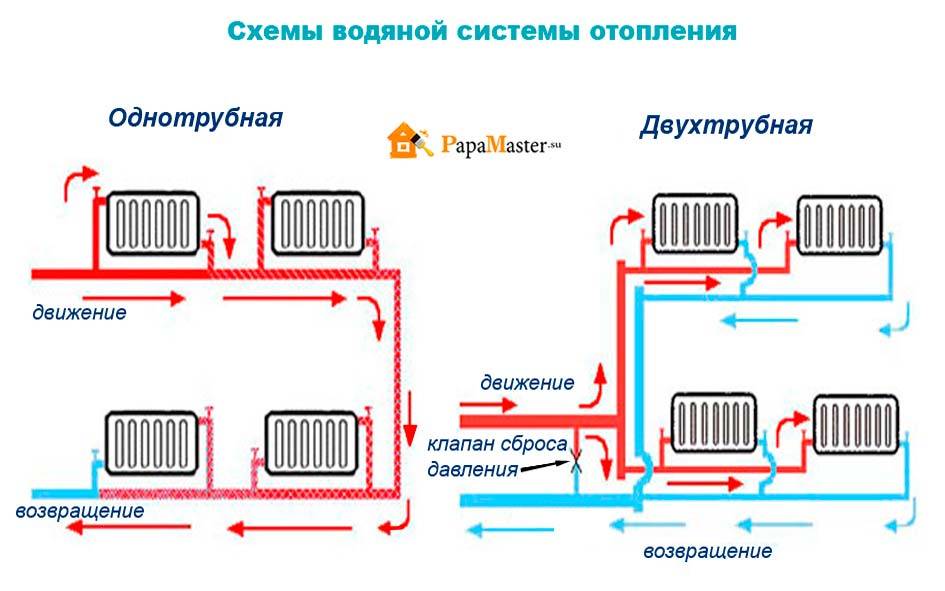

Ways to reduce heat loss

There are several ways to store heat while transferring it. As a rule, all of them are used in combination in order to maximize the effectiveness of measures. First of all, this is a reduction in the surface area of heat radiation. It is known from the laws of geometry that the optimal shape for pipes is a cylinder. It has the smallest outer surface area in relation to the cross section. That is why heat pipes have a circular cross section, although other shapes might be convenient for installation.

The second way is to isolate the surface of the pipeline from the external environment. With this method, there is no active transfer of energy to air molecules from a heated surface. Ideal insulation with this method would be to create a vacuum layer around the pipe, which is widely used in thermoses and Dewar vessels.

Finally, the reflection of infrared radiation coming from the pipe in the opposite direction can help. The effect is achieved by the use of reflective coatings made of metal - usually aluminum - foil.

Who should pay for the replacement of pipes in the basement -

Hello, I live on the ground floor, the apartment is divided into three rooms, a hot water pipe burst in our basement (that is, there is no water only in our apartment, there is water in the whole house), the management company says that the tenants must replace it themselves. Such a question, should we pay money for replacing the pipe, or should the management company do it?

Victoria Dymova

Support Officer

Similar questions

- Who should, after replacing the pipes of the in-house heating system, eliminate the consequences (if the wallpaper was damaged during gas welding)? 23 August 2016, 14:56, question #1354083 5 answers

- Replacement of pipes and mixers in a communal apartment June 14, 2015, 20:38, question No. 871057 2 answers

- At whose expense should there be a replacement of the pipe from the central water supply to the column in the private sector? July 28, 2017, 13:34, question #1708933 1 answer

- Who should pay for the repair of heating pipes? 10 February 2017, 21:20, question #1534698 1 answer

- Do we have to pay for the replacement of the pipe or should the housing department replace it for free? 16 July 2016, 13:56, question #1316494 1 answer

The need to insulate heating pipes

Due to the high cost of energy carriers, thermal energy must be used rationally, which means that only rooms that need it should be heated. If uninsulated pipes pass through a non-residential area, such as an attic or basement, then the heat is not being used for its intended purpose. This circumstance leads to a decrease in the performance of the heating system and an increase in the cost of purchasing fuel.

Insulation of the outer section of the heating main leads to a decrease in the likelihood of the coolant freezing in the event of a sharp drop in temperature outside. True, freezing of the heat supply structure is unlikely, but traffic jams may appear.

For this reason, the insulation of the pipeline laid outside the building is a prerequisite for the operation of both internal and external sections of the heating system. Properly selected insulation thickness can protect the elements of the heating system from various kinds of damage, serious breakdowns and corrosive processes.

Why is it necessary to insulate heating pipes?

Usually, the owners of cottages insulate only those heating pipelines that are located outside the dwelling. There, heat losses are most likely and large-scale. No wonder all city heating mains are so carefully insulated. You also need to carefully choose the pipes themselves for heating.

Power engineers have already learned how to count their money. However, the pipes of the heating system in the basement or boiler room should also be insulated. Heating such non-residential premises in the house is a waste of money.

Insulation of heat supply pipes allows you to save on home heating and extends the life of pipelines

It is important to consider the quality of thermal insulation. There are five good reasons to cover heating pipes with a heat insulator:

There are five good reasons to cover heating pipes with a heat insulator:

- Protection of the coolant against freezing.

- Prevention of condensation.

- Reduced heat loss.

- Extending the "life" of boiler equipment and pipelines.

- The possibility of laying outdoor sections of the heating system in the ground above the freezing point.

Pipes are insulated in the basement, in the attic, in the boiler room and in outdoor areas. Mounting insulation on risers inside the house in living rooms is not worth it. If this is done, then the heat will still get into the room, but already through the radiator. There is no point in such actions. Money will be spent on a heat insulator, but zero will come of it.

When the coolant moves through insulated pipelines, it does not waste thermal energy in vain. All the heat is used to heat the necessary rooms. At the same time, the boiler and pumping equipment in the boiler room do not have to operate at maximum conditions in order to maintain a comfortable temperature in the rooms.

If the external heating main is well insulated, then it can be laid in the ground at a shallow depth - then it will freeze only if the coolant supply is interrupted for a long time and in very severe frost

Another couple of disadvantages of heating pipes without insulation are condensation and freezing. In operating mode, when a coolant circulates through the system, most often heated water, there are no problems with its freezing inside and condensation outside. But in case of accidents on the heating system, the pipelines begin to “get wet”, and then freeze.

The heat-insulating material in such a situation gives several additional hours, during which the coolant may cool down, but not so quickly.

In general, heat supply pipes are insulated:

- when laying communications of the heating system outdoors;

- on sections of pipelines located in unheated subfloors and attics;

- when installing heating mains and branches from them to risers in the basements of apartment buildings.

Insulated pipes are warm batteries while reducing energy costs. Here it is better to spend money on thermal insulation materials than to pay huge heating bills. It is always more efficient to insulate than to spend money on fuel for a stove or boiler.

It's interesting: All about insulation with foil (rolled, shiny) (video)

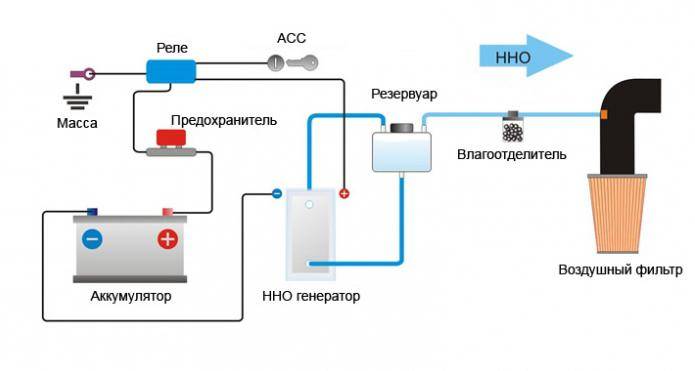

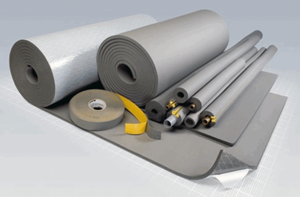

K-FLEX

The company produces thermal insulation from foamed rubber. Materials from K-flex stand out for their high performance and thermophysical characteristics. They have low thermal conductivity, are durable, vapor-tight, fireproof, environmentally friendly, and easy to install.

Heat insulators from K-flex

They are produced on the basis of synthetic foamed butadiene-acrylic rubber with closed cells.Forms of insulation - sheets or tubes with a self-adhesive protective coating. Thermal barrier K-Flex differs:

- Duration of service with the preservation of technical characteristics;

- Steam and water resistance;

- Low thermal conductivity;

- Elasticity in a wide range of temperatures;

- Resistant to mold and microorganisms;

- The ability to die out on its own in case of fire, and due to the presence of fire retardants in the composition, the material prevents the further spread of the flame.

Do I need to insulate the plumbing?

Often the question of whether it is necessary to insulate the water supply arises on a frosty morning, when it is already late - the water from the tap does not flow. It is in such a situation that the homeowner has no doubts about the need for this event.

Indeed, pipe insulation is not always necessary. It all depends on the location of the house, climatic conditions, the time of residence of the residents and the features of laying water communications.

When it is decided to deepen the water pipes to the level of freezing, then there is no need to save on an additional depth of 0.5 meters. Otherwise, you should take care of thermal insulation

If family members come to rest only in the warm season, then there is no need for warming. To prevent accidental rupture of pipes due to frozen water in cold weather, when there is no one in the country, you just need to properly preserve the system, preparing it well for the winter.

Insulation is not required and the water supply, stretched at a sufficient depth. According to the norms, water pipes should be correctly laid to the following depth: 0.5 meters + the depth of soil freezing in a particular region

This is an important condition that must be observed so that you do not have to redo everything anew after the first winter.

If the water supply is not insulated and not deep enough, then there is a danger of freezing of the entire layer of soil and the formation of ice inside the pipe

For residents of the northern regions, the level of freezing is 2.5 m or more. This greatly complicates the process of deepening the pipeline to the desired level. Yes, and the cost of such an event will not be cheap. Here you can not do without warming.

It happens that it is not possible to make a trench of the required depth for laying water pipes. In such cases, insulation is a necessity. Another point is the entrance of the water pipe to the house

This area in cold weather often enjoys increased attention from many homeowners. Therefore, you need to take care of the insulation in a timely manner by choosing the right material.

If the water in the pipe freezes, then at best, users will be left without water, and at worst, the pipe will break and costly repairs are ahead to find this area and fix the problem.

Another place in the pipeline that you need to remember is the entrance of the pipe to the well / well. It all depends on the characteristics of a particular water supply and the method of arranging this site. If this is a well and the pipe is immersed in it, then we must not forget about its insulation by choosing a material that is resistant to ultraviolet rays and precipitation.

Applied thermal insulation materials

When deciding how to insulate a water pipe in the ground and inside the house, it is necessary to ensure that the following requirements for thermal insulation are met:

- minimum coefficient of thermal conductivity of the material;

- stable shape retention under mechanical action;

- inability to absorb moisture or the presence of protection against it;

- easy installation work.

Especially for the insulation of pipelines, manufacturers of building materials produce assembly heat-insulating elements in the form of tubular shells, half-cylinders and segments. Sheet insulation is still considered a traditional material, with which pipes are simply wrapped.

glass wool

Fiberglass thermal insulation is used for warming water pipes only in dry rooms. The durability of this material, good thermal insulation properties and low cost lose their significance due to the ability of glass wool to actively absorb moisture. Therefore, the insulation of a water supply system in a private house requires the mandatory presence of a waterproofing layer, which increases the cost of insulation and complicates installation.

Basalt insulation

They are made in the form of flat mats, semi-cylinders and segments. The ability to absorb moisture is present, but it is much lower than that of glass wool. Recommended for insulation of pipes in dry rooms. Basalt heaters are not used for insulation of underground pipeline lines.

To insulate pipelines, manufacturers manufacture products with a protective layer of foil isol or glassine already glued. The complex manufacturing technology of the material increases its cost. As a result, the insulation of small diameter pipes often becomes uneconomical.

Styrofoam

A dense, strong and durable material with excellent thermal insulation properties is best suited for insulating a water pipe in the ground. It is produced in the form of split tubes and semi-cylinders.There may be a surface protective coating of polymeric materials or foil.

polyurethane foam

This type of insulation is used for the manufacture of pre-insulated PPU pipes in the factory. Such systems are considered the best protection against heat losses and all types of external influences. But the main disadvantage for private developers is the need to attract specialists to carry out installation work.

Foamed polyethylene and artificial rubber

Especially for the thermal insulation of pipelines, tubular casings of various diameters are made from these materials. They are put on the pipe during installation work or on already installed pipelines. To do this, a longitudinal incision is provided along the length of the casing, which allows you to open the shell and put it on the pipe, performing the installation yourself.

Tubular insulation made of polyethylene foam and artificial rubber:

- has good thermal insulation properties;

- does not pass or absorb moisture;

- easy to mount;

- durable and affordable.

However, the low mechanical strength of these materials does not allow their use in underground laying. The weight and pressure of the soil will lead to compaction of the layer and loss of thermal insulation properties. Therefore, use is only allowed with open pipe laying.

Thermal insulation paint

This innovative material is a thick paste-like composition that is applied to the surface of the pipeline. A layer of paint 4 mm thick corresponds in its properties to 8 mm mineral wool insulation.

The coating is characterized by high strength, wear resistance and high resistance to moisture.The main disadvantage is the high cost - more than $ 150 for a bucket of 10 liters.

3 Types of overlays

Several fundamentally different types of insulation have been developed. They are applied in different ways and have different technical characteristics. The following types of heaters are used:

- roll;

- sheet mats;

- hard segments;

- sprayable liquid.

On inclined pipes, rolled materials are laid in a spiral method. On horizontal sections they are mounted longitudinally with joints and fixed with wire or special clamps. The foil layer is placed outside, providing protection from atmospheric moisture. Rolled insulation is protected from precipitation by additional galvanized casings installed on top of the insulation.

Common sheet materials include polystyrene foam and polystyrene. These materials are effective in terms of heat retention, but their installation presents certain difficulties in terms of providing an airtight shell. Sheets are arranged longitudinally, fastened with knitting wire, bandages or staples. To protect against moisture, protective casings are made of stainless galvanization on top of them.

The layer of material is soft and hard. Depending on this, rigid shells made of expanded polystyrene, polyurethane foam, polystyrene and soft casings in the form of a polymer layer are produced. Casings have the advantages that they provide complete tightness, keep their shape, and are mounted with low labor costs.

Liquid heaters are coloring and spraying. The first type is applied with a brush or roller, creating an airtight layer. Thermal paint is usually used for this purpose.The shell is sprayed with special equipment, the thickness is increased gradually and evenly. Penoizol is often used, which closes all small cracks. The disadvantage of liquid shells is their high cost.

How to perform thermal insulation of polypropylene pipes

Insulation for pipes can be of various shapes and designs: wound, glued, in the form of a shell - oval, etc. There is a wide range of insulation materials, linings and auxiliary insulation compounds available for use in hot water systems.

The list is constantly changing as new synthetic materials are developed or how to apply them. For example, the latest innovation in heat engineering is the use of antifreeze as a coolant for closed systems.

It does not make sense to consider any specific manufacturer of heaters, you need to pay attention to the types of materials used

How to insulate heating pipes with your own hands

The sequence of actions in the form of step-by-step instructions:

calculation and purchase of thermal insulation material;

wrapping the pipe with foil tape or foil. Foil

acts as a heat reflector;

installation of insulation around the pipe. Sectional rigid

(casing) or soft insulation is simply “put on” on the pipe. As for soft

materials, then they need to be cut into blanks, equal in width to the diameter of the pipe.

Then wrap around the pipe and fix with tape, wire or

plastic clamps. Hard insulation is the hardest part. From it you need

create a box around the pipe (or use pipe shells of the appropriate

diameter);

inspect the insulated pipe for the presence of "bridges

cold" and eliminate them;

fasten the thermal insulation material to the pipe with

plumbing or metallized tape;

if necessary, cover the thermal insulation material

protective material (film) and seal the joints with adhesive tape.

The cost of insulating heating pipes, despite their

the initial value, quickly pay off by saving on payment

home heating bills.

Insulation of water supply pipes in a private house is an important step in creating a comfortable microclimate and reducing the cost of space heating in private and apartment buildings. Consider in the article the requirements for insulation for polypropylene pipes, whether it is necessary to insulate heating and plumbing.

In private houses, communications have two vulnerable areas for freezing. These sites are located on the street when laying communications from the well to the house or in an unheated basement. If you have not done basement insulation, then it is necessary to protect the pipes in the basement of a private house from heat loss. Consider how and how to insulate communications on your own, tell you what materials to use.

Is it necessary to insulate polypropylene pipes in a private house? If you did not spend during construction, then it is simply necessary to protect communications from heat loss. If a country house is rarely used in winter, then communications can freeze, regardless of what material is used for the water pipe - metal-plastic, HDPE or galvanized steel.

How to insulate pipes in a private house with your own hands

When a cold water pipe enters a warm room, condensation will always form on it.If the pipe is insulated, then you will protect the room from the possible appearance of dampness. Heating houses also need thermal insulation in order not to waste excess heat in a given room, but to redirect it to the maximum to living quarters, reducing their heating costs.