- The main types of sealing materials (characteristic)

- Sealing tapes

- Polymer sealants

- Mastics based on petroleum products

- Epoxy resin

- Portland cement

- Advantages and disadvantages

- How to seal sewer pipes: an overview of technological processes

- Films for sealing pipes

- Sealing gels

- Epoxy and bituminous resins

- cement patch

- Main types of sealing materials

- Sealing Tape

- silicone material

- Sealing materials

- Tapes for sealing

- silicone sealants

- Sealing sewer pipes with other sealants

- Cement

- Types of sealants for sewers

- Silicone

- Epoxy

- Aluminum tape

- Mastic for sealing

- Why sealing sewer pipelines is necessary

- Types of sealants

- Ribbon

- Silicone compounds

- Other formulations

- The most common sealing methods

- Types of common types of sealants, their properties, rules for use, pros and cons

- Metal polymers

- Plastic sewer pipes and their repair

- Advantages of polymers

The main types of sealing materials (characteristic)

Previously, oil paint and sanitary flax were used as sealing materials.But modern technologies offer a much wider choice of different sealing materials.

Sealing tapes

These are self-adhesive tapes, somewhat similar to a skein of white tape. They are available in various widths and are mainly used for plastic pipes inside residential areas. Such tapes not only protect against water leakage, but also help to strengthen various related elements such as plugs, joints, and so on.

Of the main advantages of this sealant, the following can be distinguished: lack of electrical conductivity, reduced risk of corrosion of sewer pipes, ease of use and at the same time a high level of reliability of the material.

Sealing tape example

It is important to remember that under the influence of ultraviolet rays such tapes quickly deteriorate, therefore it is recommended to use them only inside residential premises. However, if there is still a need to use it in the sun, then the tape is covered from it, for example, with a special protective film

In order for this material to have the intended effect, the pipes must be cleaned of dust and dirt, and then thoroughly wiped or dried. A primer is applied immediately before gluing the tape. After that, the tape is wrapped around the pipe in a spiral, tightly, without folds with a half overlap.

Polymer sealants

Otherwise, they are also known as silicone rubber, since the main material in this case is silicone rubber. They are considered one of the most popular sealing agents, also because, if desired, you can choose such material in any color, including the same as that of the sewer pipe. They are mainly used to strengthen joints and seal fistulas.They can have both neutral and acidic compositions. Acid options are cheaper, but some pipes are not resistant to acids, and in general, such compounds are not recommended for fragile elements. Neutral options are used in all cases where acidic ones cannot be used.

Among the advantages of this type of product, the following can be distinguished: when using mold and rot, it does not appear, even over time, when it hardens, the composition becomes like rubber and perfectly protects sewer pipes from leaks. In addition, silicone sealants adhere well to pipe material, they are durable, resistant to moisture and temperature extremes, and also serve for quite a long time.

Polymer sealant for sewer pipes

The sealant is squeezed out with a special gun for installation, however, if one is not at hand, then you can use an ordinary hammer.

Mastics based on petroleum products

Also good for sealing sewer pipes, especially for filling sockets. There are several main varieties: bitumen-polymer, bitumen-talc, bitumen-rubber, bitumen-asbestos polymer. Mastics are both cold and hot method of application. Those with a cold method are a little more expensive, but they are simple and safe to use. Before using such products, it is advisable to turn off the water supply, and the pipes themselves must be cleaned, degreased and dried.

Epoxy resin

This variety is often used at home. In essence, resin is a universal adhesive. Before use, it is mixed with a special hardener. The required mixing ratios are indicated on the packaging by the epoxy resin manufacturer.By the way, it is impossible to deviate from the indicated proportions, this can lead to unexpected and unpleasant consequences. From suddenly boiling mixture, to the lack of effectiveness of the resin as a sealant for sewer pipes.

Portland cement

It is a dry mixture of gypsum, clinker and calcium silicates with special additives to increase the reliability of sealing. Before use, the composition is diluted with water to a thick solution. It is necessary to apply the resulting slurry immediately, since it hardens rather quickly (from 5 to 10 minutes) and turns into a monolithic structure with frost resistance, high strength, and the ability to repel water.

Advantages and disadvantages

The advantages include the following qualities:

- Moisture and frost resistance, which allows the mixture to be used, including for external pipes;

- High strength and reliability of the solidified solution;

Portland cement - one of the sealants for sewer pipes

And as a drawback, it is worth noting the fact that it is necessary to work with a diluted mixture very quickly, otherwise it will harden and be useless.

How to seal sewer pipes: an overview of technological processes

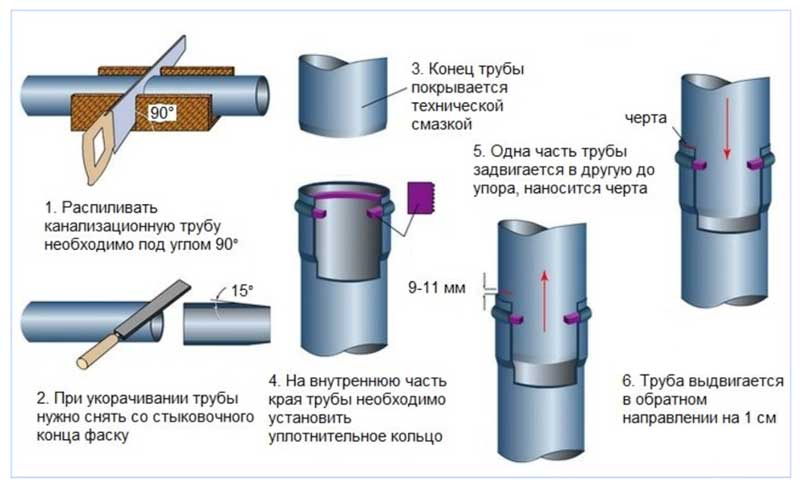

The process of preparing the joint, in most cases, is implemented according to a typical scheme:

Prepare the pipe - remove rust

- The pipe is cleaned of rust, degreased and dried.

- With a bell do exactly the same manipulations.

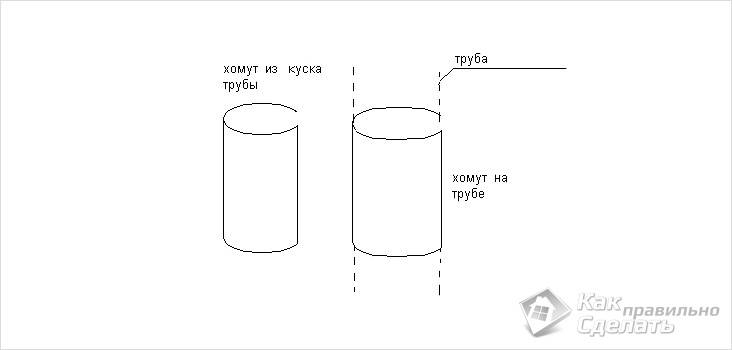

- The next step is to install the shoulder (smooth part of the pipe) into the socket, followed by wedging the gap with wooden or metal wedges.Using these elements, it is possible to combine the central axis of both the first and second pipes by laying the pipeline elements along one central line. However, this step is not demanded by every sealing material.

But the sealing process depends on the physical properties of the sealant. Therefore, we will have to consider each sealing option separately from the others.

Films for sealing pipes

Films for sealing are made from thick polyethylene, the strip of which is rolled up. And this strip is wound on the shoulder of the socket connection, before the pipe is installed in the socket. Moreover, the film does not need to be spared - excess material will “come out” of the joint when installing the pipe into the socket.

After the “winding” is completed, the film is protected with a cover that does not let in sunlight.

Sealing gels

Sealing Gel

Silicone gels for sealing are introduced into the gap between the pipe and the socket. Moreover, in horizontal pipelines, the gel is injected without removing the wedges. But after the gel has hardened, the wedges are removed from the gap and the cavities are filled with another portion of the gel. But vertical installation involves the preliminary application of a layer of gel-like paste on the pipe and socket, followed by assembly of the connection.

The outer borders of the joint can be protected with polyethylene tape or cement filling. Moreover, the latter method will be clearly preferable to the first option in terms of strength characteristics. However, removing a cement filling is a very difficult operation.

Epoxy and bituminous resins

Epoxy-based solutions or bituminous mastics are introduced into the gap after pre-treatment of the surfaces to be joined with a primer - a highly diluted epoxy resin.As a result, the primer enhances the adhesion of the resin (mastic) and increases the degree of tightness of the joint.

Sealing pipes with liquid mastic

In addition, epoxy resins can also be used in the form of two-component "cold welding" compositions. But this method of installation is used only for urgent repairs. After all, cold welding is completely inelastic and does not withstand linear loads.

In vertical lines, the mastic is poured into the gap between the pipe and the fitting.

In horizontal pipelines, a more original filling technology is possible, which looks like this:

- Two holes are drilled in the socket.

- Next, plug the gap between the pipe and the socket with tow.

- After that, liquid mastic is poured into the upper (along the slope) hole and continue to fill the joint until sealant flows from the second hole.

True, in this way it is possible to fix only a very large coupling with a noticeable gap between the pipe and the socket.

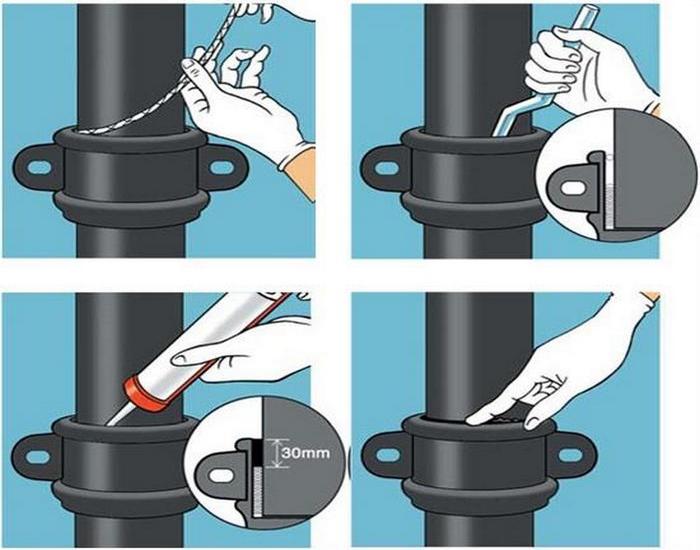

cement patch

Sealing sewer joints

This method of fixation begins with filling the mounting gap with tow, and this organic sealant is literally rammed into the joint between the pipe and the socket. And for greater tightness, the tow is impregnated with epoxy or silicone.

After further "tamping" becomes impossible, and the joint is 2/3 filled, you can start making a cement patch. It is prepared from two parts of Portland cement and one part of asbestos fiber, mixed with water in a ratio of 9 to 1.

The mixture thus obtained is introduced into the mounting gap with a spatula.

Main types of sealing materials

There are many means and materials by which reliable isolation of wastewater systems is carried out. It is often difficult to choose the most suitable option.

For such purposes, silicone sealants, technical sulfur, tapes, hemp and jute ropes, mastics and resins are used. To understand how to seal the joint of sewer pipes in one case or another, you should consider the most common means.

Sealing Tape

Special self-adhesive tapes, which contain bitumen-polymer materials, are designed for sealing water supply and sewer systems. The tape can be simple or foil, summer (withstands temperatures up to +300°С), winter (retains original properties in the range of -200…+100°С) and heat-resistant (withstands heating up to +1500°С).

The material has many advantages:

- Does not deform during operation.

- Does not conduct electricity, protecting metal from corrosion.

- Tapes are steady against any mechanical influences. They do not exfoliate, do not rot, are resistant to chemicals.

- Properly selected sealant will withstand any temperature conditions and will last at least 30 years, retaining its original properties.

Sealing tapes are easy to work with. The surface on which the product will be glued is thoroughly cleaned, degreased and dried. The end of the pipe is wrapped so that the tension provides tightness, but does not overtighten the material. Each next row is glued to the previous one, covering half of it. Thus, the insulation will be the most durable, since a double protective layer is formed.

silicone material

Silicone or polymer sealants are in high demand due to their performance and insulating characteristics. There is a wide range of products of this type, designed for different materials, for use in a given environment and temperature. They include rubber, which provide reliable adhesion to any surface. After drying, the material remains elastic and does not collapse under pressure, does not crack.

Silicone sealant for sewer systems there are 2 types:

- Acid. Has an affordable price. It may react with some materials, leading to their destruction, therefore, it is necessary to carefully read the instructions for use.

- Neutral. Suitable for all surfaces. They do not contain aggressive components. The price of those is an order of magnitude higher than the acid ones.

The most commonly used silicone liquid sealants and nails for sealing sewer pipes made of metal and plastic. They are great for joining different materials.

There are products that can firmly adhere even to wet surfaces, therefore, with the help of silicone sealant, spot repairs of sewer systems are carried out in case of a leak.

A mounting gun is used to apply the product. A thin uniform strip of sealant is squeezed out around the entire circumference of the pipe. Then, with a spatula or hand, the line is leveled.

Sealing materials

Tapes for sealing

Both regular tapes and foil tapes are produced.

Self-adhesive tapes, which have anti-corrosion properties and are specially designed for sealing pipe joints, are one of the latest modern sealing products. They have many positive properties:

- Self-adhesive anti-corrosion tapes are highly effective and easy to use.

- Sealing films, thanks to their high-strength polyethylene backing, are characterized by good service properties.

- They are used to ensure the protection of various types of pipelines in the complex, as they have dielectric and anti-corrosion properties. In addition, sealing films are used for sealing linear elements of sewer pipes.

- Sealing using tape is possible not only when sealing the joints of sewer pipes, but also when sealing plugs, tie-ins, turning corners, bends, etc.

Before sealing a sewer pipe using sealing tapes, remember that they are sealed in the following sequence:

- surface preparation is necessary for applying the tape: it must be dry, dust-free and clean;

- it is necessary to ensure a constant tension of the tape, which is wrapped around the pipe, and also to exclude the appearance of folds and wrinkles;

- the tape must be applied with a 50% overlap in a spiral, as a result of which the entire surface to be insulated will necessarily be under two layers of film.

Sealing sequence (some tapes require primer treatment)

Pro tip:

Such films do not tolerate exposure to UV radiation.That is why, when pipes for sewerage are located in an area that is open to the sun, an additional protective layer must be provided over the film.

silicone sealants

Silicone is the most well known sealing material.

Silicone rubber forms the basis of silicone sealants. Silicone sealants in general are a composition of different substances that provide high sealing qualities. Silicone sealants have good adhesion to surfaces, while not requiring that they be pre-treated with primers.

According to the type of hardener in its composition, silicone sewer pipe sealant is divided into:

- Acid. Acid silicone sealants are quite inexpensive, although they do not accept application to some surfaces that can interact with acids.

- Neutral. In this regard, neutral silicone sealants are considered more versatile.

With the help of silicone sealants, it is possible to seal the joints of sewer pipes:

- from metal;

- from plastic.

After vulcanization, the silicone paste turns into a substance that is similar in properties to rubber. Moisture in the air is involved in the curing process of silicone sealant.

Pro tip:

Squeezing out the sealant is quite simple - using a mounting gun. In its absence, you can use an ordinary hammer by inserting its handle into the tube and pressing like a piston.

How to squeeze out silicone sealant without a mounting gun

Sealing sewer pipes with other sealants

In addition to the above means, sealing pipes for sewerage is also carried out using other means:

- Epoxy resin - at home, it serves, as well as glue based on it, the most common tool that is used when connecting sewer pipes.

- Portland cement is a fairly common component of most sealing mixtures - it is used in the preparation of mixtures from asbestos cement and when caulking the connection of the socket of pipes for sewerage from cast iron.

- Oil bitumen and asphalt mastic - will be required for the preparation of the fill, which is designed to seal joints and fill the sockets of ceramic pipelines.

- Hemp or jute rope, resin strand - are used when sealing pipe sockets for sewage from cast iron and ceramics. The use of a combination of rope and resin impregnation would be preferred.

- Technical sulfur - used to ensure tightness, mainly, the joints of the sockets of pipes for sewerage made of cast iron. Before pouring into the joint slot, it should be crushed, and then heated until melting.

Technical sulfur can also be purchased in crushed form.

With such an abundance of materials, the question is unlikely to arise: “How to cover up the sewer pipe?”.

Cement

Sealing the joint with cement

Sealing the joint with cement

When sealing a cast-iron socket, Portland cement can be used. This substance dries quickly and provides reliable protection against leaks and accidents. For sealing, a high-quality grade is used - "Portland cement".When working with Portland cement, it is necessary to apply the mixture over the joint.

A sanitary winding is applied to the end of the pipe; resin strands can be used for thick channels. The end is inserted into the socket, compacted and filled with Portland cement. This design will last for many years.

True, when dismantling it, your followers will have a lot of difficulties. But that's another story.

Types of sealants for sewers

Silicone material is the main and most common for sealing pipes. With the help of such a sealant, it is possible to process both metal and plastic pipes. Silicone sealant will protect against mold, rot and various contaminants.

Silicone

Silicone sealant for sewer pipes can be acidic and neutral. The first one is much cheaper, but only suitable for large and thick pipes, and the neutral one can be suitable for any pipes, but it costs an order of magnitude higher. All silicone sealants are reliable for use both inside and outside the structure. The composition of silicone sealant includes rubber, which itself seals, and together with additives makes the product resistant to temperatures.

Important! Before using silicone sealant, you need to buy a special mounting gun. If there is no gun, you can use a hammer and squeeze out the substance

You need to be careful when choosing a silicone sealant and pay attention to the expiration date, silicone must be of high quality and securely packaged

Epoxy

Epoxy resin is a special type of sealant. It is used in various designs.It serves as a protective, additional coating for pipe joints, which can later be subjected to thermal heating or, conversely, will be greatly cooled. In the modern world, epoxy is rarely used for insulation, it is an expensive material.

It will be interesting: How not to make mistakes when soldering plastic pipes

Previously, it was used together with glass wool or jute. Epoxy in combination with jute or fabric will help to fasten pipe joints very reliably. Often epoxy resin is used as a sealant for industrial pipes, in this case this method is more reliable and durable. It is also used at the joints of ceramic water supply pipes. Such material is also resistant to chemical reactions.

For sewer pipes, epoxy resin is used to seal the joints of pipes with a bathroom, toilet bowl and kitchen sink, where high humidity and ordinary silicone will not last long. It is also better to use epoxy for cast-iron, steel pipes, for plastic this type of sealant is not so important, plastic pipes can easily be attached only to silicone.

Aluminum tape

Aluminum tape is a modern material that is not yet often used by craftsmen when sealing sewers. A huge plus of such a tape is that it will protect against corrosion, it has increased strength and heat-resistant. In terms of reliability, this tape can compete with silicone sealants, but its price is high, and if you need to seal a lot of pipes, this option is not very economical.

Aluminum tape is a material that is undesirable to use for large sewer pipes, aluminum acts with other chemical elements, and such a reaction can cause rapid wear of the material.Also, aluminum tape is now very often embedded in plastic pipes (especially embossed ones) where damage can easily occur at the bend, the aluminum tape will help eliminate the place of possible leakage.

Such pipes are more expensive, but they are used in the bathroom and in the kitchen, where the sewer is subject to heavy load. When choosing, such pipes can be combined with cast iron or plastic pipes, but aluminum tape can also be used.

Mastic for sealing

From mastic for sealing, several effective ones can be distinguished. Among them are bitumen-rubber, polymer and asbestos. Usually bituminous mastics are used for joints of cast-iron pipes, in the installation of cast-iron sewer systems. They require pre-cleaning of pipes, as well as adhere to technology when using. It is necessary to wait for a certain time for the bituminous mastic to solidify, otherwise it may cause leakage.

Very often, in the old fashioned way, paint is used to protect the outer joints of pipes. This method is effective, but not as durable as any of the sealants.

It will be interesting: The subtleties of connecting a shower cabin to the water supply

It should be borne in mind that the paint begins to crack over time and leaks are possible. Various bituminous mastics are still popular in large industries, sealing large pipes that must withstand heavy loads. Mastics are also used to sewer houses where the pipes are underground. Mastics tolerate cold and heat well. They can also be used for plastic pipes, they will fasten the joints well, they will last a long time, and this type of insulation is inexpensive, so the process will be economical and low-cost.

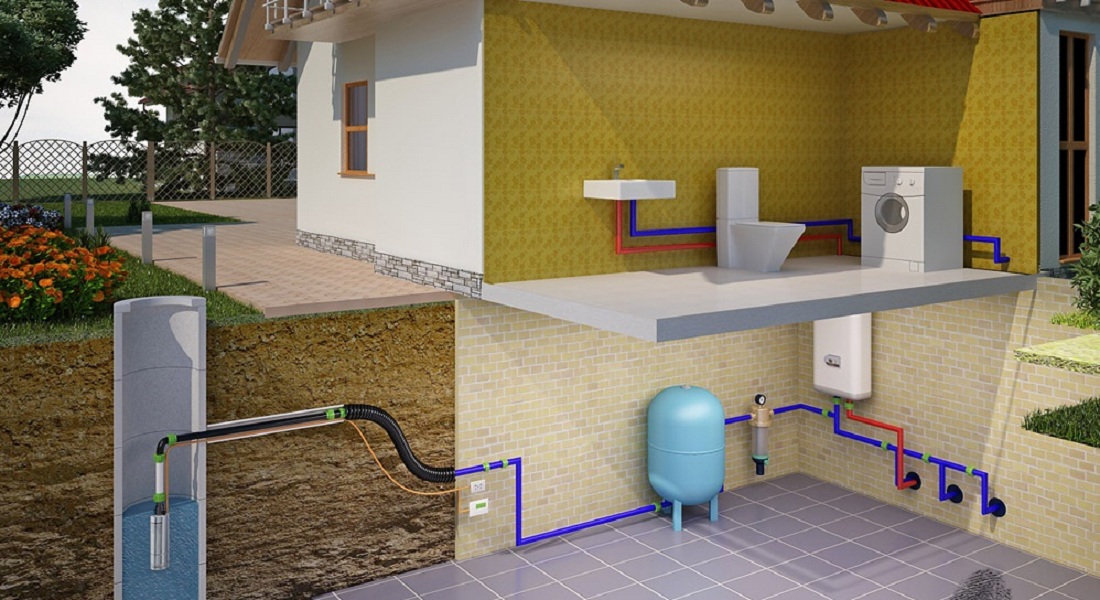

Why sealing sewer pipelines is necessary

Sewer pipelines in the private sector, unlike urban conditions, need improved sealing for the following reasons:

- Soil instability. Loosely connected pipes placed under a layer of earth, when flooded with groundwater or during a spring flood, as a result of weakening or subsidence of the soil, can disperse, which will lead to depressurization of the joint and ingress of wastewater into the soil.

- Temperature effect. In winter, during severe frosts, the soil may freeze to the area where the sewer line is located - this will lead to freezing of sewage and the formation of a plug. If liquid is subsequently introduced, the tubulars may rupture under pressure or as ice expands as a result of thawing.

- temperature fluctuations. When hot drains enter the sewer system, hotter areas at the joints can expand, leading to leaks.

- temporary aging. Over time, the tightness of the sewer line connections decreases due to the loss of their physical properties by the material of manufacture and rubber rings in the pipes. This can cause depressurization of the connection and leakage of drains.

Fig 2. The method of sealing pipes made of cast iron

- Difficulty repairing leaks. Since a private sewer line is usually located underground with a slight slope, it is quite difficult to determine the location of the leak - if it occurs at a high point, then the drains will flow down the slope, making it difficult to find. In most cases, you will have to dig out the entire highway in order to carry out repairs.

- Increased damage from leaks.When it enters the soil, sewage, together with groundwater, can reach the aquifer with a shallow well or well. This will lead to the contamination of water with pathogenic bacteria, as a result of which residents may be left without drinking water.

- Strong regular leaks can cause an unpleasant odor due to the presence of gases harmful to humans in the air: hydrogen sulfide, ammonia, methane.

Almost the same problems will have to be faced, with the exception of contamination of water, soil and unpleasant odors, in the event of a depressurization of an underground water main, if it consists of pipe sections and does not have a welded joint.

Types of sealants

Sealing of sewer pipes is carried out using different materials. The choice of option is carried out depending on the material of manufacture of pipes. Let's describe the most popular types of sealing compounds.

Ribbon

This is a very convenient material to use, it is a tape with a bitumen-rubber base and an upper copper or aluminum layer. Material advantages:

- simple use, the joint is simply “bandaged” with tape;

- anti-corrosion properties, provided by the presence of a metallized layer of copper or aluminum;

- sealing reliability;

- is not a conductor of electricity.

The disadvantage of the material is its destruction under the action of sunlight, so it is used only in places protected from ultraviolet radiation. Or use an additional winding of sunscreen material.

The material is used to seal joints of pipes made of different materials, as well as places for installing tie-ins, plugs and any other elements. To seal the sewer pipe, you need to do the following:

- prepare and thoroughly clean surfaces;

- apply the tape in layers with an overlap in a spiral.

Silicone compounds

Silicone has excellent sealing qualities, therefore, when assembling sewer systems, sealants based on this substance are often used. This material:

- provides a high level of sealing;

- has good adhesion;

- serves for a long time;

- provides high mechanical strength, resistance to elevated temperatures and moisture.

When performing work, a liquid sealant is applied to the workpieces, but upon contact with air, the material hardens, forming an elastic and reliable coating. Sealants are available in two types:

- Neutral. This is the best option, it is suitable for working with various types of pipes.

- Acid. This option is cheap, but it has a significant drawback - it cannot be applied to surfaces that can be destroyed by contact with acid.

Neutral sealants can be used if pipelines are assembled from metal or plastic parts. It is recommended to apply the composition using a special mounting gun, this device helps to apply the material evenly.

Other formulations

In addition to the most popular sealants described above, other materials are used to prevent fluid leaks. It:

- Epoxy resin. This is a two-component composition that polymerizes in air to form a sealed film that reliably protects the joint.

- cement mortar.This material is used when sealing socket joints of cast iron pipes.

- Bituminous mastic. This material is most often used in the process of assembling ceramic pipelines.

- Sulfur technical. This material was used often in the past, in our time it is practically not used. With the help of sulfur, the gap in the cast-iron socket is sealed. To do this, sulfur is melted and poured into the gap through a funnel.

The most common sealing methods

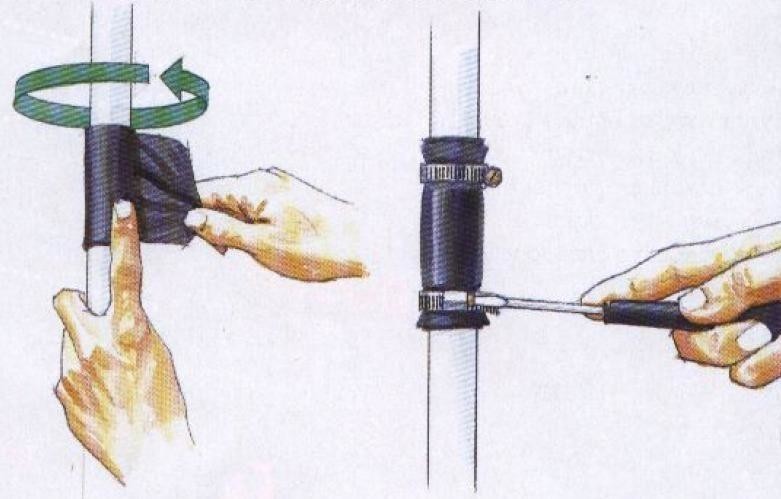

Silicone sealants. This material is a mastic that can harden when exposed to air. One of the advantages of silicone sealant is the absence of the need for pre-treatment of the pipe surface with primers. For its manufacture, silicone rubber is used, into which special additives are added to enhance the degree of adhesion and, accordingly, the strength of the sealing layer.

The work takes a minimum of time and does not require professional skills. For extrusion, a mounting gun is used. If it is not at hand, and the sewer pipe flows at the joints, you can use a simple hammer, the handle of which will serve as a piston. Upon completion of the vulcanization process, silicone mastic will turn into a kind of substance similar in properties to rubber.

Table number 1. Consumption of silicone sealant

Meters per cartridge 110 milliliters.

| Depth of a layer germ., mm | 20 | 12 | 7 | 5 | ˗˗˗ | ˗˗˗ | 8,0 | 7 | ˗˗˗ | 3,0 | 6,0 | 10 | 1,5 | 2,5 | ˗˗˗ | 12 | 1,2 | 2,1 | ˗˗˗ | 15 | 1,0 | ˗˗˗ | ˗˗˗ | Meters per file-package 600 milliliters. |

| Depth of a layer germ., mm | 20 | 12 | 7 | 5 | ˗˗˗ | ˗˗˗ | 15,0 | 7 | ˗˗˗ | 6,0 | 11,0 | 10 | 3,0 | 5,0 | ˗˗˗ | 12 | 2,4 | 4,0 | ˗˗˗ | 15 | 1,9 | ˗˗˗ | ˗˗˗ |

Types of common types of sealants, their properties, rules for use, pros and cons

In order to make repairs with high quality and not return to it as long as possible, you need to choose the best method for sealing the seam in the sewer. Each type of sealing material has its own scope of use. In addition, it is necessary to take into account the operating conditions of the system, the economic feasibility of using a particular option.

Types of common sealants

Metal polymers

Metal polymers are an innovative pipe repair technology. It is also suitable for high pressure pipelines. Sewer systems operate by gravity, without pressure. Therefore, the use of metal polymers in the general case is not economically feasible. However, in critical areas, in systems operating at the limit of design capacity, the use of this method is justified. In this way, you can close the joint of any sewer pipe.

Plastic sewer pipes and their repair

plastic sewer

plastic sewer

Many people think that PVC pipes cannot be repaired because they are easier to replace, but this is not true. It is not only possible to repair them, but also necessary. Next, you will learn how to fix a leak from a plastic pipe.

First of all, as in the first case, free the sewer pipes from the accumulated water. To do this as quickly as possible, use a specialized fitting that is mounted in the pipeline. Next, a layer of high-quality glue must be applied to the damaged area, on which the patch is installed.

Installing a patch on a plastic pipe

Installing a patch on a plastic pipe

If you use high-quality glue, then you will not need additional materials for connecting pipes.After hardening, which takes about 1 minute, your leak will be completely eliminated, but it is not recommended to use the pipe right away, it is best to let the patch fix for 3-5 hours after the repair.

Advantages of polymers

As noted earlier, polymers are most often used in the pipe production process. In such a material, the main advantage lies in the ability to soften. That is, under the influence of high temperature conditions, the polymer becomes soft. As soon as cooling occurs, it returns to its original state. Of the other advantages of polymers, it is worth noting:

- Resistance to corrosive processes.

- No need to insulate the pipe, which will be laid in the ground.

- Resistant to aggressive environments and chemicals.

- Smooth inner surface for no clogging.

- Low weight.

- The ability to equip engineering communications of almost any complexity due to convenient installation.

- Long service life.

example

The only drawback of the polymer is considered to be the limitation of throughput. However, such an unpleasant moment can be eliminated by selecting a pipe with a large diameter.

An important role in the connection is given to fittings. With the help of these connectors, the system is hermetic and does not allow unpleasant odors to enter.