- Selection and installation of a pump for water supply at home

- Concrete well waterproofing technology

- Seam cleaning

- Surface preparation

- Applying waterproofing to joints

- Applying insulation to the surface of concrete rings

- Types of wells

- What happens in the absence of normal sealing?

- Seam technology

- Preliminary work

- Repair of dry seams and cracks

- Repair of leaking seams

- Hydroseal functions

- The taste and color of the water has changed

- Sealing joints between concrete rings

- How to seal seams in an existing well

- Surface preparation

- Elimination of leaks

- Waterproofing seams and joints

- Restoration of destroyed concrete

- Surface waterproofing

- Surface care

- Types of waterproofing wells

- Internal waterproofing

- External insulation

- What will be needed?

- Execution of work

- Roll insulation method

- Impregnation Method

- The method of shotcreting the walls of a structure

- The need for waterproofing

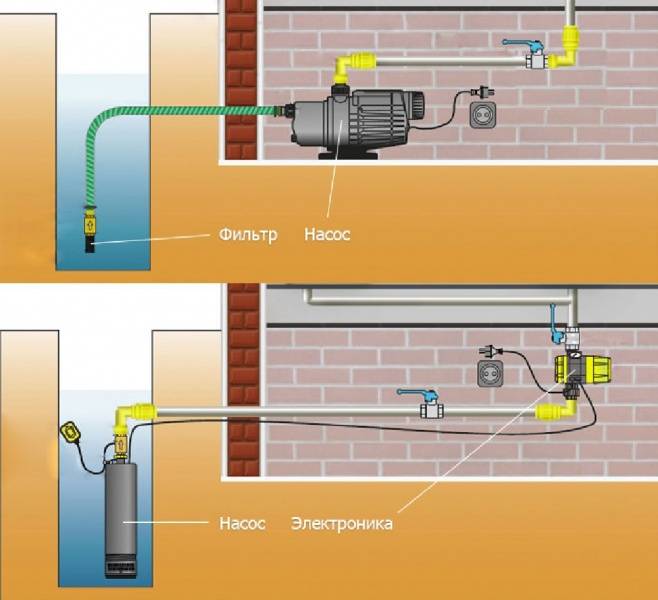

Selection and installation of a pump for water supply at home

The choice of a surface pump is more preferable if we evaluate the issue from the point of view of the current repair and maintenance of the unit, which is much more convenient to carry out in a heated basement room than to take it out of the well every time.The water supply of a country house from a well by means of a surface vacuum pump is limited by the suction depth, the limit value of which is 9 meters. With a greater distance from the level of the suction pipeline to the intake end of the flexible conduit lowered into the well, a surface pump with an external ejector or a submersible model of the unit is required.

Water supply system with surface pump

The suction depth of the pump depends on the method of laying the conduit adopted for water supply from the well, and is proportional to the depth of the trench for laying the water pipe and the installation mark of the surface unit. That is, if the floor level of the basement of a country house, in which the vacuum pump and related equipment is located, is two meters below the ground level, then by laying a water pipe and making a tie-in to strengthen the well shaft in the horizon with a suction pipe, you can get water from a depth up to 11 meters instead of 9.

According to its characteristics, the water supply of a country house from a well, made at a depth coinciding with the level of the basement, is also justified by the fact that the water conduit will be below the freezing mark of the soil, which means that it will not need thermal insulation and heating to prevent water from freezing in winter. For the coldest regions of Russia, the soil freezing depth reaches 2 meters, therefore, by making the trench a little deeper, which will correspond to the level of the basement floor, which can reach a height of up to 2.5 meters, the owner of the garden property is guaranteed to prevent freezing of water in the pipes.

Concrete well waterproofing technology

When planning the repair of an underground structure, the nature of the damage is taken into account: the methods and means used depend on the degree of watering of the seams. Waterproofing is carried out in accordance with the requirements of building codes and regulations. Before applying the sealant, the contact surfaces are prepared with a primer.

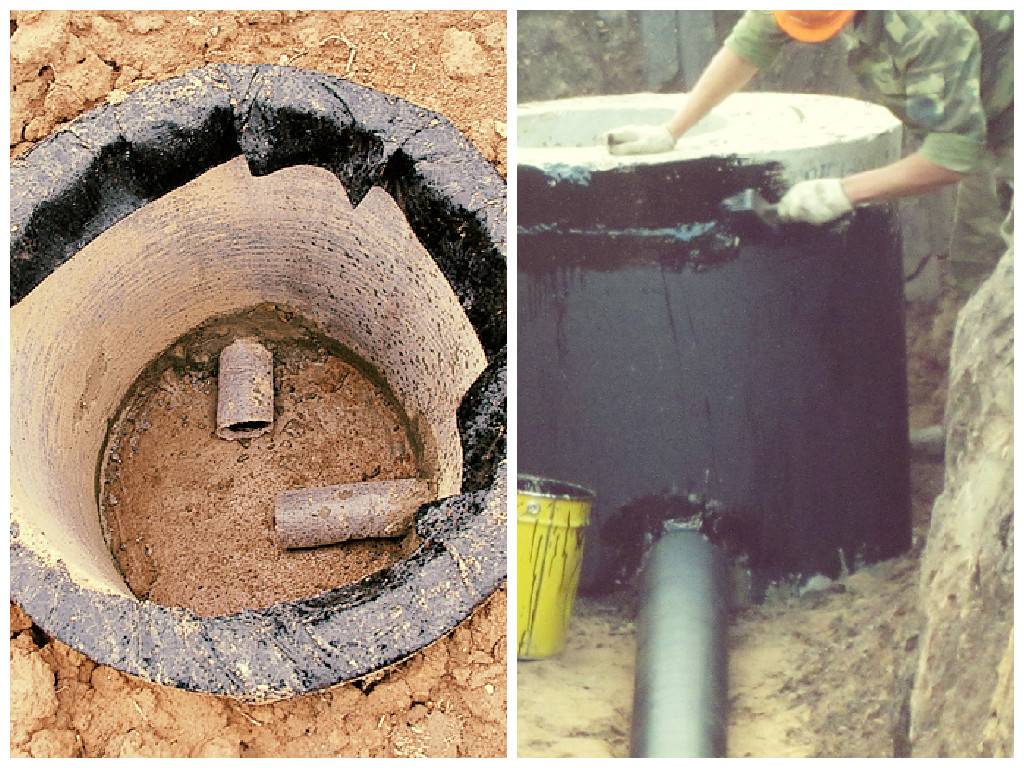

Seam cleaning

cleaning wells made of concrete rings.

To get to the problematic place inside the well, the equipment is dismantled from its trunk and the head is exposed. If necessary, pump out water.

A ladder with a working platform is lowered into the underground working. To inspect and clean the joints of the rings from the outside, you need to dig a ditch around the well to the depth of the alleged leakage.

Surface diagnostics are carried out from top to bottom using a scraper, a metal brush and pressure water. Damage found should be carefully examined.

Unstable surfaces are removed in the following order:

- Chasing - the joint is deepened with the help of cuts around the grinder or chips with hammer blows on the chisel. You can use a hammer drill or impact drill.

- Cleaning the damaged area from destroyed concrete, dirt and dust. To do this, you need a scraper and a brush.

- Washing the cleaned joint with water.

The result is a rough surface that promotes adhesion of the repair compound. Depending on the material used, a primer or sealant is applied immediately.

Surface preparation

It consists in priming before applying the sealing composition. If the elements of the reinforcing frame are exposed during cleaning of the joints, the metal is treated with an anti-corrosion agent.

Preparation of surfaces in contact with waterproofing is carried out in the following sequence:

- Expansion of small cracks. It is carried out with an extension of 20-30 mm in any direction to a depth of 5-50 mm.

- Sealing of notches and chips. A mixture of cement and sand is used in a ratio of 1: 2. Water is added 0.5 parts. Factory-made compositions are also used.

- Surface priming. For preparation, bitumen-based compositions are applied - bituminous primers. The number of layers is one or 2, 0.1 mm each. Consumption - 150-300 g / m².

After drying, the primers proceed to the next stage of work. Before coating the surface with a protective layer, it is moistened.

Surface preparation.

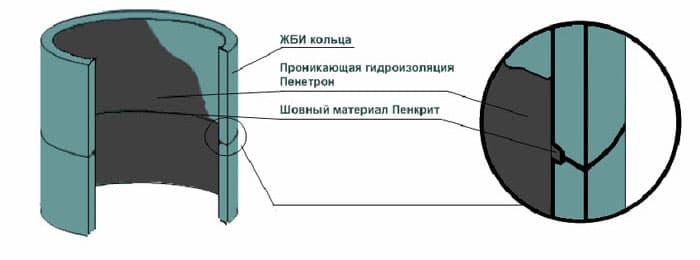

Applying waterproofing to joints

Precast concrete manholes are vulnerable to water intrusion at structural junctions. At the construction stage, the joints on the outside are smeared with mastic and pasted over with a waterproofing tape that completely covers the joint. From the inside of the barrel, the seams are covered with a repair compound that is safe for humans.

When performing work on an existing well, seal connections located above the water level, if it is drinking water. The seams are sealed in sections of 10-20 cm, vertical cracks are puttied from the bottom up.

If a jet is knocked out of the gap, then you can avoid the removal of the sealant as follows:

- drill 25 cm below the joint 1-2 holes Ø20-25 mm to redirect the flow of groundwater;

- close the main hole with a waterproofing mixture, filling the gap by 70% so that the expanding composition does not destroy the structure;

- fix the hydraulic seal by hand for a period of 5 seconds to several minutes, depending on the properties of the sealant;

- clog the drainage holes with rubberized tow, a layer of filling solution or wooden plugs.

The bottom filter is cleaned after sealing all the cracks. If necessary, the crushed stone layer is replaced with a new one.

Applying waterproofing to joints.

Applying insulation to the surface of concrete rings

External waterproofing of wells is carried out during the construction period, when there is free access to the outer surface of the lining. It is produced after processing the joints on both sides of the concrete cylinder. In a multilayer protective structure, mastics and rolled waterproofing materials are used.

Work sequence:

- bituminous mastic is applied;

- the rolled material of the first layer is wrapped around the assembled structure in a horizontal direction with coating the edges of the tape with mastic;

- the strips of the second rolled layer are laid with the joints coated with a sealant.

The mechanized method of applying waterproofing consists in spraying or shotcrete: the cement mixture is fed under pressure through a nozzle onto the surface to be treated. Layer thickness 5-7 mm, dries 2-3 days. After that, the procedure is repeated. The third coating is applied with mastic or hot bitumen.

Types of wells

There are 2 main types of design by purpose:

Lookouts. They are designed to control the operation of the sewer line in a particular area.

Distribution. Their design involves several inlets and outlets, due to which the main line is branched into several.

Wells can have a different shape:

- with a round perimeter;

- with a square perimeter.

According to the material are distinguished:

- concrete;

- brick;

- polymeric.

To drain wastewater from a large apartment building or industrial building, it is advisable to choose a concrete or stone structure; for a private house, polymer containers or an assembly of reinforced concrete rings are used. There must be a hole in the well for the main pipe and for the outlet of the distributor.

What happens in the absence of normal sealing?

Under the expression normal sealing, we mean work performed in accordance with technical standards. The use of good, high-quality hydraulic compositions, and not cement-sand mixtures with the addition of sodium liquid glass, or without it at all, all these materials crumble quite quickly, and are unable to cope with the task of sealing. As a rule, they are used by well maintenance companies with advertisements of the following type: "PRICE FOR CLEANING - 4 THOUSAND RUB., EVERYTHING, EVERYTHING INCLUDES, AND PUTTY INCLUDED." Keep in mind, when ordering such services in companies, your joy from this kind of work done will be short-lived. High-quality slurries are an order of magnitude more expensive than the usual M-200 cement mixture and a bottle of liquid glass, and the time for high-quality sealing is required much more than for smearing the mortar on the walls. In the absence of high-quality sealing, the upper water, not purified by soil, will enter the mine, contaminating it with microorganisms along the way and saturating it with washed soil. Leaks of water through the bottom joints-seams will lead to the fact that you will have muddy water, since dirty water from the bottom of the seams will get into the clean water from the bottom at the bottom. It also happens that nothing flows from anywhere, and the water from the tap periodically flows dirty.This is most often caused by open joints-seams located in the water column, that is, where the water stands. When an empty well is refilled, water enters the walls through sealed seams and its level rises along with the level of water in the well itself. Water replenished the well, settled, became clean. Then, by pumping out the water with a pump, you lower the level of the water column, thereby exposing the depressurized joint, at this moment the water flows from behind the walls into the mine, carrying the soil with it, the water becomes cloudy, the filter systems become clogged, and the sinuses behind the walls become thicker. For shallow wells, for this reason, dips can form around the well, which subsequently leads to its loss, or to costly repairs. It is often easier and cheaper to dig a new one than to repair such a well.

Trust your well to professionals right away, because as practice shows, for the first time people-clients turn to those companies where it is cheaper, and they try to shift the annoyance and disappointment they have received from the choice they made to all market participants in the well field of activity. And then everyone becomes guilty, but not the owners of the wells themselves, who made the wrong decision. Make the right choice, and then you will not have to regret the wasted time and money. Perhaps a lot of other information and articles on our website will help you not to make a mistake and make the right choice.

Seam technology

To decide how and with what to seal the seams in the well, you need to see if water is flowing from them, since the technology for repairing dry and wet seams is different.

Preliminary work

Before sealing the seams between the rings in the well, some preparatory measures should be taken:

Clean the walls of the shaft from dirt, algae and other deposits using mechanical cleaning methods or a jet of water under strong pressure;

Cleaning with a Karcher high-pressure device

- Remove the destroyed concrete from the joints, beat it off where it is cracked and does not hold well;

- Expand and deepen the seams, clean them.

In a word, the repaired surface must be clean and durable.

The photo shows the brackets fixing the concrete rings

Repair of dry seams and cracks

The seams in the well are sealed with dry mixtures mixed with water. The most affordable option is cement and sand. But such a composition, under the influence of moisture and frost, will not last long, and will begin to collapse again. To prevent this from happening, liquid glass is introduced into the mixture.

When working with it, you should remember that it hardens very quickly, so the seams must be prepared in advance for sealing, and the mortar should be made exactly as much as you can use in 5-10 minutes. The process itself consists in covering the joints with mortar with a spatula, as is done when plastering walls.

Sealing joints with cement mortar

When deciding how best to seal the seams in the well, do not try to simplify your work and use various sealants, mounting foam or epoxy for this purpose. At best, you will not achieve the desired effect, at worst, you will harm the quality of drinking water, make it unsafe for consumption.

Repair of leaking seams

If a top water seeps through the cracks and potholes in the walls of the well, it is pointless to seal them with cement mortar - it will wash out without having time to set and harden.How to cover the seams in the well in this case?

To do this, quickly hardening expanding materials are used - the so-called hydraulic seals (HydroStop, Waterplug, Peneplug and others). They harden very quickly, without forming cracks and reliably sealing the leak.

Fast setting waterproofing compound

Hydraulic seals are absolutely waterproof, resistant to temperature changes, thawing salts and other aggressive influences. Their only drawback is their high price. A three-kilogram package costs an average of 800-1000 rubles.

Waterproofing seams in a well using a hydraulic seal is possible in two ways:

Just a solution. It is prepared according to the manufacturer's instructions - most often it is diluted in a clean dish with water heated to 20 degrees in a ratio of 5: 1. the proportion may vary depending on the size of the defect. The solution is kneaded in a small amount, as it quickly hardens, stirs very quickly and is pressed into a pre-embroidered hole with your own hands. Then it is held manually for 2-3 minutes.

If the groundwater behind the walls of the well is under pressure, and the flow between the rings is very strong, you can try the following method. Drill one or two holes with a puncher 15-20 cm below the leaking seam.

Water will rush into them, the pressure between the rings will weaken or disappear altogether, and sealing the seams in the well will be easier. When the mortar sets, the holes can be filled with fitted wooden chopsticks and also covered.

When working with a perforator, remember the close proximity of water and electricity, follow safety precautions

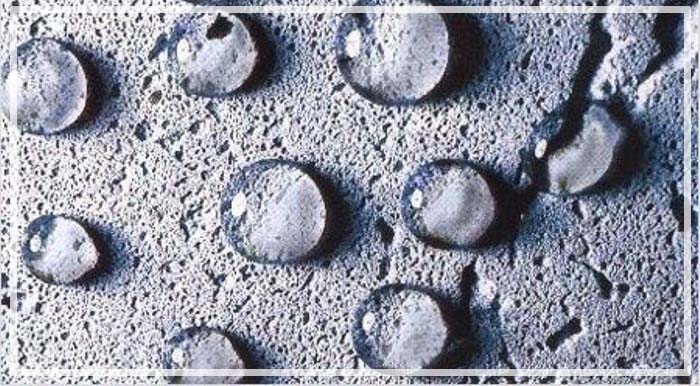

Unfortunately, even the highest quality well repairs cannot guarantee that leaks will not appear over time in other places. Therefore, it is necessary not only to waterproof the seams of the well, but also to treat the entire inner surface of the shaft with special elastic compounds.

After drying, they create a continuous film, sealing all small cracks and preventing them from growing. The composition adheres well to the surface, resistant to water and frost.

If the upper seams constantly leak and diverge, it makes sense to close them up not only from the inside, but also from the outside, by digging the soil around the well. After the repair work is completed, it is advisable to arrange a clay castle around the source or make a blind area.

Hydroseal functions

Characteristics of a professional hydraulic seal

A universal, fast-hardening waterproofing cement composition is called a hydroseal. It is a dry mix diluted with water. Consists of Portland cement, sand or quartz, chemical additives. Portland cement is a hydraulic binder with a high content of calcium silicates, consisting of ground cement clinker, gypsum, and special additives. Differs in high durability and other improved properties.

A mixture of cement hydroseals is in great demand. Many varieties of this material are sold from different manufacturers. The hardening speed of such mixtures can be 10–60 seconds or up to several minutes. Therefore, depending on the scope of application, when buying, you must take into account this property and choose the right brand.

It is interesting: How to find water for the well: a few proven water search methods

The taste and color of the water has changed

The process of transition of drinking water into a cloudy liquid with incomprehensible impurities and an unpleasant odor usually takes a long time. The main reason is that the waterproofing has ceased to fulfill its functions or there are holes in the reinforced concrete rings. This usually happens gradually, but seismic activity or large-scale earthworks nearby can cause a well to fail quickly.

Waterproofing includes seams between the rings and a clay castle around the head. You can see their damage with the naked eye. Cracks, sprouting plant roots, various debris, wet streaks on the walls of the well and the formation of shifts in neighboring rings testify to them.

To restore the tightness of the joints of the rings, the worker goes down on a safety cable, inspecting and removing unsuitable grout. The well is pumped out first. The cost of sealing seams depends on the scale of destruction, the building mixture used and the complexity of the work. The perforation of a well shaft can be pressure, that is, water flows into it. Conventional cement mortar in such cases is useless, it is necessary to use hydraulic seals with instant setting.

After sealing the seams, the bottom of the well is cleaned of debris, if there was a bottom filter at the bottom, it must be lifted up for washing or replacement. This item increases the price of repairs, so builders do not recommend laying filtration layers in each well, but only if necessary.

Full-fledged disinfection with chlorine-containing preparations is carried out when the well is heated with wastewater or if the remains of a dead animal or rotting vegetation are found inside.In other cases, preventive treatment with less aggressive drugs or weak concentrations of chlorine is recommended.

A more problematic repair case is the displacement of the rings. It is more difficult to close the gap between them, and there is no guarantee that after a few days the pressure of the soil will not continue to deform the shaft. For a quality repair, it is desirable to reinforce adjacent rings with metal brackets or strips to stabilize the barrel. Then the seams are cleaned, pressed with clay and filled with mortar. The use of tow and tarred ropes is an outdated and inefficient method.

Sealing joints between concrete rings

No matter how the waterproofing of the septic tank from concrete rings is performed, it will not be able to provide complete tightness without the mandatory processing of the joints between the rings. Even at the stage of installation work, a waterproofing and shock-absorbing gasket should be laid between the rings.

It is best to use concrete-rubber gasket. Granules of bentonite clay present in its composition, upon contact with water, are able to increase their volume by 3-4 times. Such a reaction of clay allows you to maximize the filling of cracks and voids present between the concrete rings of the sewer well.

Concrete-rubber gasket under the action of moisture increases in size up to 400%, while filling all the voids and providing maximum sealing of the annular joint

Concrete-rubber gasket has a high level of plasticity. This quality allows you to maintain the tightness of the septic tank even in the case of a slight displacement of the concrete rings.The joints should be sealed not only between the rings, but also when installing the first ring on a concrete base.

You can do it easier and instead of an expensive concrete-rubber gasket, put ordinary hemp, jute or linen ropes. The ropes themselves will not provide a tight seal, so they must be impregnated with fiber rubber. The ropes should be laid on a polymer-cement mixture, which can be replaced with a mixture of cement with PVA glue.

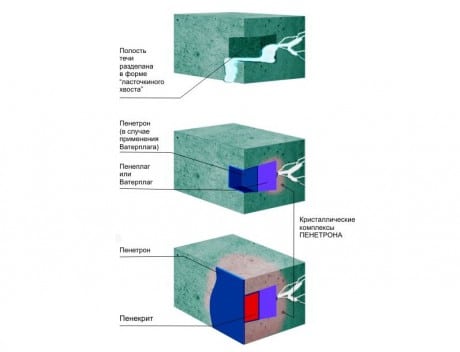

How to seal seams in an existing well

If the seepage of groundwater occurs between the seams in the existing well, it is necessary to carry out a whole range of waterproofing works.

Surface preparation

Loose concrete is removed mechanically (using a jackhammer). To clean concrete from materials that prevent the penetration of active chemical components, the surface is treated with a metal brush. Paint residues, efflorescence, dirt, dust, laitance are removed.

Along the entire length of the seams, joints, junctions, cracks and around the entry points of communications, U-shaped grooves with a cross section of up to 25x25 mm are made. The resulting fines are also cleaned with a metal brush. If there is an active leak in the seams, such places must be processed and the cavities should be shaped like a “swallow's nest” to a depth of at least 50 mm.

Elimination of leaks

- The required amount of special solutions "Peneplug" or "Waterplug" is being prepared. Stirring of mixtures is carried out no longer than 1 minute. The prepared cavities, made in the form of a "swallow's nest", are half filled with the material of the mixtures, pressed and held until the material finally sets.

- The required amount of the Penetron material mentioned above (or another similar solution) is being prepared. They process the internal cavity of the leak.

- The required amount of the Penekrit solution is prepared, which fills the remaining half of the cavity (the approximate consumption of the solution is 2.0 kg / dm 3).

Elimination of pressure leaks in the well. The consumption of materials Peneplag and Waterplug - in terms of dry mix is 1.9 kg / dm 3.

Waterproofing seams and joints

- Prepared strains are moistened.

- A solution of the "Penetron" material is being prepared, which is applied to the brushes in one layer with the help of a synthetic brush (consumption - 0.1 kg / m.p.).

- The "Penecrete" solution is being prepared, which is used to fill the fines tightly (consumption 1.5 kg / m.p.).

Restoration of destroyed concrete

- In cases where exposed reinforcement is found, concrete is removed behind the reinforcing bars until they are completely clean. Rust is removed chemically or mechanically from the metal to bare metal. Anti-corrosion coating (zinc, epoxy or mineral) is applied to the rust-free fittings.

- The surface layer of concrete is moistened until completely saturated.

- The Penetron solution is being prepared, which is applied with a synthetic brush in one layer on a concrete damp surface (consumption - 1.0 kg / m 2).

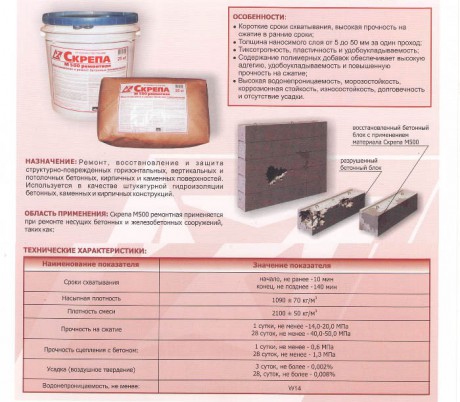

- A solution of "Scrape M500 repair" is prepared and applied to the surface to be treated over the material "Penetron" (consumption - 2.1 kg / dm 3).

Features and technical characteristics of the material

Surface waterproofing

- The concrete surface is thoroughly moistened.

- The Penetron solution is prepared and applied to the surface with a synthetic brush in two layers.The first layer must be applied on wet concrete, and the second on top of the first, still fresh, but already cured (consumption for the first layer - 600 g / m 2, for the second - 400 g / m 2). Before applying the second layer, the surface must be dampened again.

Waterproofing of water wells is carried out with a mandatory measurement of the composition of the water after completion of work, as well as testing the strength of the water supply system

Surface care

The treated surface must be protected from negative temperatures and mechanical damage for at least 3 days. The surface with the Penetron material applied to it must remain wet all this time, cracking and peeling should not occur. Humidification can be carried out by water spraying and covering the treated concrete with polyethylene film. If the surface is treated outside the well, the moistening period should be increased to 14 days.

As you can see, the process of eliminating leaks is quite long and laborious. Therefore, it is much easier to seal the seams during the construction of the well.

Concrete wells are created from individual elements that are installed on top of each other for the entire height of the shaft. This design is considered quite strong and durable, but it has one significant drawback - the joints between the rings that are not treated in a certain way can let water through. Properly executed waterproofing of a well made of concrete rings makes it possible to eliminate this problem.

Types of waterproofing wells

Installation of an underground structure is accompanied by waterproofing works of the following types:

- pasting sealing along the bottom of the structure;

- filling gaps and joints with sealants;

- installation of a polymer liner inside the mine shaft;

- the use of bituminous mastic, roll insulation to protect the outer walls;

- plastering - possible from any side of the structure;

- the use of modern sealants to seal leaks from the inside of the well.

The choice of waterproofing method is carried out at the stage of designing an underground working, when planning repairs during operation. The decision is made depending on many factors and circumstances, but the best result is a combination of several methods.

Internal waterproofing

The process of waterproofing a well from groundwater leakage from the inside is in many ways reminiscent of an exterior finish. In the case of a working well, preliminary pumping out of water and drying of concrete walls will also be required. Next, the search and removal of contaminants and unstable areas is carried out. All found chips, cracks and depressions are embroidered and sealed. The seams between the rings deserve special attention: they must be deepened by completely removing the old mortar. When the leveled areas and joints are dry, the inner surface is completely covered with a waterproofing material. Reliable protection against moisture is achieved with a two-layer laying of the mixture.

The interior decoration of wells is allowed to be carried out using the following materials:

- Cement putties.

- Molten bitumen.

- Cement-polymer mortar.

- polymer compositions.

Internal waterproofing must be durable and, in the case of a drinking well, environmentally friendly

The first and second methods are the most inexpensive, but they are only allowed to be used for waterproofing sewer wells.Drinking hydraulic structures are usually treated with polymeric compositions.

External insulation

The main purpose of performing external insulation work is to protect against the negative effects of groundwater. At the same time, it is necessary to minimize or completely neutralize such impact.

BC 1xBet has released an application, now you can officially download 1xBet for Android by clicking on the active link for free and without any registration.

It is best to perform waterproofing from the outside even at the stage of erecting a hydraulic structure. If this has not been done at this stage, then in order to get to the outer surface of the walls of the well, it will be necessary to do a large amount of excavation. Although in any case it is more profitable and cheaper to repair an old well than to build a new one.

What will be needed?

SNiP standards allow external insulation work using the following materials:

- To seal the well from the outside, rolled bitumen materials are most often used, for example, roofing material, as well as special mastics for it. Instead of roofing material, you can take penetrating waterproofing.

- You will also need cement mortar. It will help repair the seams, eliminate damage and cracks in the walls, and also perform a blind area.

- To protect the hydraulic structure from precipitation, it is necessary to make a so-called clay or sand and gravel lock. To do this, you will need clay, coarse sand, or a mixture of sand and gravel.

- Non-shrinking waterproof cement can be a good alternative to external insulation. To apply it, you need a cement gun.

Execution of work

To seal the well from the outside, it is necessary to prepare it.To do this, it is necessary to dig out the outer walls of an already operating structure to a depth of 4 m. All loose concrete from the walls should be removed with a jackhammer. Then the remains of concrete, salt deposits, dirt, moss and mold are washed off or cleaned off the surface. For cleaning, you can use different tools - steel brushes, chisels, spatulas, a grinder or special nozzles for a drill.

To perform external insulation work, one of three methods can be used. Each of them does not contradict the requirements of SNiP.

Roll insulation method

Sealing the well from the outside with the help of rolled bituminous materials is carried out in the following sequence:

- First, a primer is applied to the outer surface of the reinforced concrete rings to improve adhesion to the material subsequently used.

- When the primer dries, you can start repairing the walls of the well, if they need it. The seams between the rings are sealed. Using a solution, repair potholes, cracks, level the surface. When all repaired areas are dry, they are treated with a primer.

- Next, a coating composition can be applied to the walls of the structure. Bituminous or tar mastic is suitable for these purposes.

- After that, a rolled insulating material is glued to the surface. Usually do 3-4 layers. All seams between the strips of material are carefully smeared with mastic.

Impregnation Method

Waterproofing a well from concrete rings using deep penetration impregnations is performed in the following sequence:

Priming of reinforced concrete walls is not necessary. The surface of the walls should be moistened.

After that, a deep penetration waterproofing mixture is applied.

We pay special attention to the processing of seams between the rings.

Perform surface refinishing. And let it dry for three days.

For protection against cracking during the drying process, the surface should be moistened and protected from mechanical damage.

The method of shotcreting the walls of a structure

According to SNiP, the method of isolating reinforced concrete wells by means of concrete shotcrete is done in the following order:

- With the help of a cement gun, concrete mortar is applied to the walls of the structure. In this case, the layer thickness should be at least 5-7 mm. We carefully process the seams.

- The solution should set. This will take 10-12 days. During hardening, to protect against cracking, the surface is periodically moistened.

- After that, perform the second layer and give it time to solidify.

After performing one or another method, further work is carried out in the same way. The space around the well can be filled up, that is, a castle can be made there. To do this, a sand-gravel mixture is first poured, then the soil is laid and the surface is compacted. Around the structure, a blind area is made of concrete with a slope from the walls of the well.

The need for waterproofing

This design has a number of advantages over wooden well log cabins, common in the recent past. The most important advantage of concrete is its durability. Unlike wood, it does not rot when it comes into contact with water. Also, the installation of concrete rings, although it requires the involvement of heavy construction equipment, is much faster than the installation of a wooden frame.

However, concrete structures also have their own drawback, without which the use of well water is permissible only for technical purposes - for mopping or watering the garden. We are talking about sealing the seams in the well. No matter how well the reinforced concrete rings are cast, their ends are never perfectly even. As a result, when installing them on top of each other, seams with gaps are often formed, sometimes reaching a width of 1-2 cm.

Sometimes the use of such water can lead to serious diseases - dysentery, gastrointestinal disorders. And the very quality of clean drinking water is spoiled for a long time. It becomes cloudy and unpleasant in taste. To avoid such problems, it is necessary to waterproof the seams of the well.

No less acute is the issue of the tightness of sewer collectors on the site. Fortunately, if the sewer closes on a plastic septic tank of the latest design. But most sewer wells are still made from the same concrete rings. If they have unsealed seams, then there is a high possibility of pathogens from the sewers entering the surrounding soil. And from there, with the flow of groundwater, to water supply sources - to aquifers, streams and rivers. That's why, waterproofing of sewer wells must be carried out without fail, in accordance with the provisions of the current SanPiN and SNiP standards.