- Coloring technology

- Materials and tools

- Preparatory work

- Coloring instructions

- Convectors

- Paint selection

- Preparatory work before painting

- Heating battery painting process

- How much does it cost to paint a heating battery?

- The choice of paint for the radiator

- Features of applying paint

- Preparatory stage

- Preparation of tools and materials

- Features of applying paint to radiators

- Types of paints

- Special

- The best alkyd paints for heating radiators

- Tikkurila Empire

- SADOLIN MASTER 30

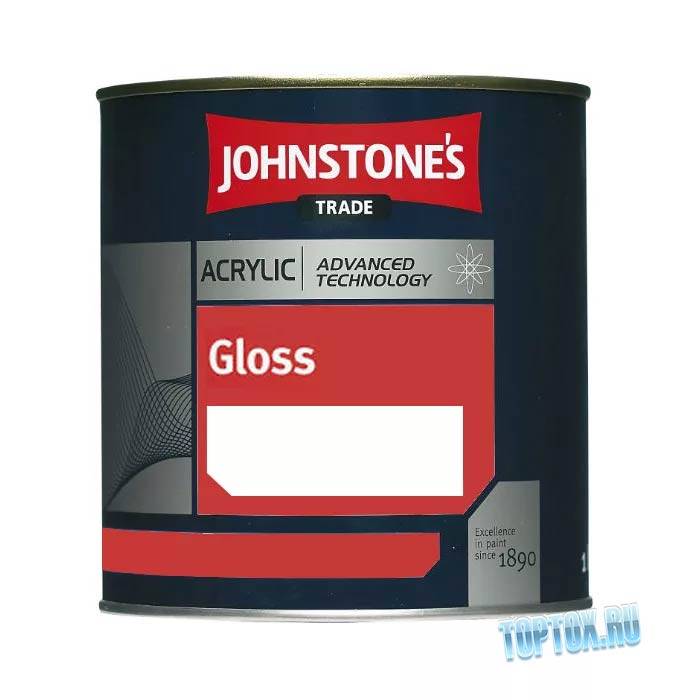

- Professional Gloss JOHNSTONE'S

- Why paint a radiator

- Choice of color for heating appliances

- Preparing batteries for painting

- Coloring

- Types of paints for batteries

- acrylic enamel

- Alkyd enamel

- Water based enamel

- oil enamel

Coloring technology

Before painting radiators during the heating season, you should familiarize yourself with the rules for performing work and purchase the necessary materials and tools.

The quality of painting depends on compliance with the technology of preparing the surface for painting work and on the right paint. The very process of painting a hot battery is accessible to any beginner, but some of the secrets of craftsmanship below will help you complete this job faster and with higher quality.

Materials and tools

Before you paint hot radiators in an apartment, you need to purchase materials and tools.

From the materials you will need:

- paint (alkyd or acrylic, special water-based paint is also suitable, but it is better to refuse oil paint, as it dries for a long time);

- solvent for old paint;

- primer for metal;

- polyethylene film for floor and wall protection.

You need to prepare the following tools:

- scraper for removing the old coating;

- sandpaper of medium grit;

- flute brush 50 and 20 mm wide;

- brush with curved handle 20 mm wide.

Preparatory work

First of all, it depends on the correct preparation of the base whether it will be possible to paint the batteries in winter with high quality.

When preparing the surface radiator for painting, you must adhere to the following sequence of actions:

- The battery must be free from dust and dirt.

- Next, the radiator is carefully inspected in order to identify pockets of corrosion on the surface.

- At the next stage of preparation, you need to remove the old paintwork, for which sandpaper and a scraper are used.

- The cleaned surface of the radiator is treated with a primer solution. Applying a primer to the surface to be painted allows you to level the base, remove small pores, which will ensure more reliable adhesion of paint and metal. The primer is selected according to the type of paint.

- The place of work is covered with plastic wrap. You need to protect not only the floor, but also the walls around the radiator.

The main difficulty of the preparation is the removal of the old coating. There are several ways to get rid of old paint, but the chemical method is considered the most affordable.To prepare the wash composition, you will need to purchase: soda ash - 1 kg and slaked lime - 1 kg, 5 liters of water will also be required.

Wash solution preparation process:

- hot water is poured into a large container (at least 10 l) and soda ash is dissolved in it;

- then slaked lime is added in small portions;

- the mixture is thoroughly mixed, after which it must be allowed to stand for 10-15 minutes.

The finished mixture is applied to the surface of the radiator, kept for 5-10 minutes and the paint is scraped off with a scraper.

After completing all the points of preparing the surface for painting, you can proceed to the main work.

Coloring instructions

When painting a battery, it is recommended to adhere to the following rules:

- Check whether the walls and floor are securely protected from paint ingress. If necessary, put additional sheets of film;

- Before starting work, you should read the instructions for the colorful composition and, if necessary, mix the contents of the can to obtain a homogeneous mass;

- They start painting the radiator from the most inconvenient and hard-to-reach places. For these works, narrow flute brushes and brushes with a curved handle are used;

- The outer parts of the radiator are painted with wider brushes or a small roller;

- It is recommended to paint from top to bottom. Thus, it is easier to avoid smudges;

- To obtain a reliable coating, two coats of paint must be applied. The second layer is applied after the first layer has completely dried.

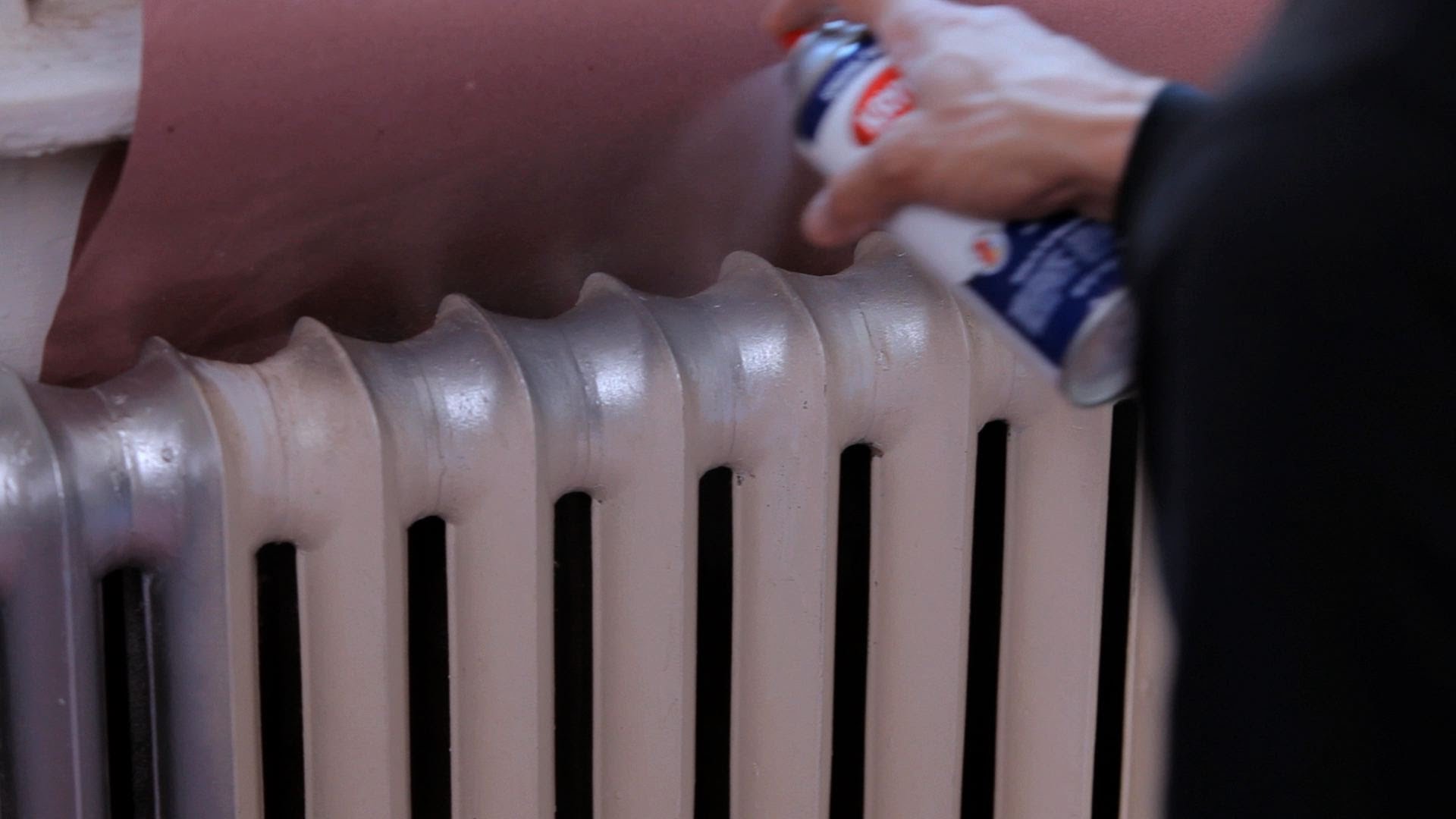

If an aerosol spray can was chosen for work, spraying is carried out from a distance of at least 300 mm.

Upon completion of work, it is recommended to ventilate the room.

The above recommendations allow you to remove the question of whether it is possible to paint the batteries with the heating turned on - if all the requirements are met, heating radiators can be painted even at high temperatures in the heating system.

Convectors

Painting radiators and heating pipes has some features. The pipes on which the ribs are fixed in the casing are not painted in principle, and it is not at all necessary to improve the appearance of elements that are not in sight. Moreover, a layer of paint can reduce the heat transfer of this heater.

Heating convector

This is of particular relevance in relation to aluminum convection plates. As a rule, they are located on the pipes of the heating elements more densely than steel ones.

For this reason, they are quite easily clogged, including the material from which the dyes are composed. In this case, it is optimal to give the desired tone only to the removable case.

Paint selection

Main selection criteria:

- Safety - the absence of hazardous components in the composition of the paint that evaporate when heated.

- Heat resistance - the paint must be resistant to thermal stress (80-90 ° C).

- Resistance to fading and mechanical abrasion determines how long the coating will not require updating.

- Adhesiveness - in other words, the ability of the composition of paintwork materials to adhere strongly to the surface.

- Anti-corrosion properties of the paintwork, i.e. the presence of substances in the composition of the paint that save the radiator from rusting.

Before painting, it is important to make sure that the paint composition is specifically designed for painting radiators. The purpose of the paint is noted when marking. But if for some reason this information is missing, you need to choose heat-resistant dyes

But if for some reason this information is missing, you need to choose heat-resistant dyes.

The composition distinguishes: alkyd, oil and water-based paints:

- Oil paints dry for a long time, emit a strong odor during painting and drying, quickly wear off, crack under high temperatures, poorly protect against corrosion, and they are not recommended for painting batteries. Low price, cannot smooth out all the disadvantages when working with oil paints.

- Water-dispersion paint is safe, low cost and fast drying. However, this type of coating is short-lived and resistant to abrasion, therefore, such a coating will need to be updated quite often. Acrylic paint also belongs to the dyes of this group, which is distinguished by resistance to temperature extremes, strength in relation to mechanical stress. It is durable, retains an attractive appearance for a long time, does not fade for a long time. With the help of acrylic paints, a durable coating is created that has a juicy bright color, resembling plastic with a slightly shiny sheen.

- Alkyd paint is suitable in all respects for use as a coating for radiators: it has a uniform composition and is highly resistant to abrasion. The composition of alkyd paints includes substances that resist corrosion processes. One of the interesting types of alkyd is hammer paint. With its help, a coating is created that distinguishes an uneven surface, resembling chasing in appearance, this allows you to hide irregularities and gives originality.However, the alkyd coating, with all the pluses, has a persistent unpleasant odor that disappears for a long time, and sometimes, when the batteries are strongly heated, it appears even after complete drying. The paint dries very slowly and is best used only where there is good ventilation. In addition, the paint does not retain color well, and eventually begins to turn yellow.

- Among other types of paint and varnish coatings that are suitable for painting radiators are dyes based on silicate resins and aluminum. If we discard the only drawback - a strong pungent odor that they emit during the staining and drying process, then this is one of the most stable types of coatings that have excellent adhesion: no primer is required for painting, since the paint itself provides a strong adhesion of the composition to the surface.

- Serebryanka - a mixture of aluminum powder with varnish - is another type of coating that is often used for painting batteries, it can be applied both to the primer and to the old paint due to its high adhesiveness.

Preparatory work before painting

So, the paint is chosen! Now you need to prepare the radiators and heating pipes for painting. The final result of staining and its durability will depend on the quality of such work.

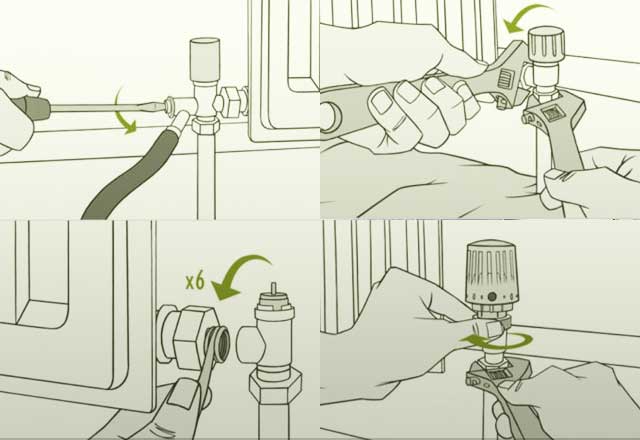

Preparation for painting the battery is carried out in several stages:

Peel off old paint

The old paint is being cleaned. This can be done with tools or using special washes. To speed up the softening process, after applying a flushing agent to the surface of the battery, it is wrapped with plastic wrap.After some time, you can easily remove the old paint with a spatula or a wire brush.

A layer of anti-corrosion primer is applied to clean batteries. This will protect the battery from rust for a long time and provide better adhesion of the surface to the paint. If you want to save time by not spending on a primer, but at the same time, prevent the appearance of rust, you can purchase a special paint that already contains anti-corrosion additives.

The better to paint radiators and whether it is necessary to use additional anti-corrosion agents depends on the operational state of your heating system.

Dust, dirt and particles of old paint from all parts of the radiator are carefully wiped off with a damp cloth.

The battery is sanded with fine sandpaper from all sides, special attention should be paid to places with rust. To prevent it from appearing on the painted surface, clean these areas to bare metal.

The surface of batteries and pipes is degreased with white spirit or any other solvent.

Having dealt with the preparatory work, consider how to paint an old radiator to improve its appearance.

Heating battery painting process

For uniform drying and prevention of smudges, painting work is recommended to be carried out with the heating turned off and cold batteries. Of course, in hardware stores you can be offered a special paint, which supposedly is successfully applied to hot surfaces. But, nevertheless, we advise you to wait until the end of the heating season or, if possible, shut off the heating system in order to reduce the temperature of the radiators.

Painting radiators

Before starting work, you need to protect the floor from dripping paint. To do this, it is covered with unnecessary pieces of paper, fabric or protective construction film. If you plan to use an airbrush for painting or will paint the batteries with spray paint, then other nearby interior items must also be protected from splashes.

To paint the battery, you will need special brushes that make the job much easier. Now they can be bought at any hardware store - these are flat brushes with long curved handles. With their help, you can easily reach hard-to-reach surfaces and recesses.

Following some tips, you can quickly and efficiently paint radiators:

- It is recommended to start painting from the inner floors, so you will less stain your hands and brushes.

- Paint should be applied in a thin, even layer.

- Allow the first coat to dry for at least 24 hours before applying the second coat.

A small amount of money, a little of your efforts, and the result is obvious - the old radiators have become like new!

How much does it cost to paint a heating battery?

Quite a bit, compared to the cost of dismantling and replacing them. Get paint, a couple of brushes and you can get to work. Regular painting of radiators not only transforms the interior, but also prolongs the life and efficiency of the entire heating system.

Published: 22.10.2014

The choice of paint for the radiator

However, when choosing a coloring composition, the following recommendations should be taken into account:

the selected paint must be resistant to high temperature effects (from 80 to 90 ° C);

when choosing which paint to paint the radiators with, it should be understood that the composition must have a uniform structure and have good wear resistance so as not to lose its attractive appearance during operation;

it is extremely important to make the paint resistant to the appearance of various harmful formations on the surface of the radiator, such as corrosion.

Correct painting of heating pipes, how exactly and what kind of paint is better to paint

Features of applying paint

Applying this or that type of paint to radiators is not an easy job, as a person who is far from understanding the technology of painting work might think. After all, the reliability of the coating and its durability will depend on how correctly all stages of painting were observed.

Preparatory stage

Painting with acrylic paint

Preparation of radiators for painting is the most important and the first stage, on which the final result largely depends. First you need to thoroughly wash the heater, using for this purpose a special spray bottle with washing liquid, a soft rag and a brush. Even new batteries need preliminary preparation, since even the highest quality paints without their characteristic odor should lie on the surface smoothly and evenly. Next - it is necessary to degrease the devices, as well as clean them with sandpaper to remove various irregularities on their surfaces and better adhesion to the paint.

Before applying the coloring composition, the old coating layer should be removed, and the places subject to corrosion should be treated with special compounds.

Preparation of tools and materials

Before removing the old layer of paint and applying a new coating, make sure you have the right tools and abrasives on hand:

- Tassels.

- Drill bits.

- Sandpaper for removing old paint.

- degreasing composition.

- Primers with metal corrosion protection components.

- Abrasive - for removing thick layers of old coating.

Features of applying paint to radiators

Acrylic enamel for radiators

In order for the end result to be as you expect, you should not only choose the right paint, carefully carry out all the preparatory work, but also apply a new composition, according to the rules:

All restoration and painting work should be carried out during the period of turning off the heating in order to avoid stains and ugly stains.

It is important to apply the paint from top to bottom so that random streaks that may appear do not spoil the already treated surface. Batteries must be covered completely, including the back and inside of them. In order to paint hard-to-reach places, there are special battery brushes that have a curved shape.

It is most effective to process the device in two thin layers to avoid unevenness. But at the same time, it is necessary to wait until the first applied layer is completely dry. And only after that you can apply the next layer of the coloring composition.

The aesthetics of the battery will depend on how carefully the paint, oil or any other, will be used. For convenience, spray cans, special rollers and brushes are often used. It is recommended to start the process from the most inaccessible places, applying the composition evenly.

If the technical parameters of the radiator allow you to remove it from the hinges and cover it completely with paint, then this will be the best option.

In order to paint hard-to-reach places, there are special battery brushes that have a curved shape. It is most effective to process the device in two thin layers to avoid unevenness. But at the same time, it is necessary to wait until the first applied layer is completely dry. And only after that you can apply the next layer of the coloring composition.

The aesthetics of the battery will depend on how carefully the paint, oil or any other, will be used. For convenience, spray cans, special rollers and brushes are often used. It is recommended to start the process from the most inaccessible places, applying the composition evenly.

If the technical parameters of the radiator allow you to remove it from the hinges and cover it completely with paint, then this will be the best option.

When carrying out painting work in the summer, it is necessary to keep windows open in order to protect yourself from the negative effects of coloring compositions. In addition, you need to use respirators and gloves, so that after finishing work on painting batteries, do not spoil the skin of your hands with various solvents, rubbing paint stains.

Types of paints

Paints for radiators are available in different forms. They are designed for painting different metals. Some are suitable for outdoor use, others only for indoor use. What means are better, worse, for a beginner who first decided to make repairs with his own hands, do not immediately understand.

There is a basic classification of colors. Paint for heating radiators happens:

We paint the heating radiator ourselves

This type is used for painting pipes very rarely. Cons are as follows:

- cannot be used at high temperatures;

- they smell unpleasant, and the smell is corrosive, you have to ventilate the room for several days.

There are a number of advantages:

- the assortment is rich;

- affordable price.

It is better not to use enamels for painting batteries. They are often used for outdoor work, painting walls.

Dye for heating radiator without smell

Such paint for radiators is widely used. Its peculiarity is that after drying, the surface resembles plastic.

The main difference is that the material is odorless. The advantage is that it dries very quickly. After 1.5-2 hours, the surface of the pipes will already be dry. But you need to apply such paint on a prepared surface. First, the radiator must be primed. The surface is painted in several layers.

The advantage is that when applied, the paint does not reach for the brush. The consistency is similar to sour cream. It does not spread. The good material is that if a beginner decides to do the work with his own hands, then it will not be difficult for him.

Note! Acrylic paint material is good that it can be applied even on a hot pipe. It will not affect the quality of the paint in any way.

But you need to pay attention, the surface must be dry. Moisture is not allowed

Like all materials, it has its downsides. This is low adhesion. After 2-3 years, the paint begins to crumble, but this material is better suited for radiators than enamel.

Choosing paint for heating radiators

This type is suitable for radiators. The paint is heat resistant. After drying, a smooth, pleasant gloss is formed.The composition contains white alcohol, so it smells unpleasant. The smell is persistent and will last for several days.

Differs in high quality. The service life is long. It tolerates both high and low temperatures.

- takes too long to dry

- bad smell.

We must remember! If overheated, even if the ink material is completely dry, the smell may reappear.

Special

Designed for a certain type of surface. Each type has specific features. Made for radiators, does not smell and dries quickly. The applied layer instantly adheres to the surface of the pipes. Minus the high cost. But all the advantages of paint will block this disadvantage.

The best alkyd paints for heating radiators

Tikkurila Empire

The paint is offered by a well-known Finnish manufacturer. A ready-made concentrate and a special diluent white spirit are used. Alkyd paint is semi-gloss and high quality.

- there is no risk of the slightest smudges when painting radiators;

- optimum adhesion to metal pipes is guaranteed;

- even the slightest smell is excluded;

- there is the possibility of coloring heating devices in the desired colors and shades;

- easy and quick application of the paint layer.

- requirements for indoor conditions (temperature should be from 5 degrees Celsius, air humidity - from 80%);

- careful preparation of the radiator is required for further successful painting;

- relatively high consumption of the finished solution (10-12 liters per square meter).

SADOLIN MASTER 30

The Swedish manufacturer offers high quality alkyd paint for metal batteries. The paintwork will have a semi-matt pleasant sheen.

- surface protection from rotting, corrosion changes, fungus and mold is guaranteed;

- even the slightest smudges are excluded when processing batteries with paint;

- there is increased resistance to atmospheric influences;

- provides resistance to abrasion;

- fits perfectly on almost any surface;

- can be dyed in any color and shade.

- has a smell (weak, but it will be necessary to ventilate the room after the event);

- high price.

Professional Gloss JOHNSTONE'S

High-quality paint from a British manufacturer is ideal for working with metal heaters. The basis of the product is a strong alkyd resin, which contributes to the creation of a durable coating.

- creating the perfect paintwork;

- pleasant shine due to the special texture of the paint;

- increased resistance to adverse external factors: temperature, shock.

When choosing a paint, it is desirable to take into account the features of its composition and main characteristics.

- Oil paints are offered at affordable prices. In addition, their assortment surprises with its diversity. You need to prepare for a long drying time and an unpleasant odor.

- Acrylic paints dry quickly and are odorless. However, the ideal color is not always obtained.

- Alkyd paints have increased resistance to high temperatures and adverse mechanical factors. However, when painting there is a pronounced smell. In addition, it takes a long time to dry.

- Heat-resistant paints are ideal for hot batteries, because they do not turn yellow and can withstand even the highest temperatures.

Today there are various battery paintsTherefore, it is important to carefully study the available products, their characteristics, pros and cons. By choosing the right paint and taking into account the basic recommendations when applying it, you can count on a successful update of the condition of heating radiators

Why paint a radiator

In our harsh climate, additional heating sources are indispensable. Of course, modern technologies do not stand still and more and more often underfloor heating systems are installed in houses under the laminate, but the batteries we are used to can still be found in many houses.

Without radiators in our climate is not easy. Such cast-iron, bulky structures are appropriate only in an industrial loft style.

Batteries, no matter how useful they are in the winter season, are constantly criticized. Their design rarely fits into the interior of the room.

In addition to the bulky and awkward design, batteries are not so easy to care for. Firstly, they perfectly collect dust, which must be periodically “sweeped” with the help of all sorts of tricks. But periodically they need to be painted, which is even more difficult to do. How to do it right, we analyze in stages.

Choice of color for heating appliances

The home master may be faced with the question of what paint to choose for radiators. The solution to this issue depends on the preferences of the owner.

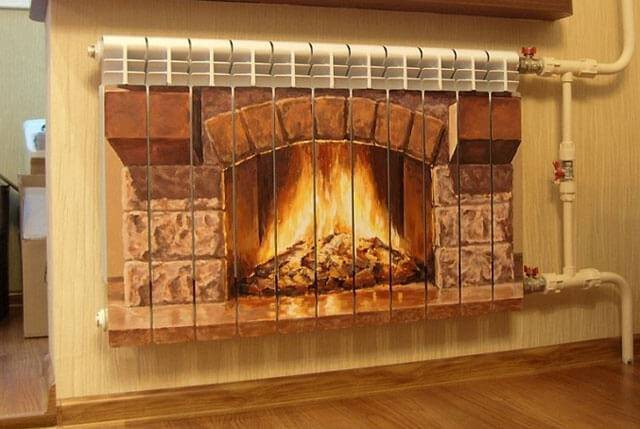

The classic option is heating appliances painted with white paint for radiators. In Soviet times, all cast-iron batteries had this color. The heat dissipation efficiency of a radiator depends on color to a very minimal extent. Therefore, heating devices may well correspond to the general interior of the room.

Today, designers offer a large number of solutions in which the radiator acts as a decorating element and harmoniously fits into the interior of the room.

In some cases, radiators are painted in bright rich colors, thereby focusing on this particular element. The result is a composition based on contrast.

Recently, when deciding what color to paint radiators, you can notice the increasing popularity of the ombre technique. In this case, the first section has a pale color, and each next one or two shades darker. The last section is painted in a bright saturated color.

Radiators in the children's room can be painted with interesting patterns or painted in different colors.

For painting heating appliances, special knowledge and skills are not required. Having studied the subtleties and nuances of this process, you can do the work yourself. And if you follow the painting technology and correctly determine what paint to paint cast iron batteries with, you can get a high quality result.

Preparing batteries for painting

The process of preparing radiators for painting is a very important stage of work, as it is necessary to perform several tasks:

- One of the tasks is to increase the adhesive ability of materials, as well as protect the metal from corrosion.

- If the batteries are old, covered with several layers of paint, cleaning them is necessary to increase heat transfer.

It is recommended to carry out all work both on preparing surfaces and on painting them at the end of the heating season.An exception may be the use of paints and primers designed for applying them to hot surfaces.

So, the preparation of radiators for painting consists of several operations:

Cleaning surfaces from dust and greasy deposits. Dust accumulated inside the sections is removed using a vacuum cleaner with a crevice nozzle or a narrow brush. You can also apply a wet cleaning method using water with detergents. If fatty contamination has formed on the battery, which often happens in kitchen conditions, then they can be removed with dishwashing detergent. If necessary, a damp cloth is applied to heavily soiled places, under which greasy stains soften and it will be easier to clean them off.

Cleaning cast iron radiators with a metal brush attachment mounted on a grinder. The work is dirty and tedious, but, alas, the quality will not be the same without it ...

Removal of rust and old paint. Next, new batteries must be cleaned of rust deposits, and old ones from numerous layers of paint. There are two cleaning methods - mechanical and chemical.

- The mechanical method is more laborious and will take quite a long time. It is carried out using a metal brush fixed on a grinder or in an electric drill chuck. However, this method is only suitable for cast iron radiators. Modern batteries made of thin sheet steel or non-ferrous metals can be seriously damaged by a hard wire brush. In any case, you should work at low speeds. The paint from the surface of the batteries must be completely removed.

- Another cleaning method is the use of chemical compounds, with which paint or rust is washed off surfaces. The compositions are produced in the form of a solution, paste, gel or aerosol.

Remover for removing paint from wood and metal surfaces

Each of the options for chemical compositions is used in different ways - on the packaging, the manufacturer gives instructions for their use, which must be strictly followed. For example, pasty substances are applied to surfaces with a natural bristle brush, after which the battery is covered with plastic wrap for a period specified by the manufacturer. The exposure time can vary from twenty minutes to several hours. The paint should soften, after which it is cleaned from wide surfaces with a spatula, and its residues mechanically using a metal brush.

Aerosol washes are convenient to use, since when sprayed they penetrate into the most inaccessible places of the radiator sections. The principle of operation of these compositions is comparable to any type of washes - the paint softens, then it is removed with a spatula and a brush.

However, it should be warned that the chemical compositions are not harmless. They have a strong pungent smell, so the room where they are used must be well ventilated. In addition, it is necessary to protect the respiratory tract with a respirator, and hands with protective gloves. When choosing this cleaning method, it is necessary to purchase compounds that indicate that they are safe when applied to metal.

In order for the paint to lie well on the surface, it is recommended to pre-paint by applying a layer of primer

Priming of radiators. The next step is to apply primer to the cleaned surfaces.This treatment is designed to prevent the occurrence of corrosion centers, as well as to create optimal conditions for the adhesion of paint materials. The composition selected for priming must be designed for metal surfaces and be compatible with the paint that will be used to paint the radiators.

If domestic paint is purchased, then GF-021 primer is well suited for it. When using paint compositions of foreign manufacturers, you can apply the primer "Sigma" or "Dulux".

The final stage of painting proceeds after the complete drying of the primer layer.

Coloring

Before painting, the heating must be turned off. There is paint for cast iron radiators, which is designed for painting heated surfaces.

However, these are special formulations, which are few on the market and their price is usually much higher. Conventional paints dry too quickly on hot surfaces, causing streaks or smudges. If the drying mode is violated, wrinkling of the surface film occurs.

If it is impossible to turn off the heating, but painting still needs to be done, then in this case the paint should be applied in a thin layer - this minimizes flaws.

Types of paints for batteries

Today, many manufacturing companies offer a fairly wide range of products such as odorless paint for radiators. Thanks to this, buyers have the opportunity to choose the most suitable type for themselves:

- acrylic enamel;

- Alkyd enamel;

- Oil enamel;

- Water based.

All types differ from each other in production technology, composition and characteristics.

acrylic enamel

Acrylic paints:

- They do not have a characteristic smell and are great for interior work.

- Their widespread use in everyday life is also due to the fact that they dry quickly enough,

- characterized by high moisture resistance,

- uniform application on any surface,

- and are absolutely safe for humans.

- Due to the fact that the composition of the substance includes special additives, the paint layer does not begin to crack and turn yellow when the temperature of the radiator or battery rises.

- In addition, it should be noted that manufacturers offer a huge range of colors, so acrylic paint for heating radiators is often used in the decoration of surfaces.

As for the disadvantages, the most significant of them is the high cost. However, it is fully consistent with the good performance of the paint.

Alkyd enamel

Alkyd paints, manufactured using the latest technologies, have the following advantages:

- The surface covered with a layer of such a substance is resistant to elevated temperatures - it does not crack when heated to 120C;

- High strength;

- Homogeneous layer structure during application;

- Good resistance to abrasion during operation of radiators and radiators;

- A wide range of colors allows you to choose almost any color;

- The layer remains intact for a long time.

However, in addition to the advantages, there is also a disadvantage - an unpleasant odor remains for several days after painting, which can later appear with sufficiently strong heating. In addition, some brands sometimes fade a little, and may also change the shade.

Water based enamel

Water-dispersion paint for hot radiators, odorless, is an excellent option for coating radiators. It differs from other species in a number of features:

- It is made on the basis of ordinary water, so it is absolutely safe for people and the environment;

- Special dispersed particles are not harmful;

- There is no unpleasant smell;

- It takes very little time to dry completely;

- Applies easily and evenly;

- Due to the water-repellent effect, painted batteries can be washed without destroying the layer;

- Suitable for use in a wide variety of spaces.

The disadvantage is not too diverse colors, because basically it is only white.

oil enamel

Oil products are in rather high demand due to a number of their advantages:

- Absence of a sharp and unpleasant odor after application and further heating of batteries and radiators;

- They are divided into colored and colorless;

- Easy to apply on metal surfaces;

- Form a uniform layer;

- Great for use inside both residential and non-residential premises;

- Low cost compared to other types of battery paints;

- It can be used for artistic design of surfaces - applying patterns and complex patterns.

The downside is that it takes a very long time to dry completely. This is due to the fact that a solvent is added to the paint.