- What to look for when buying PVC glue?

- Choosing the type of glue

- Characteristics of the adhesive solution

- Safe use and storage

- Cold welding of PVC pipes

- Methods for connecting plastic pipes

- Why and how to use "cold welding"

- Features of "cold welding"

- Adhesive pipe technology

- Advantages and disadvantages of gluing PVC pipes

- Installation of plastic pipes with glue

- Advantages of glued pipe joints

- Overview of the best brands

- Manufacturers recommendations come first

- Instructions for glued pipe joints

- The main types of glue

- The composition and principle of action of adhesive materials

- How to glue polypropylene pipes

- Causes and remedies for pipe leaks

- Conclusions and useful video on the topic

What to look for when buying PVC glue?

When purchasing glue for PVC pipes, you should study the information on its use indicated by the manufacturer on the tube or can.

When gluing plastic pipes, you should buy time-tested brands of adhesive solutions - Tangit glue (Germany), Griffon (Holland), etc.

You also need to find out some useful properties of the adhesive solution - the setting time of the adhesive, etc.

At a temperature of 18-25 degrees Celsius, the setting time of the adhesive solution is 4 minutes.When the temperature rises to 40 degrees Celsius, the setting time becomes 1 minute.

In addition to this parameter, the color and density of the adhesive solution, the viscosity of the mixture, etc. are indicated on the adhesive package. In such a situation, you can find out how the adhesive solution is used and the storage conditions for the adhesive residue.

The glue is applied in a thin layer on the parts to be glued only after degreasing.

Choosing the type of glue

When installing thermal insulation in rooms, builders insulate not only the facade, but also the inside of the house. Therefore, glue for polystyrene is made in 2 types - for interior and exterior use.

Styrofoam Adhesive for outdoor work must have the following characteristics:

- strong adhesion to pipe sections;

- resistance to sudden changes in temperature;

- should not have harmful toxins in the adhesive composition;

- ease of use, etc.

Experienced installers choose those adhesive solutions that do not have special conditions for use.

One of these solutions is tangit glue, which is made in Germany:

Characteristics of the adhesive solution

Tangit glue for PVC pipes is used when joining pressure plastic pipes used when connecting gas and water pipelines to the house.

Such an adhesive solution has the following advantages.

- reliably glues PVC pipes for a long time;

- the adhesive solution is easy to use - there are brushes in the jar of glue;

- similar adhesive for PVC plastic has been used in 120 countries for 30 years;

- after 4 minutes, glues PVC pipes for sewage to each other, etc.

Indications for use:

- before applying glue to the tube, it is necessary to clean the pipe surfaces from grease stains and dirt residues;

- shake the tube of Tangit glue well;

- then you need to apply an even layer of adhesive solution: first inside the sleeve, and then - on the tube;

- further, you should insert the tubular product into the coupling until it stops;

- further, you need to firmly hold the pipe part for 30 seconds - 1 minute until the glue dries;

- then remove excess adhesive with paper towels.

The tubes must not be moved for 5 minutes after gluing. At a temperature equal to 10 degrees Celsius and below, the tube cannot be moved for 15 minutes.

In such a situation, the filling of the new piping system with water cannot be started earlier than 24 hours after the last pipe gluing.

When gluing a plastic pipeline, it is impossible to rotate and move the elements

Safe use and storage

When using Tangit glue, the following safety rules must be observed:

- Tangit glue for PVC pipes, like other adhesive solutions, is highly flammable. It is necessary to use such glue for polypropylene pipes in a well-ventilated room;

- when using it, you can not light a fire, smoke, turn on electrical equipment and do welding;

- when applying the Tangit adhesive solution, use protective gloves;

- do not forget the tube or jar of glue after use;

- glue can only be stored in the original tube or jar, at a temperature equal to 35 degrees Celsius as a maximum;

- do not throw away glue residues into the sewer.

When disposing of such an adhesive solution, get the glue in the tube dry.

If a dry mix is purchased, then the consumption of the adhesive solution is 500 g per 1 sq. m. pipe surface.

When using a foam adhesive solution, the consumption of glue will be as follows - 1 bottle per 6 square meters. m.

The specific amount of adhesive required depends on the material from which the tubes are made (polypropylene, polyethylene, etc.).

Cold welding of PVC pipes

When installing plastic pipes with a socket, welding of PVC pipes is used by gluing. This connection method is called "cold welding". We will devote our article to its consideration.

Adhesive bonding is extremely easy to perform

Methods for connecting plastic pipes

There are several methods for connecting PVC pipes to each other:

-

- Chemical, or adhesive.

-

- Physico-chemical:

-

- Mechanical:

Advantages of the chemical method over others:

-

- Improving the efficiency of assembling water supply and sanitation systems.

-

- Reducing the risk of leaks that can occur when mechanically joining or butt-welding pipes.

-

- Reducing the complexity of the process.

-

- Less power consumption.

-

- Reduction of material consumption.

-

- Low installation cost.

The adhesive method successfully connects pipes of various diameters: 6–400 mm.

Glue for cold welding PVC

Comparing the adhesive connection of pipes with welded and mechanical, one can notice some similarities and differences:

This is the difference in installation methods, based on it you can evaluate their complexity and choose the most suitable method.

Why and how to use "cold welding"

Features of "cold welding"

-

- For work, an adhesive is used, specially designed for connecting pipes and fittings (fittings) made of chlorinated polyvinyl chloride (CPVC).

-

- The adhesive dissolves the surfaces of the parts to be joined by one third of the thickness, i.e. cold diffusion welding is carried out.

-

- A process such as soldering PVC pipes is influenced by various conditions:

-

- Pipe gluing works can be carried out at a wide range of air temperatures: 5–35°С. The use of frost-resistant glue makes it possible to work at temperatures down to -17°C. In hot weather, bonding should be done as soon as possible to avoid the adhesive drying out before installation is complete.

The number of joints that can be made with 1000 ml of glue

-

- According to its properties, the adhesive should be:

The container with glue should be tightly closed with a lid between direct work to avoid evaporation of volatile components.

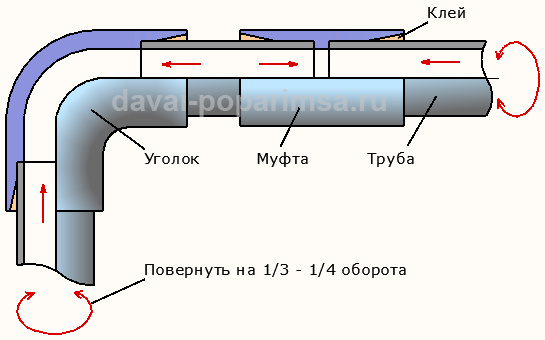

Adhesive pipe technology

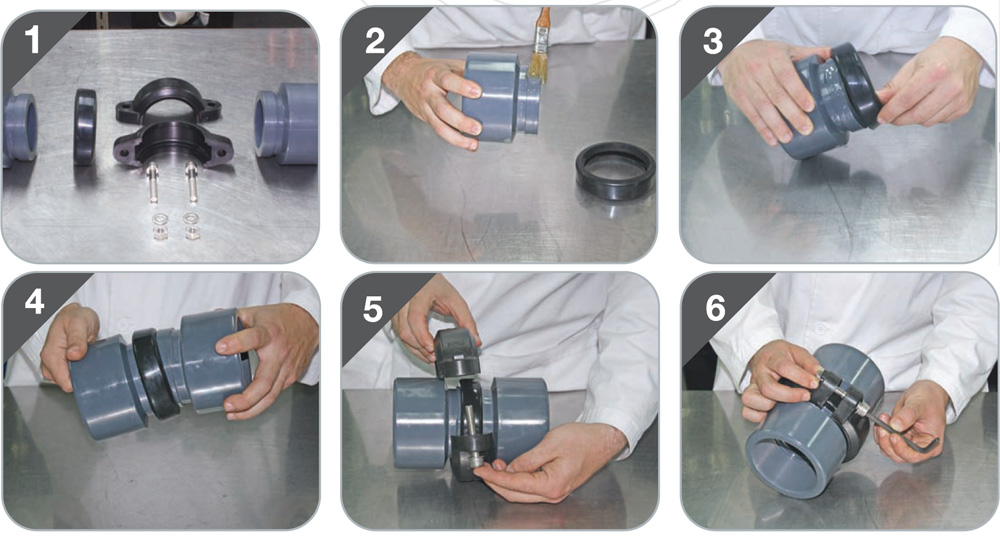

Soldering PVC pipes into a socket is carried out in several stages:

Scheme of "cold welding" of PVC pipes

-

- Exactly cut off the required piece of pipe. For this can be used:

-

- Chamfer the end of the pipe at a 15 degree angle using a bevel cutter. Burrs should be avoided.

-

- Clean the fitting socket and pipe from dirt and dust, remove moisture.

CPVC pipe cleaner can be used to effectively clean the parts to be joined. It prepares surfaces well for gluing.

-

- Apply glue. The work is done with a brush carefully on the surface of the pipe and socket.

-

- Insert the pipe into the socket immediately after applying the adhesive layer.

-

- In order for the adhesive to be evenly distributed over the surfaces to be glued, turn the fitting 90 degrees relative to the pipe.

-

- Fix the parts for 20-30 seconds.Do not re-turn connected parts after they have been fixed! The whole bonding process should be completed within 1 minute.

Waiting time of the connection before the test supply of the transported liquid or gas

-

- Upon completion of gluing, check for the presence of a uniform layer ("roller") of glue around the circumference.

-

- If necessary, remove excess adhesive with a soft cloth.

Advantages and disadvantages of gluing PVC pipes

Connecting pipes with glue or cold welding, unlike other joining methods, has the following features:

- Ease of installation. Connecting elements with glue is perhaps the easiest way to lay pipelines in comparison with other methods. For example, pipelines made of PP polypropylene are mounted by soldering, this requires a special soldering iron and good installer skills. Pipes made of metal-plastic, cross-linked and heat-resistant PE polyethylene, popular among the people, are usually connected using tension or press fittings, which requires special tools and expensive fittings. Theoretically, any user can do the installation of an adhesive PVC pipeline with their own hands; this does not require special skills, expensive tools and components.

- High speed of work. Glue for polyvinyl chloride is classified as a quick-drying compound; after washing and joining the parts, the setting time of the joint takes no more than 10 seconds.

- Ease of installation. For laying the pipeline on the adhesive does not require the presence of electricity, operations can be carried out at any positive temperature of the air.The method provides convenient installation in the most inaccessible places, which cannot be achieved using soldering irons or fittings.

- High connection strength. The principle of action of the adhesive is based on the dissolution of polyvinyl chloride, while mutual diffusion of the material of the connected fragments occurs, linking them into a single whole. It is clear that such a connection is very strong in comparison with other docking methods and is in no way inferior to soldering.

Rice. 4 Threaded PVC fittings and fittings for gluing

- Versatility. With the help of adhesive PVC pipes, water and sewer networks are mounted, which cannot be said about other materials for their manufacture - polypropylene, metal-plastic and cross-linked (heat-resistant) polyethylene are used only for laying water pipes. PVC pipes are indispensable for the installation of pressure sewers - the methods of arranging it using products from other materials are more laborious, require special equipment (for example, soldering machines, electric couplings for soldering polyethylene) and take much more time.

- Restrictions when laying high-temperature pipelines. Most glued PVC pipelines have an upper temperature limit of no more than 60 ° C - this limits their use in hot water supply and heating lines. The chlorinated variety of CPVC polyvinyl chloride can be used for domestic hot water supply, however, the upper temperature limit of 95 ° C makes their operation in heating mains unsafe.

- A wide range of. Adhesive pipes presented in the distribution network usually have diameters from 16 to 500 mm; a wide range of smooth-walled fittings and fittings is provided for their joining.Also, many manufacturers supply the market with a wide range of PVC adhesive threaded fittings and shut-off valves in the form of ball valves.

- Aesthetics. Pipe joints with glue have an aesthetic appearance due to the use of a transparent composition that does not leave visible marks on their surface.

- Fragility. A distinctive feature of any PVC elements is low flexibility and elasticity. Pipes do not withstand sharp impacts and mechanical stress in the form of bends and excessive physical impact on the shell - this leads to cracks.

Rice. 5 Fittings and combination fittings CPVC Corzan with thread transition

High price. Main disadvantage adhesive PVC pipes - unaffordable retail price for a huge number of consumers due to the fact that the goods are supplied to the market by European manufacturers from Italy and Holland. For one linear meter of a product with a diameter of 110 mm for pressure sewage, where the use of adhesive PVC is most rational, you will have to pay a minimum amount of 300 rubles. A piece of 25 mm pipe 1 m long will cost the consumer 80 rubles, which is also a rather high price. If we additionally consider the cost of glue, a liter jar of which costs from 1000 to 2000 rubles, then the costs will become quite significant. It should be noted that some companies, for example, the Russian Agrigazpolimer, offer PVC pipes and fittings for glue of their own production at prices three times cheaper than the above European counterparts. This is quite attractive for large, small companies, private customers.Also, if you do the installation of a glued PVC pipeline with your own hands without calling hired specialists, you can get significant financial savings.

Rice. 6 PVC physical characteristics

p>

Installation of plastic pipes with glue

Installation of propylene and PVC pipes can be done in several ways - using a welding machine or by gluing with special adhesives. The strength of the joint obtained using glue is comparable to welding, which is why this method is called cold welding.

Installation of propylene and PVC pipes can be done in several ways - using a welding machine or by gluing with special adhesives. The strength of the joint obtained using glue is comparable to welding, which is why this method is called cold welding.

Manufacturers present a wide selection of various types of adhesives that allow you to effectively connect pipeline elements.

The advantage of using the adhesive method:

- the material of the product is not damaged during installation;

- the possibility of connecting various parts;

- fast fixing of connections;

- stress is evenly distributed over the entire bonding surface.

Advantages of glued pipe joints

Pipes made of polymers are welded, glued or mechanically interconnected. The first way is the most popular. For welding, special equipment and nozzles are used, selected according to the diameter of the pipeline.

It is better to entrust such work to professional craftsmen. The option is to rent or buy your own machine. It's expensive, but it will help you learn another useful skill.

The method of joining with glue is less common, but no less effective. It is called "cold welding". Glue seams are just as (and sometimes even more) reliable as welded ones.The only caveat: almost all types of adhesives for plastic pipes are designed for cold water systems and can quickly lose their properties under the influence of high temperatures.

Advantages of gluing PVC pipes using special compositions:

- Reducing the risk of leaks. When gluing pipe sections, the parts are connected at the molecular level. The seams are absolutely tight, and they can start to leak only under the influence of high temperature or pressure.

- Minimum labor costs. For gluing pipes, no additional complex processes are needed. This is a simple method that does not require special skills.

- Fast and cheap installation. All operations can be done by hand. It is enough just to buy materials and choose the right adhesive composition. No need to look for a welding machine.

- Low energy consumption. The device for welding polymer pipes is powered by the mains, and no equipment is required for gluing parts. This is an additional savings on materials and energy resources.

- Versatility. The method is suitable for connecting pipeline parts of any diameter - from 6 to 400 mm. It can be used in the installation of plumbing and sewer systems.

Cold welding is a cheap and convenient way to install a pipeline. To use it, you do not need anything that can lead to an increase in the cost of work: you do not have to spend money on additional connecting elements or special equipment.

The principle of operation of all types of adhesives for polypropylene pipes about the same. The compositions partially dissolve PVC and firmly bind the particles. The compositions include additives that improve adhesion.When gluing, the solvent evaporates quickly, and the composition hardens, gaining strength. The result is a high strength joint.

On the market, you can find products for creating high-strength joints from both foreign and domestic manufacturers.

Overview of the best brands

In all ratings of adhesives for PVC pipes, the leading brands are Tangit (Germany), Genova (USA), Griffon (Netherlands), Gebsoplast (France). Buyers speak well of the adhesives "Phoenix", "Vinilit", "Mars" and others, but they are not so in demand and popular.

All types of adhesives for polymer pipes operate on the same principle, are available in packages of various sizes, and the appropriate composition should be selected depending on the purpose and technical characteristics.

Manufacturers recommendations come first

When working with adhesives, you should always read the manufacturer's recommendations. Many trains should not be left open for more than a few minutes, as they quickly seize, which makes them difficult to use further. The average time during which the adhesive can remain open is 4-5 minutes.

When buying a specific brand of glue, you should pay attention to its preparation for work. Some types are easy enough to mix, but two-component compositions have to be combined correctly, to monitor their consistency. There is a risk of improper mixing, which leads to loss or change in adhesive properties

There is a risk of improper mixing, which leads to loss or change in adhesive properties.

Color and viscosity matter. Experienced plumbers prefer medium-viscosity formulations. They are easy to apply, and when connecting parts, such glue does not spread, it does not have to be removed once again with napkins.With regard to color, the colorless composition is suitable for white and colored pipes. It is not visible, even if the drops protrude beyond the glued area and freeze.

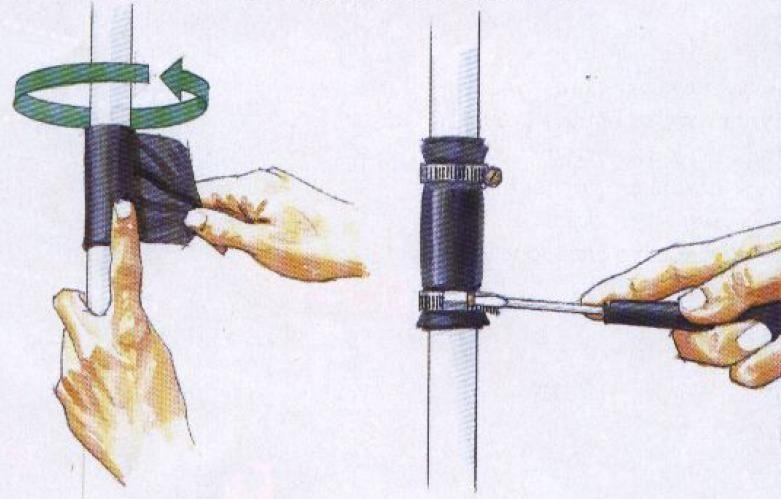

Instructions for glued pipe joints

Before adhesive bonding, make sure that the fixtures used and the parts to be joined are suitable and in good condition. Check the homogeneity, fluidity and shelf life of the adhesive.

- Cut the pipe perpendicular to the axis. To obtain a high-quality cross section, it is recommended to use special pipe cutters with rollers for cutting thermoplastic pipes.

- Bevel at a 15° angle. This operation must be carried out without fail, since as a result of improper processing of the ends, adhesive scraping from the surface of the fitting may occur, as well as a violation of the connection.. When performing this operation, use the appropriate chamfer cutters.

- Measure the depth of the fitting and make an appropriate mark on the end of the pipe.

External diameter

de(mm)Glue depth

L (mm)Chamfer width

Sm(mm)16 14 1,5 20 16 1,5 25 18,5 3 32 22 3 40 26 3 50 31 3 63 37,5 5 75 43,5 5 90 51 5 110 61 5 160 86 5 225 118,5 5&pide;6 Table 1: Insertion depth, adhesive bonding and chamfer width

- Using a clean paper towel or piece of cloth soaked cleanser Primer, remove any remaining dirt and/or grease from the outer surface of the pipe along the entire length of the adhesive joint, as well as from the inner surface of the fitting.Dry the surfaces for a few minutes and then apply the adhesive. It should be remembered that cleaners, in addition to rinsing and cleaning, also soften and prepare the surfaces to be joined for the application of adhesive, which allows you to obtain an optimal connection.

- Apply the adhesive in an even layer to the longitudinal surfaces of both components to be joined (external surface of the pipe and internal surface of the fitting) using an appropriately sized applicator or coarse brush (Table 2).

Outer pipe diameterde(mm) Type and size of brush or applicator 16-25 Round shape (8-10 mm) 32-63 Round shape (20-25 mm) 75-160 Rectangular/round shape (45-50mm) > 160 Rectangular/cylindrical (45-50mm) Table 2: Characteristics and sizes of brushes and applicators

It is recommended to use an applicator/brush that is at least half the diameter of the pipe.

The adhesive must be applied to the entire length of the pipe and fitting surfaces to be bonded:

- to the full depth of the fitting;

- for the entire length of pipe gluing, previously marked on the outer surface.

- Quickly insert the pipe into the fitting to the full depth of the connection without rotating it. Only then can both ends be turned slightly (no more than ¼ turn of pipe and fitting). Turning the components distributes the applied adhesive even more evenly.

- The insertion of the pipe into the fitting must be carried out quickly (it is recommended to perform all necessary actions within 20-25 seconds).

Given the outside diameter of the pipes and various manufacturing difficulties, inserting the pipe into the fitting must be done:

- manually by one person, if the outer diameter is not more than 90 mm;

- manually by two people, if the outer diameter is between 90 and 160 mm;

— using a suitable pipe connector if the outer diameter is more than 160 mm.

- Immediately after inserting the pipe into the fitting (to the very end), press both components for a few seconds, and then immediately remove any adhesive residue from the outer surface using a piece of crepe paper or a clean cloth, and from the inner surfaces, if possible.

- Drying the glue

Leave the connected components for a while to allow the glue to dry naturally; at the same time, ensure that these elements are not affected too much. Drying time depends on the pressure to which the joint is subjected. In particular, depending on the ambient temperature, the minimum times are:

- before affecting the connection:

— from 5 to 10 minutes at an ambient temperature of 10°C and above

- from 15 to 20 minutes at an ambient temperature of less than 10 ° C

- for repair joints that are not hydraulically tested, for all sizes and pressures:

- 1 hour at any pressure

in relation to connections that are subjected to a hydraulic test for pipes and fittings of any diameter up to PN 16:

- at least 24 hours.

The indicated time required for proper drying of the adhesive is based on an ambient temperature of around 25°C and certain climatic conditions (humidity, temperature, etc.).

For more information, we recommend contacting our technical service department and/or the respective adhesive companies.

The main types of glue

Adhesive for propylene pipes, PVC and their analogues can be divided into the following types:

- Thermosetting - consists of thermosetting resins (epoxy, polyester, etc.).

- Thermoplastic - represents solutions based on rubber and resins that retain their properties during installation. Thermoplastic compositions under the influence of temperature can dissolve.

Adhesives for PVC pipes are divided according to the number of components:

- on one-component - immediately ready for use (glue Moment, etc.);

- two-component - are several compositions that require additional preparation (epoxy glue).

Two-component mixtures are stronger than ready-made ones and require more time to work. Term storage of such compositions is longer, since the various components do not enter into a chemical reaction and in this case, hardening does not occur.

By consistency, adhesive compositions are liquid, semi-liquid and thick. The choice of adhesive for mounting polypropylene pipes depends on such parameters as the curing rate and operating temperature range.

The speed of solidification is on average 3-6 minutes at room temperature. If the air temperature increases to + 40 degrees, then the setting time is reduced to one minute.

The operating temperature range for the installation of PVC pipes by adhesive method ranges from +5 to +35 degrees. Lower temperatures have a negative effect on the tightness of the joint.

Different types of adhesives also differ in such characteristics as viscosity and color, which can be used when installing pipes in any particular case. Thus, mounting with viscous materials is more convenient in work, they are easier to apply to the object.

The color of the adhesive is taken into account when installing internal pipelines that are visible

The composition and principle of action of adhesive materials

You can glue a plastic sewer pipe using special foam adhesives.

PVC adhesive is a two-component plastic adhesive.

Several additives are added to the adhesive for polypropylene, with the help of which they control the time for the formation of the viscosity of the adhesive solution.

The technology of gluing plastic tubes is that when the adhesive solution hardens, the chains of PVC polymer molecules that are in the tube elements to be bonded are intertwined.

The result is a pipe connection that has the same properties as a non-glued PVC pipe.

How to glue polypropylene pipes

For the connection process you will need:

- PVC pipe;

- pipe cutter;

- adhesive agent;

- a special gun for easy application of glue produced in tubes;

- brush (natural bristles) for applying the mass, packaged in jars.

- Mark the desired length on the pipe.

- According to the marks with a pipe cutter, pipes are cut.

- The edges are cleaned with sandpaper to roughen, which provides better adhesion.

- Mark with a marker to what distance the connection will occur.

- Degrease the ends with acetone or alcohol.

- Apply a thin layer evenly adhesive solution.

- The connection is made according to the marks.

- If there are surpluses, they are removed.

- Wait for complete drying (about a day).

- Check - pressurized water supply.

During operation, it is necessary to maintain an operating temperature of 5-35 degrees.

Recommended videos on the topic:

In case of emergency repairs, you will need to turn off the water supply, since the flow will not fully correct the problem.After that, the leakage site is dried, cleaned and degreased.

Fine sandpaper is used to clean the plane to roughen it so that the adhesion is better. Next, the adhesive is evenly distributed and a sealing tape is applied in a spiral. Water is filled into the system after the repair joint has dried.

In the process of work, fuzziness may arise:

- Bad adhesive. Occurs due to the application of the adhesive solution not on the entire plane or the application was uneven.

- Non-gluing. Occurs due to overexposure of the adhesive layer without bonding.

- The softness of the connection. It is possible that during the commissioning of the product, the pipes did not wait for complete drying, or the temperature regime was not observed during operation.

- The porosity of the connection. Occurs when air appears in the adhesive layer, which indicates poor pre-mixing.

Causes and remedies for pipe leaks

There are many reasons that cause an emergency:

- installation work was carried out with obvious violations;

- the presence of marriage in the manufacture of fittings and pipes;

- improper operation of the sewer.

What actions should be taken first of all:

- In the problematic pipeline, turn off the water supply valve.

- The segment to be replaced is wiped dry and the boundaries are marked with a marker with a small margin of 2 to 4 cm on each side of the leak.

- Scissors cut off the selected part of the segment and prepare a new pipe.

- Threads are cut at the junction of the pipes, taking into account that the thread corresponds to half the length of the coupling.

- Pipes are connected using fittings and couplings.

Sealing with sealing tape is a fairly new and very convenient method that was created specifically for for tight sealing of pipe joints.

What to do if a long crack appears? How to close the sewer pipe in such an emergency? Immediately you need to identify the cause of the formation of a crack. Usually in such places moisture appears and condensation forms on the pipe. Next, follow these steps:

- Push the crack as wide as possible so that the sealant can easily penetrate deep into.

- Then degrease the surface of the crack and dry well.

- A layer of sealant is applied to the damaged area and allowed to dry a little.

From experience it follows that in order to avoid the occurrence of cracks in the future, it is necessary to insulate pipes as best as possible. And if a through crack appeared, then how can you cover up the sewer pipe? Such serious damage is sealed with a two-component adhesive composition, which is prepared according to the instructions. Then it is applied to a prematurely dried and degreased surface.

Conclusions and useful video on the topic

With the help of cold welding, truly high-quality water and sewer pipelines are assembled. Moreover, the method can be equally effectively used when laying communications in a private and multi-storey building.

If there is no self-confidence, it makes sense to hire professionals. But for homeowners who know how to handle tools, it will not be difficult to do the work on their own. To help craftsmen, we offer useful video materials.

Why is it better to glue PVC pipes? An experienced master answers:

How and with what it is possible to cut polymer pipes is described in the following video:

The ideal choice is a multifunctional tool that cuts pipes smoothly and immediately chamfers:

The choice of glue directly depends on the type of pipes, so they should pay attention to:

There is no simpler technology for connecting polymer pipes than gluing. The method is cheap, convenient, and in terms of efficiency it is not inferior to welding. Almost anyone can handle the installation of the pipeline with glue, because. he doesn't need any special skills.

The main thing is to choose the right pipes, glue and tools, and be careful and accurate when working.