- wall mount

- Operating instructions for gas boilers Ariston

- How to install a wall-mounted boiler

- Switching on the gas boiler

- First start-up and adjustment of the boiler

- Performing the first run

- Adjustment manipulations with the control panel

- Maximum/Minimum Power Testing

- Putting equipment into operation

- Specifications

- Removing air pockets in the system

- Clogged heat exchanger reduced capacity

- Recommendations for turning on the Baxi gas boiler

- The main models of boilers "Ariston"

- BCS 24FF

- Uno 24FF

- Genus

- Egis Plus

- Self-assembly of wall-mounted gas heating boilers

- Filling the heating system with water

- Specifications

- First start-up and adjustment of the boiler

- Performing the first run

- General characteristics of Ariston boilers

- What are the advantages of Ariston gas boilers

- General characteristics of Ariston boilers

- Characteristics of Ariston boiler models

- Ariston Genus

- Ariston Clas

- Ariston Egis

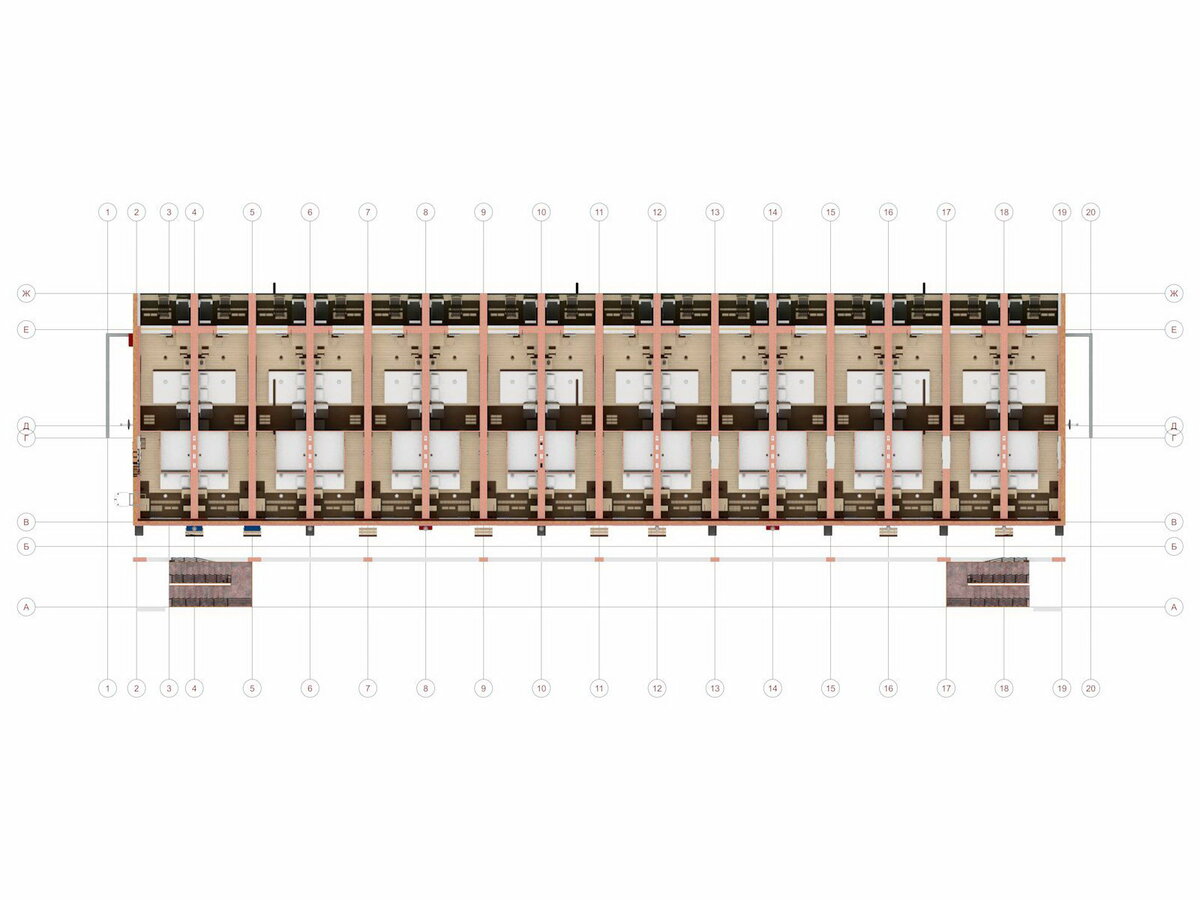

- Tables with three-digit codes, descriptions and set values

wall mount

Initially, I installed a coaxial angle on the boiler and measured the distance from the edge of the boiler to the center of the corner - it, as indicated in the instructions, was 105 mm.

The distance from the center of the corner to the top of the boiler is 105 mm

You can immediately fix the narrow clamp, remembering to put the sealing gasket.

Before tightening the clamp, it is necessary to insert a sealing gasket

My house is sheathed on the outside with vinyl siding, so I immediately decided to make the markup so that the hole for the pipe fits entirely on one strip of siding.

On some sites, they suggest first making a hole for the chimney, and then screwing on the mounting plate. I decided to screw the bar first. As mentioned above, the kit comes with two nail dowels. They are designed to mount the boiler to a brick or concrete wall. Since the house was built from sandwich panels, I screwed the bar with roofing wood screws.

The bar is set horizontally in level and fixed with five galvanized self-tapping screws.

Further in the wall, a through hole with a diameter of 10 mm was drilled. Center holes matched the center of the coaxial pipe. The hole for the pipes was cut from both sides using an electric jigsaw.

After cutting the hole and hanging the boiler, you can install a coaxial chimney

It is better to install the chimney together - one pushes the pipe from the outside, the other puts on the inner insulating gasket (made of hard plastic) and the clamp (it is more convenient to immediately screw the screws into the clamp).

Pipe installed, clamps tightened

Due to the fact that the outer insulating gasket is quite elastic, it fits snugly enough to the siding.

Coaxial pipe after installation

This is where I end. Next, we will have to solder polypropylene pipes, connect polypropylene pipes with metal-plastic pipes and install additional taps on the heating system.Only after that you can start Ariston.

To be continued…

Operating instructions for gas boilers Ariston

Before purchasing an Ariston gas boiler, you need to understand that if the buyer does not understand its installation, it is better to contact experienced specialists and entrust all the work to them. After all, even with the most detailed instructions, it is not a fact that the case will end successfully. In this case, there is every chance of damaging the equipment, after which you will have to call repairmen, and this will result in additional costs.

It is very important to keep children away from the equipment. To do this, after, it is necessary to have a conversation with them and explain in an accessible language that nothing can be twisted and put on the unit, only an adult should do this

If the family leaves, for example, on vacation, after the boiler is turned off, it is also necessary to shut off all pipes for the supply of gas and water. Only after that the equipment is disconnected from the network.

If a display is provided on any model, all indicators that it displays must be strictly controlled. It can display malfunctions or deviations from normal operation that occurred during the heating process.

One of the most important points in the instructions for gas equipment is safety. Before connecting the boiler, you need to familiarize yourself with it first.

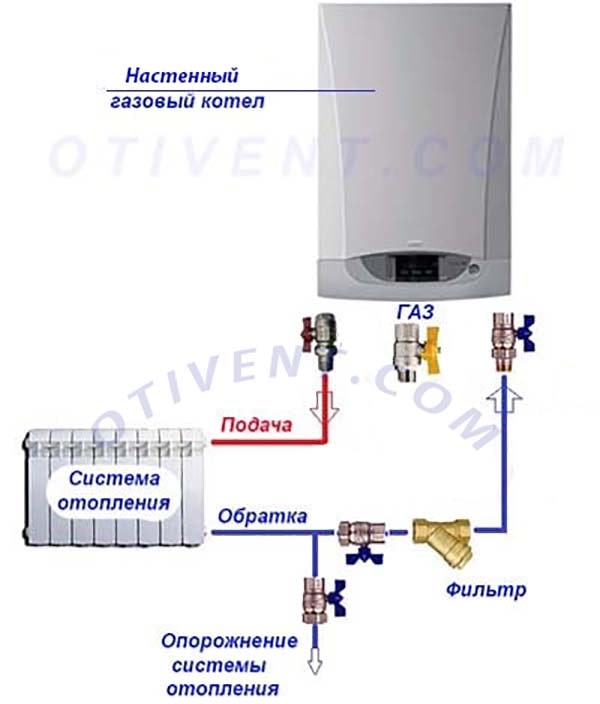

How to install a wall-mounted boiler

Before installation, unpack the heat generator and check that the appliance is complete. Make sure the stock fasteners fit your walls. For example, special fasteners are required for aerated concrete, ordinary dowels are not suitable.

We follow the following work order:

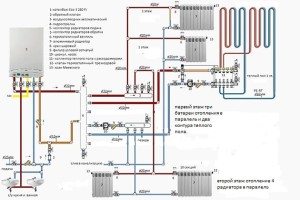

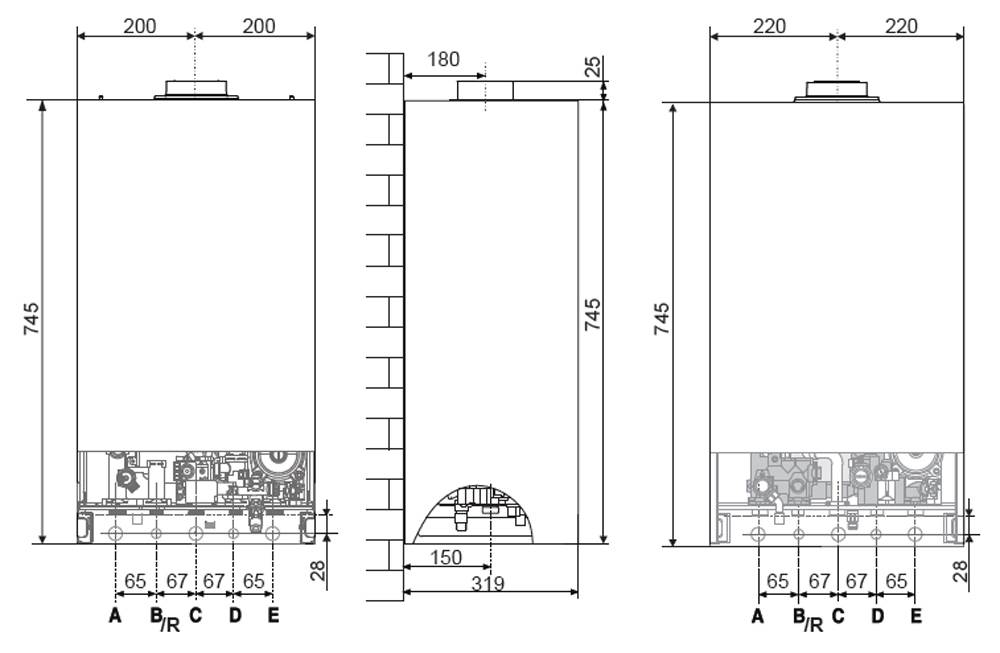

- Mark the contour of the heating unit on the wall.Make sure that the technological indents from building structures or other surfaces are observed: 0.5 m from the ceiling, from the bottom - 0.3 m, on the sides - 0.2 m. Usually, the manufacturer provides a diagram with dimensions in the instruction manual.

- For a turbo boiler with a closed chamber, we prepare a hole for a coaxial chimney. We drill it at a slope of 2–3 ° towards the street so that the resulting condensate flows out. The process of installing such a pipe is described in detail by us separately.

- The heat generator comes with a paper installation template with pre-drilled holes. Attach the sketch to the wall, align with the building level, fix the diagram with tape.

- Drilling points should be punched right away. Remove the template and make holes 50–80 mm deep. Make sure that the drill does not go to the side, this happens on brick partitions.

- Install plastic plugs in the holes, screw the hanging hooks to the maximum depth using pliers. With the help of a second person, carefully hang the machine.

When marking holes in a wooden log wall, make sure that the fastener is on the crest of the log. Hooks screw directly into the tree, without plastic plugs.

Switching on the gas boiler

A prerequisite for warranty service of a gas boiler is the implementation of the first inclusion exclusively by a master from the gas service. If the user follows all the instructions and safety precautions for self-starting, then you can also count on the reliability and durability of the heating system.

The initial start-up of the wall-mounted boiler is carried out strictly after checking the following points.

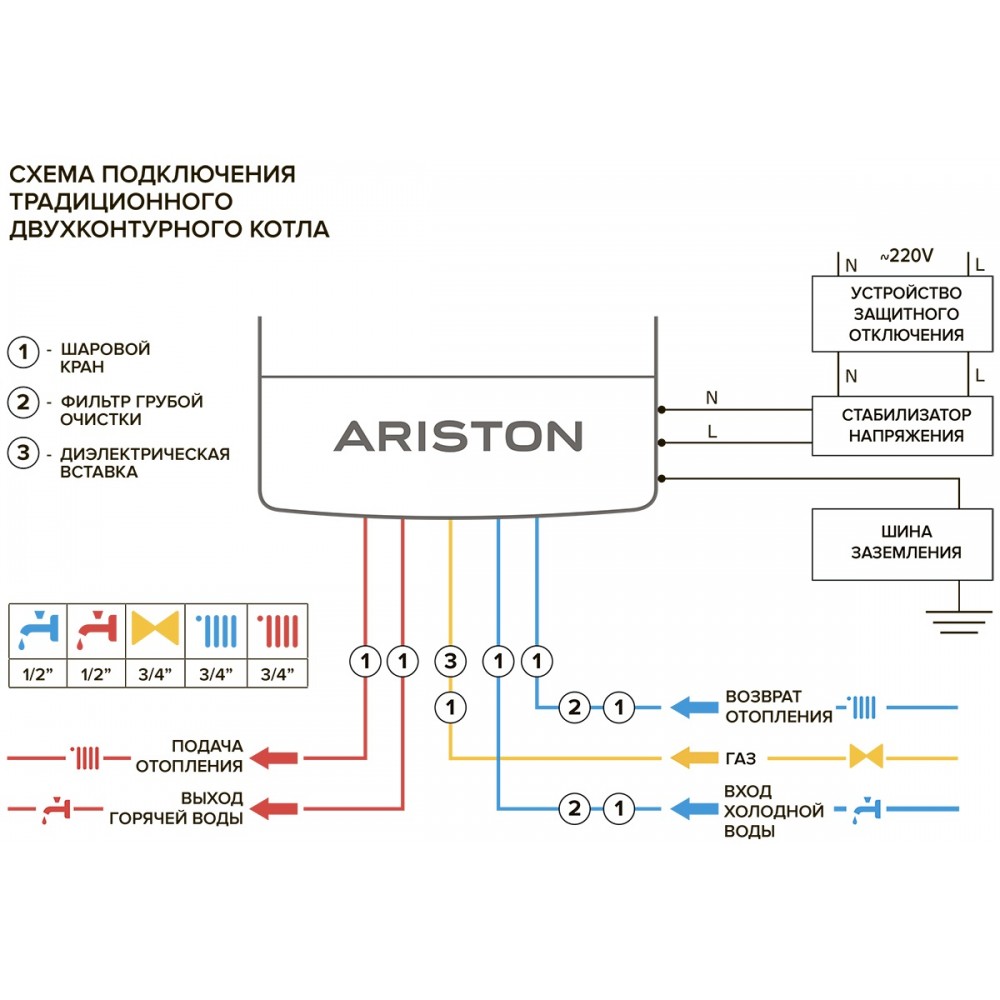

The first step is to make sure that the gas pipes are tight with the gas valve closed and open.If within 10 minutes after connecting all the pipes no gas flow is recorded, then it can be argued that the system is tight.

The gas supplied from the main pipeline must comply with the requirements specified in the instructions for the boiler. When transferring the unit to the processing of a liquefied mixture, it is necessary to change the nozzles in advance.

You also need to check the pressure level in the system. It must be as recommended. The air intake and carbon dioxide exhaust pipes should be checked for blockages.

Sometimes users face the problem of poor pump circulation. Often the cause is low mains voltage. This problem is solved by installing a stabilizer

Make sure that the room with the boiler has a working ventilation system. In addition, the safety smoke pressure switch is checked.

After carrying out the preliminary work, the procedure for starting the boiler follows:

- The gas boiler is connected to the network, the gas supply to the device is opened;

- Check that all valves are open at the inlet and outlet of the coolant to the unit;

- Press the button or turn the switch on the boiler dashboard, depending on the activation method specified in the instructions.

You can adjust the temperature using the corresponding buttons. Working in automatic mode, the boiler independently turns on the burner if it is necessary to heat the water in the system. If the boiler is double-circuit, then in the event of turning on hot water, the burner automatically turns on for heating.

It is recommended to set all boiler parameters on the boiler display after the initial start-up. The instructions usually indicate the sequence of necessary actions.

The interlock system cuts off the gas supply if the burner does not ignite within approximately ten seconds. When starting for the first time, it may be necessary to remove the ignition lock due to the presence of air in the gas line. You need to wait until the air is displaced by the gas. The lock is removed when the device is restarted.

To start a floor gas boiler, you need to carry out the same preparatory procedures as for a wall-mounted one. Before starting directly, it is necessary to ventilate the boiler room, make sure that all taps of the heating pipes are open and that there is draft in the chimney. You can check the traction with piece of paper.

There are two options for turning off the floor gas boiler. It is possible to turn off only the main burner or the main burner together with the pilot

Turning on the floor boiler:

- The door of the device is opened, the position of the boiler control knob is checked in the off position.

- The gas valve opens.

- The control knob is set to the piezo ignition position.

- Next, you should press the handle for 5 - 10 seconds so that the gas passes through the pipes and displaces the air. The piezo ignition button is pressed.

- Then the presence of a flame in the burner is checked. If the burner does not ignite, then the procedure is repeated.

After ignition of the main burner, the heating temperature can be adjusted using the control knob.

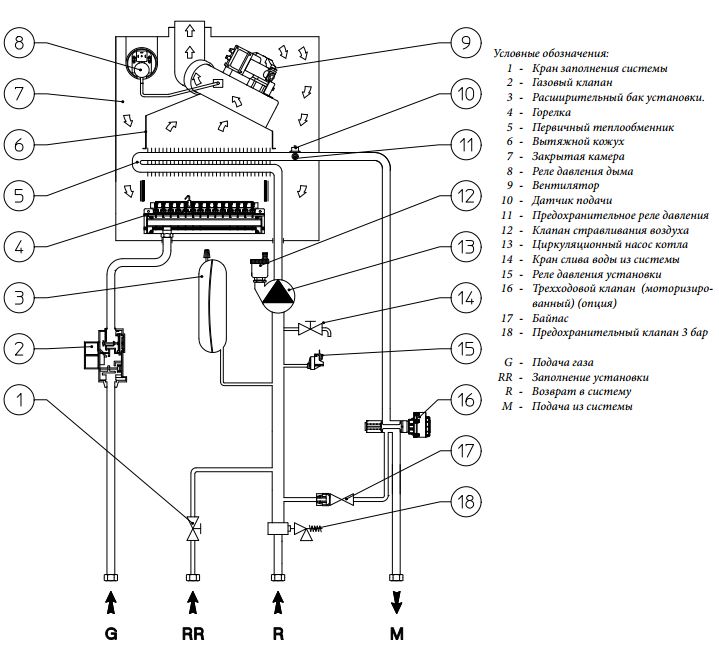

First start-up and adjustment of the boiler

When the installation and connection work is over, you can proceed to setting up and testing the equipment.

Performing the first run

The initial action that accompanies the first start-up of an Ariston brand gas boiler is to fill the heating circuit with water.In this case, it is necessary to set the air valves of the radiators to the working (open) state.

The same actions aimed at bleeding air from the system apply to the boiler circulation pump. As the circuit is filled with water, air is removed from the system, the water pressure on the pressure gauge reaches 1 - 1.5 atmospheres, the valve on the feed line is closed.

The first start-up of a gas boiler is usually accompanied by preparatory operations related to filling the system with water, venting air, checking the tightness of gas lines

At the next stage of commissioning of a gas boiler, actions related to the gas supply are performed.

The procedure is approximately the following:

- open the doors and windows of the working room;

- eliminate the presence of sources of open fire;

- check the burner circuit and control system for leaks.

Testing the control unit and the burner for tightness is carried out by briefly opening (no more than 10 minutes) the main shut-off valve of the gas line. In this case, the solenoid valve and the manual damper of the boiler are set to the closed position. With this position of the system, the gas flow meter should show a zero result (no leakage).

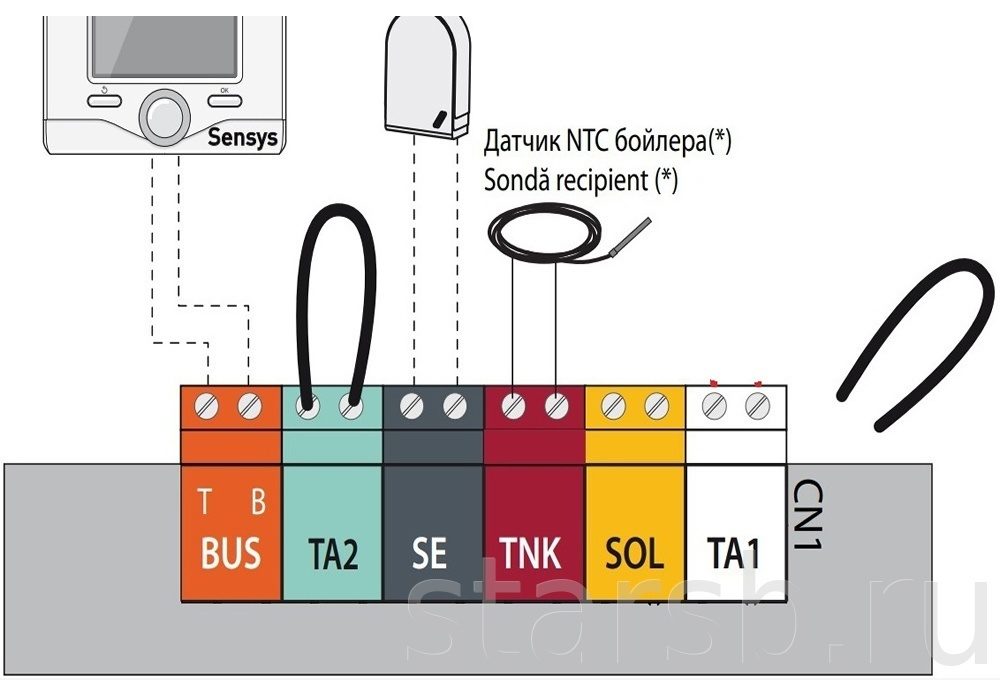

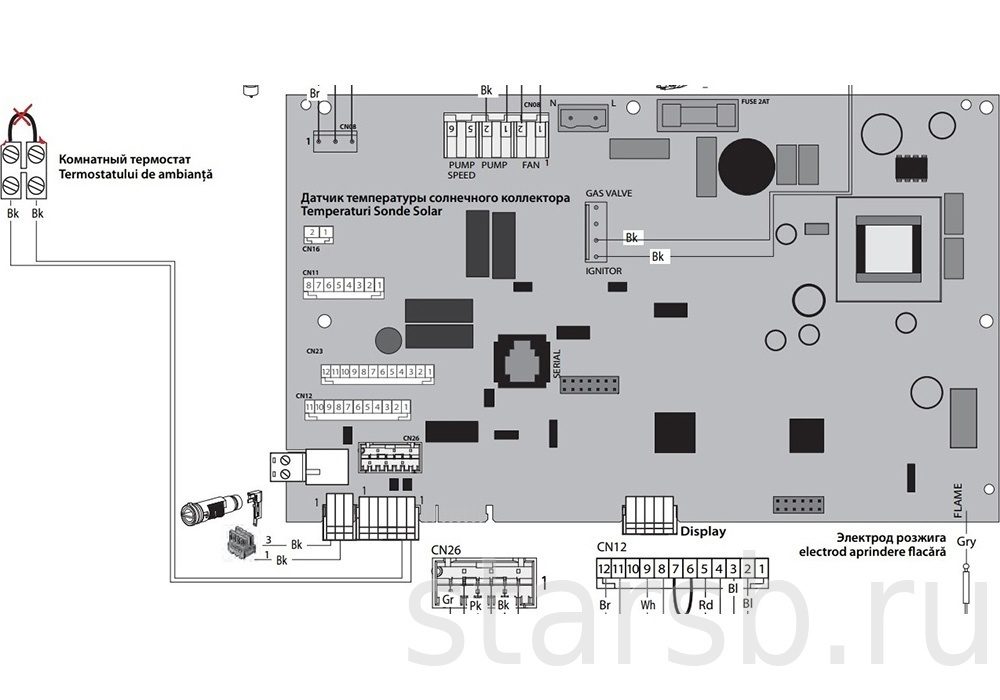

Adjustment manipulations with the control panel

Modern gas heating equipment is equipped with a control panel where the user can set the desired operating parameters of the unit. Next, we will take a closer look at how to set up a household gas boiler of the Ariston brand.

Control during operation of the boiler, as well as control in the first start-up mode with the necessary settings, is carried out through the user control panel Ariston

Actually, the user's actions on the control panel are obvious here:

- Switch on the device by activating the ON/OFF button.

- Mark the operating mode parameters on the display.

- Mark the service mode functions on the display.

Next, the gas parameters are checked, for which the front panel of the boiler is dismantled, the control panel plate is lowered and test manipulations are performed with the connection of the measuring pressure gauge to the pressure taps.

These operations are the prerogative of gas service specialists. Independent execution is not recommended, as it is necessary to clearly know the functionality of the equipment.

Keyboard layout of the Ariston remote control: 1 - information screen; 2 – DHW temperature regulation; 3 – mode selection key (Mode); 4 - "Comfort" function; 5 – ON/OFF key; 6 - "Auto" mode; 7 - reset key "Reset"; 8 - regulation of the temperature of the heating circuit

The boiler is then started in test mode via the system function "Chimney sweep". To enter the test mode, activate the Reset button and hold it down for at least 5 seconds. The test mode is exited by re-activating the reset button.

Maximum/Minimum Power Testing

This type of test also provides for control sampling of pressure at specialized points of the equipment, followed by measurement of parameters on a pressure gauge. It is necessary to disconnect the compensating tube of the combustion chamber. Again, the "Chimney sweep" mode is used, activated through the control panel.

Similarly, the boiler is tested for the minimum power level. True, the adjusting screw of the modulator is additionally used if it is necessary to correct the value of the minimum operating pressure of the boiler. On this occasion, a video is posted below, where for some reason the modulator is called a motor.

Putting equipment into operation

The process of starting the device provides for the following user actions:

- Activate the ON/OFF button.

- Select standby mode.

- Hold down the Mode button for 3-10 seconds.

- Wait for the bleed cycle (about 7 minutes).

- Open the line gas cock.

- Switch on the DHW operation mode with the "Mode" button.

If all actions were performed by a master of a specialized company, then he checks the compliance of the gas pressure during the operation of the unit and draws up an appropriate act.

And also instructs on the safe operation of gas equipment and puts the boiler on a guarantee.

Specifications

Almost all gas boilers from the Ariston brand have a capacity of 15 to 30 kW. Thus, each client will be able to choose the necessary indicators for the size of his apartment or house. It is also worth noting other distinctive characteristics of such gas equipment:

with maximum efficiency, boilers have a high level of efficiency;

all wall-mounted boilers have Russian instructions and designations on the equipment itself, so citizens do not have problems with controlling the unit;

most models from this manufacturer are able to perfectly cope with water in the system and low pressure;

special attention to this equipment should be given to those people in whose houses power surges often occur. Ariston boilers can easily cope with such jumps in the network;

all models are very easy to operate

To start using the boiler, you do not need to study the instructions for a long time, all the features of operation are intuitive and accessible even for those who install such a unit for the first time.

In some cases, the boiler cannot simultaneously heat water and provide sufficient space heating, this applies to budget models. In this case, a person needs to think about installing an additional boiler.

Removing air pockets in the system

Better to start with batteries. To remove air jams, a Mayevsky crane is usually installed on them. We open it and wait for the water to run. Did you run? We close. Such manipulations must be done with each heater separately.

How to start the boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-feeding the system with liquid.

Now, the most difficult thing is that starting gas boilers requires venting air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny cap in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electric power and set the water heating regulators to the working position.

Releasing air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and a loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is airy, it will be so. We take a screwdriver and slowly unscrew the cover in the middle of the pump - as soon as water begins to seep out from under it, we twist it back.After two or three such manipulations, the air will come out completely, incomprehensible sounds will subside, the electric ignition will work and start working. We check the pressure again and, if necessary, add water to the system.

Basically, everything. While the system is warming up, you can do a detailed study of the instructions (if, of course, you have not already done so) and debug the system, which involves starting the boiler. Everything is simple here - the batteries closest to the boiler must be screwed on, and the distant ones should be run to the fullest. Such debugging is carried out by means of control valves installed on the pipe connecting the supply to the heating radiator.

Clogged heat exchanger reduced capacity

Often scale or dirt build-up on the inner walls of the heat exchanger is the cause of problems with hot water. If tap water does not undergo preliminary filtration (coarse cleaning) and the temperature of hot water is too high, the heat exchanger walls become overgrown with scale and dirt over time, their thermal conductivity and flow area decrease. Each time the user increases the DHW temperature on the boiler more and more to get the desired result on the mixer. As the temperature rises, scale builds up even faster and eventually boiler DHW temperature at maximum, and the water does not heat up enough. This process has a particularly negative effect on a boiler with a bithermic heat exchanger. Plate heat exchangers lend themselves well to flushing.

Recommendations for turning on the Baxi gas boiler

If you wondered how to turn on the Baxi floor-standing gas boiler, you must follow a certain technology. In the first step, you must open the gas cock, usually located under the equipment itself.

It is important to make sure that the system has the right pressure, only then can power be supplied to the device. Then you should press the "Start" button and set the device to the "Winter" or "Summer" mode

The panel has special buttons with which you can set the desired temperature values in the boiler and hot water circuits. This will turn on the main burner. If you have purchased a gas boiler, how to turn it on, you need to ask before unpacking the goods. After you have carried out all the above actions, you need to make sure that the boiler is working, this will be indicated by a special symbol of a burning flame on the display.

The main models of boilers "Ariston"

Below are popular products that are positively evaluated by experts and owners.

For ease of evaluation, the main characteristics are given in a standard tabular form. For each gas double-circuit wall-mounted boiler "Ariston 24", the manufacturer's instructions and accompanying documentation contain extended information about the product.

BCS 24FF

| Options | Values | Notes |

| Type, power | gas | Convection boiler "Ariston" 24 kW double-circuit. |

| Efficiency, % | 93,7 | Consumption per hour - 1.59 kg (2 cubic meters) of liquefied (natural) gas. |

| Productivity, l/min | 13,5 (9,6) | At +25 °C (+35 °C). |

| Equipment | — | Electronic control, automatic diagnostic system, combustion control, shutdown in case of overheating. |

Uno 24FF

| Options | Values | Notes |

| Type of | gas | Convection, double-circuit, 24 kW. |

| Efficiency, % | 92,5 | — |

| Productivity, l/min | 13,9 (10) | At +25 °C (+35 °C). |

| Equipment | — | Electronic control without display, combustion control, shutdown in case of overheating. |

Genus

| Options | Values | Notes |

| Type of | gas | Closed chamber, dual-circuit, from 23.7 to 30 kW of power in different modes. |

| Efficiency, % | 94,5 | Consumption per hour - 1.59 kg (2 cubic meters) of liquefied (natural) gas. |

| Productivity, l/min | 14,5 (11,6) | At +25 °C (+35 °C). |

| Equipment | — | Electronic control, circulation pump, automatic diagnostic system, expansion tank. |

Egis Plus

| Options | Values | Notes |

| Type of | gas | Convection, double-circuit with a closed chamber, up to 28.7 kW. |

| Efficiency, % | 94,5 | Consumption per hour - 1.59 kg (2 cubic meters) of liquefied (natural) gas. |

| Productivity, l/min | 13,6 (9,7) | At +25 °C (+35 °C). |

| Equipment | — | Electronic control, expansion tank, shutdown in case of overheating. |

Self-assembly of wall-mounted gas heating boilers

Do-it-yourself installation of a gas boiler - we do it rightHowever, not all manufacturers of gas heating equipment allow the installation of their heating units on their own:

- companies Ariston, Viessmann, Bosch and a number of others oblige buyers to install a wall-mounted gas boiler exclusively by employees of certified centers;

- some manufacturers, such as BAXI, Ferroli, Electrolux, are more loyal to this issue, do not prohibit unauthorized installation of wall appliances. But in any case, for commissioning activities during the arrangement of the heating structure, services will be needed from specialists who have permission to connect gas and electrical equipment.

Filling the heating system with water

Starting a gas boiler begins with filling the heating system with water. Everything is simple here - modern double-circuit boilers do not require the installation of a special system feed unit.It is already built into the boiler and is equipped with a special faucet, which, as a rule, is located at the bottom of the boiler in close proximity to the cold water connection pipe. Open the make-up tap and slowly fill the system with water.

Starting the boiler - how to fill the system with water

A very important point in the operation of any boiler equipment is fluid pressure. To control this parameter of the heating system, almost all boilers are equipped with a pressure gauge. In the process of filling the systems with water, it is necessary to monitor the pressure and after it reaches 1.5-2 atm, the filling of the system will need to be stopped. In principle, the indicator of the working pressure of the boiler, depending on the manufacturer and model, may vary - therefore, see the exact figure for the working pressure in the instructions for the boiler.

Do-it-yourself first start-up of a gas boiler

Specifications

Almost all gas boilers from the Ariston brand have a capacity of 15 to 30 kW. Thus, each client will be able to choose the necessary indicators for the size of his apartment or house. It is also worth noting other distinctive characteristics of such gas equipment:

with maximum efficiency, boilers have a high level of efficiency;

all wall-mounted boilers have Russian instructions and designations on the equipment itself, so citizens do not have problems with controlling the unit;

most models from this manufacturer are able to perfectly cope with water in the system and low pressure;

special attention to this equipment should be given to those people in whose houses power surges often occur. Ariston boilers can easily cope with such jumps in the network;

All models are very easy to operate.To start using the boiler, you do not need to study the instructions for a long time, all the features of operation are intuitive and accessible even for those who install such a unit for the first time.

To start using the boiler, you do not need to study the instructions for a long time, all the features of operation are intuitive and accessible even for those who install such a unit for the first time.

In some cases, the boiler cannot simultaneously heat water and provide sufficient space heating, this applies to budget models. In this case, a person needs to think about installing an additional boiler.

First start-up and adjustment of the boiler

When the installation and connection work is over, you can proceed to setting up and testing the equipment.

Performing the first run

The initial action that accompanies the first launch of an Ariston brand gas boiler is water. In this case, it is necessary to set the air valves of the radiators to the working (open) state.

The same actions aimed at bleeding air from the system apply to the boiler circulation pump. As the circuit is filled with water, air is removed from the system, the water pressure on the pressure gauge reaches 1 - 1.5 atmospheres, the valve on the feed line is closed.

General characteristics of Ariston boilers

The description of Ariston gas units must begin with the characteristics of their main part - the burner. This element is used to burn fuel and to transfer thermal energy to the heating system.

Types of boiler burners:

- ordinary

- modulation

The modulating burner is more convenient to use. It provides for automatic power control depending on the temperature of the device.

According to the type of removal of combustion products, burners are divided into:

- closed type

- open type

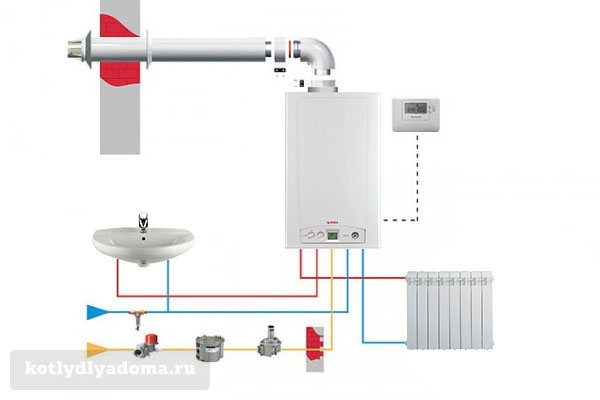

Units with a closed type burner are safer to operate. The combustion products of natural gas in this case do not enter the room. Use is not required. A coaxial pipe is simply connected to the device and brought out.

The design of the coaxial pipe provides for the presence of two layers, which ensures the simultaneous removal of waste and the flow of air from the street into the burner.

Equipment with an open burner provides for the mandatory use of a chimney to remove combustion products.

What are the advantages of Ariston gas boilers

Recently, the popularity of the Ariston brand has increased significantly due to high-quality gas boilers, and this is not in vain. operates silently and consumes as little fuel as possible. This will allow the owners of the unit to save on utility bills and, at the same time, provide comfort and warmth to the house.

The client will receive a high-quality device that provides round-the-clock water supply and heating of the house, even with a large area of up to 500 square meters. Also, do not forget about the durability of the service of each boiler. The terms specified in the guarantee are much more modest than they actually turn out to be. In terms of dimensions, the equipment is much more compact than other brands, which means that it can be installed absolutely anywhere, even in a small apartment with limited space.

General characteristics of Ariston boilers

The description of Ariston gas units must begin with the characteristics of their main part - the burner. This element is used to burn fuel and to transfer thermal energy to the heating system.

Types of boiler burners:

- ordinary

- modulation

The modulating burner is more convenient to use. It provides for automatic power control depending on the temperature of the device.

According to the type of removal of combustion products, burners are divided into:

- closed type

- open type

Units with a closed type burner are safer to operate. The combustion products of natural gas in this case do not enter the room. Use is not required. A coaxial pipe is simply connected to the device and brought out.

The design of the coaxial pipe provides for the presence of two layers, which ensures the simultaneous removal of waste and the flow of air from the street into the burner.

Equipment with an open burner provides for the mandatory use of a chimney to remove combustion products.

Characteristics of Ariston boiler models

A distinctive feature of Ariston boilers is their high quality. After all, the name of the company is translated from Greek as “the best”.

Its products are especially popular among middle-income consumers. Gas boilers of this brand are purchased for space heating up to 500 sq.m. The company's products are universal. The transition to liquefied fuel is carried out only by replacing the burner.

Practical to use are dual-circuit wall-mounted gas appliances. It is represented by three lines, each with its own modifications.

For all modifications of boilers, the common is:

- small size.

- hot water supply, in the absence of its centralized supply.

Different modifications differ in structure, the common thing is their low cost and high-quality performance of parts.

Basic equipment of units from Ariston:

- double .

- electronic control module .

- carbon monoxide control.

- support of the microclimate in the building or in a separate apartment.

- control of water freezing inside the system.

Let us consider in more detail the existing types of Ariston equipment.

Ariston Genus

- Are issued with the double heat exchanger. All modifications are double-circuit and are mounted on the wall.

- This model is considered the most functional of all Ariston devices. It has an LCD display, a control panel with buttons. Ariston Genus can be configured to work offline for a whole week.

- The display shows basic information about the status of the device and a list of possible errors. The burner is modulating, that is, fully controlled by electronics. This function increases the comfort of using this model of gas appliance, due to the minimum control by the consumer.

The Ariston Genus line includes Evo and more expensive Premium models.

The Evo model is a two-circuit gas appliance with a burner of both types: open and closed.

Genus Premium condensing boilers. They are used for heating residential buildings and commercial buildings. Power range from 24 kW to 35 kW.

Ariston Clas

- Small size device.

- This is a boiler with two circuits and a graceful appearance. The reduced dimensions did not impair its functionality in any way.

- Expansion tank for 8 liters. Hot water is heated fairly quickly

Existing modification:

- Evo is available in open and closed combustion chambers. Power with an open burner - 24 kW, with a closed - 24 - 28 kW.

- Premium Evo condensing type appliance. Has advanced comfort and freezing functions

- Premium simple condensing unit.

Ariston Egis

- Installed mainly in rooms up to 200 sq.m.

- The most common Ariston gas appliance model in our country. It heats water with a stainless steel heat exchanger, and a copper heat exchanger is used for heating.

- The compact device, differs in profitability and can be used under complicated weather conditions. For example, at sharp sub-zero temperatures.

- The device is equipped with a modulating gas burner, which allows for electronic control over the operation of the boiler.

This model is adapted to work in harsh climatic conditions. Normally withstands changes in gas pressure. The device is equipped with a collector into which condensate flows. This ensures operation at temperatures below 50 degrees.

Tables with three-digit codes, descriptions and set values

The values added in the white fields are the values used in my boiler. If there are no corrections, then I have the same values as those printed in the table. To enlarge, click on the photo of the table.

Double-circuit gas appliances make our life more comfortable and enjoyable. They are quite practical to use, suitable for heating country houses and small apartments. They are used for heating industrial or warehouse buildings, the area of which is not more than 500 sq.m.

The advantages of Ariston boilers are that in addition to heating buildings in winter, they heat water used in everyday life all year round. It is quite convenient and does not require the installation of additional equipment.