- Installation and connection of new equipment

- Dismantling the gas stove

- Faucet replacement

- Installation and connection of a new gas stove

- Leak test

- Acceptance of work by the gas service

- Wizard's advice

- Technology features

- Connecting the cylinder to the gas stove

- Preparation of materials

- How to choose the right jet

- Features of the choice of equipment

- Determination of a place for a gas cylinder

- How to connect with a pipe?

- Difference in slabs

- Why do you need a gas stove to give under the cylinder

- Is self-connection allowed?

- How to act?

- Features of the operation of gas cylinders

- Gas connection installation

- Connecting the hose to the gas stove

- Is self-connection allowed?

- What hoses and tubes to use for connections

- Required parts and tools

Installation and connection of new equipment

The gas stove replacement scheme is as follows:

- dismantling of obsolete or unusable equipment;

- crane replacement;

- installation of a new plate;

- its connection;

- tightness check;

- acceptance of work by the Mosgaz service in Moscow, Lenoblagaz in St. Petersburg, and so on.

Dismantling the gas stove

To dismantle obsolete equipment, you must:

- turn off the valve located on the pipe to turn off the gas supply;

- check the absence of gas by turning on one of the burners;

- disconnect the gas supply;

- disconnect the stove from electricity (if necessary).

After performing these operations, the stove can be removed from the kitchen.

Disconnection of old equipment from gas and electricity supply

Faucet replacement

If the gas valve does not meet the safety requirements or does not shut off the gas supply completely, it is recommended to replace the valve before installing new equipment.

As a rule, the installation of equipment and its connection by the gas service is carried out, since in order to increase the level of security, it is recommended to disconnect the entire entrance from the gas supply. However, if it is possible to block in an individual living space, then having certain skills and all the necessary equipment, the work can be done independently.

The replacement of the crane is carried out according to the following scheme:

- crane dismantling. In most cases, threaded valves are installed on gas systems in apartment buildings, the dismantling of which is quite easy. However, in old houses, welded valves can also be installed, the dismantling of which is carried out with the help of a grinder (only after turning off the carrier supply);

If the work is carried out without turning off the gas and by one person, then after dismantling the valve, a special plug is installed on the pipe. If there are two or more workers, you can plug the pipe with your hands.

- if the thread on the gas pipe is damaged or missing, since welded equipment was installed, then the next step is to cut the thread using special equipment;

- thread sealing;

- removal of the plug and installation of a new faucet.

Procedure for replacing a gas valve

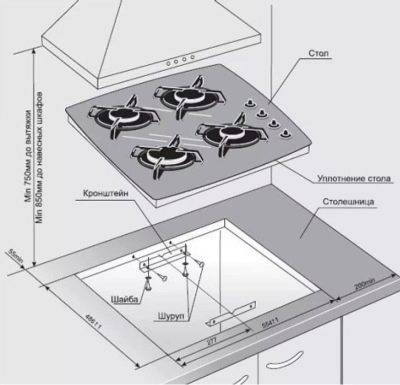

Installation and connection of a new gas stove

A new plate is being installed on the prepared site. When installing, it must be aligned horizontally. For this, most modern stoves of the Hephaestus type are equipped with adjustable legs. In the absence of such a function, the exposure is carried out using various gaskets.

Level alignment

Next, the flexible connection is connected to the plate and pipe. For this:

- the thread on the eyeliner (pipe) is sealed with the selected material;

- the eyeliner is fixed;

- in a similar way, it is connected to a gas stove;

Connecting the gas hose

- if necessary, the stove is connected to the power supply system.

How install and connect gas stove yourself, look at the video.

Leak test

After completion of all work, it is required to check the connections for tightness. The operation is performed in the following order:

- preparation of soap solution;

- applying the solution to the connecting nodes.

If the solution begins to form bubbles, the connection is not tight and the problem must be corrected before the system is put into service. The absence of bubbles indicates the complete tightness of the system.

The presence of a leak in the gas supply system

Acceptance of work by the gas service

After all the work has been completed, an application is sent to the gas service to put the stove into operation. At the appointed time, specialists will check the correct connection and tightness. Based on the inspection, permission will be given to use the gas stove or an order to eliminate the identified deficiencies.

If you perform all the work according to the attached instructions and in a well-ventilated area, then you can completely avoid negative consequences during the work and save on paying for the services of specialists.

Wizard's advice

Summing up, we can distinguish a number of rules that experienced craftsmen adhere to:

- access to the hose joints and valves must be free;

- the hose should be located behind the stove freely, without bending or pressing against the wall;

- the hose cannot be painted, as the paint can damage the material of the product and cause it to crack;

- all work is carried out with the gas turned off;

- if necessary, plug the pipe, use a damp cloth made of dense fabric;

- upon completion of work, it is imperative to wash the docking points to identify a possible gas leak. The appearance of bubbles indicates insufficient tightness of the assembly.

Built-in appliances are very popular in the kitchen.

Technology features

A standard household gas stove consists of two parts: a hob and an oven. In the classic version, both the oven and the hob have one solution: they work on gas or electricity. In combined models, gas is burned in the burners, and the oven is powered by electricity.

Stove with gas hob and electric oven

Hobs can be made of enameled or stainless steel, glass ceramic or anodized aluminium. Most modern models are equipped with burners of different diameters. The larger the burner, the higher its power. The combination of burners of different power allows you to cook food in dishes of various capacities as conveniently as possible.

Cooking surfaces can be equipped with very good functionality and security systems: electric ignition, languishing function, continuous burning, shutting off gas when the flame goes out, etc.

Electric ovens in combined gas stoves can be of two types:

- Classic. Structurally, classic ovens include an upper and lower heating element. Optionally, they can be equipped with a skewer and (or) a grill grate;

-

Multifunctional. In addition to the classic arrangement of heating elements, multifunctional equipment can have additional side and rear heating elements, be equipped with convection, self-cleaning and even microwave functions.

Classic oven device

It should be understood that the presence of a mass of options in the oven not only simplifies the operation and maintenance of the device, but also significantly increases its cost.

That is why, in order not to overpay when choosing a gas stove with a multifunctional electric oven, you should pay attention to models with only the options you need.

Electric oven with convection

Connecting the cylinder to the gas stove

If a person does not know the rules for connecting a gas cylinder, it is better to contact a qualified specialist. But, there are times when it is impossible to call a specialist, most likely such cases occur in summer cottages. If you follow the installation rules, then anyone can connect the cylinder.

Preparation of materials

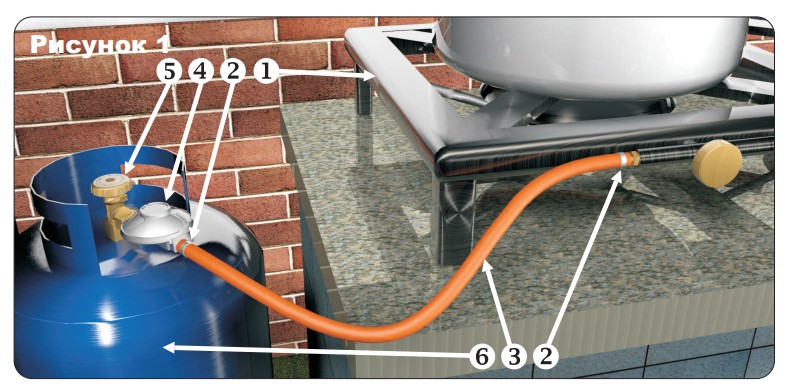

Preparation for connecting the cylinder must have the following mandatory elements:

- A special stove for a country house, designed for the installation of a cylinder.

- Appropriate capacity, i.e. propane gas tank.

- Special mechanism, for the normalized use of gas, reducer.

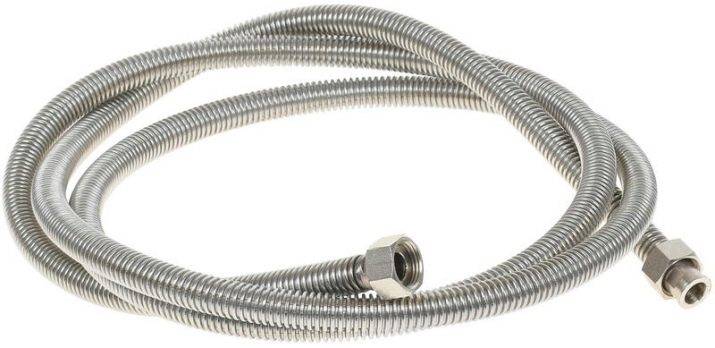

- The gas hose must be at least a meter long, this is in accordance with the correct distance between the stove and the gas container. In this case, the hose should not be stretched. The best length option is 2 meters.

- For a rubber hose, it is necessary to have fittings and screw clamps that are interconnected. If the hose is bellows, threaded adapters are required.

- To check the connections between the hose and the cylinder, it is necessary to have a soap-based solution. After installation, it is used as a test tool, if there is a leak, soap bubbles appear. Then you need to carefully reconsider the connection.

Reference! For high-quality installation of the cylinder to the furnace, it is better to buy elastically flexible hoses to avoid deformation and cracks leading to leakage.

How to choose the right jet

Reducers with the possibility of reverse regulation, it is recommended to use in the application of propane tanks. One requirement, the reducer must be suitable for the size of the cylinder used.

When choosing a reducer, it is necessary to take into account the temperature of the room in which the gas cylinder will be used. It often happens that the gas supply through the reducer is difficult, since the low temperature makes the gas liquid. In such cases, you need to buy a gearbox with a special heating system.

Features of the choice of equipment

Installation of a cylinder in an apartment, house or country house must be carried out in accordance with all safety rules.

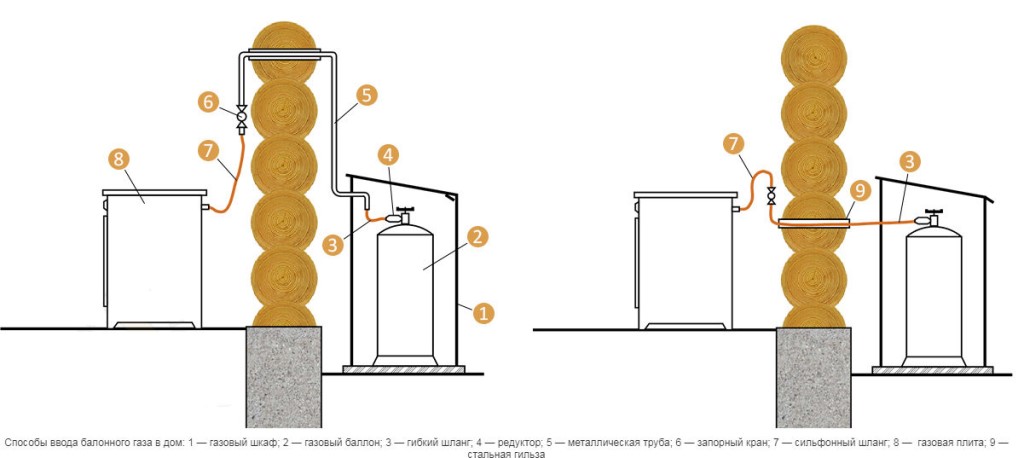

In the installation of gas equipment, there are several options. Consider three types of connection.

- Use of flexible hoses designed for combustion media. The gearbox is installed using a standard fitting and a screw clamp; a fitting is also installed at the inlet of the gas stove. To connect the gas pipeline, use a conical thread. When choosing a hose, you need to stick to the length, it should not be more than one and a half meters, for a good overview of the condition of the shell and identifying various kinds of damage. Bellows hoses can also be used, they are resistant to temperature changes and various damages. Installing flexible hoses through walls is strictly prohibited. If, however, such a need exists, you must follow all the instructions, which means that the concrete hole in the wall must be with a special metal cover. In the middle, there should be a smaller metal pipe. The rest of the space can be filled with a silicone-based sealant.

- Connection, has a gas valve installation, use it to stop the supply of a combustible mixture. Blocking is also needed for the safety of the furnace. Two types are used, a ball or plug valve, used for periodic maintenance.

- Additional materials, this is a metering device, it is connected to the gas delivery link. Accounting is necessary, since when gas is consumed, the device reacts and delivers the combustible mixture. Such a device is installed on the main networks.

- When connecting several cylinders, a connecting ramp is used. The device reduces gas evaporation and minimizes the risk of cooling in the jet. The installation of the device can be done by yourself, if the material of the gas pipeline is available.

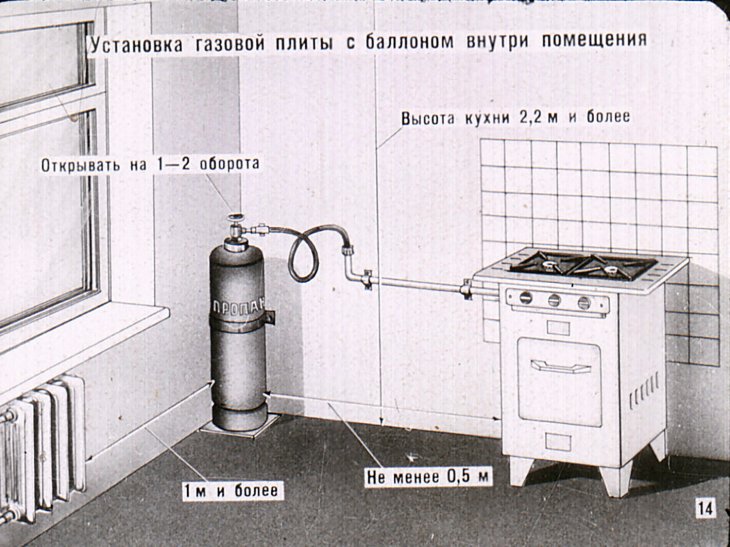

Determination of a place for a gas cylinder

For the correct installation of a gas cylinder and stove, there are some recommendations that will ensure people live. After all, the most important thing is safety. It is forbidden to install containers in rooms intended for habitation of residents of the house. Propane gas is heavier than air, with the slightest leak, the gas will accumulate on the lower floors.

How to connect with a pipe?

This option is rarely used due to the complexity of the installation. Installation according to this technology is carried out using a pipe of a certain length, bent at a given angle, with cut threads. The latter will be required for winding the couplings through which the household appliance is connected to the gas pipeline.

In practice, two connection options are used. The first involves the use of two couplings, with the help of which the pipe is connected at one end to the gas pipeline, and at the other end to the household appliance. The second option is more complex in terms of execution technology. In this case, one end of the pipe is welded to the gas pipeline, and the other is connected to the outlet pipe of the stove using couplings.

There is also a third option. In this case, copper pipes are used, to the ends of which fittings with union nuts are soldered. But, regardless of the connection method chosen, this type of connection does not allow, if necessary, to move the gas stove to the side.

Difference in slabs

Cooking stoves sold in stores use natural gas - methane - for combustion. The nozzle, which is located inside the burner, is designed to work on this type of fuel. If such a stove is properly connected to a gas cylinder, as many try to do, it will work inefficiently. The flame will not create the desired temperature and will smoke.This is because the propane-butane mixture is in a liquefied state, while methane is in a pressurized gaseous state. There is more liquefied gas per unit time, so the jets must be smaller. Therefore, before connecting the gas cylinder to the stove, the jets should be replaced. They come with a plate.

To change them, you need to remove the top surface of the kitchen appliance. To do this, remove the burners. Then press the side locks and remove the top cover of the stove.

Changing the nozzle in the oven is also not difficult. To do this, remove the back wall of the oven, after which access to the inside of the oven will open. The jet is connected to a gas supply tube, which is fixed with a metal bracket on the body. There is a rubber gasket between the tube and the jet, which must be installed when replacing the jet. It is very small and can be overlooked. It must be removed carefully so as not to damage it.

Why do you need a gas stove to give under the cylinder

Modern man is accustomed to convenience. He is not satisfied with decisions that are accompanied by unnecessary difficulties. From this point of view, electricity is the most convenient. A stove equipped with an appropriate heater is easy to use. The position of the regulator precisely sets the temperature regime. Easily meet the safety requirements.

Such exotic "equipment" is used as an entertainment attraction. The practical value of a classic samovar is minimal

The advantages of electric heating are obvious. But it should be noted the shortcomings that complicate its use:

- high cost of energy resources;

- dependence on the functionality of centralized networks;

- high power consumption;

- stationary placement.

Significant inconvenience is caused by the use of solid fuel. Wood-fired ovens create a unique flavor of dishes. But they take a long time to melt. They take up a lot of space and unnecessarily raise the indoor temperature after cooking is complete. Such equipment must be connected to the chimney. The project will require significant financial investments and labor costs.

Furnaces in dachas perform decorative functions. They are used as an effective means of heating when weather conditions worsen.

If we evaluate the significant factors in the complex, it is not difficult to draw a preliminary correct conclusion. gas stove for cottages under the balloon - profitable option:

- It weighs a little, takes up little space.

- A personal fuel supply ensures good autonomy.

- The equipment is ready for immediate use after connection.

- Her movement is not accompanied by unnecessary difficulties.

Is self-connection allowed?

Almost all gasmen unanimously claim that it is necessary to connect a propane cylinder to a gas stove only with their participation, paying them money for calling a master. However, this connection is quite allowed to be done with your own hands at no additional cost.

There is nothing fundamentally difficult in this matter. Connecting a gas hob to a cylinder consists in choosing a place for a container with fuel and organizing an outlet from there in the form of a pipe or flexible hose to the stove.

The cylinder is independently connected to the stove or with the call of a gas fitter - according to the law, all responsibility for the safe operation of gas appliances lies solely with the owners or tenants of a residential building

The cylinder is independently connected to the stove or with the call of a gas fitter - according to the law, all responsibility for the safe operation of gas appliances lies solely with the owners or tenants of a residential building

To perform such work, it is required to have only elementary skills in handling wrenches. Plus, you will have to carefully study and fully comply with the fire safety rules for gas equipment.

A household propane cylinder is allowed to be installed both inside a residential building and outside. But fire regulations recommend choosing a place to store gas on the street, and not in the kitchen or back room of the cottage. For outdoor installation, a longer pipe or hose will be required, but the risk of fire and / or explosion will be less.

How to act?

You take any of the steps below at your own risk. The site administration is not responsible for any negative consequences associated with such an installation. For work you will need:

- jigsaw (can be replaced with a circular saw);

- FUM tape;

- mounting wrenches;

- toilet soap solution.

To properly connect the hob, you first need to choose the installation location. Most often they try to bring the equipment closer to the gas pipelines. But if redevelopment is to be (or possible), corrugated bellows hoses are used. Next, a hole of the required size is prepared with a cutting tool in the countertop. Remove all dust and remaining sawdust.

The next step is to stick a special foam tape around the perimeter of the recess. It is either taken from the delivery set or purchased separately in specialized gas equipment stores.

Next, you need to connect one end of the flexible hose to the main pipe or to the cylinder. The opposite end is connected to the inlet channel of the hob. The required hole is located at the bottom of the household appliance.

Therefore, when connecting gas hoses to the built-in model, it is necessary to open the doors and remove the shelves on the corresponding cabinet. The hose is screwed tightly, it must be sealed with FUM tape. Next, scroll the valve to the "fully open" position. The burners do not ignite.

It is necessary to cover all joints with soapy water. Normally, no bubbles should appear. But suppose the foam still appeared. Then you need to re-tighten the nut in the problem area. Then check it again with foam. The procedure is repeated until even small gas bubbles cease to appear.

Most standard kits include two types of jets. The one with a thicker hole is for main gas. The one with a smaller inlet is for connecting to cylinders. It is always the jet for docking with the gas pipeline that is set by default. If there is a need to change it, the keys included in the kit are also used.

Gas panels with electric ignition will need to be connected to the mains. An outlet must be placed near the household appliance. Its load capacity is determined very carefully. Ideally, not only the maximum current consumption should flow freely through this outlet, a reserve of about 20% in power should be provided. Hobs are always mounted in thick worktops (wood layer at least 3.8 cm).

If you try to install the panel on a thin base, the system may fail suddenly.According to standard rules, hobs with electric ignition are installed using any hoses, except for those with a metal braid. No matter how good such sleeves are, they can lead to fire and gas explosion if a short circuit occurs.

For information on how to properly connect gas to the hob, see the following video.

Features of the operation of gas cylinders

The liquefied gas in the cylinder is under pressure, and when it is supplied to the gas equipment, it changes into a gaseous state.

This process is accompanied by a sharp decrease in temperature, and with intensive use of the equipment, the temperature can drop to a critical value, at which further conversion becomes impossible.

The simplest solution is to reduce gas consumption. You can also resort to additional heating of the cylinder, but it is forbidden to use sources of heating with an open flame. Insulation of gas cylinders is not allowed, but it is possible to use special "heating jackets" and thermal covers.

Thermal covers protect gas cylinders from a critical drop in temperature

Thermal covers protect gas cylinders from a critical drop in temperature

Owners of gas cylinders may also face similar difficulties in winter if the cylinders are in an unheated room. In this case, it is best to use special propane-butane mixtures with different percentages of components.

The standard gas mixture for the warm season contains 60% butane, 40% propane. Critical cold winter mixes can contain 80% propane and 20% butane, but the mix is much more expensive.

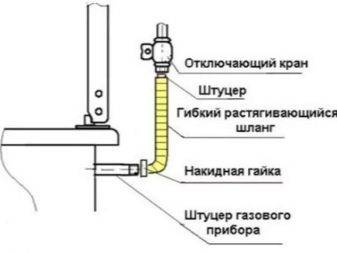

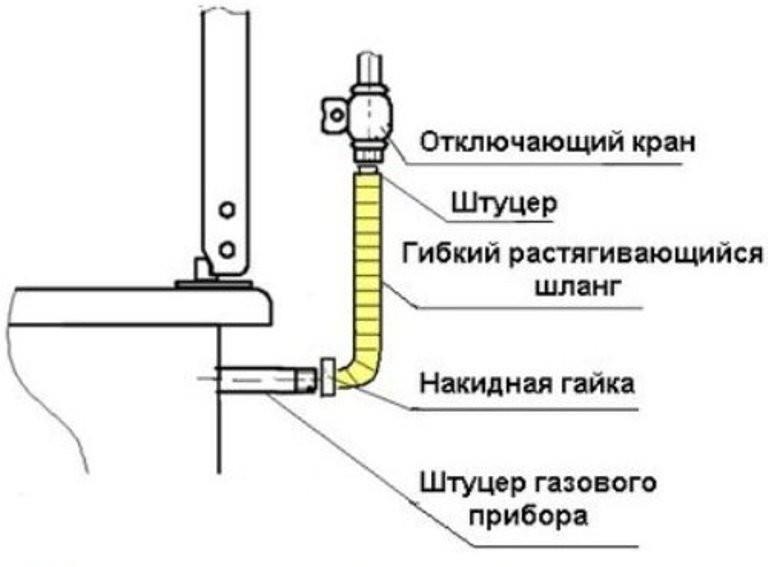

Gas connection installation

The installation of the bellows gas hose is subject to the following rules:

- it is unacceptable to hide the eyeliner in the wall, since any leak that is not detected as soon as possible can lead to emergencies, damage to property and death of people;

- do not install a hose with a large number of kinks;

- the ingress of condensate on the equipment will help to reduce the life of the eyeliner.

Mounting scheme:

- choice of installation location in accordance with the recommendations given above;

The optimal scheme for connecting a gas stove

- shutdown of the gas supply to the premises. To make a temporary shutdown, you can use the tap installed in the apartment, and in its absence, you need to contact the management company;

Individual tap for shutting off gas

- dismantle the old eyeliner (if any);

- if there is no supply and tap, then before connecting the equipment on the pipe, it is necessary to cut the thread and install a tap that allows you to shut off the gas supply directly in the living room. For example, to troubleshoot equipment;

- dielectric installation;

- a flexible hose is attached to the faucet. As a rule, in this situation, the “nut” connection method is used;

When connecting the eyeliner, special attention is paid to the installation of the sealing gasket. A joint without a gasket will not be completely sealed. To increase the tightness, you can additionally use FUM tape or other similar material.

To increase the tightness, you can additionally use FUM tape or other similar material.

- connection of the piping to gas equipment using an o-ring.All nuts and fittings must be fixed with an open-end (wrench) wrench without any extra effort. Even slight overtightening can lead to damage to the seal and rapid depressurization;

Connecting the plumbing to the equipment

- examination. To detect a leak, you can use a soap solution and an ordinary brush (sponge). If soap bubbles appear on the surface when applying the solution, then the connection is not tight.

Soap leak detection

How to connect a gas stove yourself, look at the video.

If it is not possible to carry out the work on the installation of equipment on your own, it is recommended to contact the specialists of the gas service. Replacing the eyeliner will cost approximately 300 - 500 rubles.

Connecting the hose to the gas stove

To connect the hose to the stove, look at its back wall. Here you can see the inscription "exit". Immediately you will need to determine what kind it is. Perhaps it will be made absolutely straight or have a slight angle.

This is very important as the hose must not be kinked too much. When the pipe is located a little to the side, and the exit is made straight, you will have to purchase an additional metal threaded square. When the thread diameter is 3/4 inch, you will also need to install an adapter (futorka) with a diameter of half an inch

When the thread diameter is 3/4 inch, you will also need to install an adapter (futorka) with a diameter of half an inch.

Usually in all kitchens, the gas riser is installed in a certain corner. A welded tube equipped with a ball valve departs from it for connecting a gas hose.

The union nut is screwed onto the faucet. When the faucet has an internal thread, the hose must be screwed into it.

Before you connect a hose to the "output" of the system, you need to put a paronite gasket. It is usually sold as a set.

But it is better to purchase such a gasket on the market, equipped with a metal mesh. It will serve as protection against possible pollution.

After installing the gasket, the flexible hose is screwed to the plate outlet and tightened with an open-end wrench.

Then the gas leak is checked. All connections must be washed thoroughly. Open the faucet and turn on the gas. The absence of bubbles at the joints indicates that the system is ready for operation.

Is self-connection allowed?

Almost all gasmen unanimously claim that it is necessary to connect a propane cylinder to a gas stove only with their participation, paying them money for calling a master. However, this connection is quite allowed to be done with your own hands at no additional cost.

There is nothing fundamentally difficult in this matter. Connecting a gas hob to a cylinder consists in choosing a place for a container with fuel and organizing an outlet from there in the form of a pipe or flexible hose to the stove.

To perform such work, it is required to have only elementary skills in handling wrenches. Plus, you will have to carefully study and fully comply with the fire safety rules for gas equipment.

A household propane cylinder is allowed to be installed both inside a residential building and outside. But fire regulations recommend choosing a place to store gas on the street, and not in the kitchen or back room of the cottage.For outdoor installation, a longer pipe or hose will be required, but the risk of fire and / or explosion will be less.

Read also: How to wean a chicken to hatch eggs

What hoses and tubes to use for connections

According to the rules for the safe operation of gas equipment, it is not allowed to use oxygen and hydraulic hoses for laying gas pipelines. This is due to the high temperature difference between the transported gas and the external environment, which leads to accelerated degradation of the hose material and the appearance of microscopic leaks. With the properties of liquefied gas to accumulate in rooms, such phenomena pose an increased danger.

There are three options for connecting a gas cylinder to a stove. The first is to use special flexible rubber hoses for flammable hydrocarbons. In this case, their connection to the gearbox is carried out through a standard fitting with a screw clamp. The same fitting is installed on the inlet pipe of the gas stove, the hose is also connected to it with a clamp. If it is necessary to connect two pieces of hose, it is not allowed to use double-sided fittings, instead of them, threaded connectors with double crimping of the shank with clamps should be used. A distinctive feature of such connections for gas pipelines is the conical thread and the absence of elastic seals.

Connecting the plate to the cylinder using flexible hoses has a number of limitations. The length of the hose must not exceed 150 cm, its gasket must remain visible in order to constantly monitor the condition of the sheath and avoid damage. Some of the restrictions can be partially circumvented by using metal bellows hoses.They form a semi-rigid frame, which can have an almost unlimited length, while maintaining resistance to temperature effects and mechanical damage.

At the same time, safety rules prohibit the passage of flexible and semi-flexible ducts through walls where their condition cannot be visually assessed. If it is necessary to connect the stove with a cylinder installed on the street, a steel pipe case should be embedded in the cement mortar in the hole in the wall. Inside the case is a steel tube of smaller diameter with threads at both ends, the space between the walls is filled with a plastic sealant, such as mounting foam or silicone. The connection of bellows or flexible hoses must only be carried out through threaded adapters of the appropriate type.

Required parts and tools

To properly connect the stove, you should use the following tools:

- special hose (1.7 meters);

- ball joint made of brass;

- wrenches;

- gaskets;

- screwdrivers;

- special tape for sealing;

- brush and tube of foam.

7photos

At the junctions, various gaskets play an important role, most often these are such materials:

- thread "Loctite 55";

- FUM tape.

It is best to use only those materials that are recommended by gas workers. The Loctite 55 thread is a reliable material that ensures the correct fastening of the working elements in the most difficult areas. It has a high density and plasticity (length can be from 14 to 162 meters), in places of threaded connections it provides perfect sealing. In this case, the pressure in the pipe can be quite high. The material is universal and suitable for any connection without any restrictions.

FUM tape is another type of sealing that can withstand significant loads, it is made of a special 4D fluoroplastic. There are three types of tapes in total.

- The first type is called "Mark 1". It can be used in aggressive environments (acids, alkalis, etc.).

- Grade 2 works best in nodes where various oxidizers are present. Has no lubrication.

- Grade 3 is a universal tape that can be used both in industry and in everyday life. In fact, these are thin threads that are assembled into a film coating.

FUM type tapes meet all the necessary requirements:

- high resistance to high temperatures;

- absence of corrosion phenomena;

- durability;

- lack of toxins;

- creating a good seal.