- Equipment in a closed system with forced circulation

- How to install a double-circuit gas boiler in a private house

- Parallel operation of boilers on wood and gas

- 1 scheme (open and closed systems)

- Advantages and disadvantages

- 2 scheme, two closed systems

- Heat supply through 3-way valve

- System with a heat accumulator, why is it

- Main types

- How to make heating with two boilers

- Connection of electric and gas boilers

- Connection of gas and solid fuel boilers

- Connecting a solid fuel and electric boiler

- 5 Gas connection

- Electric and diesel heat generators

- One-pipe scheme with Leningrad

- How to connect a device for a boiler with two circuits

- Wiring diagram

- Direct heating device

- Indirect and combined heating

- Materials and tools

- Step-by-step installation and quality control

- What documents must be prepared and who issues them

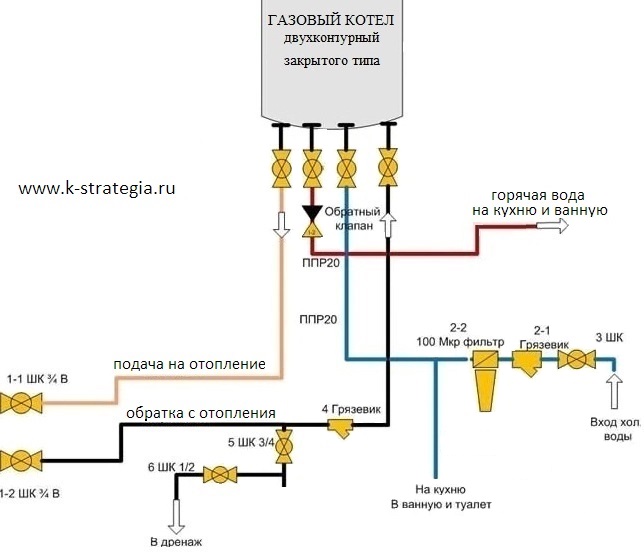

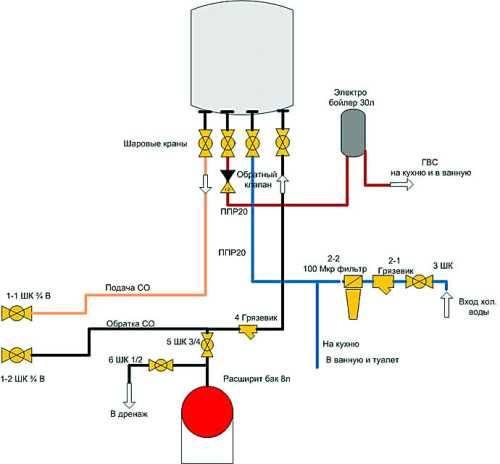

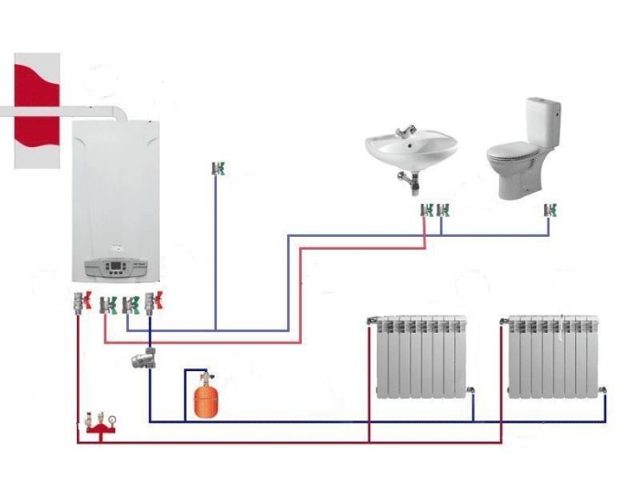

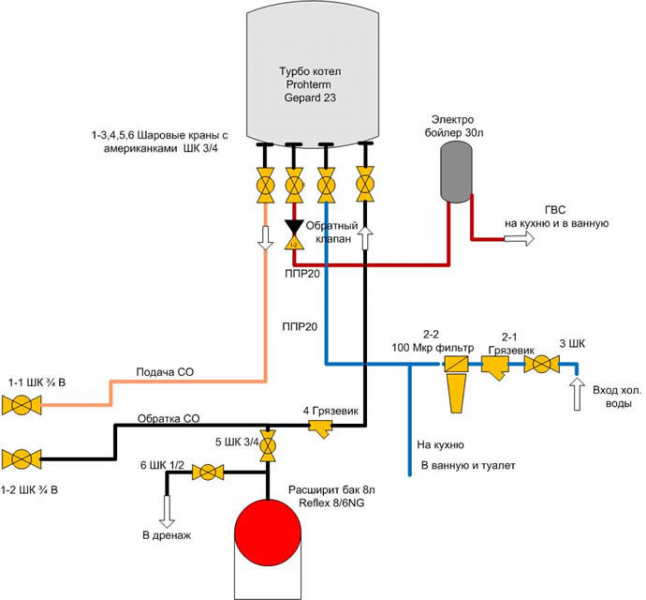

Equipment in a closed system with forced circulation

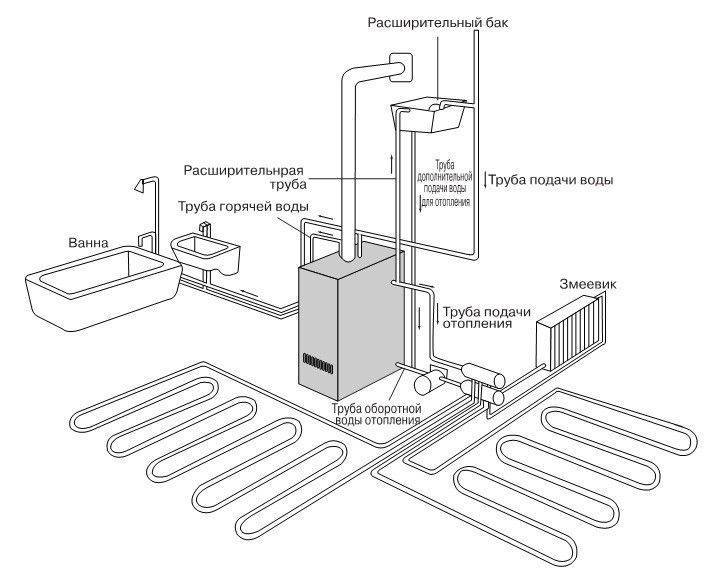

When the heating system is not in communication with the surrounding air and operates under pressure, such circuits are only closed.

In this case, the following equipment is required to tie the boiler:

- pump 100-200 watts, which should be installed on the supply;

- membrane-type expansion tank to provide the coolant with additional volume during expansion;

- safety valve for coolant discharge, in case of exceeding the permissible pressure;

- an automatic air vent that will help the air lock that has appeared to leave the system on its own so that the coolant circulates freely along the circuit;

- pressure gauge - to control pressure.

These are required items. The following options may also be included in the scheme:

- filter for gas unit;

- filter at the inlet to the heat exchanger to protect against debris;

- a heat accumulator, which is advantageous to be paired with solid fuel or electric boilers to save energy.

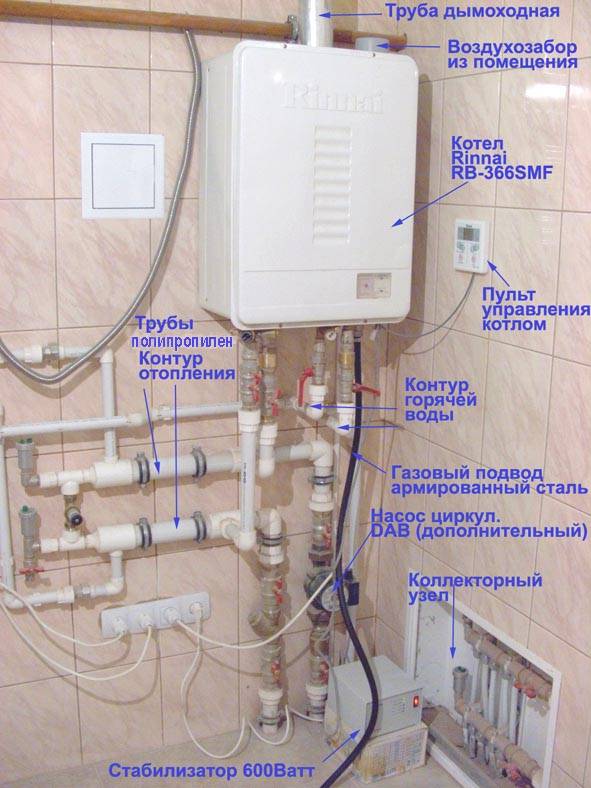

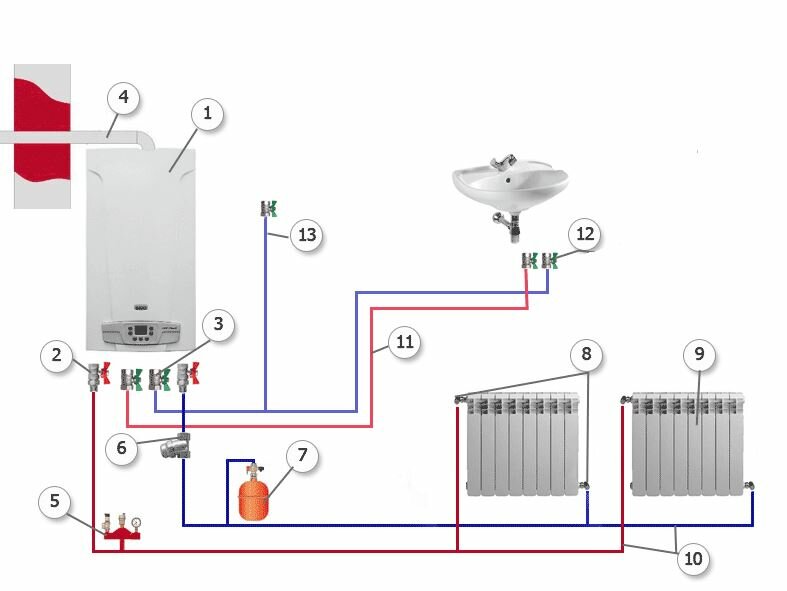

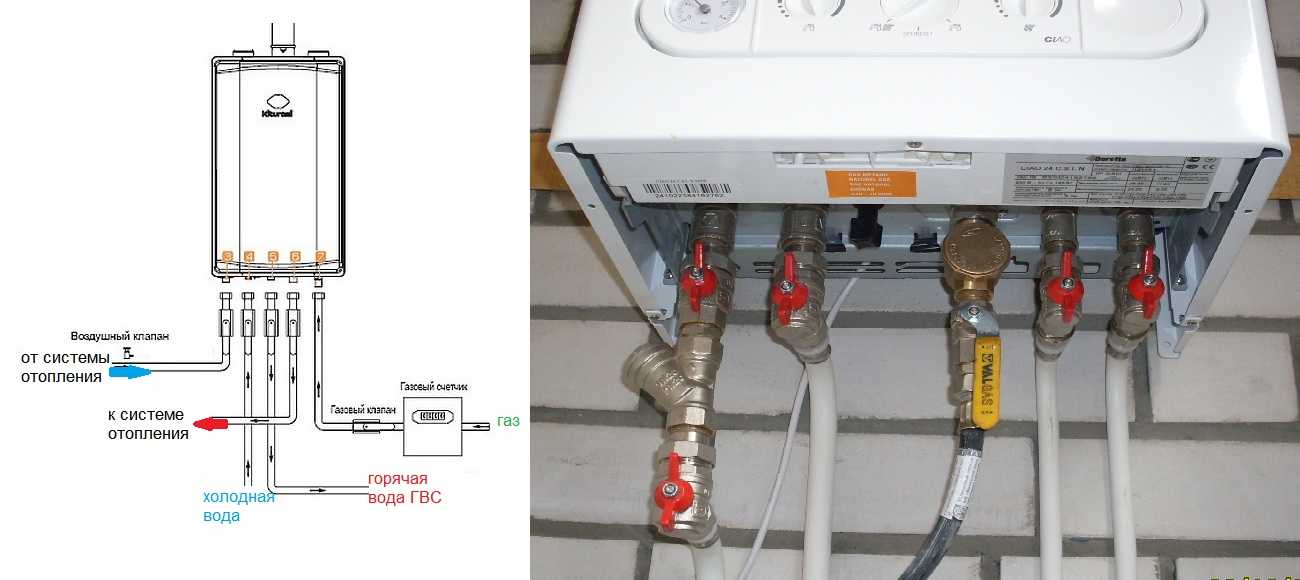

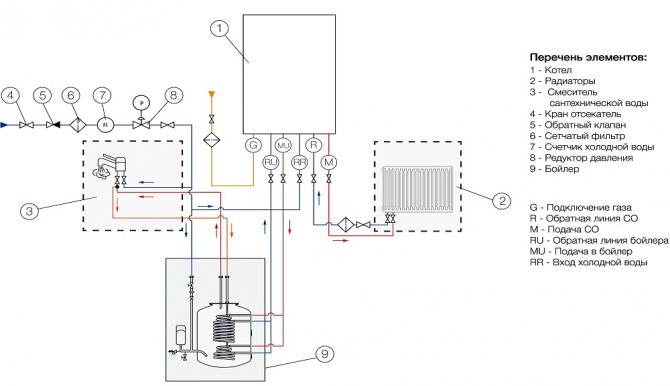

How to install a double-circuit gas boiler in a private house

- May 03/

- admin /

- popecham

Varieties of gas equipment A double-circuit gas heating boiler in a private house will become not only a guarantee of heat supply, but also the use of hot water. There are two main types of this equipment: a flow boiler and a boiler. The scheme of their functioning is based on the amount of hot water used.

The convenience of a double-circuit boiler lies in the rapid heating of water. For example, in a minute such a boiler heats up 6 liters of water up to 37 degrees.

Installation of a flow gas boiler is carried out when the flow rate of water heated to 30ºС does not exceed 15 l / min. The boiler, equipped with a built-in boiler, provides a constant supply of hot water in the amount of at least 50 liters.

Heating system.

Depending on the method of removing the burning gas, a double-circuit boiler can be:

- chimney (output of combustion products into the chimney);

- condensation (removal of condensate into a sealed chimney);

- turbocharged (a fan is used in the chimney).

There is also a division of boilers into floor and wall products. Many people prefer the latter. Firstly, the use of a wall-mounted gas boiler is considered more convenient both in a private house and in an apartment. It can be connected to thermostats. Secondly, the boiler is equipped with all elements of the heating system:

- expansion tank;

- firebox;

- air circulation pump;

- protective fittings;

- electronic control unit.

The main advantages of using a wall-mounted heating boiler are:

- economy of fuel consumption;

- ease of installation (due to low weight and compactness) and maintenance;

- silent operation (achieved by the hydraulic system);

- the ability to connect to other external devices;

- installation anywhere at home or outside.

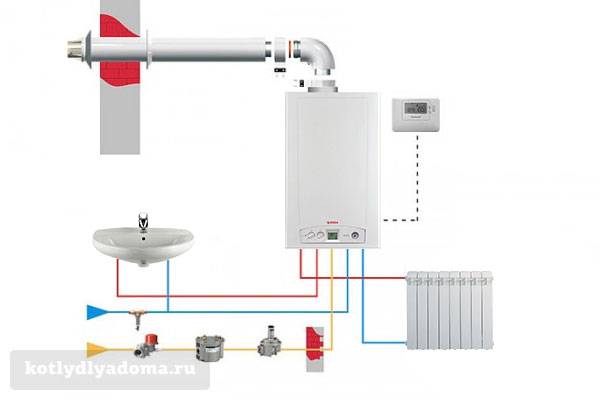

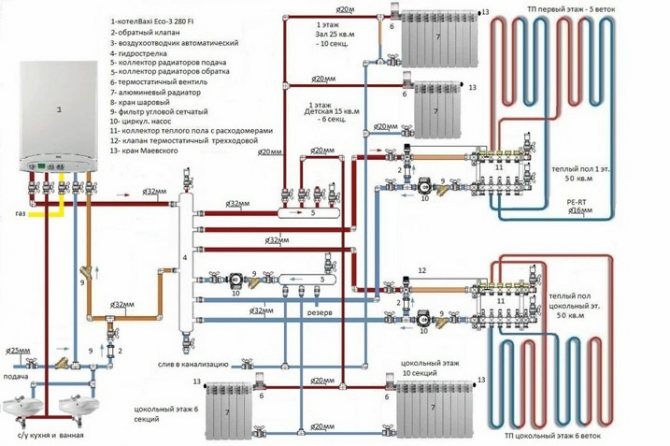

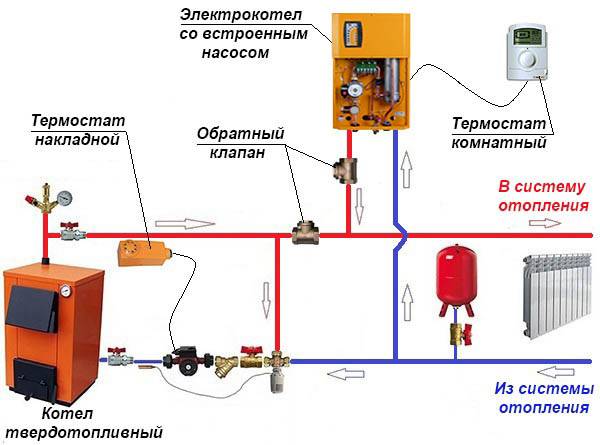

Parallel operation of boilers on wood and gas

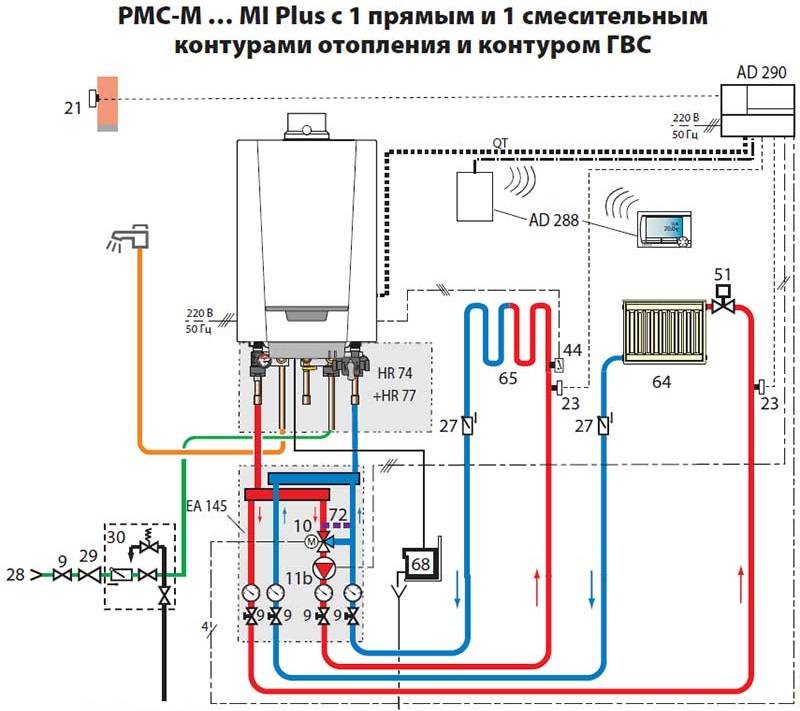

This option of heating the house from two boilers provides for their separate connection to the circulation system. Each heat source must have its own circulation pump at the return inlet. For a wall-mounted gas boiler, this is not necessary, the pump is already installed in it by the manufacturer. In the event of a burnout of solid fuel, the temperature of the coolant will decrease and the gas boiler will automatically turn on.

An important design point is the binding of a solid fuel boiler with metal pipes and the presence of an emergency discharge device with the simultaneous supply of cold water to the return line.

1 scheme (open and closed systems)

This method is convenient because the liquids of the two systems do not mix. This allows you to use different coolants.

Advantages and disadvantages

| pros | Minuses |

| Possibility to use different coolants | A large number of additional equipment |

| Safe operation, the reserve tank will dump excess water in case of boiling | Efficiency is lower due to excess water in the system |

| Can be used without additional automation |

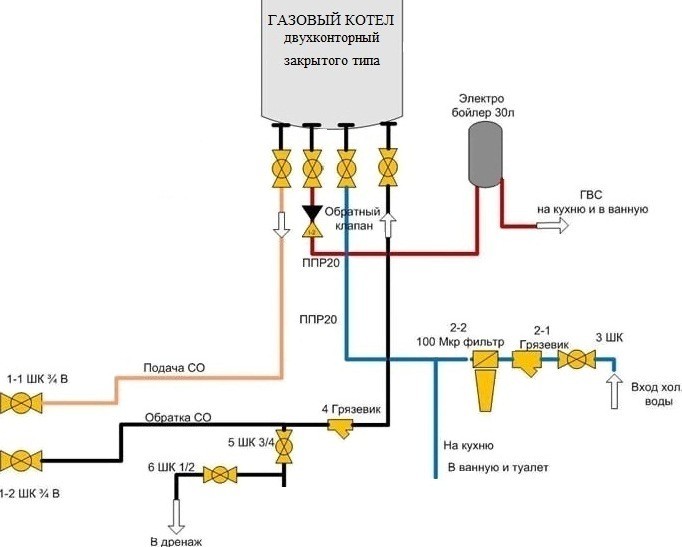

2 scheme, two closed systems

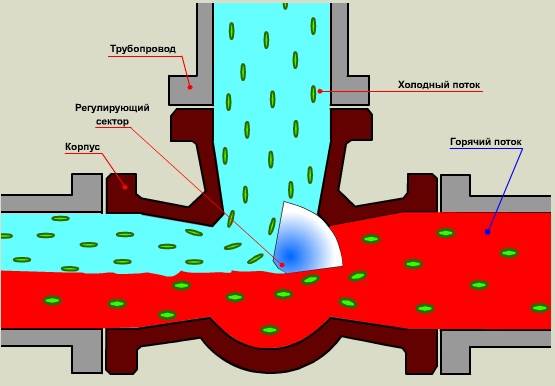

It uses a closed system, which eliminates the need for a heat accumulator. The control is carried out by thermostats and three-way sensors. Operational safety is ensured by automation.

Here we use the battery for excess heat. Thus, we increase the efficiency of the system and eliminate the need for temperature sensors and automation.

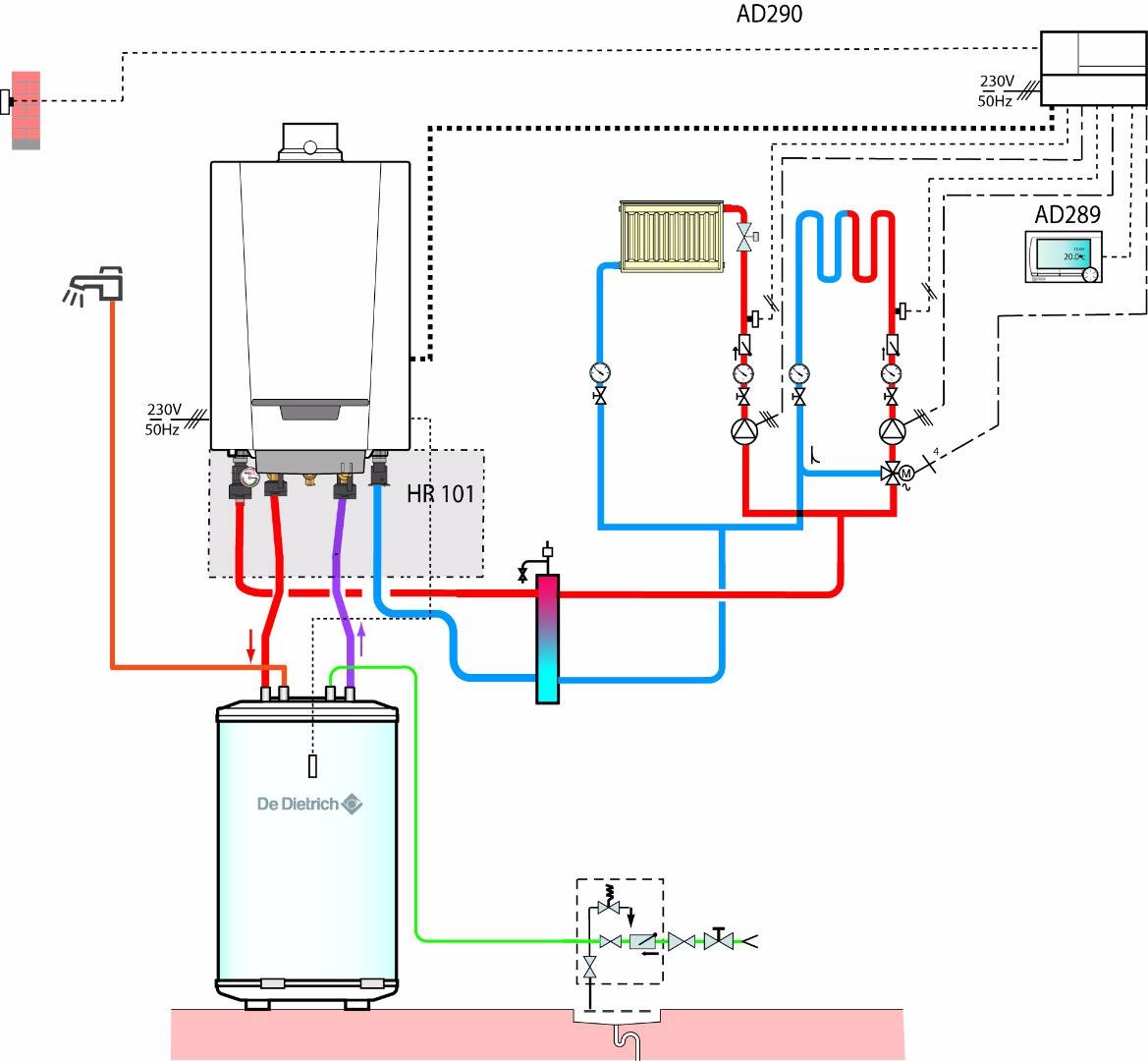

Heat supply through 3-way valve

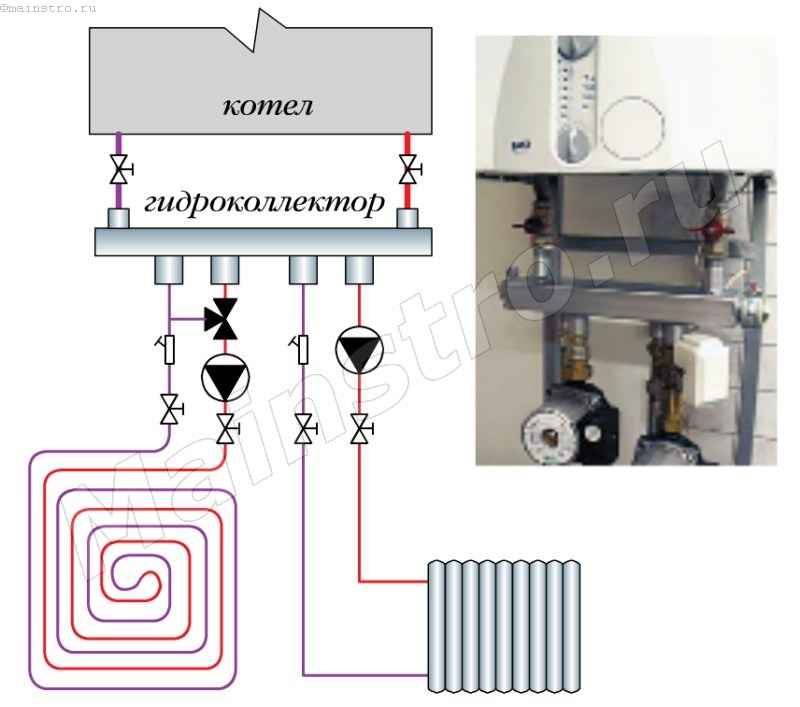

Each boiler must be equipped with its own circulation pump, and another pump will be required to circulate through the heating system appliances. An automatic air vent must be installed at the top of the hydraulic separator, and an emergency drain valve at the bottom.

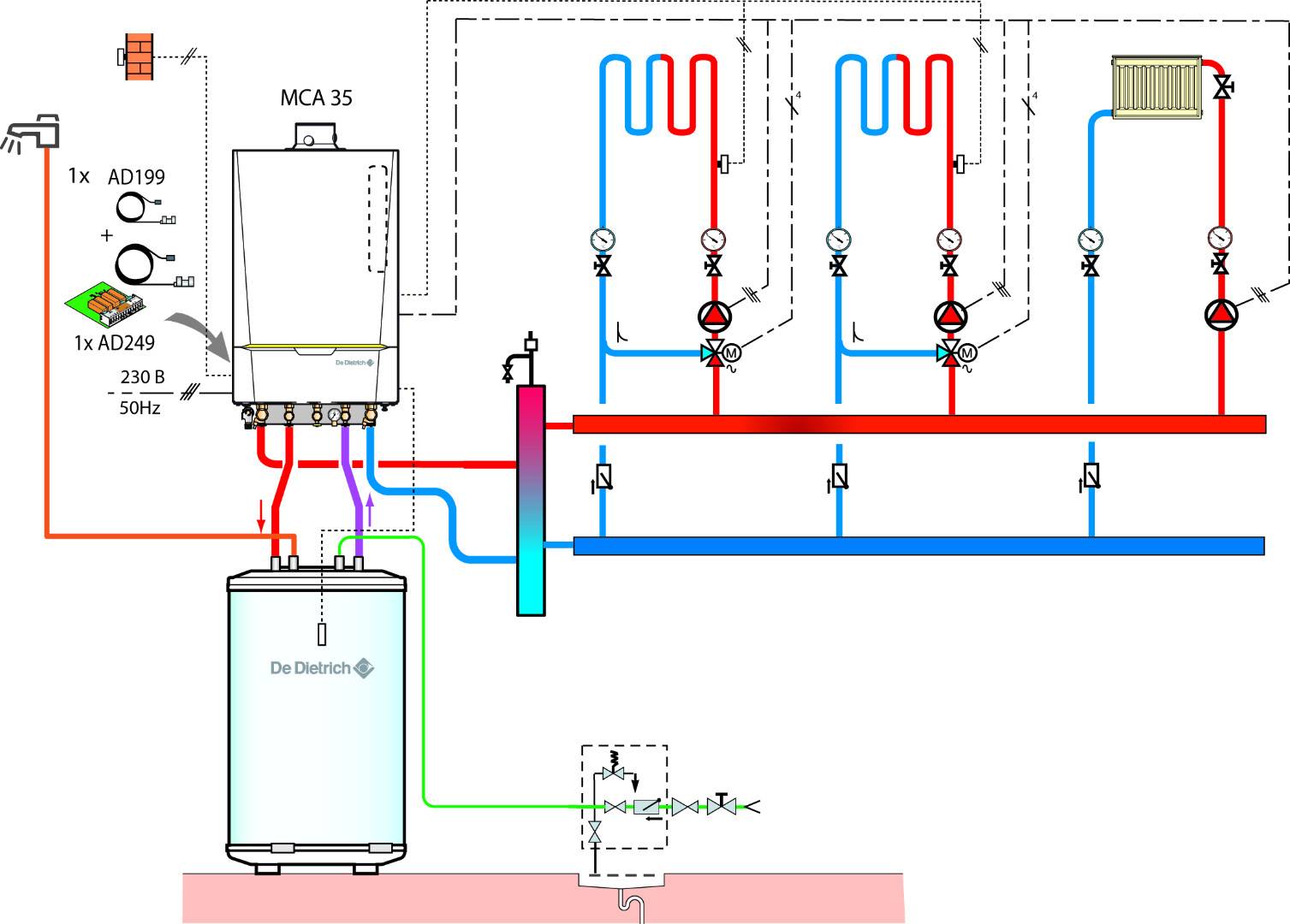

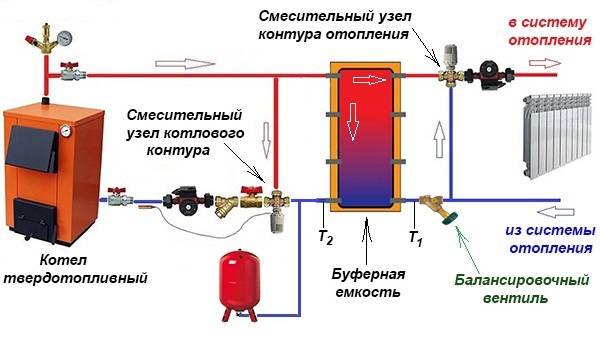

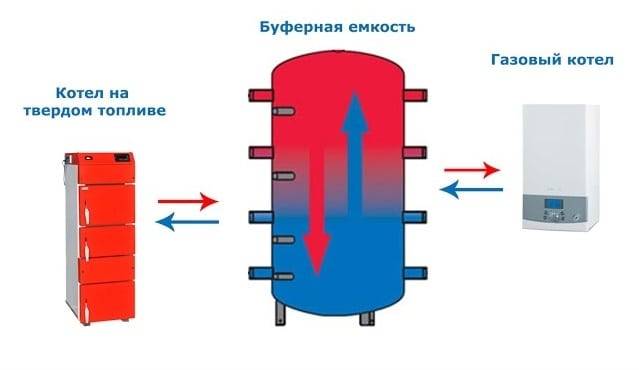

System with a heat accumulator, why is it

The heat generated wood-fired boilerenters this container. From not, through a coil, a heat exchanger or without them, into a gas boiler. The automation of the second understands that the water has the required temperature and turns off the gas. This will be so long as there is enough temperature in the heat accumulator.

A heat accumulator or a heat-insulated container with a built-in coil, designed to accumulate heated coolant and supply it to the heating system.In this scheme, the gas boiler, heaters and battery are connected by pipelines into one closed-type system. Solid fuel boiler connected to the built-in battery coil and thus heats the coolant in a closed system. The organization of the heating work in this scheme occurs in the following order:

- firewood burns in a solid fuel boiler, and the coolant is heated from the coil in the tank;

- solid fuel burned out, the coolant cooled down;

- the gas boiler turns on automatically;

- firewood is laid again, and a solid fuel boiler is ignited;

- the temperature of the water in the accumulator rises to that which is set on the gas boiler, which stops automatically.

This scheme requires the highest costs for the purchase of materials and equipment, but it has a number of advantages:

- a solid fuel boiler can operate in an open circuit;

- the highest level of security;

- no need for constant replenishment of the firebox with wood or coal;

- coolant circulation through a closed-type system;

- the possibility of simultaneous operation of two boilers simultaneously and each separately.

Among the additional costs, it is necessary to take into account the purchase of an accumulator tank with a coil, two expansion tanks and an additional circulation pump.

calculate the required capacity

Main types

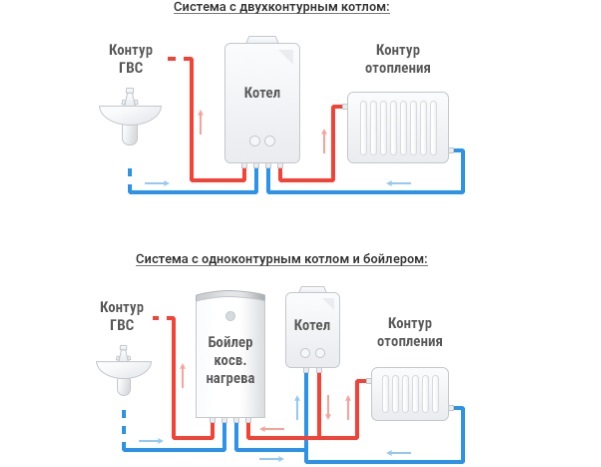

Gas boilers are classified according to various criteria: purpose, power output, type of thrust and installation method. Single-circuit boilers are installed exclusively for heating the house, double-circuit boilers allow not only to warm the premises, but also to provide the house with water with the possibility of heating it.

Low-power boilers are regulated according to a single-stage principle, units of medium productivity - according to a two-stage principle. In high-performance boilers, modulated power control is usually provided.

Boilers of closed type operate on ventilation draft. There are also gas boilers with natural draft - open type, or atmospheric.

Installation of gas boilers in a private house is carried out either by mounting on a wall or on the floor. In the first case, copper heat exchangers are used, and in the second, cast iron or steel.

The optimal solution for use in a private house is considered to be a flow-through double-circuit boiler with a boiler operating on automation. It provides space heating in the cold season and water heating for cooking, washing dishes, taking a shower.

The automatic system, which includes a double thermostat and a microprocessor, greatly simplifies the process of adjusting the equipment, allows you to monitor the temperature in rooms and on the street, set a program to reduce heating to a minimum if there are no people in the house (for example, in the daytime, when everyone has gone to job).

Installing a fully automatic boiler will save you 30% to 70% fuel compared to manual or semi-automatic boilers.

At the same time, in the absence of electricity, an automatic home boiler room will not be able to provide full-fledged heating of the house, therefore, when installing the boiler, force majeure situations must also be foreseen.

When buying a gas boiler, be sure to check the availability of a certificate and equipment. If necessary, additionally purchase fasteners for mounting the unit on the wall.

How to make heating with two boilers

Creating a circuit for two heating boilers is associated with an obvious decision to maximize the functionality of diverse types of heating systems for a private house. To date, several connection options are offered:

- gas boiler and electric;

- solid fuel and electricity boiler;

- solid fuel boiler and gas.

Before proceeding with the selection and installation of a new heating system, we recommend that you familiarize yourself with the brief characteristics of the operation of joint boilers.

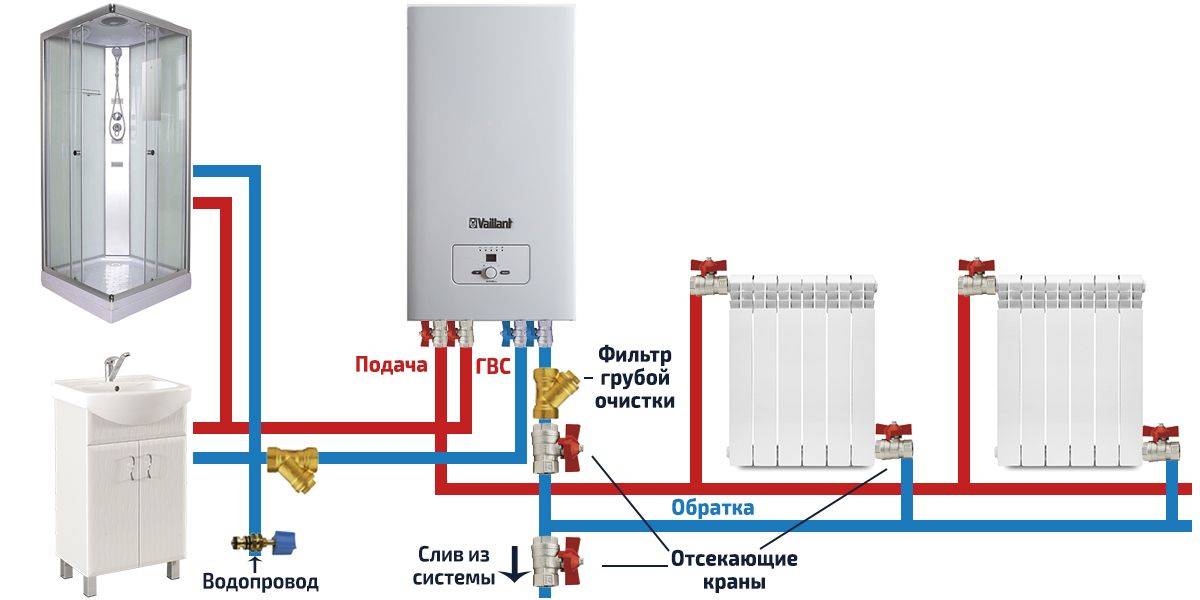

Connection of electric and gas boilers

One of the easiest heating systems to operate involves combining a gas boiler with an electric one. There are two connection options: parallel and serial, but parallel is considered preferable, since it is possible to repair one of the boilers, replace and shutdown, and also leave only one to work in the minimum mode.

Such a connection can be completely closed, and ordinary water or ethylene glycol can be used as a coolant for heating systems.

Connection of gas and solid fuel boilers

The most technically difficult option, as it requires careful preparation of the ventilation system and premises for overall and fire hazardous installations. Before installation, read the installation rules separately for gas and solid fuel boilers, choosing the best option.In addition, the heating of the coolant is difficult to control in a solid fuel boiler, and an open system is required to compensate for overheating, in which the excess pressure is reduced in the expansion tank.

Important: a closed system when connecting gas and solid fuel boilers is prohibited and is considered a serious violation of fire safety. Optimum performance of two boilers can be achieved using a multi-circuit heating system, which consists of two circuits independent of each other. Optimum performance of two boilers can be achieved using a multi-circuit heating system, which consists of two circuits independent of each other

Optimum performance of two boilers can be achieved using a multi-circuit heating system, which consists of two circuits independent of each other.

Connecting a solid fuel and electric boiler

Before connecting, evaluate the technical characteristics of the selected electric boiler and read the instructions. Manufacturers produce models for open and closed heating systems. In the first case, the best option is to focus on the operation of two boilers on a common heat exchanger; in the second, it can be easily connected to an already operating open circuit.

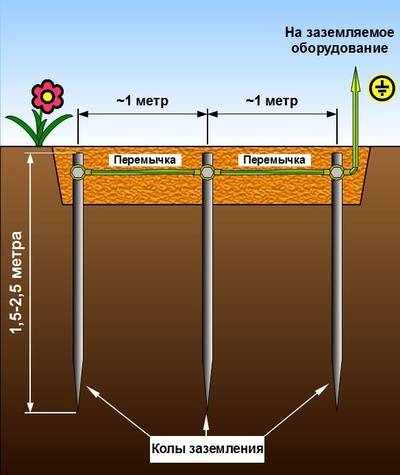

5 Gas connection

It is recommended to use steel pipes to connect the boiler to the central gas pipeline. Connection is made with a pipe. To ensure the necessary tightness, threaded connections are sealed with tow and covered with paint.

A filter is installed on the valve that shuts off the gas, which protects against the ingress of small debris and condensate.Further, the gas pipeline is connected to the filter using a flexible connection or pipe. Do not use a rubber hose, as over time it cracks and gas seeps through the cracks. Corrugated hose is the best choice for flexible connection. It is made of stainless steel, strong, durable, resistant to high humidity.

At the last stage, the connection to the central gas line is made using a union nut with a paronite seal. Tightness is determined using a soapy solution, which is applied to the joints. A sign of a gas leak is the presence of bubbles. The correct connection of the gas system is checked by a representative of the gas service.

Before the first start-up of the heating system, water is pumped into it. The procedure should be carried out slowly so that the existing air comes out of the pipes. Filling ends when the liquid pressure in the line reaches two atmospheres. At the same time, the tightness of the water supply is checked, all leaks are immediately eliminated. Found faults are eliminated and the system performance is checked. The first start-up must be supervised by a gas service representative.

Electric and diesel heat generators

Connecting a diesel fuel boiler to a radiator system is identical to piping gas-using installations. Reason: the diesel unit operates on a similar principle - an electronically controlled burner heats the heat exchanger with a flame, maintaining the set temperature of the coolant.

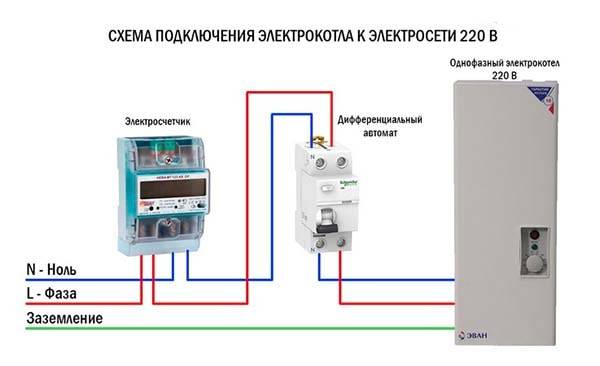

Electric boilers, in which water is heated by heating elements, an induction core, or due to the electrolysis of salts, are also connected directly to heating.For maintaining the temperature and safety, the automation is located in the electrical cabinet, connected to the network according to the above wiring diagram. Other connection options are shown in a separate publication on the installation of electric heating boilers.

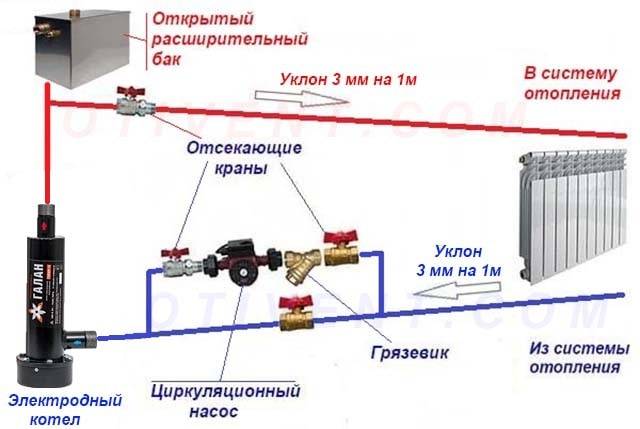

Wall-mounted mini-boilers equipped with tubular heaters are intended only for closed heating systems. To work with gravity wiring, you will need an electrode or induction unit, which is tied according to the standard scheme:

If you figure it out, then the bypass is not needed here - the boiler will not work without electricity either.

One-pipe scheme with Leningrad

Dividing the gravity scheme is a difficult task. If the boiler is used in a private house, an apartment with one floor, the number of radiators not exceeding 5-6 (the exact value depends on the power of the boiler), it is realistic to provide a single-pipe Leningrad.

The scheme, called the Leningrad one, is an installation method when the highway is located at floor level, exactly on the surface. Batteries are inserted with a bottom connection.

Positioned horizontally. The only vertical element of the circuit is the accelerating riser. It is withdrawn from the boiler, bent, connected to the tank.

Installation of a horizontal pipeline for a natural cycle is carried out at an angle. The angle rarely exceeds 30 degrees.

Leningrad wiring in one pipe works in small rooms.

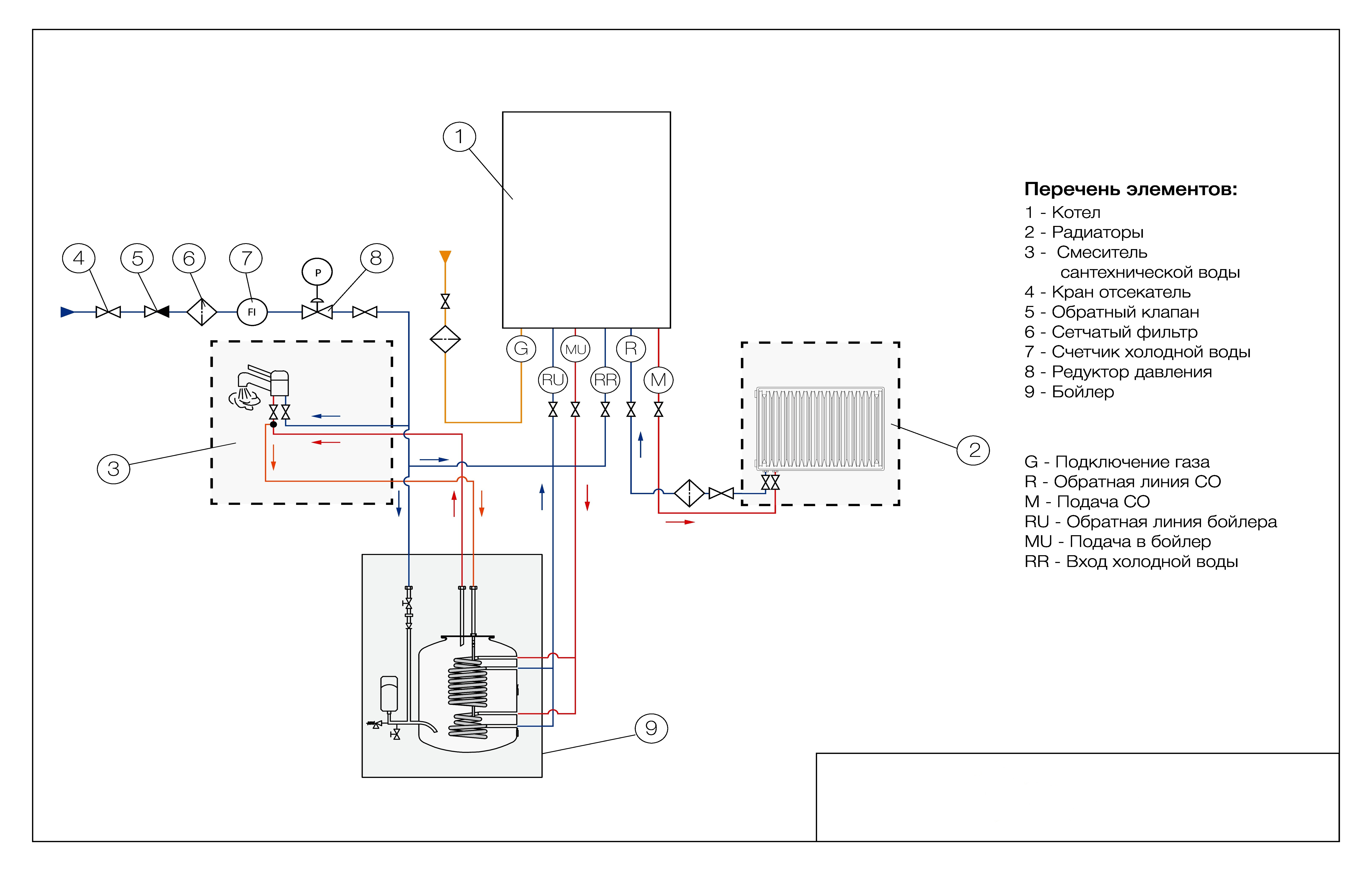

How to connect a device for a boiler with two circuits

The boiler is selected, having decided on its type, location and volume relative to the power of the water heater. In indirect and combined type drives, it is recommended to provide additional protection against scale inside the coil.

Attention! It is forbidden to connect the boiler until the boiler is put into operation by the gas service

Wiring diagram

The connection diagram depends on the type of tank:

Direct heating device

The inlet pipe of the storage tank is connected to the cold water inlet. Outlet branch pipe - to the entrance to the second circuit of the boiler.

Cold water enters directly into the boiler, where it heats up to 60 ° C under the influence of a heating element.

From the boiler, the liquid is sent to the boiler, losing several degrees of temperature along the way. Passing through the second heat exchanger of the heating device, water restores losses and goes to the DHW system through the boiler outlet valve.

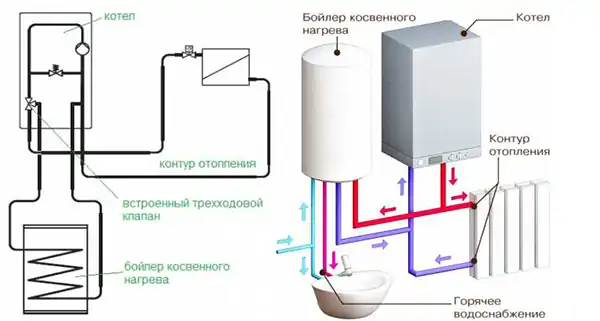

Indirect and combined heating

They have two additional branch pipes from coils. They are connected to the first circuit of the boiler. The scheme of work assumes that the heated coolant of the heating system will first pass through the storage coil, and only then go to the radiators.

Due to this, the main heating gradient of tap water is provided by a coil. Cold water is introduced directly into the accumulator, the heated liquid is discharged to the boiler's DHW circuit.

When clocking, that is, periodically turning the burner on and off by the automation of the boiler operating with an indirect heating boiler, it is recommended to change the tank connection scheme. Boiler clocking indicates that the water in the storage tank does not warm up to the required 60 °C.

The pipes of the DHW circuit of the water heater are muffled, the water from the boiler is immediately sent to consumers.The rate of heating of the liquid depends solely on the power of the heating system; it is impossible to operate this scheme in the summer.

Photo 3. Wiring diagram for an indirect water heating boiler for a double-circuit gas boiler.

Materials and tools

The internal elements of boilers are made of copper, steel or cast iron. Heating elements and coils are made of copper or steel. The steel walls of the tank are subject to corrosion, the service life does not exceed 15 years. Cast iron walls are twice as massive and more expensive, but they work properly for up to 90 years.

When installing a boiler, detachable pipe connections are provided. For this you need:

- tape measure, pencil, chalk;

- puncher with a set of drills (for making holes for the pipeline, wall mounting elements);

- adjustable and wrenches (models with ratchet are recommended);

- Screwdriver Set;

- pliers;

- wire cutters;

- means for sealing joints (flax, FUM tape, plumbing thread);

- sealants;

- shutoff valves, tees;

- fitting;

- pipes.

If it is not possible to arrange detachable connections, polypropylene pipes are used, which are welded on site.

Step-by-step installation and quality control

All work is carried out with the equipment turned off and the liquid removed from the system.

- Marking fasteners with a pencil or chalk. Drilling mounting holes.

- Checking the bearing capacity of the wall. Actual for hinged models. The fasteners supplied with the drive are installed on the wall, loaded with bags of cement or sand at the rate of a double supply.

If the wall material can withstand a load of 100 kg, then you can hang a boiler with a volume of up to 50 liters without fear.

- Placing the container on the wall or on the floor.

- Plumbing connection.

- Installation of overpressure valves along the water course.

- Installing an expansion tank.

- Filling with water and checking the tightness of the connections. If the system filled with water did not leak during an hour of inactivity, then the tightness of the joints is satisfactory.

- Turning on the equipment to the network, checking the operation.

What documents must be prepared and who issues them

After the project is completed, it will be necessary to obtain approvals from the gas service and utilities.

First you need to decide on the documentation. Source

Document preparation process:

- Obtaining technical conditions (TU). You need to go to the local gas workers. To file an application, you need the hourly fuel consumption of the boiler, which is determined by the design decision. Technical specifications are issued in 1-2 weeks.

- According to the specifications, they carry out a project for the installation of gas equipment, usually it is included in the "Gas facilities" section of the general project for the boiler.

- The developed project is submitted for approval to the gas distribution company that issued the specifications.

At the same time, the technical passport of the boiler unit, factory instructions, certificates and examination of the compliance of the boiler with state standards are submitted to the same organization with the application.

Coordination can take place within 10 days and up to 3 months, everything will depend on the complexity of the material. In case of refusal, the inspection must issue a list of corrections to eliminate the deficiencies.

If all the amendments are made, the project is stamped and the installation of the boiler can begin. Unauthorized connection to the gas main entails the imposition of huge penalties on the owner of the boiler.