- The dangers of ignoring repairs

- List of some repairs

- Folk remedies and preventive measures

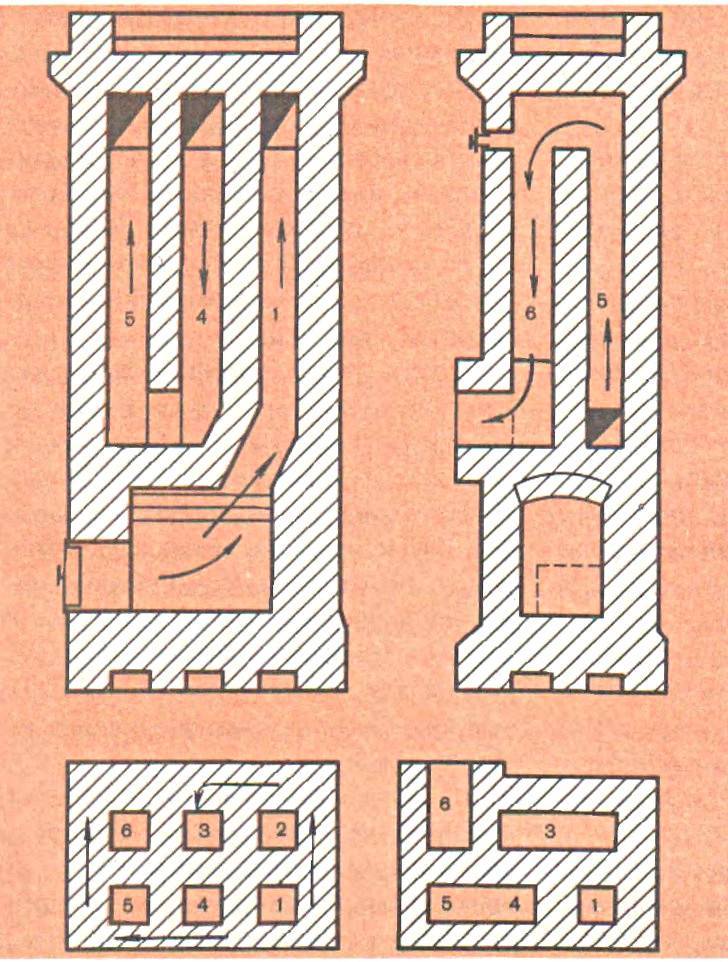

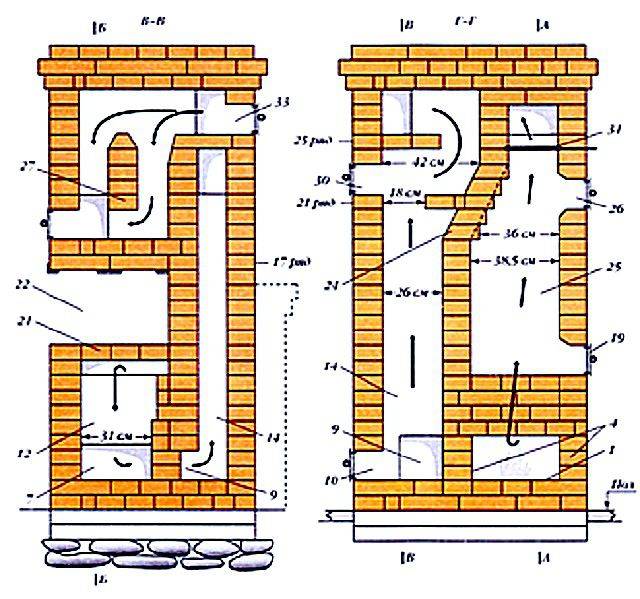

- Types of furnace repair

- Furnace repair with lining

- Chamotte mortar - the best way out

- Chimney cleaning methods, tools and fixtures

- Mechanical cleaning method

- Chemical cleaning method

- Folk methods for cleaning chimneys

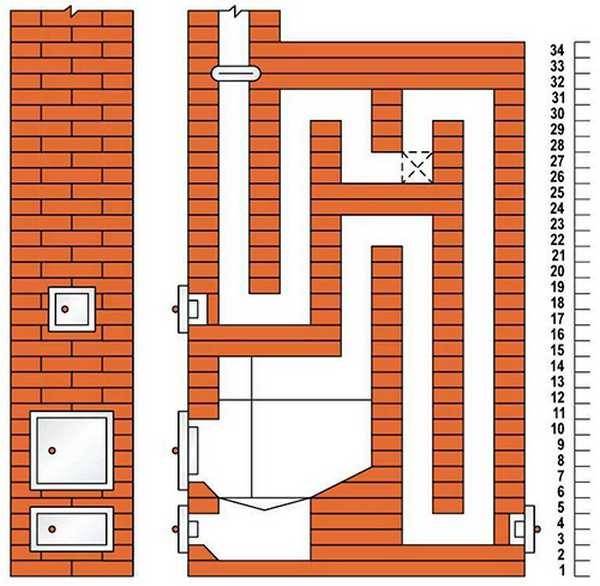

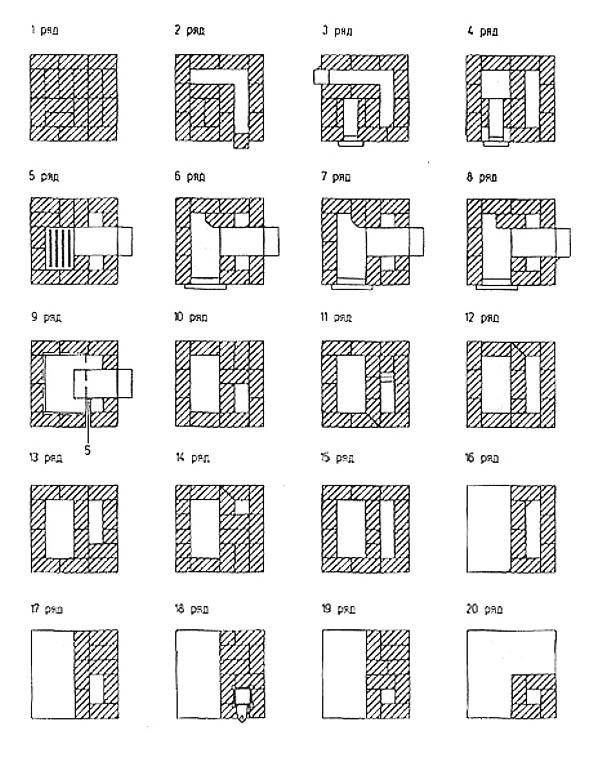

- Do-it-yourself brick oven repair

- Replacing the pre-furnace sheet

- Types of furnace malfunctions. minor damage

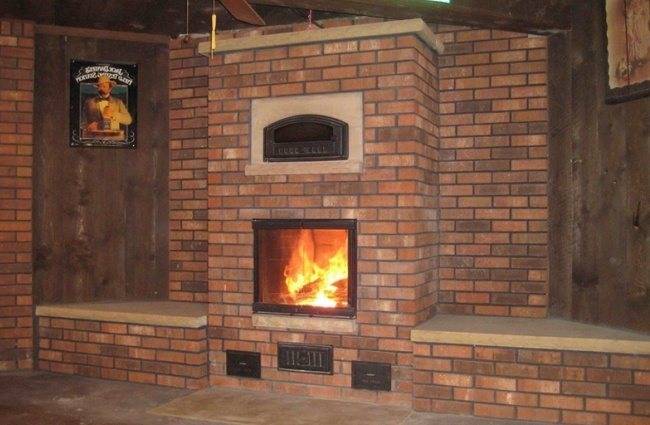

- Repair of fireplaces and brick ovens

- How to repair a pipe and a chimney?

- How to replace bricks?

- Replacement and repair of tiles

- What's the best way to close gaps?

- Replacing the pre-furnace sheet

- Regular oven repairs

- Causes of furnace failure

- The composition of clay mortars for laying furnaces

- Table 2: COMPOSITION OF CLAY SOLUTIONS (in parts by volume).

- How to close the cracks in the oven

The dangers of ignoring repairs

A malfunction of the oven not only reduces the efficiency of the work process, but also increases the danger of using it. Heating equipment without proper repair can cause a fire in the house and harm the health of residents. In case of carbon monoxide poisoning, which is able to penetrate through cracks in brickwork, a lethal outcome is not ruled out.

A small breakdown in the furnace structure eventually leads to the destruction of the entire structure.To avoid irreparable consequences, you should regularly inspect the heating equipment and monitor its working process. Timely repair of a brick oven is the key to its long, efficient and safe operation.

List of some repairs

So, you have decided to repair the fireplace yourself. What prompted this decision? Usually, there are two main reasons, which are the disappearance of traction and the appearance of cracks on the walls of the fireplace.

Furnace restoration

- Small cracks can be filled with gypsum mortar. If a crack has formed not only in the finish, but also in the brick itself, then a specially prepared clay mortar will come to the rescue. Clay, sand and cement are mixed in a ratio of 3:8:1. Having brought the mixture to the desired consistency, we will prepare the surface. The place where the crack has formed must be deepened. Then, with a damp cloth, you will have to remove dust and crumbs so that the solution sticks better. A tourniquet molded from the finished solution closes up the resulting space.

- The cause of weak traction is usually a fallen brick. We have two tasks: to remove the fragments of the old brick and install a new one in its place. The success of this work depends on the foresight of the stove-maker who laid the pipe. Anticipating that sooner or later the chimney will have to be cleaned, experienced craftsmen advise making several cleaning doors along the length of the channel. If this is not possible, then secret hatches are left, which are covered with bricks without mortar. To make it easier to find them later, the bricks are not laid along the plane of the wall, but are given out a few millimeters ahead. After that, the chimney is finished with plaster.During the cleaning, you should find the protrusions and beat off the plaster, and the desired brick will be removed with ease. The hatch for access to the chimney is ready.

Over time, any fireplace, any stove outwardly change. Cobwebs of cracks appear, rows of masonry are displaced relative to each other. The metal walls of the hearth burn through, and condensate in the pipe has long provoked the development of rust.

The fireplace system is ready to work again

The master will replace the nodal metal parts of the firebox, strengthen the structure with ties, which will be masked with a layer of new plaster. With this approach, it will be useful to refresh the exterior with new materials.

Good to know: How to make a small fireplace with your own hands, step by step instructions

If the fireplace initially did not work correctly, the flame was constantly extinguished during ignition, and at any stage the smoke penetrated the room, then you need to analyze the design. In this matter, only the master will certainly say whether it is cost-effective to repair the fireplace or it is more profitable to break it and build a new one, in which all the shortcomings will obviously be eliminated.

Folk remedies and preventive measures

If the chimney is laid out correctly and the fuel used is dry and of good quality, soot will not accumulate on the walls, so you will not need to think about how to clean the soot from the stove, or you will rarely need to do this. A lot of soot is formed when household waste and garbage are burned, as well as coniferous firewood and raw wood.

There are several folk tricks on how to keep the chimney clean:

- Before mechanical removal of soot, it is recommended to burn a bucket of dry chopped potatoes or peelings. The released starch will soften the layer of soot.

- The addition of salt to the fuel prevents the accumulation of soot on the walls.In addition, salt gives a beautiful flame.

- Dry aspen firewood is considered the best way to clean the chimney from soot. The high combustion temperature and the special gas help push deposits out and evacuate them from the chimney.

You can understand that the chimney of the furnace needs to be cleaned by the color of the smoke coming out - it acquires a darker shade and becomes denser. At the same time, when the chimney clearance narrows, the color of the flame in the furnace becomes dark orange. If you notice any of these signs, you should immediately clean your chimney to avoid fire or carbon monoxide poisoning. If you don't want or can't do it on your own, hire a professional chimney sweep or stove maker.

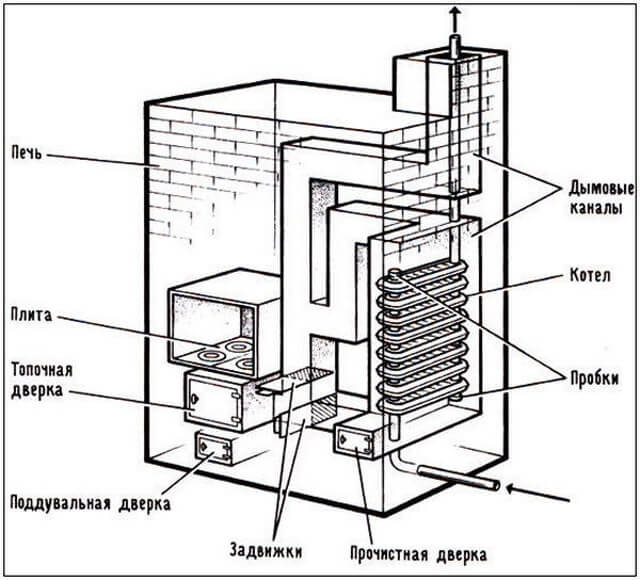

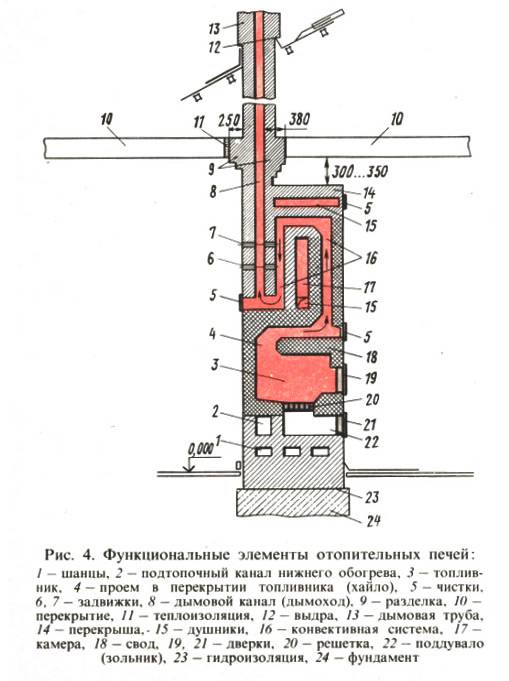

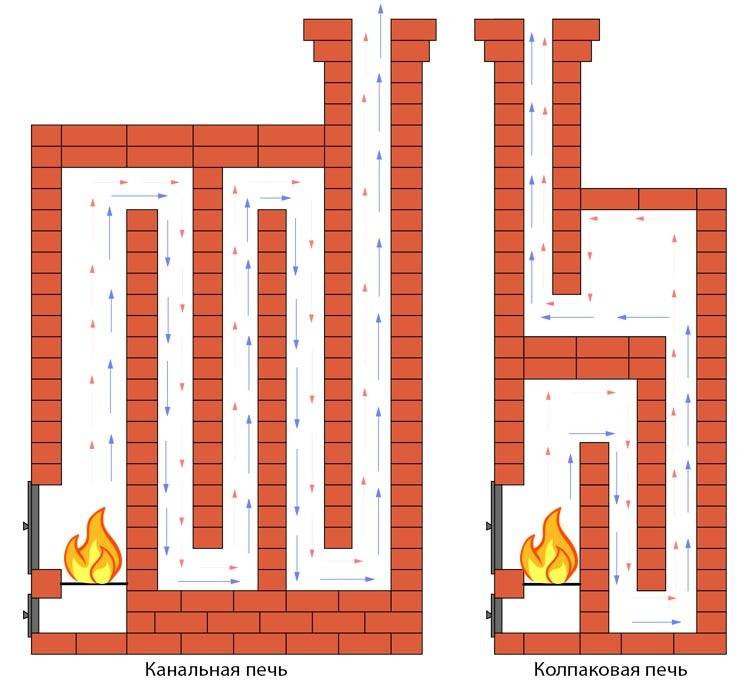

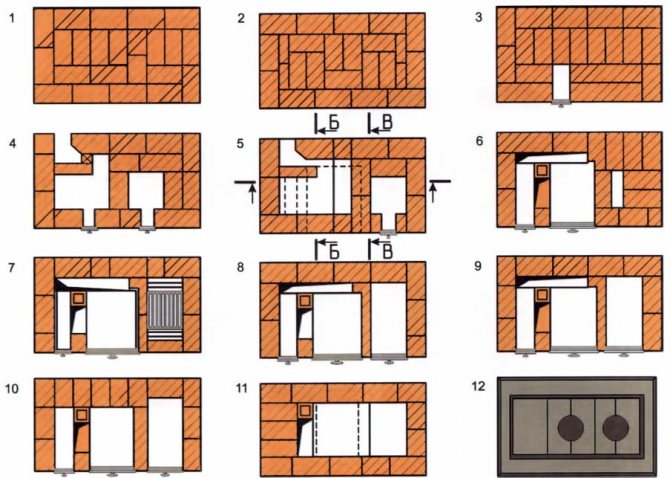

Types of furnace repair

Various repairs are being carried out to help eliminate the cause of the destruction. Today, such repairs can be divided into 3 broad categories:

- capital;

- partial;

- current.

The simplest is the current repair of the furnace, which consists in the fact that the structure is regularly inspected and cleaned. The furnace must be periodically cleaned of soot, fuel residues, and ash. If during the inspection chips, cracks, falling out bricks are found, then immediately you need to start repairing. The complex of works is simple, it does not require the presence of a professional stove-setter at all.

Table of compositions of mortars for laying the furnace.

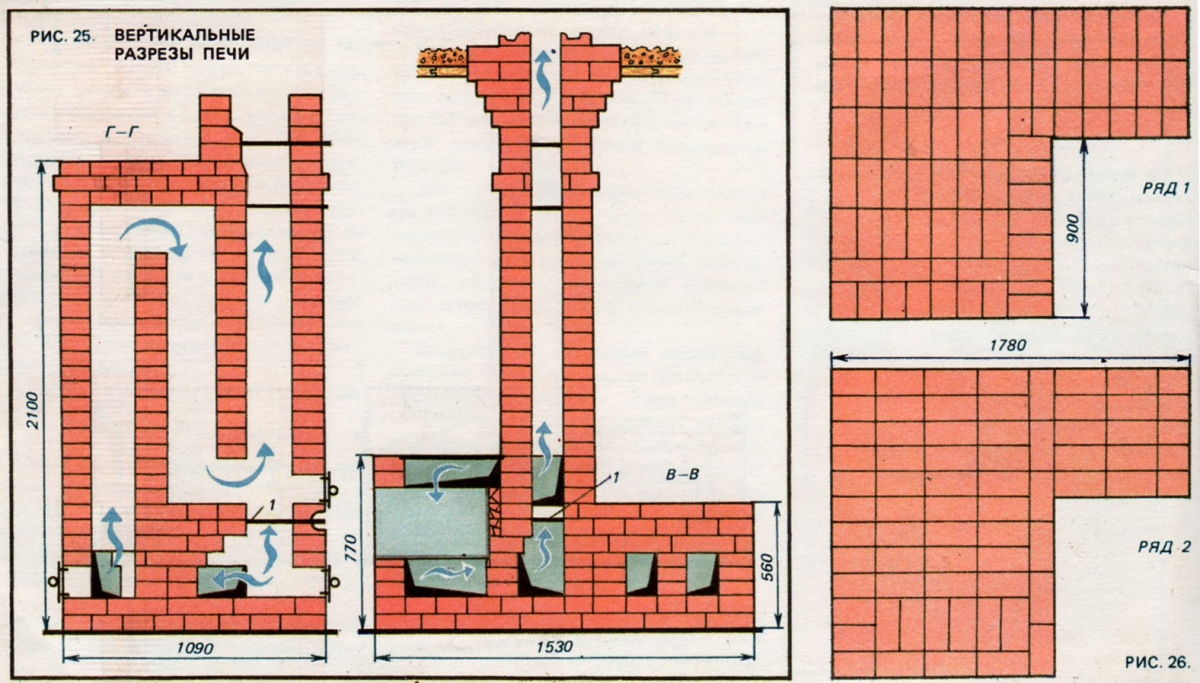

Partial repair is more complicated, it requires the replacement of any structural parts. It can be individual bricks, grates, cast-iron plates and much more. But such repairs are not always possible to do with your own hands.For example, to replace the damper, it is imperative to call a stove-maker, even if there is already little experience in servicing such structures. Partial repairs include chimney repair, channel cleaning, new firebox lining.

Major repairs are the most difficult and demanding. Be sure to invite a professional, as do it yourself fix the oven it is forbidden. In rare cases, the structure is already at the stage of destruction, requiring dismantling and reconstruction of its individual parts. To prevent this from happening, it is necessary to trust the installation of fireplaces and stoves only to experienced specialists, and during operation, follow all recommendations exactly. This is especially true for those stoves that are designed for heating, heating water. With the decorative repair of fireplaces, everything is much simpler, it rarely causes problems.

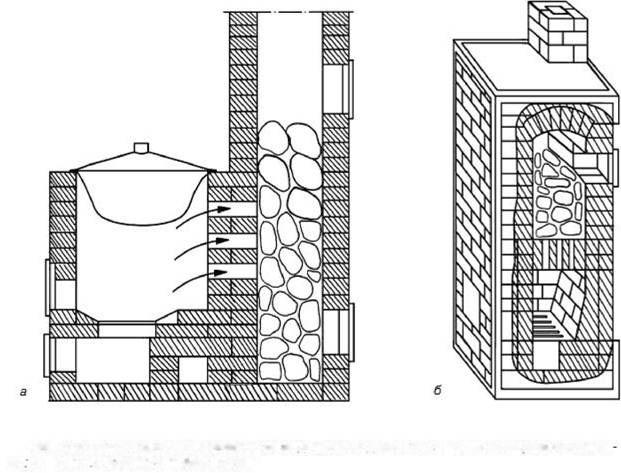

Furnace repair with lining

Modern summer residents, keeping up with the times, often install an autonomous water heating system in their homes and use old stove structures for this. Most often this happens when a centralized gas supply is carried out near the house. And it would, of course, be a sin not to take advantage of this circumstance. But at the same time, I want to keep the old stove. Therefore, gas burners and heat exchangers are installed in them.

With gas heating, problems with cleaning stoves and chimneys disappear, but the repair of brick stoves remains an urgent issue. Indeed, under the influence of a gas flame, the bricks are still subject to thermal expansion, as in the case of firewood, respectively, gaps appear that require timely sealing.Those methods that are described above help to get rid of them for a short time, but over time they appear again, and everything needs to be repeated all over again.

Chamotte mortar - the best way out

Mortar packaging

Fireclay bricks and fireclay clay are the best materials for those structures that are exposed to high temperatures, and fireclay mortar is no exception. It is suitable not only for the repair of household furnaces, but also for the construction of muffle or steel furnaces as an internal coating and an additive to masonry mortar.

This is a ready-made mixture, which can be purchased at stores selling sauna stoves and other building supermarkets. All operations for preparing the surface of the furnace are similar to those described above. The solution is prepared according to the instructions placed on the packaging with the material.

The surface of the furnace is moistened with water, after which a layer of fireclay mortar is applied with a conventional brush or spatula. After one layer, you can apply a second, but much thinner than the first. After everything is dry, you can fire up the oven and watch how the mixture becomes stone-like. After a few days, small cracks may appear. In this case, we dilute the fireclay mortar again and cover the problem areas with a thin layer with a brush.

Chimney cleaning methods, tools and fixtures

There are several methods for cleaning the chimney pipe in private homes. All these methods, as a rule, do not cause difficulties for independent application.However, we do not advise you to clean the chimney yourself if you are not sure of your abilities, or the condition of the chimney leaves much to be desired due to wear and tear.

Mechanical cleaning method

The mechanical method is the most effective and time-tested method. Remember how in the old days they portrayed a chimney sweep? The main tool of his labor is a long stick with a brush at the end. In our time, no fundamental changes have occurred, except that the tools and devices are adapted to real conditions.

Cleaning is desirable to carry out in the warm season, in the absence of wind. Before directly cleaning the chimney, close all the openings of the stove in the room, so soot will not enter the room. An open hearth or fireplace is enough to completely cover with a wet rag. On the roof, be sure to secure yourself with a safety cable. Feet must be firmly supported.

Tool used for cleaning:

- Scraper, which is used if the soot layer is too thick.

- Metal ruff. They lower it into the pipe with the help of a cable, sometimes a weighting agent in the form of a core is attached from below. Such a device (total weight of at least 9 kg) passes through the entire pipe, cleaning off soot.

- Stiff bristle brushes with flexible holder. Used for square and rectangular pipes.

- Core or weight. Use if a blockage has formed due to accumulated debris or collapsed masonry.

It is also possible to clean the pipe from the inside of the room, if the design allows, and the entrance to the roof is difficult. Of the tools, a ruff on a flexible holder is used. The disadvantage of this method is that the soot falls down and it is necessary to protect the furniture and surfaces with a tarp.Professional chimney sweeps in such cases use a special "vacuum cleaner" to collect soot. Also, cleaning from the inside of the room is used in the presence of bends in the chimney.

If there are no special tools for cleaning in the arsenal, you can make them yourself. So, for example, you can make a full-fledged brush from an ordinary plastic bottle. The video provides detailed instructions:

Chemical cleaning method

It is used to prevent contamination of chimneys. Agree that it is better to use this method once or twice a year than to bring the state of the chimney to a deplorable state.

Chemical cleaning agents are a special powder or briquette, which when burning forms a specific gas that destroys carbon deposits. The soot accumulated in the chimney simply crumbles from the walls and is removed along with the ash. These methods are very effective for ceramic chimneys or pipes from stainless steel.

Chemistry can be divided into three groups:

- Paper bags with granulated substances of Czech production. Laid together with firewood. Remove dirt up to 2mm thick.

- Briquette in the form of a log. Can be used with firewood or burned separately. Softens soot and facilitates mechanical cleaning.

- Powder, analogue of the Czech cleaner, but Russian-made.

Chemical cleaning methods will be ineffective if the deposit is already too large and can only be removed mechanically. Therefore, as mentioned above, such funds are effective only as a preventive measure.

Folk methods for cleaning chimneys

If the pollution is not too great, then you can use one of the popular methods for cleaning the chimney.It will not be possible to remove old deposits, but as a preventive measure, these methods have proven themselves on the positive side.

- Salt. Once a week, add regular table salt (100-200g) to the firewood. It interacts with water in burning wood and releases an acid that binds soot and prevents it from settling on the walls. Do not use if you have a metal pipe as this will corrode it.

- Starch. When burning potato slices and their peels, starch is released, which decomposes soot, but "potato raw materials" must be burned at least a bucket at a time. You can also use other products containing starch (peas, beans).

- Alder, aspen or walnut shell. Aspen, alder or walnut shell firewood burns very hot. The high temperature simply burns the soot formed. With good draft, black flakes will fly out of the pipe, and then crumble into the furnace for several days. This method is effective, but can cause a fire.

Do-it-yourself brick oven repair

So we all know perfectly well that without exception, all brick ovens are not durable and will sooner or later require repair. Constant mechanical loads of temperature fluctuations gradually crumble the clay mortar from the seams near the stove doors, stoves, and ovens. The reason for this is the difference in the thermal expansion of brick and metal in the furnace. Over time, such chipping leads to the appearance of open slots that let smoke into the interior of the room. Of course, a competent stove-maker is able to save his stove from such problems even at the stage of laying a brick oven. But today we will consider the option of repairing brick ovens that have already fallen into disrepair with our own hands.

Let's start with the tavo that a thick ceramic heat-resistant sealant cord is laid around the oven doors. Its role in the furnace is to compensate for the expansion of the cast iron fittings. We also compact the cast iron plate. The old way of using asbestos materials must be eliminated due to their toxicity to human health.

In the absence of a ceramic cord, you can strengthen the solution with basalt wool or felt. Let us consider in more detail the repair of a brick oven using our example.

First, preheat the oven to medium temperature. Then, using an ax, remove the cast-iron plate.

As you can see from the picture inside, there is a lot of soot near the places where the slab was laid, the clay almost crumbled from the seams. It is necessary to completely clean the work surfaces from soot, rinse and prime with a 1: 1 mixture of water and heat-resistant adhesive. Next, we draw a heat-resistant cord and a repair mixture around the perimeter (sand + clay + 10% heat-resistant glue + 10% cement), it is unforgettable that basalt or felt can be used instead of a cord.

When repairing brick joints, we remove the remains of clay from the nick, we reliably wash the joint with a brush with water, and then prime it with a 50% solution of heat-resistant glue in water.

We continue to rub the seams with a repair mixture, leaving no voids in the seams of the brickwork.

If the gap is too large, we put a ceramic cord with a repair mixture into it. The elements of the furnace that need to be protected from contamination are covered with paint tape.

Such a cord must withstand open fire and a temperature of more than 1000 C. In Russia, they can often slip a fake instead of it, do not hesitate to check it when buying a match or lighter with an open fire.

The cord is laid around the perimeter of the landing of the cast-iron plate on drops of heat-resistant glue.

View of the furnace after repair. After a day, you can begin to slowly melt the oven, achieving a gradual drying of the solution. This repair in our case took 2 hours of working time, corrected the aesthetic appearance and smoke in the room.

We also recommend that you read the article:

Replacing the pre-furnace sheet

Sometimes, on fireproof metal sheets attached to the floor in front of the furnace, torn places form, causing certain inconvenience during cleaning. They also increase the risk of fire if the oven is located in a gazebo or similar structure with a wooden floor.

In this situation, you do not have to wait until the sheet is completely soaked, but you should tear it off and remove the nails from the floor. Then you need to put in its place a sheet of asbestos or felt soaked in a clay solution. Then lay a new sheet of roofing steel on top and attach it with nails.

Fire cuts (as a rule, these are metal sheets on the walls near the stove, although there is also a narrow brick strip).

In principle, the repair of these elements is similar to the pre-furnace sheets. Usually, cuttings fail due to settlement of structures, various mechanical shocks. The reason may be in the initially low-quality materials or installation. The thickness of the cut is determined by the dimensions of the furnace.

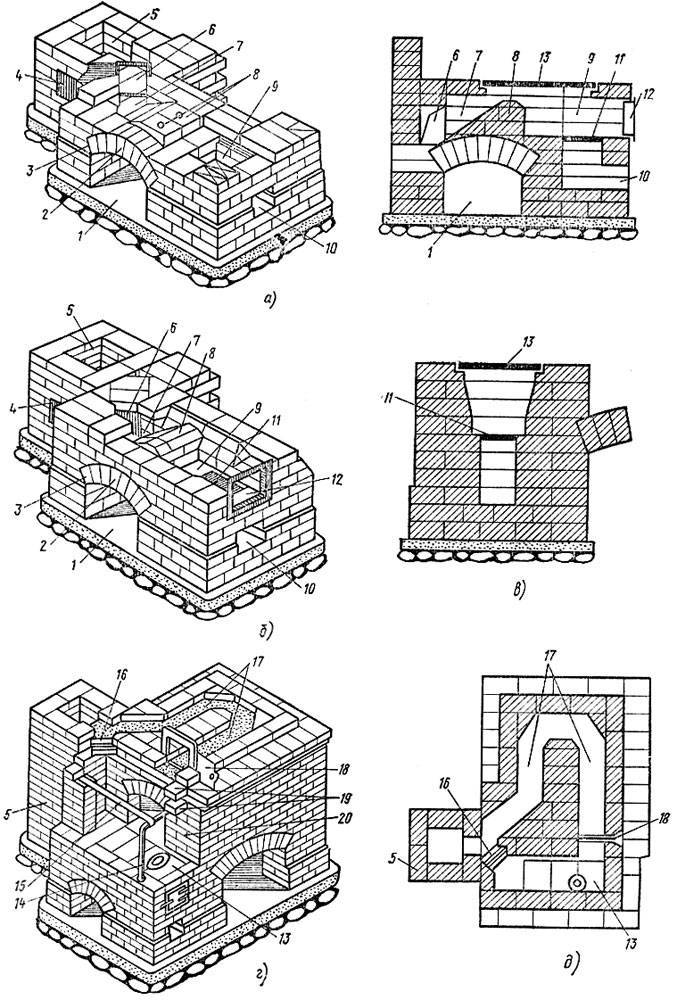

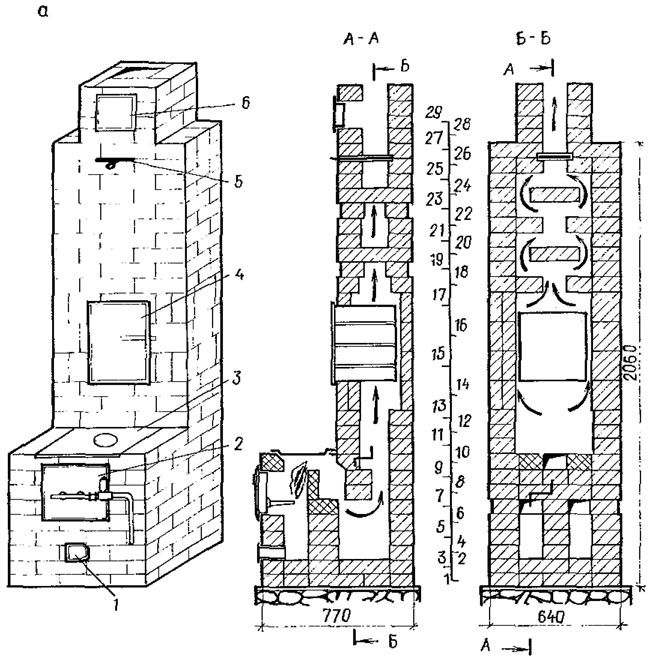

Types of furnace malfunctions. minor damage

Furnace repair can be conditionally divided into - small, medium and capital. So, minor repairs, despite the fact that its name sounds so undignified, is as important as the rest.This is not just a cosmetic repair, which can be postponed until better times, until, say, the mood to do it appears. Current repairs include replacing doors, gratings, latches, if necessary - replacing a brick or two, covering up cracks, in a word, repairing everything that can break.

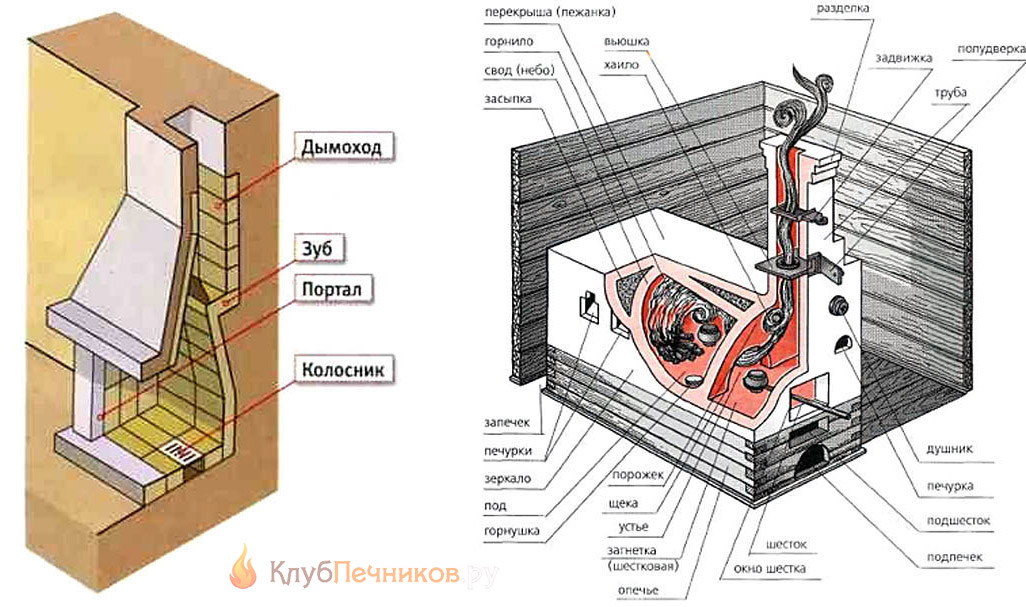

If you need to strengthen or change the furnace door, then sometimes for this you need not only to take it out along with the frame, but also to disassemble the masonry a little. Then, depending on what you planned, continue work. Broken paws of the frame must be changed, if you put a new door, put new paws to it. Before installing the door, it is necessary to thoroughly clear the masonry and moisten it with water. The frame must be installed in such a way that the paws fall into the seams. Then the masonry is already completed and the seams are filled with mortar. If the bricks become bad, we change them for new ones. During the laying process, the frame should be at a distance of 5-10 mm, which is filled with an asbestos cord. In cases where the latter was not at hand, the masonry should fit snugly against the frame and secure it firmly. In this case, the door will not be able to loosen and fall out. If you do not install the paws, then such a door will not last long and will soon fall out. The next final step is to cover the seams and cracks with a clay solution. (See also: Do-it-yourself greenhouse stoves)

To change the grate, the first step is to remove the old one and thoroughly clean the installation site of waste (ash), and only then install a new one. If the grate that you removed was a little higher and deeper, then when installing a new one, you need to be guided by the placement of the previous one and repeat its location.The entire perimeter between the brickwork and the grate should have a small gap of 5 mm, covered with ash or sand.

If, over time, cracks appear in the seams of the masonry, this can become very dangerous not only for your health, but also for life, because as soon as you notice them, the breakdown must be corrected. To do this, the seams in those places where the cracks must be cleared to a depth of 2-3 cm, generously moisten with water and cover with clay mortar. It is noteworthy that the applied solution must be thoroughly rubbed.

If everything is much more serious and cracks appeared in the bricks, then the operation of the furnace is impossible until this problem is eliminated. Bricks with cracks must be taken out, the place they occupied must be cleaned of mortar. From the new bricks, select a whole strong brick, which is perfect for the place of the cracked one, generously moisten it with water and, having smeared a solution of clay on it, insert it back. If you see that the seams remain half empty, then coat them with a solution as needed and rub it. (See also: DIY fireplace stove)

Self-repair of the furnace firebox may include the replacement of tiles. If several tiles cracked over time, then the cracks can be repaired with a gypsum mortar with aluminum-potassium alum. Chalk prepared on egg white is also suitable. If the tiles are beyond repair, it is best to replace them with ones that match in color and shape. As in the case of a brick, the cracked tile is carefully removed, the place is cleaned of mortar. The new tile is given the shape of the old one, the tiller of the tile is filled with a mixture of clay mortar with crushed bricks, and installed instead of the old one.Naturally, the strength of such “repaired” tiles is not too high, since the tiles are additionally reinforced with wire during laying, but it’s still better than using a stove with cracked tiles.

Repair of a cast-iron firebox involves welding, turning or replacing seals. It is better to entrust this work to professionals, since its cost is not too high, and such repairs can cost more for an amateur. So it’s better not to be stingy and turn to experienced workers.

Repair of fireplaces and brick ovens

How to repair a pipe and a chimney?

Repairing a rustic stove in a country house involves periodically cleaning the chimney. If you don’t want to cover your hands too much, but you need to repair the pipe, you need to throw a piece of rubber or any other “dry fuel” into the burning fire. As a result of this process, strong air currents will eliminate existing blockages. The old and trusted method of cleaning the chimney is to use salt. All that is needed is to throw the mixture inside and quickly close the chamber door, in order to avoid injury to the skin by shooting salt crystals. In critical situations, when it is impossible to eliminate the blockage of the furnace, you have to clean the pipe yourself with a special stick. However, such an occupation is dangerous, as it implies the presence on the roof. Part of the pipe facing the street is cleaned from the outside of the room.

How to replace bricks?

It happens that it is necessary to repair the furnace only in certain areas. Often individual bricks burn out and are subsequently replaced. If the site burns out, the place is pre-treated with water and prepared clay is placed in the slot.A new whole brick is well processed, moistened from all sides in a solution and placed in the right place. After that, the plate is heated, the seal with the new briquette hardens, and the result is ready.

Replacement and repair of tiles

When studying possible damage and ways to solve the problem, it is recommended to pay attention to such a case.

When a tile is damaged for some reason, you must immediately and carefully remove it from the oven.

After that, it is important to clean up all the contaminants and dip the material into a clay solution, to which brick crushed stone is first added. At the end of the replacement, all visible flaws and irregularities in the masonry are removed manually

What's the best way to close gaps?

To fix the problem of a fireplace that constantly smokes, you need to start by eliminating the holes. A smeared oven can form gaps over time, which, with the right approach, are eliminated without problems. Small holes are sealed using a special mixture. The components that are included in such a solution can be different: sand, clay, asbestos, salt. Whatever the composition, in any case, to cover the gap, clay and sand are added twice as much. Instead of salt and asbestos, cement is often included in the plastering solution. By consistency, the substance should not be very viscous, but at the same time non-liquid, since the further result depends on the quality.

Replacing the pre-furnace sheet

It is impossible to repair the iron sheets of the fireplace, which protect the room from the consequences of fire hazards. More often than not, these items need to be replaced. To do this, the old damaged sheets must be removed, the nails removed.Instead, felt or a layer of asbestos, previously soaked in a clay substance, is placed in the lower part of the surface, and covered with a new steel plate on top. Fireproof metal sheets on the walls near the fireplace also need to be replaced in a timely manner, therefore, as soon as the slightest damage is noticed, it is recommended to install new plates according to the same principle as the pre-furnace structures.

Regular oven repairs

The stove does not melt due to lack of traction

This problem may occur for the following reasons:

- a large amount of air in the pipe due to a break in work;

- lack of oxygen supply;

- powerful air flow outside;

- filling the chimney with soot.

In the first three situations, repairing a Russian stove is simple: for kindling, you need to use not ordinary paper, but something more combustible - for example, a piece of rubber. The use of fuels and lubricants for ignition is not recommended.

The situation when the chimney or pipe is clogged with soot is determined by how much time has passed since the last burning of combustion waste. This is done at least once a year, usually in the summer. If this operation was not performed on time, it will be necessary to eliminate the clogging of the chimney. First of all, you need to try to still shoot out the soot. To do this, a handful of large-sized salt is thrown into the burning stove, after which the damper quickly closes. Pieces of hardened soot will fly out with a crack through the chimney. If this does not happen, you will have to clean the chimney with your own hands through a special door. The technology of this process can be studied using the video.

Too much smoke

The cause of this malfunction in the operation of the stove may be a violation of the integrity of the brickwork of the vault, as a result of which cracks and cracks are formed that must be repaired with your own hands.

It is necessary to repair the structure with the help of such material: a mixture of medium viscosity is prepared from sand and clay; You can also use a mixture prepared in advance by the manufacturer, it is sold at any hardware store.

Loss or burning of masonry elements

The area of \u200b\u200bthe furnace in which the old brick was located is cleaned with their own hands from the remnants of clay and accumulated dust, then moistened with plain water. A small amount of clay is placed in the prepared place for the new brick. A fresh stone is dipped into the water and covered with clay on all sides except for the front, so that all joints are securely fastened. Then it is laid in place of the removed stone. The solution on which the new element is planted is prepared in the same way as the mixture for sealing cracks.

Causes of furnace failure

• poor quality of the used solution; • violation of finishing technology;

• shrinkage of a brick structure;

• uneven heating;

• non-compliance with the rules for the operation of the furnace.

If the stove has sagged due to an improperly poured foundation, smoke will pour out of all the cracks during the furnace, the doors will no longer close tightly, and the brick will gradually begin to collapse. If such problems are found, the entire structure should be immediately disassembled, the foundation strengthened and laid out again. However, in some cases, drastic measures can be dispensed with.

The fact is that a slight shrinkage of the furnace in the first couple of years is considered quite normal, and if we are talking about small cracks, it is enough just to repair them correctly.

All other reasons can be easily eliminated, it is only important to figure out how to cover the oven so that it does not crack. If no one lived in the house for a long time, then putty for the stove is not needed

A frozen chimney starts to work incorrectly, but the malfunction is easily fixed. It is enough to warm up the riser by burning paper, and the smoke will go along the right path.

If no one lived in the house for a long time, then putty for the stove is not needed. A frozen chimney starts to work incorrectly, but the malfunction is easily fixed. It is enough to warm up the riser by burning paper, and the smoke will go along the right path.

If you do not know if the stove worked before, then malfunctions in its operation may be caused by improper laying of the chimney or clogging of the channels with parts of bricks. In this case, you can not do without a major overhaul.

Well, and, of course, cracks in the chimney or in the stove itself lead to disruption of its operation and the appearance of smoke in residential areas.

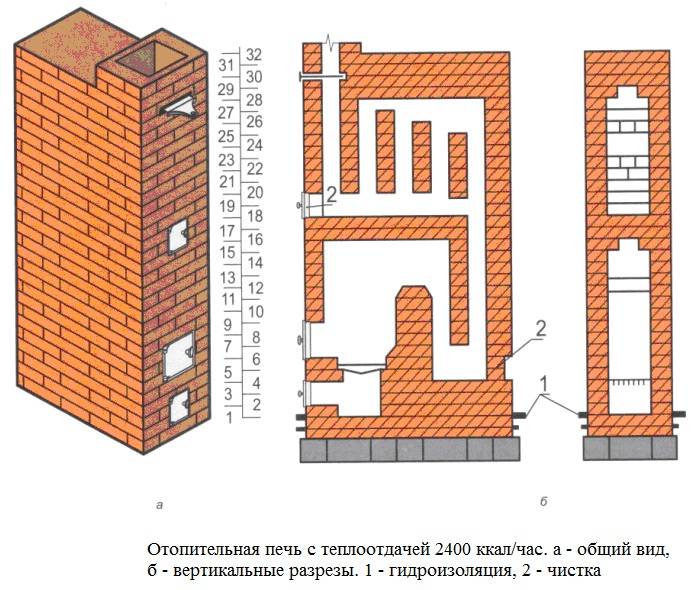

The composition of clay mortars for laying furnaces

When laying stoves from ordinary bricks are used plastic clay, predominantly red, not contaminated with random impurities. Before use in solution clay is soaked and rubbed through a mesh with holes 3-4 mm.

To prepare a solution is usually applied mountain sand, without foreign impurities and plant residues, fine-grained sifted through a sieve with holes 1.0-1.5mm.

Table 2: COMPOSITION OF CLAY SOLUTIONS (in parts by volume).

| p/n | Solution grade | Solution type | Additive type | The composition of the solution, (clay dough + additive + sand) | |

| in dry climate | in a moderately humid climate | ||||

| 1 | 2 | 3 | 4 | 5 | 6 |

| 1 | M-10 | M-2 | 1) Clay - on oily clay | without additive | 1+0+4 |

| 2 | M-10 | M-2 | 2) Clay - on clay of medium fat content | without additive | 1+0+3 |

| 3 | M-10 | M-2 | 3) Clay - on lean clay or loam | without additive | 1+0+2,5 |

| 4 | M-4 | M-4 | Clay - with black binders | black binders (tar, bitumen, pitch) | 1+(0,05…0,1)+(2,5…4) |

Note:

- Clay solutions used in summer conditions for above-ground masonry predominantly in dry climates with normal indoor humidity.

- Sand quantity in clay solutions with black binders depends on the fat content of the clay.

- Using hard black binders pre-prepare an emulsion of clay with black binders in heated state.

The water for preparing the solution must be clean. When using sea water cement rate should be increased on the 10-15%%.

How to close the cracks in the oven

In many homes, the Russian stove has served faithfully for several decades. Constant exposure to high temperatures causes one of the most common damage to the Russian stove - cracks and crevices on the surface. These cracks and crevices need to be repaired for at least three reasons:

- cold air enters the slots, which can significantly reduce the efficiency of the furnace itself;

carbon monoxide can escape through the cracks, which can cause serious poisoning, suffocation;

if small gaps are not repaired in a timely manner, they will expand over time and the furnace will require serious, major repairs.

(See also: Chimneys for stoves)

Some gaps are quite wide. In order to close holes in the Russian stove, it is necessary to properly prepare the solution. This is a rather complicated process, it can be made from clay and sand, with the addition of salt, cement, and even horse manure. However, all these solutions may be ineffective.Modern manufacturers have released a special solution based on which fireplaces, barbecues, barbecues, and brick ovens are laid. A refractory mixture called fireclay mortar may be the option you need.

First you need to prepare a small amount of solution. The consistency of thick sour cream is what you need to close the cracks. You do not need to prepare a lot of the solution right away, as it can harden before you use it.

The gap is pre-cleaned of dust and dirt. And only after that, using a spatula, fill it with a solution. For leveling, you can use a wide brush soaked in water or a wide spatula. After a while, you can heat the oven, if small cracks appear, then they are rubbed with a solution. This procedure can be carried out several times. with constant work ovens. (See also: Furnace Mortar)

With through, deep cracks, it may be necessary to re-lay the site, since the cause of the occurrence may be initially incorrect dressing of the seams of the furnace masonry or “thermal shock” from incorrect installation of metal parts.

Finishing the oven with ceramic heat-resistant tiles or painting is an excellent means of preventing wear and tear of the brickwork, and therefore cracks. You can veneer only a stove, which has a very simple shape. After such a finish, your Russian stove looks like new.