- How is scale formed and why is it dangerous?

- Cleaning methods

- How often should the boiler be cleaned?

- How to clean the boiler from soot: cleaning acids

- Combustion products and their cause

- The heat exchanger of the gas boiler is clogged with scale, what should I do?

- limescale

- Funds

- Lemon acid

- orthophosphoric

- Salt

- Sulfamic

- How to flush the heat exchanger of a gas boiler?

- Flushing the double-circuit heat exchanger

- How to flush the heat exchanger of a gas boiler?

- Cleaning - the first stage

- Wall mounted boilers with bithermic heat exchanger

- We clean the wall-mounted heat generator from soot

How is scale formed and why is it dangerous?

No liquid can compare with ordinary water in terms of specific heat capacity. Depending on temperature and pressure, this indicator varies in the range from 4174 to 4220 Joules / (kg deg). Water is non-toxic, readily available, and cheap, making it an almost ideal heat transfer medium.

And yet, N2O has a significant drawback - in its natural state it contains salts of alkaline earth metals Ca and Mg. When heated, they form on the internal surfaces of the heat exchange equipment insoluble carbonate, or, otherwise, lime deposits - scale.

Hard water is typical for a significant part of Russia, and especially for the middle zone, where the degree of mineralization reaches a maximum.

Hard water is typical for a significant part of Russia, and especially for the middle zone, where the degree of mineralization reaches a maximum.

The negative consequences of scale formation are as follows:

- efficiency decreases;

- the water pressure is reduced;

- boiler wear is accelerated;

- expenses increase.

Domestic heating boilers and water heaters are mainly equipped with surface heat exchangers, in which heat is transferred through the surfaces of metal walls. But the scale has a high thermal resistance, that is, low thermal conductivity.

For this reason, in contaminated heat exchangers, the heat transfer coefficient decreases, which leads to a decrease in coolant temperature in the heating circuit and insufficient water heating at the outlet of the hot water circuit.

If your boiler does not heat water well, check the condition of the heat exchanger, it may be due to scale, which caused a decrease in efficiency

Hard deposits with a thickness of only 0.2 mm increase fuel consumption by 3%. If the scale thickness is 1 mm, the gas overrun will reach 7%.

When heat transfer decreases, more gas is required to maintain the desired water temperature, which indicates a decrease in efficiency. At the same time, with an increase in fuel consumption, the volume of flue gases increases, the emission of harmful substances increases, polluting the air around the household and the atmosphere as a whole.

Deposits completely or partially block the flow area of the pipe, which leads to an increase in hydraulic resistance in the system, violation of the circulation of the coolant, reducing the supply of hot water at the points of water intake.

When using water of normal hardness, a layer of scale 2-3 mm thick is formed per year. With higher salinity, the rate of carbonate sedimentation increases.

Violation of heat transfer leads to overheating of pipes, which causes the formation of microcracks - future centers of corrosion. Due to the work at the limiting modes, the unit fails prematurely.

To prevent damage to equipment, scale must be removed periodically. planned cleaning of gas heat exchangers wall-mounted boilers and floor-standing units are carried out within the time limits established by the manufacturer. A simple procedure helps to maintain the energy efficiency of the equipment at the initial level, extends the period between repairs, reduces the total cost of operation.

Cleaning methods

Probably every owner of the boiler thinks about how to clean the unit and how it's right to do it. There are four main ways to clean the boiler from soot, tar and tar. Their features are the following important points.

mechanical cleaning.

It is a cleaning of a solid fuel boiler from combustion products using a special set of tools, which includes the following elements:

- poker;

- scrapers of different sizes;

- shoulder blades of various widths;

- metal brushes;

- ruffs of various configurations, you can buy them at any store, for example.

It should be understood that the boiler is cleaned of soot using these tools only when the unit has cooled down completely.

Important point:

when cleaning a solid fuel boiler, the damper must be fully open.

As for cleaning the wood boiler from tar and tar, the stages of work will be as follows:

- initially, the unit is heated up, since the resin and tar have a solid structure, which softens when heated;

- using spatulas and scrapers, substances are removed from the walls;

- after cleaning is completed, the temperature of the boiler is temporarily increased in order to burn out the remains of tar and resin.

Thus, we see that it is quite possible to clean a solid fuel boiler from soot, tar and tar with your own hands.Chemical cleaning. A feature of this method of cleaning a solid fuel boiler from harmful substances is the use of various chemicals, and the entire scope of work can be performed in two ways:

- The agent is poured directly onto the burning fuel (the composition of such substances contains a set of crystals that react with soot and tar, crumble them, and then go out with smoke).

- With the help of special chemicals, the working surfaces of the boiler that are contaminated with tar and tar are treated (as a rule, the main components of these products are solvents and acid-based reagents).

Specialist's note:

when cleaning the boiler with chemicals, safety measures must be observed!

"Soft blasting".

This method is considered an American technology for cleaning a pyrolysis or wood-burning boiler from combustion products.

Its essence lies in the fact that with the help of a special device, a special solution is supplied to the contaminated surfaces of the boiler, which includes chalk and baking soda.

Steam cleaning of the boiler.

The essence of the method lies in the fact that with the help of a steam generator, the walls of the boiler are processed, while the boiler unit also undergoes disinfection.

Cleaning a solid fuel boiler from soot, tar and tar can be done in a way that suits you in terms of financial capabilities and labor costs. And in conclusion, I would like to dwell on one more aspect of cleaning the boiler from combustion products. There are also several folk methods for cleaning the boiler from soot and tar.

So, for example, salt is poured onto burning firewood, which accompanies the removal of soot along with smoke. Also, dried potato peels are placed on the burning fuel, which, releasing starch, significantly soften the contaminated surfaces for subsequent cleaning. We hope that our information will help you so that your home is always warm and cozy.

Watch a video in which an experienced user explains in detail how to properly clean a solid fuel boiler from tar:

An indispensable attribute of any heating system is a boiler, which acts as a heat generator for heating a home.

The modern market for heating equipment is saturated with a very wide range of boilers of various types. But a special place in this assortment is occupied, which are gaining more and more popularity every day.

This trend is due to the fact that units of this type are very efficient and economical devices for heating a country house and even an apartment. In order for the gas boiler to function smoothly and stably, it is necessary to properly care for it.

One type of such maintenance is other pollution. Let's talk in more detail about why cleaning a gas unit, as well as in what ways this can be done.

How often should the boiler be cleaned?

The technical documentation for the boiler indicates how often it needs to be serviced. For closed circuits with the addition of reagents (single-circuit heating boilers), cleaning is required less frequently.It can be performed 1 time in 2-3 years. The bithermic and secondary heat exchangers must be flushed every year, and under difficult operating conditions (“bad” water composition) - twice a year.

Signs that the boiler urgently needs cleaning:

- the boiler is slowly gaining temperature;

- insufficient traction;

- the burner does not ignite or does not burn well;

- with the same gas consumption, the heat output is less;

- traces of soot or partially burnt paint in the area of \u200b\u200bthe viewing window.

Do not neglect preventive measures, because the result of this can be not only broken equipment, but also a threat to the safety of all residents of the house. Clogged chimneys and pipes with growths inside can cause serious accidents.

How to clean the boiler from soot: cleaning acids

A large number of cleaning methods have been developed. However, it should be noted that the methods that will be written below are not compatible.

For a successful cleaning process, we need:

- Ruff;

- Scraper;

- Scraper;

- Screwdrivers;

- Fabric gloves;

- and related electrical appliances.

Before any kind of cleaning, it is necessary to turn off the boiler and remove the source of combustion. After that it is necessary shut off the gas supply valve and all heating shut-off valves, then wait for the boiler to cool down completely.

Chemical cleaning is popular because of the ease in the process itself. To carry out such cleaning, the reagent is heated to the required temperature, and then, using a special pump, enters the boiler system and reacts with plaque.

The following acids are used for cleaning:

- Adipic acid;

- Sulfamic acid;

- Helium.

Adipic acid must be diluted with water and, using a pump, very carefully pour into a cooled boiler.The gas affects the carbonates, they are converted into acidic salts and then dissolved

After that, you need to release the pressure and wait for the salts to precipitate, such a precipitate is very easily washed off with running water.

Sulfamic acid also needs to be diluted with water, only in a separate container and pumped under pressure into a cooled boiler. Then we wait for a while and wash the boiler under the pressure of water.

The most famous remedy for the accumulation of soot in the chimney is rock salt. It is added to the combustion chamber when the fuel is burning. But this option with the addition can be carried out only as a preventive measure, no more. It is impossible to completely clean the chimney of soot with this option with the addition.

A tool that is more effective for cleaning soot buildup in the exhaust pipe is potato peelings. The amount required for cleaning is determined by the dimensions of the heating boiler. On average, a bucket of cleanings goes to cleaning. They are poured out during the combustion of fuel into the working chamber of the boiler. The starch that is released along with the steam softens the soot and it begins to fly out of the chimney. After carrying out such a procedure, you need to clean the boiler. Often, prophylaxis is carried out in this way before mechanical cleaning, and after that it is easier to perform.

There is also a cleaning method using aspen firewood. A couple of armfuls of such firewood are burned in a boiler.

And besides this, you need to be sure that the carbon deposits on the pipe are not thick, otherwise the pipe may burst when the soot is heated.

It is not so difficult to properly clean or wash the boiler from tar, tar or soot with your own hands. Cleaning depends on what type of boiler you have.It can be of a solid fuel type and run on pellet wood, it can be a gas or pyrolysis plant, each has its own way. For example, for Buderus wood-burning boilers, where tar accumulates, a powder cleaner is perfect. How to properly clean can be found in the video.

An incorrectly selected tool can create a malfunction. Do not be surprised then why the boiler clogs. It is the wrong set of tools that will affect the fact that the boiler can leak.

Combustion products and their cause

By-products that appear during the combustion process are:

- soot;

- resin;

- tar.

The reasons for the appearance of these substances are the following important points:

- Causes of soot:

- there is not enough oxygen for the combustion process;

- fuel combustion temperature is too low.

- Factors affecting the appearance of resin:

- low-quality fuel is used;

- the fuel material has a high degree of moisture;

- the boiler operates at a low temperature;

- too much fuel is loaded into the furnace.

- Tar appears in the following cases:

- weak injection of air flow into the combustion chamber of the pyrolysis boiler;

- incorrect design of the unit;

- low chimney.

As you can see, the main reasons for the appearance of harmful substances are poor fuel and the technical aspects of the organization of the combustion process.

Experts advise: use only high quality fuel - otherwise the wear of the boiler will increase rapidly.

The heat exchanger of the gas boiler is clogged with scale, what should I do?

The most vulnerable part of any boiler, if it is not water, is the heat exchanger. This is where the water is heated.And if it is of poor quality, or does not soften, then sooner or later such a problem as flushing the boiler or its clogging will come. What problems can create a heat exchanger and, as a result, a boiler, low-quality water?

| Type of equipment | Effects |

| Gas boiler | Increased heating time Heating quality drops The heat exchanger may burn out Scale causes heat exchanger plates to stick together Scale from the heat exchanger enters the boiler Scale growths begin to be deposited wherever water comes into contact |

It is impossible to avoid lime scale if the household does not have the right softener installed. But what if the softener is not yet affordable? How to rinse the boiler from scale with your own hands? And will it give at least some effect, at least temporary?

When the heat exchanger is clogged with hard scale deposits, the problem can be solved in two ways:

- Washing the device with caustic cleaning agents;

- Having disassembled the device and soaking the particularly affected parts in caustic solutions;

- Having bought a softener, no longer remember this problem.

It is not necessary to bring the heat exchanger to such a state until it clogs! Therefore, each consumer, when installing a boiler room, must begin with an assessment of the condition of the water. But, if this factor is already missed? The consumer will know that the heat exchanger is clogged by several factors. The walls of the heat exchanger began to become very hot, water heating takes longer, scale particles began to fall into the water from the exchanger.

The girl independently rinses the boiler with her own hands

And this is the reason to sound the alarm! It's time for a flush. She is may be capitaland may be preventive.In any case, without a softener, you will have to use both types of washes.

It is possible to wash the internal surfaces of the heat exchanger with special aggressive agents (such as anti-scale, for example, or sulfuric acid), but for this you need to know exactly in what proportions to dissolve it all, how long to keep it, and then how to remove adhering particles. Washes do not end with rinsing. If the case is running, then you will have to disassemble the heat exchanger and work mechanically - that is, scrape off the softened parts of the scale. But it is precisely in this that the disadvantages of flushing lie. They are very spoil the surface, which significantly reduces the life of any equipment.

How to flush the heat exchanger of a gas boiler? There are several simple remedies that are good as a preventive measure, and there are aggressive liquids that need to be applied according to the instructions and not often. Any housewife has vinegar and there is always citric acid in the house. Especially for those housewives who love to bake. Here they can be used for the simplest washing. It will be enough to dilute two tablespoons of flushing liquid per liter of water and hold the heat exchanger in this solution. And it is even better, of course, to drive such a solution through the device, at high temperatures. By analogy, vinegar works. Only for washing it is better to use essence, it is stronger than ordinary vinegar.

As for the purchase funds, there are a lot of them. It is easy to find them on the net, and learn how to use them. Effectiveness, of course, will have to be judged by trial and error. Everyone's water is different, and somewhere Antinakipin works better, and somewhere only a solution of hydrochloric acid can help. The situation is complicated by the ingress of dirt and dust into the heat exchanger.Which, in combination with scale, forms a poorly soluble plaque.

limescale

This is a consequence of working with water with a high threshold of calcification. A whitish deposit on the surface of the equipment is the most reliable sign of such water. But the fact that the water is not soft, the consumer will know only about a month later, when all the walls are covered with a coating. But this is only if you do not do a water test. Therefore, in order to avoid the formation of plaque, you need to start by checking the composition of the water. And it is best to put a softener if the analysis indicated that the hardness threshold was exceeded. You also need to understand that the design of the boiler will make its own adjustments to the flushing process. It is much more difficult to wash the heat exchanger of a wall-mounted boiler Baxi than a conventional floor boiler. Dismantling and assembly also takes a lot of time.

It is interesting: Gas boilers Proterm (Protherm) wall and floor - overview, model range, instructions, errors and malfunctions

Funds

To clean the heat exchanger, various means are used - from natural to aggressive, based on chemical compounds. Consider the most popular and effective components that allow for high-quality cleaning.

Lemon acid

Currently, many owners of houses and cottages choose citric acid for cleaning boilers. A similar substance is commercially available and is found in many stores. A solution is prepared from citric acid, having a concentration of 0.5-1.5%. The density depends on the complexity and prescription of pollution. A liquid heated to a mark of 60 degrees easily destroys scale and oxidation. At the same time, you should not worry about the metal coating of the equipment - it will not suffer from this in any way.

orthophosphoric

This well-known chemical compound is most often used in agriculture. You can find it just as easily. Orthophosphoric acid is used to clean heat exchangers of absolutely any kind. To flush equipment, it is recommended to prepare a 13% solution. Such a concentration will make it possible to easily and easily remove scale and almost any type of pollution. In addition, when using such a tool, a reliable protective layer is formed on the metal.

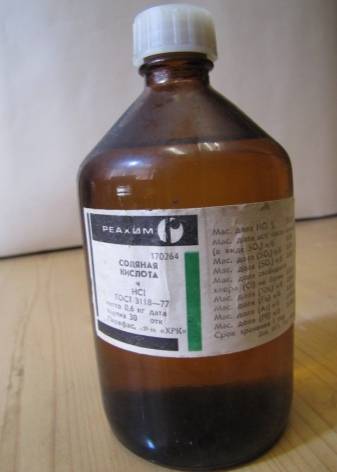

Salt

Hydrochloric acid on the territory of the Russian Federation is a precursor (a substance that is used in the preparation of narcotic substances). For this reason, getting a similar composition for cleaning equipment can be problematic. Despite this, in pharmacies you can find affordable solutions of hydrochloric acid - they are sold under the name of gastric juice.

When cleaning aggregates made of copper and stainless steel, 2-5% hydrochloric acid solutions are usually used. This liquid contains inhibitors that provide additional protection for the metal. In addition, this popular agent is able to dissolve various carbonates and oxidation products.

Sulfamic

Sulfamic acid is sold by organizations that are directly related to the chemical industry. This reagent freely dissolves various defects, if their chemical composition allows. For this reason, before cleaning the equipment, it is desirable to study in detail the structure of the contaminants that are planned to be removed.

The following products are also used to clean the heat exchangers.

- Detex. This is a special agent that effectively helps to dissolve scale, salt and oxidation products from heat exchangers made of materials such as cast iron, copper or steel.Detex is mixed with water to make a 10-17% solution.

- GEL Boiler Cleaner DE. This concentrated product contains inorganic acids and inhibitors. Such components can even fight rust. GEL Boiler Cleaner DE is used for cleaning copper and steel parts.

How to flush the heat exchanger of a gas boiler?

Do-it-yourself flushing of the gas boiler heat exchanger is carried out mechanically or chemically, with the second option being more efficient.

mechanical way. In this case, remove the heat exchanger to clean it manually. Dismantling this part is a troublesome task, the complexity of which depends on the design of a particular boiler model. In any case, the result of mechanical washing is lower than that of chemical washing.

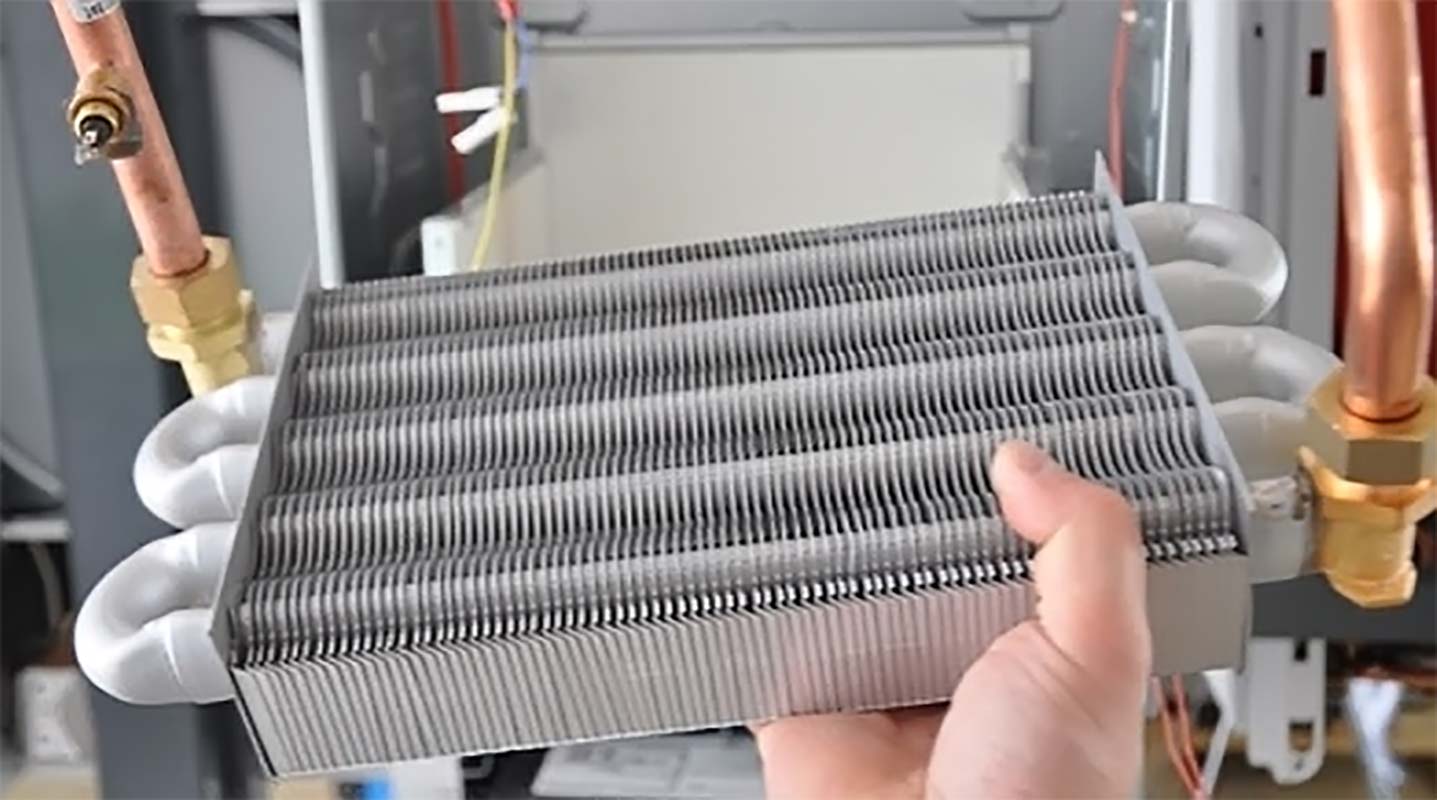

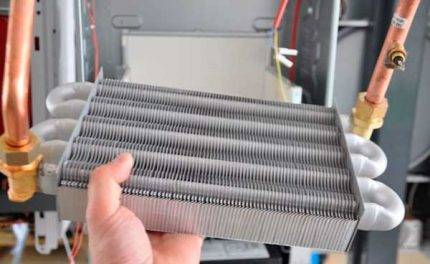

Mechanical way to clean the heat exchanger from scale

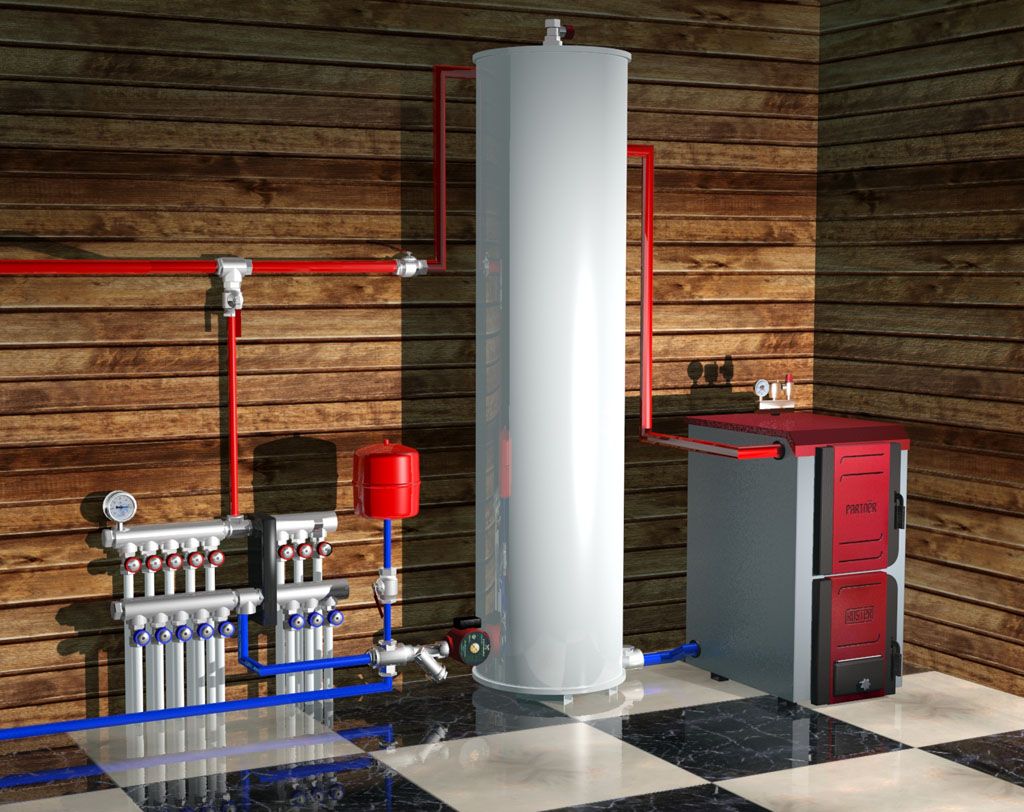

Chemical method. Allows you to flush your boiler without dismantling the heat exchanger, but requires the use of special equipment - a booster.

You can mount it yourself:

- a washing solution is poured into a tank with a volume of 15-20 liters;

- hoses connected to the pipes of the heat exchanger are lowered into the tank;

- the boiler turns on for heating (it is necessary to maintain a stable temperature of about 50 degrees);

- a circulation pump (preferably reversible) should be connected to the assembled system, which will force the flushing solution to pass through the heat exchanger.

- if you additionally install a strainer on the supply hose, mechanical impurities will not be cyclically driven through the heat exchanger.

Before connecting the equipment for flushing, it is necessary to relieve the pressure in the heating system to zero using the Mayevsky tap, drain the coolant from the heat exchanger, and clean the built-in dirt filter of the boiler (if any).

Flushing the double-circuit heat exchanger

If the double-circuit unit is equipped with a bimetallic heat generator that simultaneously heats the coolant and prepares water for hot water supply, then cleaning is carried out according to the method described above, using a booster.

For models with a secondary heat exchanger, this stainless steel part must be removed and washed separately. For dismantling, remove the front panel, unscrew and slide the control unit. The secondary heat exchanger for the gas boiler is bolted at the bottom. It is removed and boiled on the stove in water with citric acid or a special agent.

How to flush the heat exchanger of a gas boiler?

Citric acid is a popular folk remedy, the solution is prepared at the rate of 20 g of acid per 1 liter of water, but a higher concentration is also allowed. You can also use special products that are safe for metal and heating system seals.

In any case, at the final stage of cleaning, clean water should be driven through the heat exchanger with a booster to remove traces of cleaning agents aggressive to the metal, and only then bring the unit into working condition.

How to perform cleaning and flushing work without removing the heat exchanger using a circulation pump, see the following video.

Cleaning - the first stage

First of all, prepare the tools:

- screwdriver on "+" and "-";

- wrench;

- a vacuum cleaner;

- brush;

- gloves.

Depending on the model of the gas boiler, the procedure for accessing the combustion chamber may differ. In some, it is enough to remove the cover from the front side, unscrew the bolts from the combustion chamber and get to the heat exchanger, in others it is necessary to dismantle sections of the rubber seal and remove the refractory walls.

As soon as the covers are removed, you can immediately see a mountain of debris at the bottom of the boiler, which is usually sucked in from the street. This area can simply be vacuumed and dust and dirt accumulated during downtime can be wiped off.

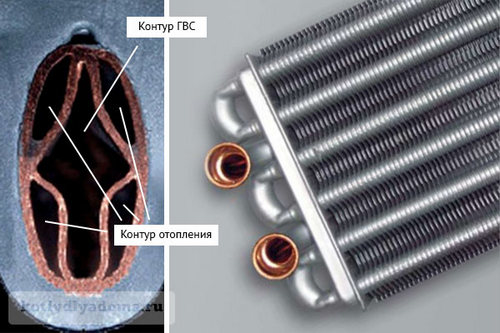

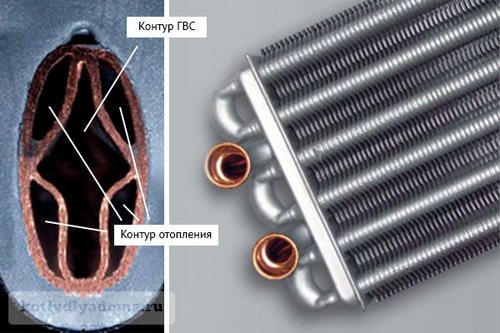

Wall mounted boilers with bithermic heat exchanger

Let's see what a bithermic heat exchanger is. From its name it is clear that we are talking about performing two different tasks within one structure (this is heating water for heating and hot water supply).

Such a simple design allows you to use the inner area for hot water, and the outer space for heating. Also, the outer tube is equipped with plates for better heat transfer, providing the greatest contact with combustion products.

Operating principle

- The plates are heated as a result of fuel combustion and transfer heat to the coolant circulating inside the heating circuit. If domestic hot water is not used, the DHW circuit is closed.

- When a hot water tap is opened, the heating circuit is blocked and the DHW circuit opens, as a result of which the coolant moving through the inner tube is heated. As soon as the hot water tap is closed, the DHW circuit will automatically close and the movement of the coolant in the heating circuit will resume.

In other words, only one of the two circuits is always in operation, while the domestic hot water receives heat from the already heated water from the heating circuit. It is believed that boilers with bithermic heat exchangers are 15% cheaper than using separate heat exchangers. But in this case, the efficiency is slightly less (by about 2%).

Advantages of boilers with bithermic heat exchangers

- A simple design that does not require the installation of a three-way valve, which often breaks down and needs to be replaced.

- Such boilers are more compact in size, since no additional space is required inside the body to accommodate the second heat exchanger.

- Hot water immediately flows from the tap during opening, in contrast to the use of boilers with separate heat exchangers.

- Due to the simpler configuration, many models are cheaper than boilers with an additional heat exchanger.

Some people mistakenly believe that the water from the DHW circuit, which is in the inner tube of the heat exchanger, still takes a significant part of the heat when only heating is required, and reduces the overall efficiency of the boiler. Practice shows that this is not the case, and there is no cause for concern here.

Flaws

- The possibility of getting burned while taking a shower. Using a boiler with a bithermic heat exchanger, you need to be more attentive to the temperature of the DHW water, especially if there are children in the house. This problem is most relevant when it is very cold outside and the heating is working at full capacity. Turning on the hot tap, it is better to wait a bit until the very hot water drains.

- The duration of operation of the boiler in DHW mode has some limitations.This point should be clarified with specialists who are well acquainted with the model of the boiler you are purchasing with a bithermic heat exchanger.

- It is undesirable to use a coolant with a high content of impurities, as this will lead to the formation of scale on the inner walls of the heat exchanger tubes. If the water you use is too hard, it must be softened, and this is an additional cost. In our practice, there are cases when the owners of such boilers did not monitor the quality of water in the heating system, and the heat exchanger failed during severe frosts. You understand what serious problems this causes.

- Difficult service. Bithermic heat exchangers are difficult to clean, even if this procedure is entrusted to professionals.

- Due to the clogging of the heat exchanger, the efficiency of the boiler decreases every year.

Sooner or later, the moment comes when the bithermic heat exchanger will have to be replaced. Costs can reach 30-40% of the cost of the boiler. Agree that this is quite a big expense. This does not include pay for work.

Without any exaggeration, we can say that bithermic heat exchangers are disposable, since their cleaning due to the specific design does not give great results.

We can only recommend the use of such boilers in combination with special cleaning systems that reduce the amount of salts in the coolant.

An example of a boiler with a bithermic heat exchanger is the wall-mounted Baxi Eco Four 24 boiler. It has compact dimensions (400x730x299 mm), relatively low weight (29 kg) and is recommended for installation in houses up to 240 m2.

We clean the wall-mounted heat generator from soot

Getting to the main heat exchanger of most wall-mounted gas boilers is quite simple. Work algorithm next:

- Turn off the gas supply by shutting off the corresponding valve.

- Remove the front panel of the unit.

- Unscrew and remove the front cover covering the combustion chamber.

So that the removed soot does not pour into the holes of the gas burner and you do not have to think about how to remove the burner for cleaning later, cover the nozzles with a sheet of thick paper or cardboard. Then, with an old toothbrush, clean the fins of the heat exchange unit from carbon deposits. If the stuck layer does not lend itself, then you can use a brush with a soft metal bristle.

At the end, sweep the unit from the inside with a brush and carefully remove a sheet of paper with soot. How to maintain a wall-mounted boiler is shown in detail in the video: