- We service the igniter and the water intake unit

- When to clean

- Difficulties with arson

- The heater starts briefly, the main burner switches off quickly

- Soot pouring from below from under the casing

- Water heats up slightly at maximum power

- Cotton in the combustion chamber

- yellow flame

- Operation of overheating and draft sensors

- Construction dust after repair

- Fault symptoms

- How to clean the gas column from soot?

- Cleaning the water heater with complete disassembly

- Fault symptoms

- When to Clean Your Gas Boiler

- How to clean the column from scale?

- Stage 1 - preparing tools

- Stage 2 - equipment preparation

- Stage 3 - cleaning the filter

- Stage 4 - replacement or correction of the membrane

- Step 5 - Checking the heat exchanger

- Stage 7 - final cleaning

- We remove soot

- How to remove soot from a heat exchanger at home

- How to disassemble and assemble with your own hands

- Shutting off water and gas

- Draining content

- Dismantling features

- Washing

- Drying

- Replacement of O-rings

- Leak test

- Operation check

- How to descale

- Ready composition from the store

- With acid

- How to clean soot from a radiator

- soap solution

- How to remove scale without removing the radiator

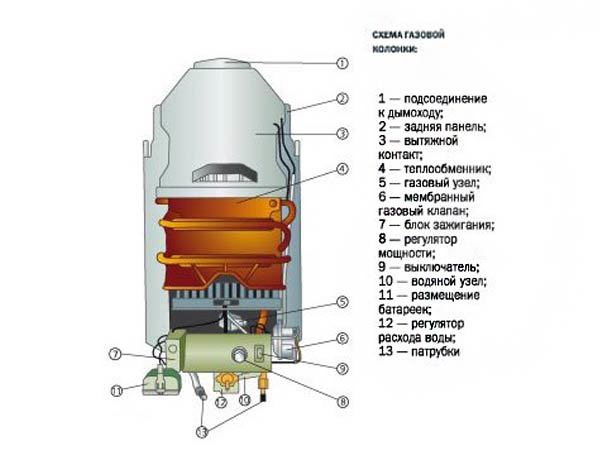

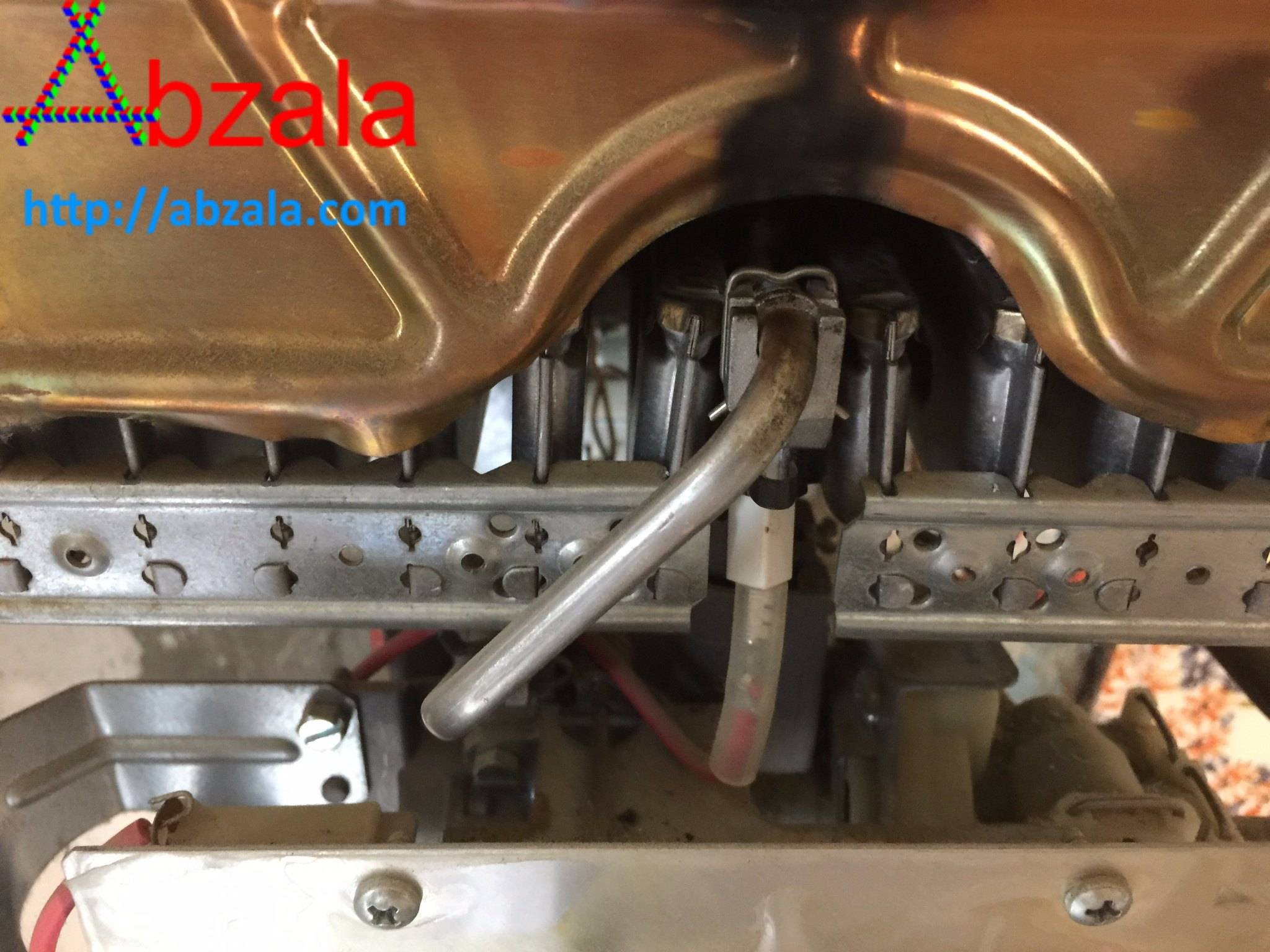

We service the igniter and the water intake unit

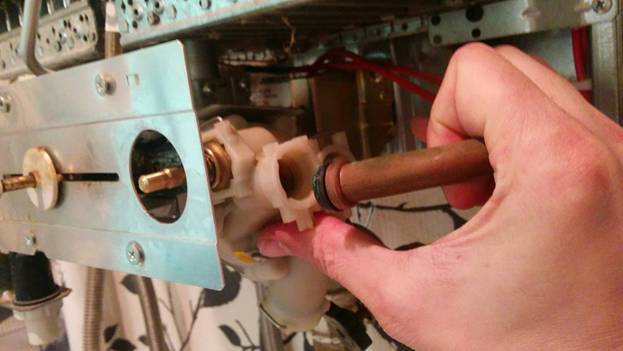

If it becomes necessary to clean the water unit, do not rush to disassemble the entire apparatus. Look at the instruction manual for the water heater, find the “frog” on the diagram and follow the following algorithm:

- Remove the control knobs and front cover.

- Dismantle the water unit by disconnecting the nozzles.

- Unscrew the screws holding the cover, remove it and get to the membrane.

- Clean the filter - mesh and water holes in the body of the "frog" using a wooden stick or soft copper wire. Remove scale with a brush.

- Rinse the parts with water and assemble the assembly. Replace damaged or cracked membrane immediately.

Clean the pilot burner jet (wick) with a thin copper wire or a toothpick moistened with alcohol. Wipe the ignition electrodes and the flask of the flame sensor (thermocouple) thoroughly from soot, otherwise, over time, the column will spontaneously turn off.

When to clean

There are several signs that indicate the need for cleaning the gas column.

Difficulties with arson

The main sign that the device needs cleaning is the difficult ignition of the igniter. It stops igniting due to a serious blockage that impairs the flow of gas. Therefore, before igniting the apparatus, it is necessary to carefully examine the igniter and check if it is clogged with soot or other debris.

The heater starts briefly, the main burner switches off quickly

Some owners of gas heating devices experience premature shutdown of the main burner. This problem leads to poor heating of the water. Most often, it stops burning and heating the liquid due to the accumulation of debris inside the burner.

Soot pouring from below from under the casing

If you do not clean the column for a long time, soot will begin to fall out from under its casing. Therefore, if there are traces of soot near the device, you will have to remove the protective cover yourself and clean all contaminated parts.

Water heats up slightly at maximum power

Some people are faced with the fact that the geyser does not warm up the water well. In order for it to better heat the liquid, you have to set the maximum power, but sometimes even this does not help get rid of the problem. Weak water heating is associated with severe clogging of the burner, and therefore, in order to normalize the operation of the device, you will have to clean it.

Cotton in the combustion chamber

Sometimes during the operation of the column in the combustion chamber, you can hear a loud bang. Many people, when such extraneous noise appears, think that the device is faulty, but this is not so. Cotton may appear due to a clogged igniter that takes a long time to ignite.

yellow flame

Each modern model of geysers is equipped with a special jet. This is a small hole responsible for adjusting the gas supply before igniting the igniter with the burner. After prolonged use, the hole becomes clogged with soot and other debris, which leads to the appearance of a yellow wick flame.

Operation of overheating and draft sensors

Several sensors are installed in gas water heaters that control draft and heating temperature. When the device overheats and traction deteriorates, they work and turn it off. Most often, overheating appears due to the accumulation of soot inside the heat exchanger. The accumulation of debris leads to a narrowing of the gas-air section and an increase in temperature.

Construction dust after repair

During repair work in an apartment or house, a lot of construction dust is generated. It can settle not only on furniture, but also on devices installed in the room. If repairs are carried out in a room with a geyser, a lot of dust can get into it, which will adversely affect the operation of the device. Therefore, after the repair work is completed, it is necessary to clean the column from accumulated debris.

Fault symptoms

The following signs indicate that the column is clogged:

- The burner ignites poorly, strong cotton can be heard;

- The heater starts, but the burner goes out almost immediately;

- Soot pours from under the casing below;

The unit works at maximum power, and the water is barely heated.

Recommendations on how to clean the gas column heat exchanger or igniter will be different, so you need to immediately understand what and where exactly the problem is. So the cotton in the chamber indicates that excess gas accumulates before ignition.

In this case, look for instructions on how to clean the igniter, which is responsible for the timely ignition of the fuel. If the flame is very weak and has a pronounced yellow color, the jet is clogged. The ignition unit in most models is easy to disconnect from the main burner, and then calmly remove all debris.

Traction and overheating sensors are triggered by the accumulation of an excessive amount of soot. It is concentrated between the fins of the heat exchanger. In this case, the cross section of the gas-air path decreases, and the operating temperatures increase. In this case, you need a liquid to clean the gas column heat exchanger from soot.

If they literally fall out from under the decorative apron, it should be done immediately.

If cleaning the gas column heat exchanger did not give the required results, check the main burner. Soot can clog its nozzles, and heating is not properly performed, again. The geyser burner and the heat exchanger are closely connected, so it is advisable to carry out preventive maintenance of both units at the same time.

The heat exchanger of the geyser must also be cleaned of scale in order to restore the normal flow area. Any deposits on the walls reduce it and negatively affect the functionality of the device.

The "overgrowth" of the internal pipe passages is indicated by a decrease in the pressure of water at the outlet of the device at a normal inlet pressure. Tap water salts cannot be put anywhere - and it is they that lead to clogging of pipe passages. Over time, as a result of their natural deposition, the walls become clogged, and the plaque is very thick and durable. In this case, cleaning the gas column heat exchanger using the flushing method helps.

To summarize, when to perform maintenance (and the sooner the better):

- The device during operation quickly goes out or does not turn on at all. First check the gas supply - if there is no problem, make sure that there is sufficient water pressure. When the pressure is also stable, test the ignition element. With a thick layer of burning and soot, it will not work normally until the pollution is removed. Solutions to the problem - cleaning the burner.

- Constant activation of the thermal protection of the device - in order to prevent the equipment from overheating, a heat sensor is provided in it. This sensor signals critical temperature rises, warns the owner about equipment malfunctions.When the sensor is triggered too often, it makes sense to clean the pipes and the burner.

- Thermal protection is triggered - the sensor in the column is provided so that the equipment does not overheat and, accordingly, does not fail prematurely. It signals an increase in current indicators above critical levels. If the sensor is triggered frequently, check the pipes - most likely, scale has accumulated there. Since scale has good thermal insulation properties, the appliance overheats and shuts down.

- The productivity of the device has significantly decreased for unknown reasons - for example, the water began to heat up slowly, the pressure dropped sharply. It is necessary to test the heat exchanger for scale and remove all deposits from the working parts of the device.

We figured out the causes and signs of blockages, now let's see how to clean the gas column with our own hands, what is needed for this.

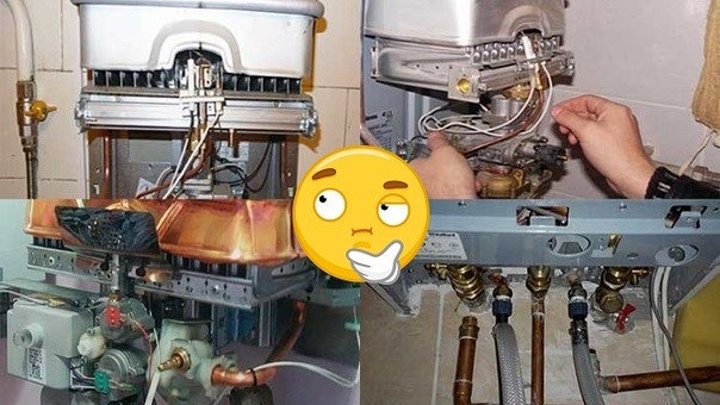

How to clean the gas column from soot?

If soot falls out of the column when it is ignited, then you have problems with combustion. It is advisable to entrust this procedure to professionals, but if this is not possible, do it yourself.

Make a soap solution.

Apply with a brush to the joints.

If bubbles begin to form, contact the gas service for troubleshooting or try to adjust the valves yourself by scrolling the washer until the desired result is obtained

But keep in mind, it’s important not to twist too much here, otherwise the gas supply will be insufficient .. The second reason is the nozzle holes are clogged

In this case:

The second reason is clogged nozzle holes. In this case:

- Remove the soot with a vacuum cleaner or iron brush.

- Take a thin copper wire and remove carbon deposits from the jets.

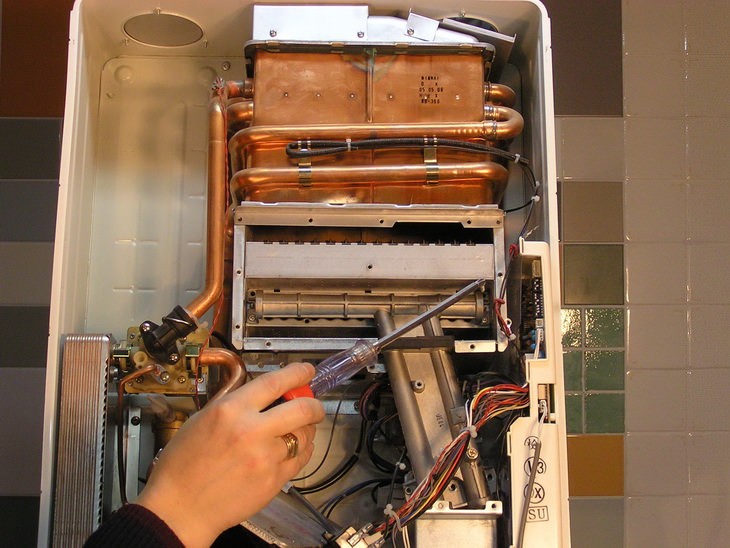

Cleaning the water heater with complete disassembly

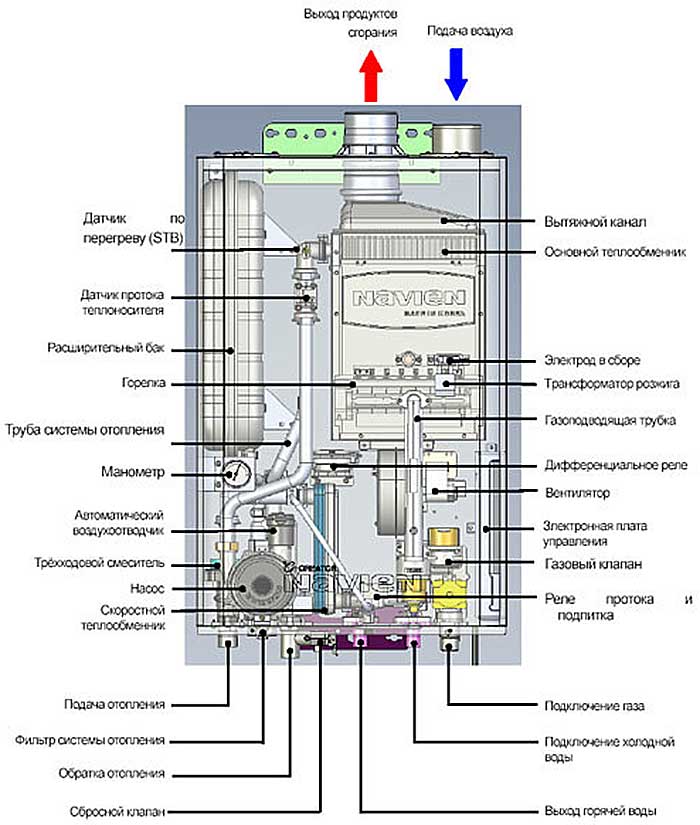

Consider the option of how to clean the geyser heat exchanger from scale with a complete disassembly of the device. This procedure is quite easy to do with your own hands. To do this, you will need the following tools: wrenches, pliers, screwdrivers.

…

The disassembly process is carried out according to the following steps:

- Close the taps of pipelines of hot and cold water, gas, and electricity.

- Putting a bucket under the nozzles, unscrew the connection nuts without losing the rubber gaskets.

- Disconnect the pipe from the chimney.

- Remove the water heater from the wall.

- Then, if necessary, remove the control handles from the front panel of the device. Unscrew two screws and dismantle the case.

- Remove the smoke collector - to do this, disconnect the wiring from the smoke sensor and unscrew the screws that fix the casing.

- Disconnect the circuit tube from the water block. The other branch pipe is freed from the nut sandwiched between a pair of self-tapping screws.

- The burner is disconnected from the valve by unscrewing the 2 screws on the flange. Lifting the heat exchanger, remove the burner and set it aside.

- Unscrew the screws connecting the radiator to the wall of the water heater, disconnect the temperature sensors and completely remove the circuit.

Checking the components of the gas column for performance

Read here how to properly disassemble the gas column

Do I need to carry out maintenance of the gas column

We examined the process of dismantling a conventional chimney gas column. Disassembly of other models may have some nuances:

- in turbocharged models, the fan is dismantled;

- in some models of Italian origin, the pipes are connected with self-clamping clamps;

- if the water heater is equipped with an igniter, then before removing it, disconnect the gas pipe leading to the wick.

Note! In the process of disassembling the water heater, rubber and other gaskets should be replaced with new ones. The heat exchanger can now be flushed

To do this, take a deep basin, pour warm water at a temperature of 50 ° C into it and add the prepared cleaning solution. After that, the heat exchanger is immersed in it so that the nozzles look out of the water. Fill the radiator with water using a watering can. Fluid with sediment particles must exit through the opposite opening. The run of water through the heat exchanger is performed until it becomes clean at the outlet. After that, the radiator should be rinsed several times with tap water.

The burner can be cleaned of soot with a solution of citric acid. After cleaning, the element is rinsed with clean water, blown and dried thoroughly. Also, do not forget about the mesh filter, combustion chamber, smoke box. They also get clogged with soot and debris.

It is important to maintain tight joints: old gaskets should be treated with fireproof sealant and tested for permeability by pressure

The duration of flushing depends on the amount of scale inside the heat exchanger and ranges from 2 hours to 2 days.

Fault symptoms

The following signs indicate that the column is clogged:

- The burner ignites poorly, strong cotton can be heard;

- The heater starts, but the burner goes out almost immediately;

- Soot pours from under the casing below;

The unit works at maximum power, and the water is barely heated.

Recommendations on how to clean the gas column heat exchanger or igniter will be different, so you need to immediately understand what and where exactly the problem is. So the cotton in the chamber indicates that excess gas accumulates before ignition.

In this case, look for instructions on how to clean the igniter, which is responsible for the timely ignition of the fuel. If the flame is very weak and has a pronounced yellow color, the jet is clogged. The ignition unit in most models is easy to disconnect from the main burner, and then calmly remove all debris.

Traction and overheating sensors are triggered by the accumulation of an excessive amount of soot. It is concentrated between the fins of the heat exchanger. In this case, the cross section of the gas-air path decreases, and the operating temperatures increase. In this case, you need a liquid to clean the gas column heat exchanger from soot.

If flakes literally fall out from under the decorative apron, the geyser should be cleaned immediately.

If cleaning the gas column heat exchanger did not give the required results, check the main burner. Soot can clog its nozzles, and heating is not properly performed, again. The geyser burner and the heat exchanger are closely connected, so it is advisable to carry out preventive maintenance of both units at the same time.

The heat exchanger of the geyser must also be cleaned of scale in order to restore the normal flow area. Any deposits on the walls reduce it and negatively affect the functionality of the device.

The "overgrowth" of the internal pipe passages is indicated by a decrease in the pressure of water at the outlet of the device at a normal inlet pressure.Tap water salts cannot be put anywhere - and it is they that lead to clogging of pipe passages. Over time, as a result of their natural deposition, the walls become clogged, and the plaque is very thick and durable. In this case, cleaning the gas column heat exchanger using the flushing method helps.

To summarize, when to perform maintenance (and the sooner the better):

- The device during operation quickly goes out or does not turn on at all. First check the gas supply - if there is no problem, make sure that there is sufficient water pressure. When the pressure is also stable, test the ignition element. With a thick layer of burning and soot, it will not work normally until the pollution is removed. Solutions to the problem - cleaning the burner.

- Constant activation of the thermal protection of the device - in order to prevent the equipment from overheating, a heat sensor is provided in it. This sensor signals critical temperature rises, warns the owner about equipment malfunctions. When the sensor is triggered too often, it makes sense to clean the pipes and the burner.

- Thermal protection is triggered - the sensor in the column is provided so that the equipment does not overheat and, accordingly, does not fail prematurely. It signals an increase in current indicators above critical levels. If the sensor is triggered frequently, check the pipes - most likely, scale has accumulated there. Since scale has good thermal insulation properties, the appliance overheats and shuts down.

- The productivity of the device has significantly decreased for unknown reasons - for example, the water began to heat up slowly, the pressure dropped sharply.It is necessary to test the heat exchanger for scale and remove all deposits from the working parts of the device.

We figured out the causes and signs of blockages, now let's see how to clean the gas column with our own hands, what is needed for this.

When to Clean Your Gas Boiler

Information on the frequency of cleaning geysers is rather contradictory. Some sources on the Internet recommend maintenance annually, others - once every 6 months, and so on. The homeowner will correctly navigate by the quality of tap water and some signs indicating that the device is contaminated:

- the heating efficiency and pressure in the DHW line have decreased - the heat exchanger is clogged;

- the igniter burns with a yellow or red flame (should be blue);

- the color of the fire on the main burner has also changed;

- the column does not ignite and turns off on its own at normal network pressure.

The average interval between preventive cleanings of an instantaneous water heater is 1 year. But you should take into account the quality and hardness of local water. If it is saturated with salts, scale will be deposited much sooner. In such cases, it is appropriate to use softener filters, otherwise all water heating equipment will quickly become unusable.

How to clean the column from scale?

The cleaning procedure is carried out sequentially in several stages. Clearly adhere to the proposed scheme below, and you will quickly solve the problem.

Stage 1 - preparing tools

To perform all the work, you will need the following tools and processing tools:

- screwdrivers - flat and cross-shaped;

- open-end wrenches of different sizes;

- a set of silicone gaskets;

- the container in which you put the removed heat exchanger;

- bucket;

- funnel or rubber pear;

- a plastic tube corresponding to the diameter of the heat exchanger tube, about 60-100 cm long;

- descaling agents: Antinakipin, Rust Cleaner, Cilit, VD-40 liquid, vinegar essence, table vinegar, citric acid;

- household cleaning products: Domestos, San-clean, etc.

Stage 2 - equipment preparation

- Before disassembling the column, check for serviceability the valve located at the inlet to the column.

- Shut off the gas and water supply.

- Remove the protective casing of the column: take a screwdriver suitable for fastening and unscrew the screws holding it.

- Loosen the nuts that hold the water filter in place.

Stage 3 - cleaning the filter

To get a really high-quality result and restore the throughput of the system, you need to know how to clean the gas column filter. This procedure is not difficult if you follow the following rules:

- Remove salt deposits and pipe debris with a brush.

- Rinse the filter under running water.

- Put it in a small container, fill it with cleaning agent.

- Leave on for 20-30 minutes.

- Rinse.

Stage 4 - replacement or correction of the membrane

Check the membrane for suitability. If it is strongly concave, then it must be replaced. In this case, we recommend that you replace the old part with a more modern silicone one.

Proceed like this:

- Close the water inlet with a lid, tighten the screws alternately to evenly tension the membrane.

- Unscrew the nuts that hold the water supply pipes to the heat exchanger. In the process of unwinding the fasteners, problems may arise, since the accumulated scale prevents them from detaching, in this case WD-40 technical aerosol will help you, it actively penetrates into the scale layer and softens it:

- Spray the product onto the surface.

- Leave for 15-30 minutes to react.

Step 5 - Checking the heat exchanger

- Disconnect the heat exchanger, turn over and place in a container.

- Using a funnel or a rubber bulb, fill the coil with the descaler of your choice:

- Use antinakipin in a warm form.

- Dissolve Cilit in water 1:2.

- Acetic acid must be located for effective exposure to the coil for at least 8 hours.

- Pour a third of the volume of the substance inside, add the rest of the liquid every five minutes as the reaction subsides (hissing).

- Leave the substance inside to act for 3-5 hours

- Drain the solution and flush the heat exchanger:

- Attach a plastic tube with one side to the coil and the other to the cold water faucet.

- Flush the coil until the water runs clear.

Stage 7 - final cleaning

Complete the procedure for restoring the health of the geyser as follows:

- Lubricate the threads on the pipes with graphite grease to make it easier to unwind the next time.

- Replace old gaskets with new ones.

- Connect pipes.

- Open the valves on the hot water and gas pipes.

We remove soot

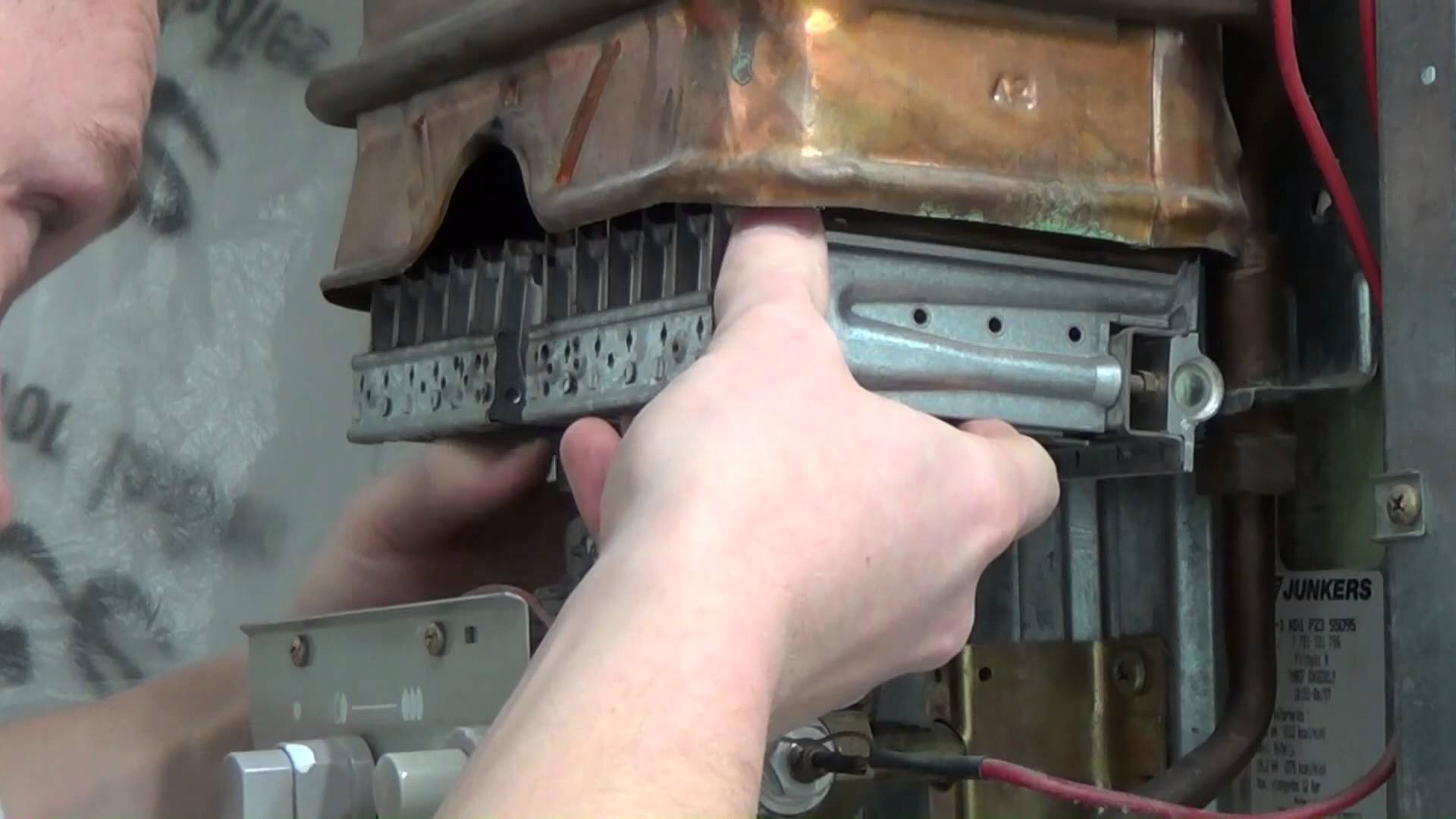

Where the heat exchanger is located, we wrote above, before starting maintenance, it is advisable to remove it from the unit, having previously turned off the gas and water, opening the tap for supplying hot water (the one located near the flow heater). Then, using a gas or open-end wrench, loosen the nut that secures the tube to the water unit, unscrew it a little (a couple of turns will be enough). The contents must be allowed to flow through the mixer, which is left open.

How to clean the gas column heat exchanger further:

- Unscrew a couple of union nuts, dismantle the assembly.

- Disassemble other elements, parts that interfere with easy dismantling. Their number depends on the specific model, the design features of the column. In some cases, it is necessary to remove the chimney diffuser, in others - the ignition group, in the third - overheating sensors, drafts. You may have to remove all the details.

- Cover the burner nozzles with a cloth to prevent soot from getting into them.

- Take the heat exchanger to the bathroom, carefully clean it with a long-bristled brush to remove all soot, rinse and dry.

- Return the assembly to its place, assemble the unit in the reverse order described above.

Do not forget to install new sealing rings at the pipe joints. It is not difficult to clean the geyser, most of the time is spent on assembly and disassembly. Work must be carried out strictly according to the rules. If you are not sure that you will do everything as it should, call the wizard.

Before starting the unit, check it for leaks. To do this, open the water supply valve, wait for the heat exchanger to fill from the open mixing valve. Then the flow is closed again, the assembly is inspected for the degree of permeability of its joints. In the absence of serious problems, the gas valve is again opened, the apparatus is started for testing in standard operating mode.

Fluid for flushing, softening joints during maintenance, use at your discretion. Chemistry simplifies the work, but it is not necessary to apply it.

Washing helps not only from soot, but also from dust.

How to remove soot from a heat exchanger at home

How to disassemble and assemble with your own hands

Disassembly and cleaning of the apparatus is carried out in several successive stages.

Shutting off water and gas

Before removing the heat exchanger, it is necessary to turn off the flow of gas and water. To do this, it is enough to close the taps responsible for the gas supply and water supply of the column. Only after closing the taps, you can start disassembling and cleaning the device.

Draining content

Sometimes a little water remains in the disconnected column, which must be disposed of in advance. Drainage of liquid is carried out as follows:

- closing all shut-off valves;

- opening a tap for hot water;

- removing the plug from a special hole for draining the liquid;

- draining water from the system;

- plug installation.

Dismantling features

Removing the heat exchanger on your own is simple, and therefore everyone can handle this work. First, the tubes are removed for entering and draining the water. To do this, you will have to unfasten the nuts responsible for fixing the pipes. They must be treated with WD-40 detergent to get rid of scale. When the pipes are unscrewed, the heat exchanger is removed.

Washing

To clean the part, a liquid prepared from hot water and citric acid is poured inside. It will help get rid of soot and other contaminants. You can also treat the surface with an acetic solution with hydrochloric acid.

Drying

The cleaned device must be dried before reinstallation. Before drying, it is thoroughly wiped with a dry towel to collect moisture from the surface. Then the heat exchanger is taken out to the balcony if cleaning is carried out in the summer. In winter, it can be dried near the battery or other heating devices.

Replacement of O-rings

To prevent water from leaking through the pipes, you will have to replace the sealing rings. Before installing the heat exchanger, it will be necessary to remove the rubber seal that is installed at the junction of the pipe and replace it with a new one.

Leak test

The assembled structure must be checked for tightness. To do this, some water must be fed into the pipes. If it does not leak, then the o-rings are installed correctly and the connection is completely tight.

Operation check

After making sure that the connection is tight, the device is checked during operation. The geyser is set on fire to warm up the water. If there are no problems during the heating process, then the device was assembled and cleaned correctly.

How to descale

With prolonged use of columns, not only soot is formed, but also scale, which must be disposed of.

Ready composition from the store

People who prefer chemical descaling often use specialty store products. They are highly effective, which allows you to get rid of even old contaminants.

Effective store formulations include:

- Boiler;

- Cleaner E;

- Detex.

With acid

Some do not want to use chemicals and use acid instead.

Salt

To clean the contaminated surface and protect it from destruction, you can wash it with hydrochloric acid. To eliminate scale, hydrochloric acid is poured into the heat exchanger and left in it for 15-20 minutes. Then an alkaline solution is poured into it, after which the mixture from the heat exchanger is poured into the sewer.

Orthophosphate

Washing the column with orthophosphate acid is considered effective against scale.In this case, experts recommend using a weakly concentrated solution. To prepare it, you will have to mix acid with water in a ratio of one to five.

Aminosulfonic

To clean the metal surface from scale, you can use aminosulfonic acid

It must be used very carefully, as it reacts with the metal and begins to corrode it. To prevent this from happening, the acid is mixed with inhibitors and water.

Lemon or vinegar

Citric and acetic acid can also be used to remove scale. However, such compounds are less effective, and therefore, in order to clean the metal, it will have to be soaked in liquid for at least four hours.

How to clean soot from a radiator

To clean the radiator from accumulated soot, two main means are used.

soap solution

Many people use conventional soap formulations to remove soot. Before using them, you need to vacuum the radiator to clean it of debris and soot particles. Then it is washed with soapy water and dried.

A small hook will help clean the radiator from a large amount of soot. After using it, it is necessary to rinse the part to wash off the remaining soot.

How to remove scale without removing the radiator

To perform this procedure, it is enough to remove the front panel of the water heater and disconnect the heat exchanger pipes from the water unit. Do not ignore the second step and do not flush the coil with the "frog"! You do not know how the detergent will affect the membrane and other parts of the water valve, so it is better not to take risks so as not to repair the unit later.

There are 3 ways to flush the heat exchanger internally:

- Connect the hoses to the heat exchanger nozzles and pour the cleaner manually through the funnel.

- Remove the geyser from the wall, turn it upside down and put it on the floor. Periodically pour a solution of citric acid into the coil and wash out the scale with water through the hoses.

- Make a booster from a circulation pump for heating - a device for pumping liquid through a heat exchanger. The scheme is simple: a pump, connecting hoses and an open container with detergent.

The burner and the gas column chamber will have to be cleaned with a brush with a long soft pile. Use a household vacuum cleaner to remove dust.