- The main causes of failure

- Regular bending and twisting of the tube

- Excessive increase in length

- Sharp temperature fluctuations

- Moving the device with a hose

- Ingress of foreign objects

- Contact with sharp objects and furniture corners

- Violation of storage rules

- Long period of operation

- Why the vacuum cleaner began to buzz loudly during operation

- The vacuum cleaner hums strongly: what can be done

- Units with a water filter

- Separator dust collectors

- Features of disassembling vacuum cleaners by brands and models

- Samsung

- Electrolux

- Breakdown prevention

- How to disassemble a vacuum cleaner?

- Problems requiring repair

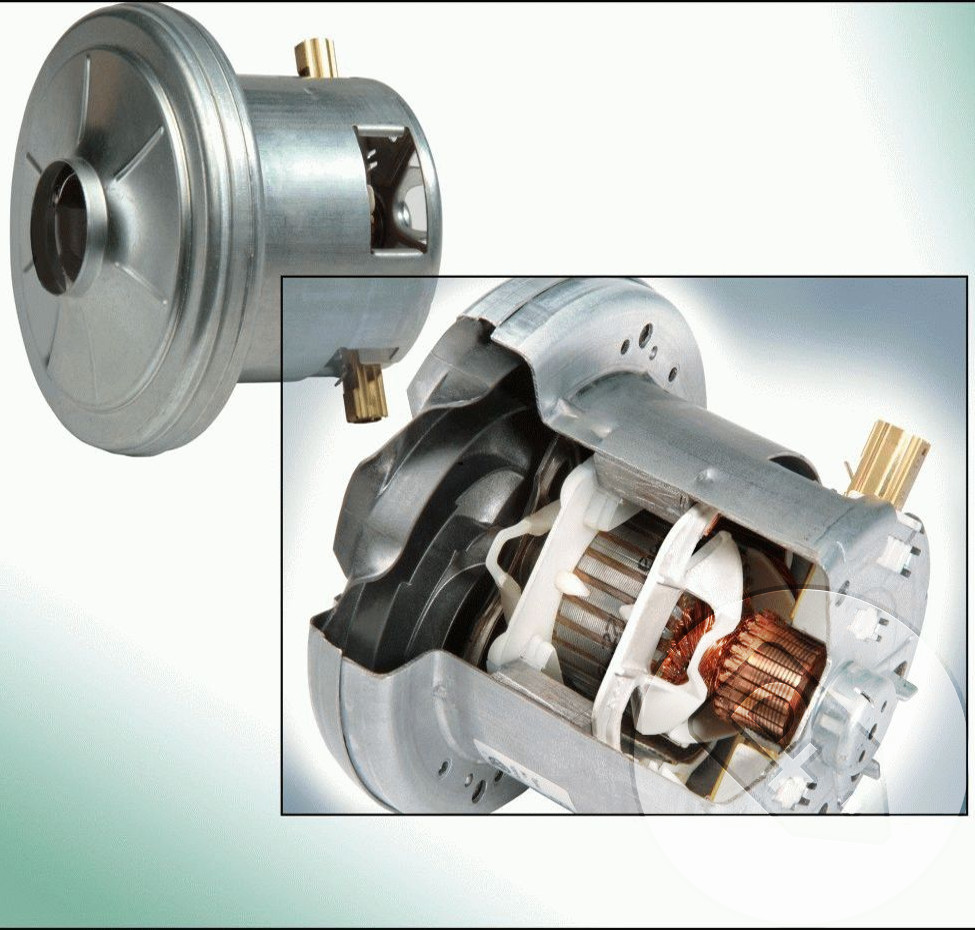

- Burning motor winding

- Worn graphite brushes

- Thermal fuse problems

- Robot vacuum cleaners

- When is the best time to seek help from an expert?

- Rules for disassembling a vacuum cleaner

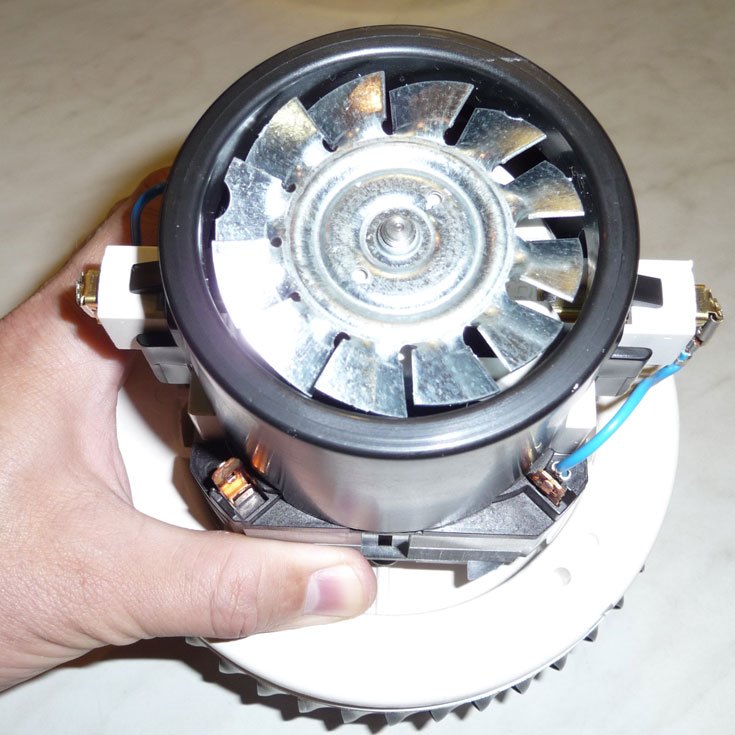

- How to check an electric motor?

- Embedded (central) structures

- Principles of operation and device

- Causes of defects

- Most popular damage

- Filter clogged

- overflowing bag

- Failure of one or more components

- Marriage or engine malfunction

- Filter clogged

- How does a vacuum cleaner

The main causes of failure

The design features of the sleeves determine the appearance of defects during the operation of the dust collector.

Regular bending and twisting of the tube

Corrugation without a frame (soft and hard), when the vacuum cleaner is not in use, retains its shape by laying in coils. With repeated repetition of the same position at the flexible pipe at the bend, the plastic wears out faster - cracks appear. Careless handling of the hose leads to twisting of the corrugation, as a result of which it breaks.

Air intake elements with a frame last longer. The reason for the violation of the integrity of the shell is also its inflection in the same place.

Excessive increase in length

The longer the hose, the more likely it is to be damaged during storage and cleaning. When not in use, it takes up a lot of space, it has to be rolled into tighter coils, which will lead to cracks. During operation of the vacuum cleaner, a long corrugation can catch on an acute angle and break. It is highly likely that the vacuum cleaner will be moved by pulling on the corrugated sleeve, which will lead to a rupture of the coils.

Sharp temperature fluctuations

Cracks appear on plastic products with a significant contrast in temperature. Moving the vacuum cleaner from a cold to a warm room and vice versa has a negative effect on the state of the polymer coating.

Moving the device with a hose

During cleaning, it is necessary to move the dust collecting unit by the handle on the body. Most often, the vacuum cleaner is moved, using the fact that it is on wheels, pulling the bar with a brush. From a jerk, the corrugation is greatly stretched and eventually bursts.

Ingress of foreign objects

The soft corrugation can be damaged by hard objects that have fallen into the hose during operation of the vacuum cleaner and stuck there. For example, when removing glass fragments, ceramics, nutshells from the floor.

Contact with sharp objects and furniture corners

The surface of the tube may be damaged when it hits the corner of a table, cabinet, chest of drawers. Objects with a sharp cutting surface must not come into contact with the hose: scissors, screwdrivers, knives.

Violation of storage rules

The manufacturer attaches an instruction manual to the model being produced, including the method of storing the vacuum cleaner during the working period. Failure to follow instructions will result in hose failure.

Long period of operation

The polymer corrugation has its own service life. With the most careful and proper use, plastic loses elasticity over time and cracks.

Why the vacuum cleaner began to buzz loudly during operation

Modern requirements for household appliances set quite stringent requirements for the permissible noise level. That is why, if the noise level of a working vacuum cleaner has become significantly higher, then this should be a signal that it requires additional attention.

The main source of noise when a vacuum cleaner is running is the engine. An increase in the volume of a running engine indicates that it is operating at increased power.

Prolonged operation in this mode leads to overheating of the engine, which is evidenced by an increase in the temperature of the air leaving the vacuum cleaner.

This can lead to engine failure and subsequent costly repairs.

The vacuum cleaner hums strongly: what can be done

If the vacuum cleaner began to buzz strongly, then what can be done so as not to call the master? For starters, simply disconnect the hose from the vacuum cleaner. If the engine stops making noise, then a blockage has formed either in the hose or in the brush / nozzle.

You can clean the hose yourself by using a cable that plumbers use when cleaning sewers.In addition, it is necessary to clean the brush, on the villi of which wool, hair, dust and other debris accumulate.

All this leads to the fact that the air is poorly absorbed, the thrust weakens, it is necessary to increase the engine power.

Important:

Before carrying out work, be sure to de-energize the vacuum cleaner by disconnecting it from the mains.

If the vacuum cleaner continues to make noise, it is necessary to clean and replace the filters. In this case, it is necessary to clean the dust and the body of the vacuum cleaner:

- The chamber in which the dust collector is located must be wiped with a damp cloth and the debris accumulated there must be removed.

- Clean all cracks, ribs, niches on the body of the vacuum cleaner where dust can accumulate.

- Inspect the place where the dust collector is attached - it must be clean, dust and sand particles will interfere with the tight attachment of the dust bag. Through leaks, dust will enter the motor, causing increased wear on the bearings.

- Blow out the engine compartment by removing the dust collector. In this case, the body must be tilted in different directions, changing the suction power - this will get rid of debris and dust that have fallen into the engine compartment.

If after that the engine continues to make noise and does not suck up dust well, it is necessary to contact a service center.

Before using the vacuum cleaner, check that all parts are in place, the filters fit snugly and there are no gaps through which dust can enter the engine compartment. In addition, loose parts due to vibration will cause additional noise, and may fail over time.

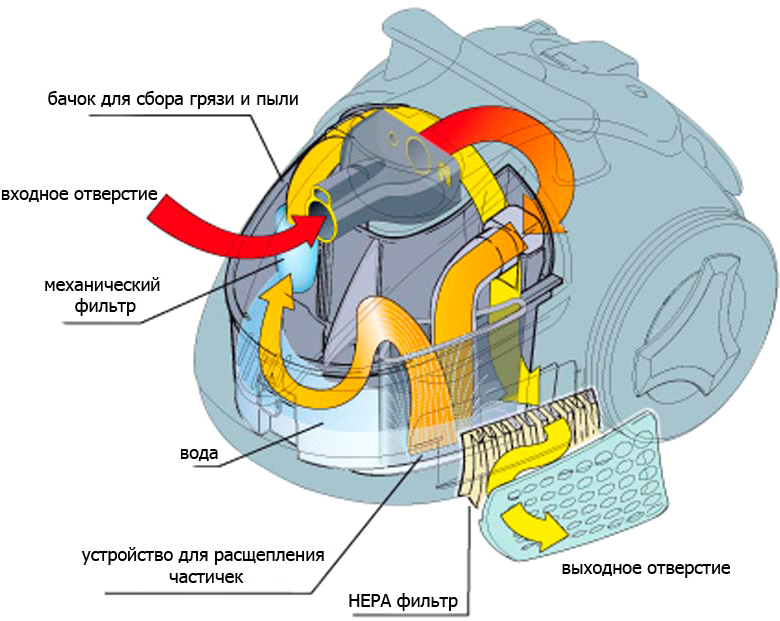

Units with a water filter

Another popular modification of vacuum cleaners, minimizing "communication" with dust and debris. Here, another container acts as a dust bag - a container with water.Garbage, large and microscopic, getting there, is quickly saturated with moisture and "stone" goes to the bottom. These models are also equipped with filters. Such vacuum cleaners effectively cope with their duties, but are not without drawbacks.

For someone, the minus will not be significant. This is a quick soiling of the container, so the owners are required to wash it after each cleaning. The container must be completely dry. Otherwise, undesirable microorganisms can “start up” in it, for which the aquatic environment is the best place to live. We are talking about mold, fungi.

Separator dust collectors

This is a relatively new variety, which is equipped with an improved aqua filter. Dust and dirt are retained inside with the help of a turbine located in the flask. Garbage, getting into it, instantly twists, thereby losing the chance to get out, and then plunges into the water, where it quickly settles.

Such vacuum cleaners, as a rule, also do not require a filter system, however, some budget models are equipped with them. However, almost all devices that have an aquafilter have a reliable system for protecting the engine from water.

Features of disassembling vacuum cleaners by brands and models

Each person thinks about repairing as soon as he hears noise in the engine. The reason for this may be dirt and dust accumulated inside the system. To check, you need to disassemble. This will require tweezers, vise, screwdrivers, wire cutters, grease. In the process of repairing equipment from the company samsung, follow all safety rules if you do not want recovery to end in injury for you. During the procedure, do not turn on the unit in the network.

Samsung

Disassemble equipment Samsung follows in order:

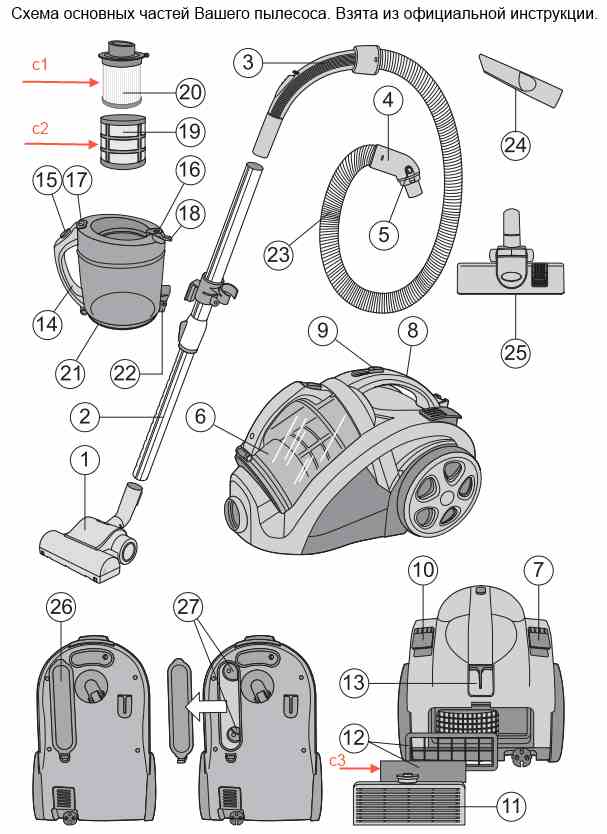

• first, remove the container that collects the dust. Then dismantle the two filters;

• use a screwdriver to remove all bolts located under the removed filters;

• after that you can remove the shell, it can be removed easily, without any special efforts;

• be able to start cleaning the case. To remove dust, use a brush or cloth, but not damp.

All models from Samsung are created taking into account three main types of filters, the method of care will depend on them: dry bag, aqua filter, cyclone.

Electrolux

Dismantling the vacuum cleaner Electrolux in some respects different from other manufacturers.

• First you need to open the compartment where the dust collects. Remove all screws and carry out the dismantling of the grille. The manufacturer usually fastens it with screws and other types of fasteners.

• After that, remove the cover from the dust collector and control buttons. Usually they are located under one block. Once this procedure is completed, you need to remove the dust container. It is mounted on latches, but depends on the type of unit.

• Next, it will be possible to separate the shell from the base. This can be done after unscrewing a few bolts

Please note that there may be more than one fastener, study the entire structure in detail

• Once the dust container has been removed, half of the procedure has already been completed. Then replace the filter located at the hose inlet. Disconnect the wires connected to the motor.

• After that, you can disassemble the motor. Dismantle the casing, for this it is enough to have a ruler made of metal.

• It is worth taking care of the removal of the impeller. In models electrolux, this part is put on glue, so you will have to use a solvent to dismantle it.

• Now you can unscrew all the bolts and examine the engine.

Once all the procedures have been performed, inspect the mechanism for damage.

It doesn't matter if it's about 1600w, 1800w or Extra 1400w, the disassembly procedure will be approximately the same. Regardless of the type of unit, its heart is the engine. It is he who draws dust into the system, and the filter protects all parts from the penetration of dirt. Do-it-yourself repair of the device makes sense only if the heart of the device is absolutely correct and works smoothly. We recommend disassembling only if you need to change the brushes, lubricate the bearings. The main advantage is that all devices inside are similar to each other, there is only a difference in mechanical details:

• element for collecting dust;

• frame;

• brush.

And the device itself remains unchanged. Therefore, if you disassembled the Philips model, you will not have any difficulties with LG or Siemens.

In this case, the process can be significantly complicated only in washing devices. They have a water pump, it is she who transfers water to the dust collector and is installed on its course. Therefore, in addition to all the procedures described, you will also need to unscrew it.

Breakdown prevention

Vacuum cleaners break down more often than other household appliances, which is associated with the installation of collector electric motors in them with a high rotational speed. Motor cooling is based on air blowing, so the operating time of the device without an air jet of proper pressure is no more than 10-15 minutes. If the vacuum cleaner is not turned off in time, serious malfunctions will occur that require major repairs.To avoid these consequences, you should follow some operating rules based on the observance of operating modes.

- The degree of filter contamination affects how hot the engine gets. To ensure normal operation, the filter element must be regularly cleaned of debris and dust.

- Moisture must not be allowed to enter the engine, so it is better to systematically change the filter for a new one than to wash it in water. In addition, it significantly reduces throughput and can cause overheating.

- The vacuum cleaner needs specialized care. Experts recommend changing the grease on the bearings at least twice a year and checking the wear of the graphite motor brushes annually.

- If the first signs of a malfunction occur, you need to proceed to their elimination, which will guarantee long-term operation and stable operation of the vacuum cleaner for many years.

So, a vacuum cleaner is an important household appliance that is used almost daily. Despite the simple design, breakdowns often occur in both foreign and domestic models. The cost of repairs in service centers is often unreasonably high, given the fact that some problems can be fixed in a few minutes by simply replacing a damaged part. However, most of the work can be done independently.

How to disassemble a vacuum cleaner?

Regardless of what kind of breakdown you encountered, in order to know its causes and why the vacuum cleaner stopped working, you should disassemble it.

Of course, each model has its own special device, but the following chain of actions will be an approximate general algorithm.

- It is necessary to dismantle the sealing grid, which is located under the cover of the dust collector area. It is fastened with two screws or other threaded connections. You can unscrew the screws with a regular screwdriver.

- When the sealing grid has been removed, detach the control box and the dust collector cover.

- Depending on the type and model of the equipment in question, the dust collector should simply be removed or unscrewed. Under it there should be a garbage collection mechanism, under which the body is connected to the motor of the device.

- To get to it, you should separate the base and body. In some models, this is done after twisting the hidden bolt, which is located in the handle.

- Usually the motor is protected by a special fabric-based gasket that is attached to the inlet of the intake hose. The gasket should be removed and cleaned or, if necessary, replaced with another one.

- Now we remove the wires responsible for the power supply from the motor. To do this, unscrew the clamps fastened with bolts.

- Now it will be necessary to check the bearing pairs that are responsible for the operation of the engine. The slightest evidence of wear is the presence of various irregularities and cracks. If there is something like that, then you should replace the parts.

Now let's move on to disassembling the motor. It should be said that the implementation of such procedures requires experience in their implementation. Otherwise, it is better to contact a specialist.

The cover must be removed first. This can be done with a straight screwdriver, strap or ruler.

It fits quite snugly to the motor, which is why you can first tap it gently in order to disconnect it. This should be done carefully so as not to cause physical damage to it.

When the casing is removed, you can access the impeller, which is held on the built-in nuts.

They are tightly fixed with glue, so you should have a substance such as a solvent on hand.

Under the impeller there are 4 screws that secure the motor. They should be unscrewed one by one.

When access to the motor is obtained, its performance should be checked.

Note that a model that can also carry out wet cleaning will be more difficult to repair, due to the fact that it will also be necessary to carry out work with a water pump. Its main task will be to supply liquid to the dust collector, which is why the pump is usually mounted at the inlet.

Problems requiring repair

In the absence of basic knowledge of electrical engineering, diagnosing the cause of an engine malfunction is quite difficult. It must be removed from the case, disassembled and ring all the elements of the circuit with a multimeter.

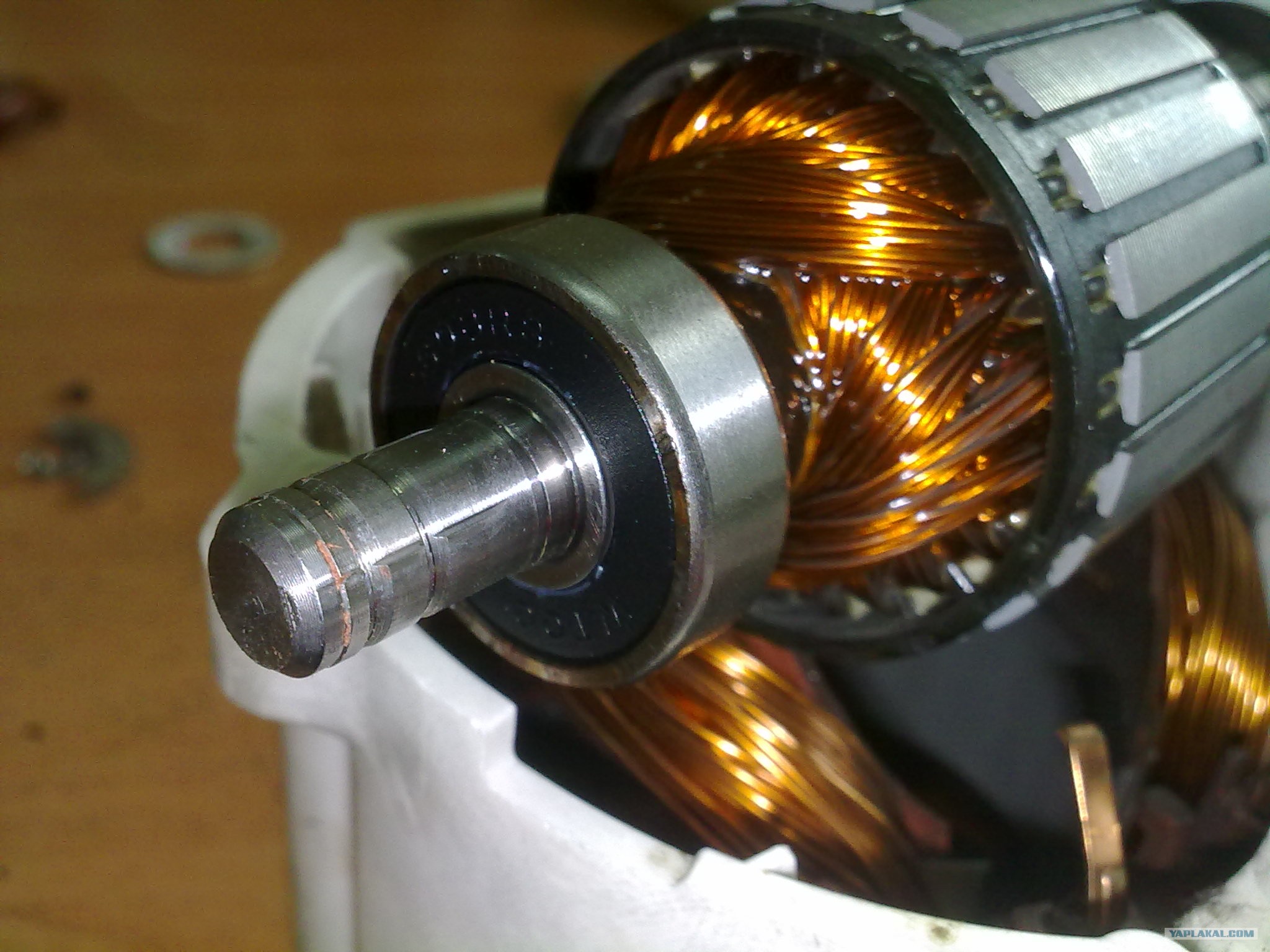

Burning motor winding

If the motor is fully functional, it may slightly spark due to dust on the brushes (it smells burnt). But strong sparking is already suspicious.

One of the causes of sparking may be a short circuit in the armature winding: then it is necessary to rewind or replace the rotor. The stator winding is checked by measuring the resistance - if it is different in several parts, the winding is rewound or changed.

Worn graphite brushes

The brushes no longer fit closely to the collector contacts for two reasons: wear and low-quality materials.Poor contact adversely affects the start and further operation of the engine.

The fact that the brush has become unusable can be determined during its inspection. Most often, replacing carbon brushes will save. If it cannot be removed, change the springs and brush holder.

Thermal fuse problems

If the fuse fails, it must be replaced.

Robot vacuum cleaners

These are the smartest and most independent assistants who are trying to oust their "rustic" cleaning colleagues. They are almost universal, as they are equally effective in removing debris from hard surfaces and carpet. In the case of small monoblocks (square, round) everything that is needed for a full-fledged cleaning is placed: a dust collector, a washing module, an engine.

The robot vacuum cleaner will be able to do scheduled cleaning in the absence of the owners, as the device is programmed with a remote control or using a smartphone. The trajectory of movement is selected thanks to sensors - infrared, laser, magnetic. Three hours of work without interruptions is provided by one charge of the device.

The device of a vacuum cleaner is not such a difficult topic to study, the biggest difficulty is choosing the right device, and it is not easy because of the indecently huge range. However, future owners can study the reviews on the unit they like, see the ratings or consult with the sellers.

If the choice is yet to be made, then maybe this video will be useful:

When is the best time to seek help from an expert?

By fixing the problem of the product yourself, you can significantly save your money. However, not every breakdown can be repaired with your own hands, there are a number of cases when you just need to seek the help of a specialist.

Signs of a serious vacuum cleaner failure are:

- Extraneous noise, hum, vibration, pops, sparks.

- Overheating during non-continuous operation.

- The smell of burnt wires.

- Independent abrupt shutdown of the device.

If you find one of these signs, turn off the product, unplug the power cord and, if possible, contact the technician.

In addition, it is worth remembering that disassembling the device requires experience in conducting such events. If you do not have this experience at all, then it would be better to immediately seek qualified help from a service center.

Rules for disassembling a vacuum cleaner

To find out the cause of the breakdown and eliminate it, you will need to disassemble the vacuum cleaner. When performing work, the following rules should be observed:

• first disconnect the cord from the mains;

• disconnect the dust transportation unit (hoses);

• remove and clean dust collectors, inspect filters;

• open the cover, which gives access to the dust collector;

• remove the HEPA filter;

• unscrew the screws fixing the cover with access to the unit;

• the fan is detected first, it must be removed (the screw heads do not need to be unscrewed, they sit on the thread, the nuts on the studs should be disconnected);

• remove the motor power connector from the socket.

Sequential actions open access to the network cable drum.

What are the most common vacuum cleaner failures? how to fix them

How to check an electric motor?

If the vacuum cleaner is buzzing, but it does not work, perhaps the whole thing is in its main part - the motor. But first you need to check the electrothermal relay, which prevents the negative consequences provoked by overheating.If you have been vacuuming at maximum speed for a long time, and the body of the device is hot to the touch, then just wait and let it cool down, and then try turning the device on again. If it still doesn't work, it's most likely the engine that's broken.

It is necessary to check the brushes: if they are worn out and worn out, the connection between the stator and the rotor may be broken, due to which the motor will stop working. In the normal state, they, adjacent to the rotor, provide a reserve along the course. If the parts are worn out, then you can try to replace them on your own by acquiring new ones. You also need to analyze the integrity of the brush circuit, stator and rotor using a multimeter. If the voltage is good, the rotor winding, which is an expensive part, could have caused a breakdown.

If there is no smell and smoke, then complex repairs and replacement of the motor may not be required. It is impossible to disassemble the engine yourself, so try to examine the wire connections through the holes in the housing.

Also evaluate the contact areas of the windings with brushes and terminals. Since the device during operation constantly and quite actively vibrates and moves along the floor by the owner, the wires can be damaged, which will lead to a circuit break. If the cable just came off, pull it up and plug it in. If it is damaged, then you can try to connect the site. If all else fails, soldering a segment a few centimeters long can help.

Embedded (central) structures

This is the rarest, exotic species. Such vacuum cleaners are not mobile, they have working parts - air ducts, motor, filters - hidden in the wall.The hose with nozzles of this miracle unit is connected not to a vacuum cleaner, but to pneumatic outlets located around the entire perimeter of the area where cleaning is required.

Inside the walls, a labyrinth of air ducts is equipped, which leads in one direction - to a common dust collector. Such a container, as well as a motor and filters, are usually mounted in the basement or utility rooms. A huge minus is that the hoses are very long, they only make cleaning difficult, interfering with it.

Principles of operation and device

Before starting repairs, it is worthwhile to carefully study the device of the garment steamer and all the technical documentation for it, determine the type of steamer, and only then proceed to repair it yourself.

There are two types on sale: floor and manual. Manual is compact, designed for ironing garments made of light fabrics, as well as disinfecting household items. Due to the fact that the volume of the tank is small, and the power is inferior to the floor type, the range of its application is not as wide as that of the latter. The vertical floor steamer is a design that looks like a vacuum cleaner with a hose and brushes. Its wheels make it easy to move. The power and volume are higher, the working time is longer.

The principle of operation of the device is based on the supply of wet steam under pressure. It is formed by boiling water from a heating element. The heating element maintains a constant temperature, ensuring the production of a steam jet directed through a special brush. The necessary pressure is created by the pump.

The floor steamer device includes the following mandatory elements:

- Boiler - a compartment where a tubular electric heater is located.

- The water tank is a closed-type tank made of heat-resistant material.

- Outlet tube for removing steam from the vessel.

- Steam hose for diverting and directing the working jet.

- The handle from the heat-insulating plastic for manipulation.

- Work surface with nozzles.

Causes of defects

Cracks, tears, punctures on the body of the vacuum cleaner hose can appear for various reasons. However, the main reason, of course, should be considered improper handling of this part.

What actions of the user lead to the appearance of defects on the body of the corrugated tube?

Consider in more detail:

- Towing the vacuum cleaner from place to place through a hose.

- Bending the tube at unacceptable angles during cleaning.

- Inaccurate use when cleaning objects with sharp edges.

- Storage not according to instructions.

The natural cause of the formation of defects should also be considered the expiration of the product's service life, wear, and poor quality of the material.

Often, violation of the rules of operation by the owners of harvesting equipment leads to the appearance of defects on the body of the corrugated sleeve. When working with a vacuum cleaner, it is not recommended to use physical force in relation to the hose directly.

Towing a vacuum cleaner from place to place by pulling the device by the working hose is a fairly common practice.

At the same time, many owners of vacuum cleaners perform such "tricks" completely unaware of the future consequences. Meanwhile, the instructions for any vacuum cleaner clearly state - you can’t do this!

A bend in the pipeline at an unacceptable angle can occur when the owner of the vacuum cleaner, in the heat of cleaning, seeks to reach areas that are theoretically inaccessible in terms of the operational and technical parameters of the cleaning equipment.

Such a fold of the corrugation sleeve contributes to the rapid appearance of a crack or rupture. Therefore, manipulations with the hose during vacuuming should prevent the corrugations from bending at steep angles.

Several times such attempts can end quite successfully. However, the strength of the material in relation to unacceptable loads is not unlimited. And therefore, at the most inopportune moment, the pipeline will simply burst in the place where there was an unacceptable bend.

Cleaning operations can be carried out in different conditions. For example, in the conditions of cleaning furniture, the frame of which has metal parts with sharp edges

If in such conditions it is careless to manipulate the hose, there are all prerequisites for the appearance of cuts on the body of the corrugation

Finally, the rules for storing cleaning equipment, specifically described in the instructions for the vacuum cleaner, should also not be violated, since a violation here is one of the reasons for the failure of the vacuum cleaner hose.

The storage conditions of household cleaning equipment accessories directly affect the quality of the material from which the same working hose is made. Therefore, violations of storage rules contribute to the appearance of defects.

So, storing the device together with accessories, or separately accessories, at a temperature below the recommended one, leads to a decrease in the strength of the material of the corrugated tube.

Sharp temperature changes, loaded state, unacceptable kinks are also critical for the hose material.

Most popular damage

If you do not clean the dust collectors in a timely manner, do not change the filters, use the device without an aqua filter to collect moisture, you will find a malfunction.

Filter clogged

The breakdown occurs as a result of rare cleaning of the dust bag or filters.Household vacuum cleaner suddenly began to work very loudly? The problem is explained by the operation in overload mode, from which the sound is amplified. Check the hose for large debris, dust clods, hair or animal hair.

Most often, a clogged filter is to blame. Important! If measures are not taken in time, suction power is lost, and the equipment may simply not turn on.

overflowing bag

Dust collectors have a certain filling limit - up to 80%. Disposable bags should be changed after each cleaning, and fabric bags should be washed thoroughly. To avoid clogging, before work, check the quality of attachment of parts, nozzles and dust collectors.

Paper bags should be changed after each cleaning, and cloth bags should be washed thoroughly. Tip! If you forget to pay attention to the amount of garbage in the bag, buy a model with a full indicator light

Failure of one or more components

The cause of excessively loud noise may be a breakdown of the motor, impeller, brushes, motor, bearings and manifolds. When everything is in order with the filters and bags, but there is a hum, contact the service center. Self-disassembly and repair will lead to a complete stop of the device.

Marriage or engine malfunction

If there is a manufacturing defect in the new technology, the buzz appears from the very beginning. Under the Consumer Protection Act, you can replace your vacuum cleaner within 14 days. If the failure occurs later, you are entitled to a free repair at the manufacturer's service center.

Vacuum cleaner motor

Filter clogged

Filter clogging is the most common problem that causes extraneous noise when the motor is running.The fact is that uncleaned filters limit the access of air to the engine, which begins to function in the mode of constant overloads. The consequence of this may be its failure as a result of frequent overheating.

There are several types of filters that are most often used in vacuum cleaners:

- Primary - collect garbage and coarse dust that accumulates in bags.

- Hera cleaning system - traps the smallest dust particles, the size of which does not exceed 0.3 microns. Depending on the type of filter, it can be washed (reusable) and, after complete drying, put back in place or replaced with a new one (disposable filter).

- Aquafilter - provides for cleaning by separately washing the dust container and the Nera filter.

The systematic elimination of filter blockages is not only the key to clean indoor air, but also the long-term operation of the vacuum cleaner itself.

How does a vacuum cleaner

The availability of self-repair is due to the simple device of a vacuum cleaner. Experts distinguish three types of structures:

• with dust bag;

• with air-water fog filter;

• with a stationary dust collector (cyclone).

Any model has the following constituent elements:

• unit for collecting dust (bag, container);

• waste transportation system (hoses, nozzles);

• the main body, in which the unit, dust collector, filtration system is mounted.

Regardless of the variety, vacuum cleaners are equipped with hoses, adapters, nozzles, which can also break during operation.