- Security

- How to make a miter box at home?

- The use of thermal methods

- Duration of works

- oblique cut

- Reasons for cutting a gas pipe

- Legal requirements for the customer and contractor

- Who should apply?

- Who is authorized to do the work?

- How to cut a gas pipe: procedure, rules and stages of work

- Connecting the system to the gas pipeline

- How to cut a pipe at an angle - marking options for round and shaped pipes

- Paper corner marking

- Marking method using a container of water instead of a template

- Using the PC program

- How to cut a profile pipe at an angle

- Precision cutting machines

- What tool can be used to cut plastic pipes

Security

The next stage is carried out by the forces of the invited brigade. Before connecting to the gas pipeline, you must:

- draw up a diagram of the connection angles;

- choose a tie-in method, calculate the order and method of pressure reduction, determine ways to maintain the indicator at the desired level;

- calculate and select the required amount of materials, tools, rescue and protective equipment;

- close taps, valves, plugs on the connected pipe;

- stock up on the required amount of water to prevent fire or fire.

Before tapping, control testing of pipes, connected system and air outlets is performed.

How to make a miter box at home?

It is equipped with saw slots designed for sawing material at a certain angle. The dimensions of the parts are not very important, but the wider our homemade device is, the wider and more accurately we can cut wide slats.

You can make markings using the methods described above, and then use small pieces of plywood and a hacksaw. And in order to fasten everything, you can use self-tapping screws or even super glue. However, all this is more complicated and will take much more time, although it will provide the most accurate result (of course, if done correctly).

However, if for some reason a situation has arisen that it is impossible to get the tool as soon as possible, you can use improvised tools, such as a ruler, a protractor or even a tile, with which it is easy to create a template with the desired markup or even recreate the miter box at home .

You will need

- - miter box;

- - hacksaw;

- - wooden blank;

- - protractor;

- - pencil;

- - a clamp or screws and a screwdriver.

Instruction

Prepare an angle template that will help you easily make an accurate cut of a piece of wood at an angle of 45 degrees. This device is a profile in the form of an inverted letter "P"; on its sides through slots for a hacksaw are made. Usually they are located at angles of 45, 60 and 90 degrees. More complex miter boxes are additionally equipped with arbitrary fixed slots, or they have a swivel design - it allows you to set the saw in the optimal position.

Buy ready-made carpentry tools from a hardware store with a wood, metal, or plastic tray. For a beginner, this is the best option. If desired, you can make a simple miter box from three planed boards or plywood strips (thickness - about 1.5-2 cm).

Drill several holes in the walls of the future miter box, apply wood glue to the ends and assemble the box (tray) of the miter box. Fix the corner template with screws. The walls of the tool must lie strictly parallel to one another; the bottom and each sidewall make up clear perpendiculars.

Mark a 45 degree angle with a pencil, add additional groove lines if necessary. In order not to be mistaken in your calculations, use a protractor.

The most important thing is the cuts. It is recommended to perform them with the same hacksaw, which will subsequently be cut in the finished miter box. Start sawing without strong pressure on the working tool, hold its blade. First cut through one sidewall, then the opposite.

Start processing lumber. Secure the miter box to a workbench or desktop with a clamp (clamps for fixing parts) or screws. Then make a mark for the future cut on the rail (board, plinth) and put the workpiece in the box. Press it firmly against one of the side walls of the template, aligning the marks with the 45-degree angle slot.

Insert a hacksaw into the grooves of the miter box and cut the workpiece. The work of the saw will be limited to fixed cuts and you will get a smooth and precise cut.

When sawing skirting boards, make sure that the corners in the room are really straight. If the walls are very uneven, the cutting angle on the blanks should be corrected.Measure with a goniometer the place of the joints of the internal walls and divide the result in half (the joint of the skirting boards "in the moustache"). To make an accurate cut, it is recommended to make grooves with a given angle in a homemade miter box. Another option is a magazine rotary tool that allows you to change the angle from 0 to 180 degrees in increments of about 15 degrees.

When installing a pipeline, it is often necessary to cut the pipe at a certain angle. Accuracy plays a big role in this task. There are several easy ways to cut a pipe at an angle.

An incorrect cut of the pipe will lead to the impossibility of mounting the structure of the form that was originally conceived. For example, if you plan to rotate the system by 45 degrees, then you need to cut the pipe at 45 degrees. To complete the task, you will need marking tools and a grinder (it can be replaced with a hacksaw).

The use of thermal methods

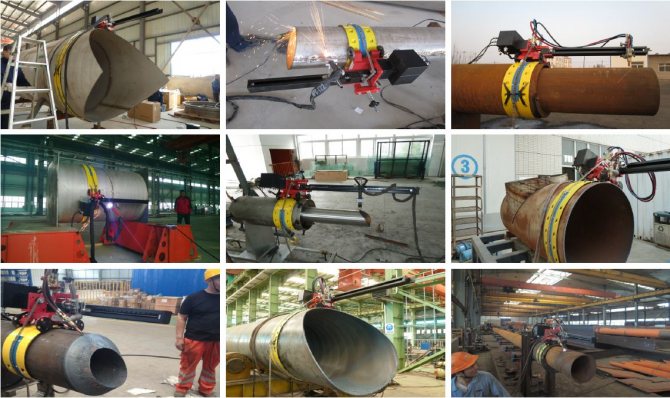

In addition to mechanical methods, thermal methods are often used, where welding or cutting machines work as a tool. For example, an oxy-fuel cutting torch or a conventional welding machine (DC/AC).

With the help of such devices, thick-walled metal pipes are available for cutting. However, it is extremely difficult to obtain a perfectly even, high-quality cut using electric welding or gas autogenous welding.

Cutting technology using electric welding and autogenous welding is widespread. The technique does not provide high cutting accuracy, but this factor is often not decisive when installing pipes.

Cutting technology using electric welding and autogenous welding is widespread.The technique does not provide high cutting accuracy, but this factor is often not decisive when installing pipes.

Usually, after thermal cutting, the products are subjected to additional processing. The cut line is aligned, the values of the required angle are adjusted. This approach is not economically viable, as it is accompanied by additional costs for machining.

As a rule, a thermal cutting technique is used in the conditions of the industrial and production sphere. True, housing and communal services also often resort to this technique.

Thermal cutting is also used to work with plastic material. There are devices - thermal guillotines. The sharp thin blade of such devices is heated to a high temperature, after which the cut is performed.

Thermal guillotines support cutting at an angle, and this is their advantage. However, to work with more rigid materials than PVC, wood, chipboard, these devices cannot be used.

To cut metal-plastic pipes, pipe cutters are needed that can evenly divide products with a multilayer structure into parts. The article recommended by us is devoted to their varieties and methods of application.

Duration of works

The duration of the work is determined by such factors:

- Structural specifications of the pipe.

- Tools used at work. The pipe can be cut with a grinder, welding method, hacksaw or pipe cutter.

- Skill and experience of the worker.

The richer both the theoretical and practical experience of the employee, and his skill, the more diverse the range of tools, the higher the dynamics of work.

It is better to contact a company with a proven track record. Her masters will master tasks of any complexity. The work is done quickly and very high quality. This is a guarantee of safety, reliable operation of gas appliances, and comfort in the apartment.

oblique cut

When changing the direction of the pipeline at an angle greater than 90 degrees, manual methods for making templates become too complicated. The use of a special program for calculating and creating patterns on a computer for any angles can come to the rescue. The method is good in that it has a high accuracy in creating paper templates and is easily implemented with a printer.

To obtain a paper pattern, the necessary data on bending angles and pipe diameter are entered into the program, after which a template is obtained, which is printed on a printer in full size. It remains only to cut it out, stick it on the element to be cut and mark its contour.

Further cutting is done using a grinder in the standard way. An important advantage of machine templates is the ability to cut them in unlimited quantities with the same accuracy.

Rice. 10 Sample calculation program

For high-quality connection of cylindrical elements of pipelines, their precise cutting at angles of 45 and 90 degrees is required. To perform these works, special patterns are used, the shape of the bends of which is calculated manually or built by a computer. They are cut out on paper and glued onto the pipe surface, then the element is cut along the paper contour with a grinder with a small disk. Thus, it is possible to obtain a high-precision corner joint with the closest possible edges.

Reasons for cutting a gas pipe

The most common motive is to carry out repairs, during which a decision is made to change the position of the stove or install new equipment. All this can encourage the owners to shorten the gas pipe.

In addition, the initiator may be a representative of the gas company, who legally requires the removal of the meter in the visibility zone.

It may also require shortening due to the inconsistency of outdated communications with modern rules. The standards are regularly updated, and the owners of residential premises rarely independently monitor the changes made.

Legal requirements for the customer and contractor

Since a faulty gas pipeline is a source of danger to people's lives, legislators have identified the customer - the initiator of cutting or moving the gas pipe and the contractor. The law imposes special requirements on the latter

Therefore, they deserve special attention.

Who should apply?

Until 2005, in the Russian Federation, municipal gas services were responsible for the condition of gas pipes and equipment connected to them. Later, the law shifted it to homeowners: management companies began to monitor intra-house networks in apartment buildings, and owners or tenants began to monitor intra-apartment networks.

In private households, this has also become the responsibility of the owners. Therefore, before shortening the gas pipe in the kitchen, it is necessary to determine the owner.

The figure visualizes the division of responsibility between the management company and the tenants. At the same time, payments for the maintenance of in-house equipment are included in monthly receipts. But for manipulations with intra-apartment networks, including for cutting pipes, residents pay separately

Confirmation of this rule can be found in Decree No. 410 dated 05/14/2013, edited by the Russian government on October 6, 2020.

According to the general provisions of this decree, when cutting a pipe in an apartment or private household, the owner of square meters or the tenant can become the customer. In this case, the lease must be formalized.

Who is authorized to do the work?

The executor is also clearly defined in the government document. This is a specialized organization that performs maintenance and repair of gas equipment under an agreement with the owners or management company. In addition, the supplier company can also take over the cutting of pipes.

The law imposes the following requirements on the performer:

- the presence in the state of certified employees with specialized education;

- availability of production instructions for gas hazardous work;

- obligatory use of control and measuring equipment.

All tools and devices used by the masters of the gas service must undergo regular calibration according to the schedule approved by the organization.

As can be seen from the above list, the requirements for the performer are quite high. Therefore, shortening gas pipes on your own or with the help of unauthorized persons who do not have a license is not worth it.

How to cut a gas pipe: procedure, rules and stages of work

Before cutting off a gas pipe, it is important to familiarize yourself with the regulations and rules for working with gas equipment. Have you noticed how few users do this? The majority decides to look into the SNiPs, already holding a grinder in their hands

Some even ignore the rules established by law.Meanwhile, each stage of this event is regulated, has a certain sequence of implementation.

Incorrectly made shortening of the gas pipeline is fraught with serious consequences, the most formidable of which is the leakage of explosives. To work, you need an accurate professional tool, experience and knowledge of safety. Without such a set, it is not worth taking responsibility for unauthorized modification of the pipe. It is better to entrust it to the master. But how do you check if it's working correctly?

In this article, we have given all the rules regarding cutting gas pipes in houses and apartments, compiled an algorithm of actions, a list of tools and materials. After reading it, you will save time on searching for information, you will be able to correctly plan your actions, prepare all the necessary documents in time and control the work of a specialist.

Connecting the system to the gas pipeline

To tie into a common highway, you will need to carry out the following activities:

- Clean the joint of debris, rust or paint.

- Make a markup, mark the place of the tie-in.

- Make holes, of which there will be two - in the case of the tee method, and one - with the coil.

- Close the cracks with clay. Processing must begin at the moment the surface is cut. This will reduce the risk of gas fire. Close the holes made immediately with a plug made of clay and asbestos, after completion of work, cool the surfaces.

- Mount the disconnecting device after the final cooling of the metal. To do this, pull out the plug and remove the part of the cut pipe.After that, insert a disconnecting device into the resulting gap - it looks like viscous clay sacks and several rubber and wooden discs. In the case of using the tee method, there will be two slots.

- Now you need to mount the pipe through which the gas pipe is connected to the main. But first, check the diameters match. If nothing needs to be adjusted, then make a hole and mount the pipe, then weld the joints and close the valve installed on the pipe.

- We close the holes and weld a new pipe. To begin with, get rid of all the remnants of metal formed during the creation of the main gap. After that, connect the pipe to the nozzle, process with clay and weld. The quality of the weld is checked with a soap solution.

If no leaks were found, then you can proceed to the finishing work - that is, backfilling the trench. Despite the fact that the work may seem very simple, they must also be carried out in compliance with regulatory documents.

As a rule, such documents contain the following information:

- Soft soil no more than 20 cm thick is poured around the mortise unit, pipe and tap, followed by compaction.

- At the very end of backfilling the trench, heavy equipment should not be allowed to run into pipes, mortise units and a ball valve.

Upon completion of construction work, it will be necessary to sign an agreement with the local gas service to start supplying blue fuel. In addition, the gas service will be obliged to carry out technical and emergency dispatch services. The same organization will deal with the acceptance of the finished gas pipeline system. After the start-up and adjustment work, it is imperative to draw up an act, as well as seal the gas control system.

How to cut a pipe at an angle - marking options for round and shaped pipes

When installing a pipeline, it is often necessary to cut the pipe at a certain angle. Accuracy plays a big role in this task. There are several easy ways to cut a pipe at an angle.

An incorrect cut of the pipe will lead to the impossibility of mounting the structure of the form that was originally conceived. For example, if you plan to rotate the system by 45 degrees, then you need to cut the pipe at 45 degrees. To complete the task, you will need marking tools and a grinder (it can be replaced with a hacksaw).

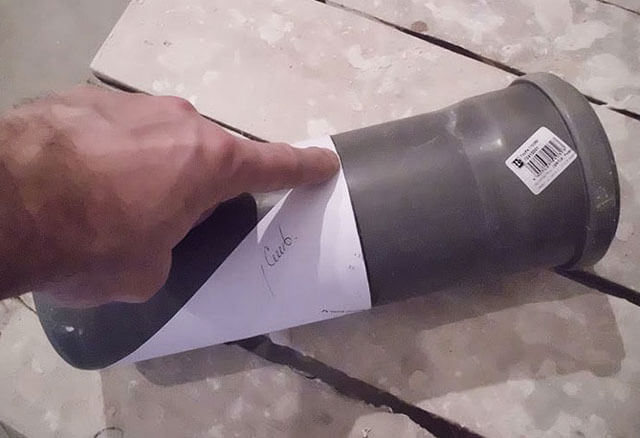

Paper corner marking

Paper sheet marking is one of the easiest ways to complete a task. Requires a square sheet. It folds exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its cross section.

Then on the smaller side an angle of 45 degrees is formed. It remains to mark the cut line with a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with narrow tape so as not to accidentally erase it. This method is excellent for long large pipes with a cut point approximately in the middle of the product.

Marking method using a container of water instead of a template

This marking method is suitable for pipes of small diameter, which are planned to be cut at a certain angle near the edge. First you need to prepare a deep container with water. It marks the planned angle of inclination. Now you need to carefully immerse the end of the product in the liquid, tilt it to the mark, and then pull it out.

As a result of such actions, a clear line of contact with water will appear on it, it must be highlighted. On it, the pipe is cut at an angle. This method is best suited for jobs where multiple markings are required.

Using the PC program

To implement this method of marking pipes for cutting, you will need a computer with special programs. First you need to draw up a drawing, which indicates the transverse dimensions of the product, as well as the planned cut angle. You need to get a virtual template.

Print it out on your printer. And here it is worth understanding that the larger the diameter of the pipe, the more sheets will be required to print it. Then you need to carefully cut out the details of the drawing from all pages and glue it, it is best to use stationery tape for this. It remains to attach the template to the pipe and apply the markup.

This method of solving the problem is highly accurate. All necessary programs can be downloaded on the Internet, they are free to download and use. There you can also find a template for cutting pipes at an angle. All you have to do is print it out and cut it out. To perform marking, the pattern simply wraps around the pipe.

How to cut a profile pipe at an angle

The marking of the profile pipe is different from the round one. Its manual execution can lead to significant errors. The best way to solve the problem is to create a cutting template from the same profile, but with a larger diameter.

You will need a small piece of profile pipe. On it, using a goniometer, mark an angle of 45 degrees.Now, with the help of a grinder, it is necessary to cut off part of the workpiece along the marked line.

The edges of the cut must be sanded, defects eliminated. It remains simply to insert the original product into the template for cutting pipes at an angle. Then you need to apply markings along the cut line of a larger profile.

And already the pipe itself is cut along it.

The text describes how to cut a pipe at an angle of 45 degrees. When the markup is already completed, it is recommended to use the grinder. It will help you make a straight cut.

You can replace it with a hacksaw. It will also be possible to cut the product by welding, but experience in handling the tool is needed, otherwise there will be irregularities.

"How to cut a pipe straight - tools and cutting methods."

Now in hardware stores you can find special tools for cutting pipes. But it is easier and cheaper to make a template yourself.

Precision cutting machines

Band saws are distinguished by high stability of the plane of movement of the blade and cutting accuracy. They are also widely used in the harvesting areas of small-scale and medium-scale production. They are characterized by versatility, reliability and high performance.

For private use, MASS from Italy offers a compact band saw unit. It is equipped with a manual clamping device and can smoothly cut pipes up to 65 mm in diameter, as well as rolled products of any profile of the same thickness.

The rotary device allows you to set an arbitrary cutting direction from 0 to 45 °. The frequency of movement of the cutting blade is up to 45 cycles per minute. An economical 370 watt motor allows you to use a regular home single-phase electrical network with a voltage of 220 V.

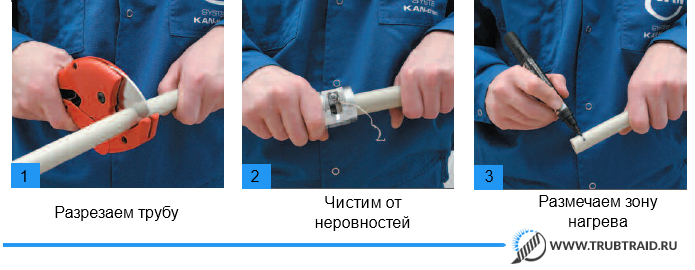

What tool can be used to cut plastic pipes

Considering that the people in our country are artisans, then they manage to use the most unimaginable tools at hand to cut pipes. But do not think that such cutting contributes to the good quality of the future pipeline. Therefore, consider the tools that allow you to cut plastic pipes with the highest quality:

- hacksaw for metal;

- self-sharpening knife (with fine teeth);

- scissors for cutting plastic pipes;

- roller type pipe cutter;

- battery pipe cutter;

- guillotine pipe cutter.

Cutting off pipes with a hacksaw or a knife should not be taken seriously, since their use leads to the end of the pipe being frayed, burrs are formed, which have to be eliminated with sandpaper or stripping with a knife.

In any case, the quality of the cut suffers. These methods can be used for single cuts. If the pipeline has a complex configuration and many connections of individual sections, then it is better not to use these tools. Pipe shears are mainly used for cutting pipes made of plastic polymers.

The sharpened blade of the knife is fixed only on one side of the tool. In place of the second blade is a fairly wide base with a slot designed to receive a cutting plate. Work with such scissors is carried out solely due to the muscular strength of a person. Between the handles of the scissors there is a rounded toothed rack, which, after closing the handles of the scissors, pushes the blade towards the base. The pipe cutting process is as follows:

- a clearly visible mark is placed on the surface of the pipe, marking the place of the cut with it;

- the base is placed over this mark, controlling its position through the slot of the base;

- then, applying force, they cut into the pipe and, gradually increasing the force, make the final cut of the pipe.

The advantages of scissors are rather high efficiency and low cost of construction. The disadvantage is considered a direct connection between the effectiveness of the tool and the physical strength of the person working with it. In addition, during the cut, it is necessary to monitor the smooth movement of the brush, otherwise the blade may simply slip off the gear rack.

It is clear that with a large number of cuts, the hand quickly gets tired, so the speed of work is reduced. In addition, scissors cannot cut large diameter pipes. The maximum diameter of processed pipes is 42 mm.

The roller pipe cutter is designed for large volumes of work. Outwardly, it resembles an ordinary clamp with movable wheels attached to the bracket. The cutting roller is located at the end of the clamp screw.

In terms of efficiency, a pipe cutter is no worse than scissors. But, unlike them, there are practically no physical efforts during work. The cutting process itself is as follows:

- at the place of the cut put a mark with a marker;

- the screw is unscrewed from the clamp, and the bracket is brought to the place of the cut;

- then the screw is smoothly tightened (so that the pipe does not burst);

- after creating the necessary force on the cutting roller, the clamp begins to rotate around the pipe, while smoothly tightening the tension screw.

Thus, a circular cut of the pipe is made, while the end of the pipe is very even, without burrs. The only danger when working with a pipe cutter is the appearance of cracks on the pipe due to too much clamping force of the screw.

Cordless pipe cutter, in fact, is a scissors equipped with an electric motor. Such a tool allows you to cut the pipe without much effort in 6 - 8 seconds. But the diameter of the processed pipes is also small here, as with conventional hand shears.

The guillotine pipe cutter is used to work with pipes with a diameter of 63 to 350 mm. At the same time, the probability of deformations or destruction of the pipe walls is reduced to almost zero. The cutting process is as follows:

- mark the place of the cut on the pipe and insert it into the guillotine, fixing it in the sector from 30 to 60 degrees;

- a guillotine blade swings around it, which is mounted on wheels;

- after the first cut of the plastic, the blade is immersed in the pipe with the help of a rotating screw handle and, thus, the pipe is finally cut.

In this case, the cut is very even, without burrs. Guillotine blades are easily replaceable. In modern guillotines, the blades are additionally coated with Teflon.