- Pumping methods

- technique

- Automatic pumping systems

- bacteria

- Pumps

- Reasons to clean a septic tank

- How to fix leaks

- What to do?

- Mechanical

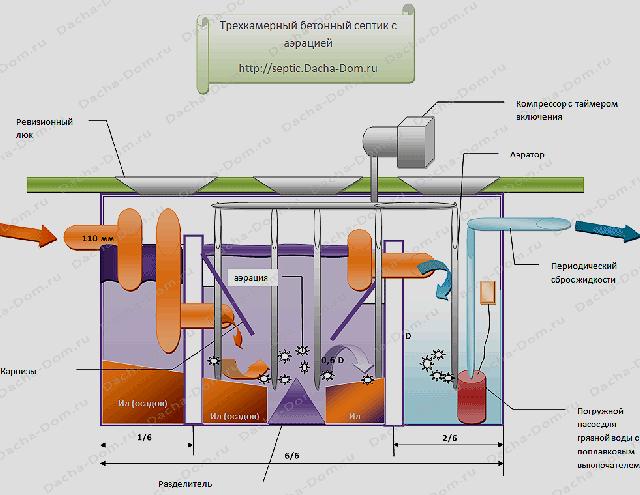

- Scheme of mechanical cleaning

- Chemical

- Biological

- Complete pumping out of the tank - a fatal mistake

- Checking the pressure accumulator

- Video - Why the pumping station often turns on

- Possible malfunctions of homemade septic tanks and their repair

- From concrete rings

- How the cesspool should be maintained and the main faults

- Drains do not go to the septic tank

- When is sewer repair necessary?

- Common problems and their causes

- Conclusions and useful video on the topic

Pumping methods

technique

Under the technique is meant powerful pumping equipment or a car with a capacity for drains (sewage transport).

Such services are provided by companies and individual entrepreneurs who come on call and, after pumping out, take all the contents to a place where sewage is allowed to drain. The service is not the cheapest, but homeowners do not need to think about where to put sewer waste.

The sewage truck arrives at the place of work, a contract is concluded for the pumping and disposal of waste. The owners must provide unhindered access to the septic tank.

The hose is long enough, but in order for it to reach the bottom, you will have to drive up close. The sleeve is lowered into the neck and the pump is turned on, sometimes you have to pour a little water into the tank to dilute the sewage.

The pump on the machine is vacuum, which means that pumping does not last long. Special vehicles leave to dispose of sewage. For the collection and storage of sewage, there are special biological sedimentation tanks. That's where the content goes.

Automatic pumping systems

Manufacturers put in their product the necessary power of the units in relation to the volume of the tank. The equipment is located in a tank with filtered water. Turns on when the chamber is full.

The pump has a special float that gives a signal to turn on when it rises. The device is absolutely sealed and constantly energized, if it is necessary to revise the capacity, the electricity will be turned off.

The equipment built into the local wastewater treatment system works only with conditionally pure fractions. That is, the effluents entering the tank first go through the stage of hard filtration, then enter the pump chamber.

The removal of water occurs through a hose or pipe outside the septic tank. Most often this is soil or a dry well, as well as the nearest ravine. This method is quite reliable and does not require additional expenses for the pump. In addition, automatic operation does not require human assistance.

bacteria

For rigid filtration of sewage waste, special microorganisms must be introduced into the chamber.

Bacteria are either anaerobic or aerobic. For some, the presence of oxygen in the reservoir is necessary, for others it is not.Bacteria live and work in the septic tank all the time, so it should not be empty. The product of the vital activity of microorganisms is gas, a small sediment forms at the bottom, which is removed using a fecal pump or a shovel.

Pumps

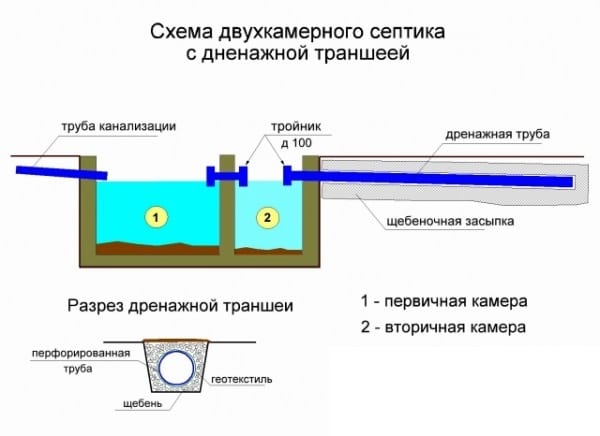

Units are divided into drainage and fecal. The first are designed to pump out the end product of filtration - water. The second ones are needed for pumping out a thick mass or slurry from the first chamber.

Fecal pumps are purchased separately and are not included with the septic tank. For high-quality work, you will have to dilute the silt deposits with water.

Reasons to clean a septic tank

The septic tank is not too complicated design. In it, waste accumulates, is cleaned due to the drainage system or the effective work of aerobic and anaerobic bacteria, and then the clean liquid follows into the ground (is brought out). Since the sewerage system of a private house functions autonomously, it requires regular maintenance. There are several reasons for its need:

- Overflow of the tank with solid deposits. If the sediment reaches the overflow level, it will cause great inconvenience to the owners and cause irreparable harm to nature.

- If people live irregularly in the house, then the septic tank, left for the winter with drains, may freeze. In this case, the body and the internal structure of the structure are threatened with damage, and the bacteria will die.

- Accumulation of waste, silting. The solid sediment that accumulates at the bottom, without cleaning, will be compressed and hardened over time. Such a mass, which seriously impairs the operation of the equipment, will be much more difficult to remove.

Many owners of country houses are interested not only in the question of how to clean the septic tank with their own hands, but also in the frequency of this operation.As a rule, the sump is removed from the sediment annually. If you let this matter go by itself, then after a few years a sediment will form in the structure, similar in consistency to clay.

The thicker the sediment layer, the more volume it takes from the chambers. Therefore, such a septic tank will become less effective, as the quality of cleaning will deteriorate significantly. In some cases, even sewage equipment cannot cope with “centuries-old” deposits: the pump is simply not able to pump out a heavy substance. Cleaning even once a year will avoid all the unpleasant consequences of sediment accumulation.

How to fix leaks

Regular leakage of waste from a septic tank is dangerous to human life and leads to the death of plants around.

The reasons for depressurization are:

- 1.cracks on the walls of the septic tank due to deformation, freezing or incorrect installation.

- 2. disconnection of the septic tank from the sewer pipes.

Cracks on the walls of a septic tank of factory origin are corrected with:

- 1.silicone sealant.

- 2. building hair dryer, heating the surface, it smoothes it.

If it leaks from the place where the septic tank is connected to the pipes, then it is eliminated as follows:

- 1.Using gaskets.

- 2.Using sealant.

- 3.using flax, cement, if the treatment plant is made of concrete.

To improve the quality of sealing, a waterproof material is applied on top of the septic tank. If the septic tank is made of concrete, sealing is increased by bitumen treatment outside the storage tank.

What to do?

If the cesspool is silted up, the question arises what to do. There are not so many options - to clean, but cleaning methods can be different depending on the type of cesspool and the available financial and time possibilities.

There are only 3 options for removing sludge from a cesspool: mechanical, chemical and biological. Each method has its own usage specifics.

Mechanical

This variation is often referred to as the goldfish method. For its implementation, special equipment is required - a fecal or drainage pump, a brush for cleaning the walls and bottom of the pit, a tank where pumping will be carried out and a hose of the required length.

Mechanical cleaning can be carried out using the services of specialists, that is, using special sewage machines and pumps. This method has significant advantages, the sludge in the cesspool will not only be removed, but also disposed of, which means there is no need to puzzle over where to put the pumped-out fecal matter. This method is great if the septic tank is silted up.

Any mechanical cleaning method has significant disadvantages, among them:

- The effect is relatively short-term, if preventive methods are not used, silting will occur again.

- Manual cleaning with scraping of walls and bottom cannot be used for plastic containers.

- You can't get rid of the bad smell.

Scheme of mechanical cleaning

Cleaning a cesspool from sludge by this method consists of the following steps:

- Lower the pump into the pit (preferably a fecal one, since the drainage one may not overpower too large fractions).

- Pull the hose from the cesspool to the drain tank (pit).

- When the pit is cleared of liquid effluents, the bottom is mechanically cleaned using brushes and other devices. The main task in this case is to remove fatty deposits.

- Next, solid particles are removed from the bottom.

- Filling the pit with water and repeating the pumping procedure.

Chemical

If the pit fills up quickly, then you should resort to a chemical method that you can implement with your own hands. This technique helps to get rid of not only the problem of silting, but also removes an unpleasant odor. For dry cleaning are used:

- Nitrates.

- Ammonium.

- Acids.

The procedure for working with chemicals is as follows:

- Buy a product, less dangerous nitrate cleaners. Measure the required amount. You can find out exactly how much you need to use on the package.

- Pour the chemical into the hole and close it.

- Wait 3 to 6 hours for the sludge and solid particles to dissolve.

- Pump out liquid effluent with a drainage or fecal pump.

- If in the future the method of cleaning the pit is different, it should be washed with clean water.

If it is not possible to call vacuum trucks, then this option, what to do if the cesspool fills up quickly, is optimal. The technique has significant advantages, among them:

- Possibility of cleaning at any time of the year.

- The odor is immediately removed.

- Availability of chemicals.

Disadvantages of chemical sludge removal:

- Not suitable for plastic containers, septic tanks.

- Having used this technique once, you will have to repeat it constantly.

- The biological method, after the chemical one, will not work.

Biological

This is a universal and safe method that is suitable for any sewerage system, including septic tanks. Before you clean the cesspool from sludge with bacteria, you should learn more about the means. These are living bacteria that are aerobic and anaerobic. The former live without oxygen, the latter only with it. In the course of their vital activity, bacteria successfully process sludge and solid fecal matter.

The procedure for using one or another tool depends on its type. In general, the cleaning procedure is as follows:

- Launching bacteria into the cesspool. Some of them are already ready to use, others need to be dissolved or diluted. Regarding the preparation of the drug, you can get information on the packaging of the product.

- Fall asleep in a hole, usually this can be done through the toilet. On average, cleaning takes 3-10 days.

- After the completion of the work of the bacteria, pump out the liquid effluents, and the resulting liquid does not require disposal, it can be used as a fertilizer.

- If you plan to use biological cleaning in the future, you should immediately launch a new batch of bacteria into the pit.

This option, how to get rid of silt in a cesspool, is safe for the environment, removes an unpleasant odor. But the biomethod does not work in winter, bacteria need a temperature of at least +10⁰, these drugs are more expensive than chemicals.

Complete pumping out of the tank - a fatal mistake

Common mistake owners make septic tanks during conservation - pumping out tanks. If there is no liquid left, the bacteria quickly die from lack of food. In this case, in the spring, you may encounter big problems in the operation of the sewer, if measures are not taken in a timely manner to increase the number of microorganisms.

The treatment plant will cease to perform its functions: the water will go into the ground simply clarified, and not purified. This threatens to contaminate fertile soils, spread pathogenic bacteria, and even cases of disease among people and domestic animals.

Do not assume that one malfunctioning septic tank "means nothing" for the environment.Groundwater travels great distances and feeds many hydraulic structures, incl. wells and wells. Consequences of dumping untreated sewage into the soil are unpredictable

If an underground aquifer comes close to the surface in a site, infiltration is possible: fecal bacteria will quickly find themselves in drinking wells and begin to spread further. Under adverse circumstances, this is fraught with real epidemics and death of livestock.

The logic of the owners of septic tanks draining water for the winter is understandable: they are afraid that the liquid will freeze and break the tank body, however, with the correct installation of the structure, this probability is extremely low. The damage that a complete evacuation of the septic tanks can cause can be much greater, so you should not make this mistake.

The wishes of the owners of septic tanks do not affect the laws of physics. If the light bulk tank is empty, it may float during spring floods.

If you remove water from the chambers of a plastic or fiberglass septic tank, then in the spring you can get an unpleasant surprise: the structure will float to the surface, breaking pipelines and raising the soil. Proper installation reduces the risks of ascent, but not as critical as the owners expect. A step by step installation guide is provided below.

Image gallery

Photo from

After the septic tank is delivered to the site, you should carefully inspect the body and make sure that there are no manufacturing defects and damage during transportation. If the model includes an electronic control system, you need to make sure its functionality

A pit is being dug under the septic tank.It must be of sufficient size so that a concrete slab can be installed under the structure and backfilled with mandatory protection against soil heaving.

A sand cushion is arranged at the bottom of the pit, and a finished or home-made concrete slab is installed on top. Special belts are attached to it on the anchors, with which the septic tank is firmly fixed. This prevents the structure from surfacing during periods when the GWL rises, but such measures are not enough if the septic tanks are empty

The distance between the tank body and the walls of the pit is filled with a cement-sand mixture. It must be dry. It is laid in layers and rammed. Only then can the structure be covered with soil. This protects the body of the septic tank during ground movements.

The first stage - inspection of the septic tank for damage

The second stage is the preparation of the pit

The third stage - fixing the septic tank to the concrete slab

The fourth stage - backfilling the structure

Soils are not static, their movements are always possible, especially during periods of sudden temperature changes, changes in groundwater level, or under the influence of other factors. Loads on the side walls and bottom of the tank can increase significantly.

Under ground pressure, an empty septic tank can either float or deform. In both cases, you will have to spend effort, time and money to restore the sewerage system. If the building is beyond repair, you have to buy a new treatment plant.

When installing a septic tank, they provide for the possibility of soil movements and protect the structure. Such measures are needed only when installing fiberglass and plastic structures, because. concrete structures are heavy and much less susceptible to external influences

All these problems, unnecessary expenses and worries are easy to avoid. You just need to properly preserve the septic tank and take into account that in winter it may be necessary to put it back into operation.

If the owner plans to visit a country house or dacha at least once a month, the treatment plant can be left "as is" - fully functional. Even volatile septic tank with running compressors too heavy on the budget.

Checking the pressure accumulator

The next device that needs to be adjusted or checked is the accumulator.

Diaphragm Hydraulic Pressure Accumulator Device

Excessively frequent switching on of the centrifugal pump in the station may occur due to the fact that there are damages in the accumulator tank that cause water leakage. Also, during operation, the rubber membrane of this device may be damaged or significantly stretched.

You can correct the deficiency either by replacing the components, or by completely replacing the accumulator.

By the way, checking the integrity of the rubber membrane in this device is very simple. This can be done without disassembling the tank. You just need to press the nipple valve located on the part of the pressure accumulator that should be filled with air. When you press the valve, air should be bled from it. If water comes out of the valve hole, then things are bad and the rubber membrane, or even the entire hydraulic pressure accumulator, will have to be changed.

Unstable, jerky operation of the centrifugal pump complex in the station can also be the result of hidden leaks in the autonomous water supply pipe system.The situation is complicated by the fact that leakage can occur in a pipe located under the surface of the earth. It is quite difficult to identify such a malfunction.

However, if you approach such a problem consistently, then it can also be solved. To do this, it is necessary to successively, segment by segment, shut off the entire water supply system and pump water into it under pressure and leave it for a while. A pressure gauge must be connected to each segment to be tested. If for several tens of minutes the pressure gauge needle maintains its position, then this segment of the water supply system has retained its tightness. In this case, you should go to the next segment and so on until a leak is detected.

Leak in the pipeline

As you can see, troubleshooting that causes the station centrifugal pump to turn on too often can take quite a long time. However, without fixing this breakdown, you run the risk of damaging your pump much earlier than the deadline set by the manufacturer.

To get more deeply acquainted with the composition and procedure for repairing pumping equipment stations. watch the video tutorial.

Video - Why the pumping station often turns on

Pump for a septic tank Your suburban area is the ultimate dream of many citizens, capable of bringing exactly the same amount.

Do-it-yourself pumping station repair If you want to move from a city apartment to a private house or country house, then you will undoubtedly have to.

Do-it-yourself heat pump There is a certain amount of heat in any environment that surrounds us, but provided that its temperature.

I have a 15 liter hydraulic accumulator in my pumping station (DAB, Italy).If you increase its capacity by adding, for example, another 50 liters, the pump will work longer to gain the desired pressure, and it will turn on less often. But will it disrupt the operation of the station?

station with an ejector what to do with it if I want to connect to the main water supply?

there is an automatic pump dzhileks jumbo 70 50 with a small hydraulic accumulator when filling the pool, the pump constantly turns on (the pool is large) is it possible to make the pump work constantly and not turn on, turn off every 2 minutes

pumping station caliber-800. After connecting the water heater to 80 liters, the water supply became jerky and the pump periodically turns on for a few seconds when we do not use water. There are no visible leaks.

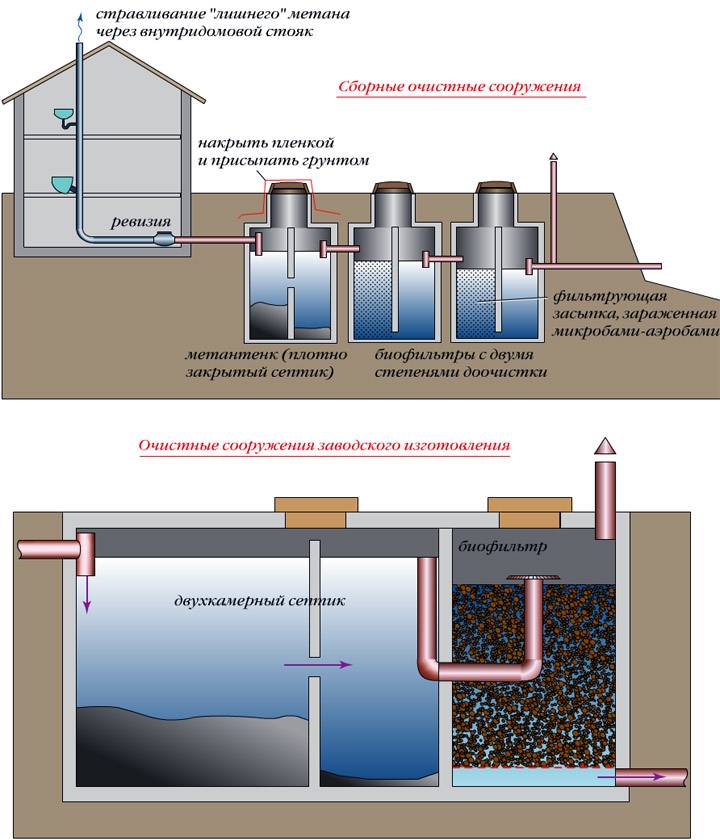

Possible malfunctions of homemade septic tanks and their repair

Homemade septic tanks also have their own history of breakdowns. And, perhaps, even more often than factory septic tanks.

These can be the following breakdowns and their elimination:

- untimely pumping of accumulated effluents - you need to pump it out with the help of a sewage machine or independently with a drainage pump;

- the inlet and outlet pipes are poorly made - they must be firmly fixed and sealed so that they do not let water through;

- poor sealing of all seams, sections of connections with the main pipeline or the body of the septic tank, if it is reinforced concrete - it is necessary to properly coat all the cracks with mounting foam or sealant, and grease the concrete wells with a water-repellent waterproofing agent;

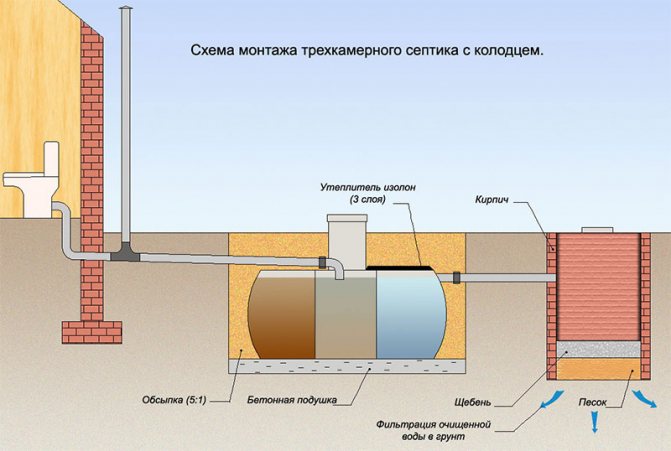

- lack or poor-quality thermal insulation - with any device of a septic tank, it is necessary to sprinkle its outer walls in the form of a pillow of crushed stone, sand and dry cement, and also use thermal insulation materials, such as geotextiles or foam plastic;

- the appearance of an unpleasant odor due to the death of bacteria - in this case, most likely chlorine-containing or other aggressive chemicals were dumped into the septic tank, and therefore the life-giving mass of bacteria died.

Important! It is necessary to pump out the entire septic tank from the drains, rinse with clean water and refill with live bacteria that would process the drains as before. pump out the septic tank and flush the drains

In any case, if you yourself installed a septic tank made of plastic or concrete rings, you will always quickly understand the cause of the malfunction of your septic tank and be able to fix it.

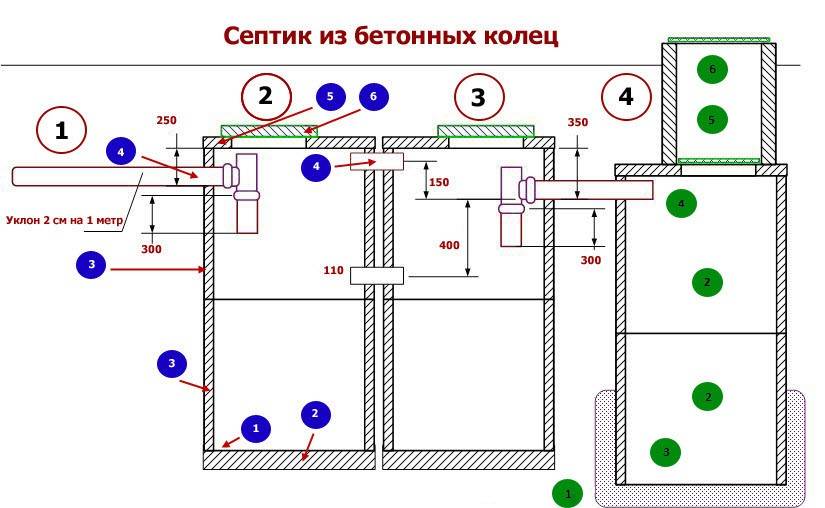

From concrete rings

Regardless of the level of groundwater in the area where a septic tank of reinforced concrete rings is installed, waterproofing of its walls is required. This is the most basic of its repair features.

Water seeps through untreated reinforced concrete very well, and therefore, as from the outside, at a high level of groundwater, water will enter the septic tank well and fill it, and water will also seep into the ground from the inside, thereby violating the integrity of the walls.

Also, along the edges of concrete rings, all kinds of chipped and crumbled areas very often appear during installation.

In connection with another ring, gaps of impressive size are formed.They should be carefully sealed with mounting foam and plastered with cement mortar, which is made or sold ready-made dry from waterproof mixtures.

Important! All other repair work, in principle, can be carried out in exactly the same way as in the case of repairing plastic treatment structures: clean the pipes from blockages, make sure that aggressive chemicals, alkalis and acids that kill bacteria get into the septic tank less. If there is any septic tank on your site, the principle of repair is the same for volatile septic tanks because their internal arrangement of devices is similar between manufacturers of different septic tanks

If there is any septic tank on your site, the principle of repair is the same for volatile septic tanks because their internal arrangement of devices is similar between manufacturers of different septic tanks.

But repairs for gravity and non-volatile septic tanks are carried out in a slightly different way. After all, they are simple in their internal structure, do not have any built-in electrical equipment, and therefore do not need to be replaced.

To prevent frequent repairs of any type of septic tank, you should carefully follow all operating instructions and regularly service sewage equipment.

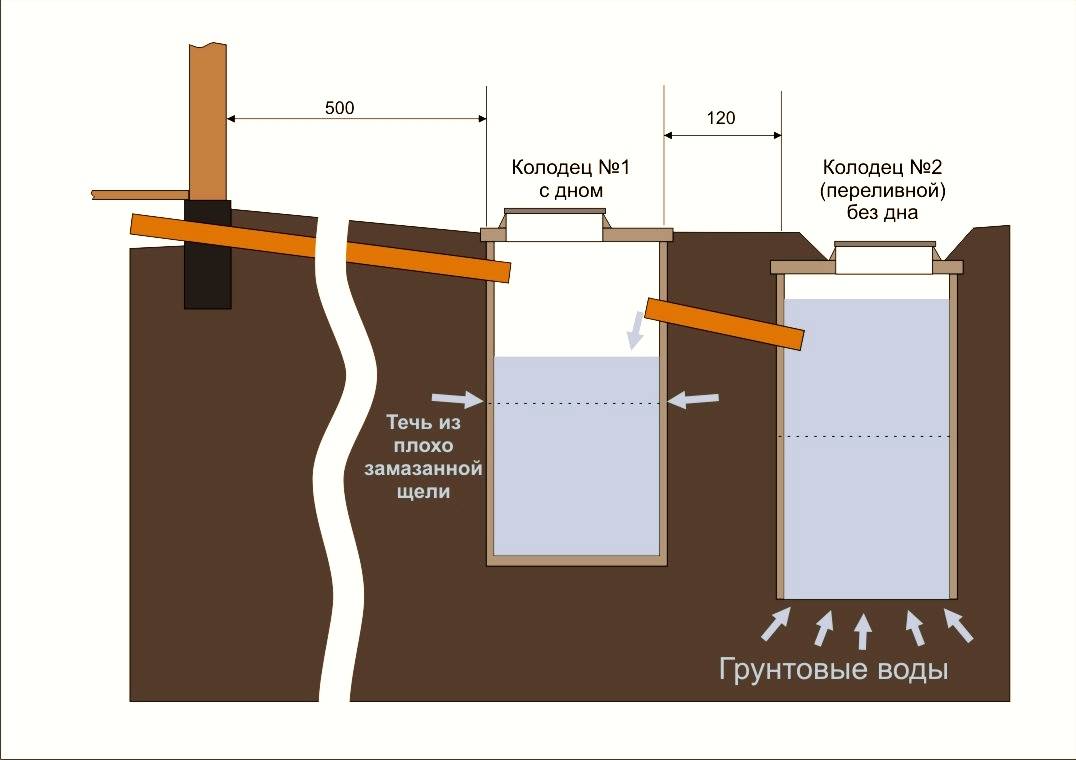

How the cesspool should be maintained and the main faults

A cesspool is an excellent method of organizing a sewerage system in a private house. It is quite easy to install and maintain.

But over time, the design may be subject to the occurrence of various defects and breakdowns, requiring their urgent elimination and repair.

Before repairing a cesspool, you will need to perform a few simple steps:

- call a sewage truck and pump out all the contents of the pit;

- examine the cesspool, determining the cause of the violation of its functioning;

- evaluate the breakdown and the cost of its elimination, decide who will carry out the repair.

Call for a vacuum truck

Of course, there can be many reasons for cesspool malfunctions. Therefore, we will consider further the main ones.

Drains do not go to the septic tank

A signal that there is a problem will be filled plumbing equipment that does not release water. If the pipeline check showed no blockage, it is obvious that it is located in the septic tank area. In this case, you need to very carefully, so as not to damage the device, dig the ground around it. Then check the inlet and outlet pipes for blockages and, if found, eliminate them. The easiest way to do this is if manholes were installed on the pipeline during the installation of the septic tank. Blockages should only be cleared with special sewer cleaning equipment, such as a hydrodynamic machine.

To seal the leak in the body of the septic tank, a welding machine for plastic or a special sealant is used.

When is sewer repair necessary?

Common problems and their causes

Most often, residents are faced with the problem of sewer blockage. There are 2 reasons why this happens:

- During the installation of the pipeline, the builders violated the technology, which led to the formation of stagnant sections. In a private house, due to the incorrect design of the system, the system freezes, and the ice plug interferes with the outflow of water.

- During operation, the sewer was used incorrectly, preventive cleaning was not carried out. Animal fat, hair, food waste, getting into the system, form impassable plugs in the places where the pipes turn.

Conclusions and useful video on the topic

Before the upcoming gasket replacement, it will be useful to watch the following video:

In some cases, problems with faucets are due to an incorrectly installed sink or the wrong choice of model. Most of the troubles can be solved on your own, but if difficulties arise, it is better to call a plumber - professional advice or repairs have not bothered anyone yet.

Please leave your comments, share your experience of using and repairing faucets, ask questions in the block below. We are always ready to clarify incomprehensible points and help in solving the problem.